Chloroacetic acid production method and chlorination reactor

A chlorination reactor and production method technology, applied in chemical/physical/physical chemistry fixed reactors, chemical instruments and methods, organic chemistry, etc. problems, to achieve the effect of shortening the reaction residence time, reducing consumption and reducing side reactions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

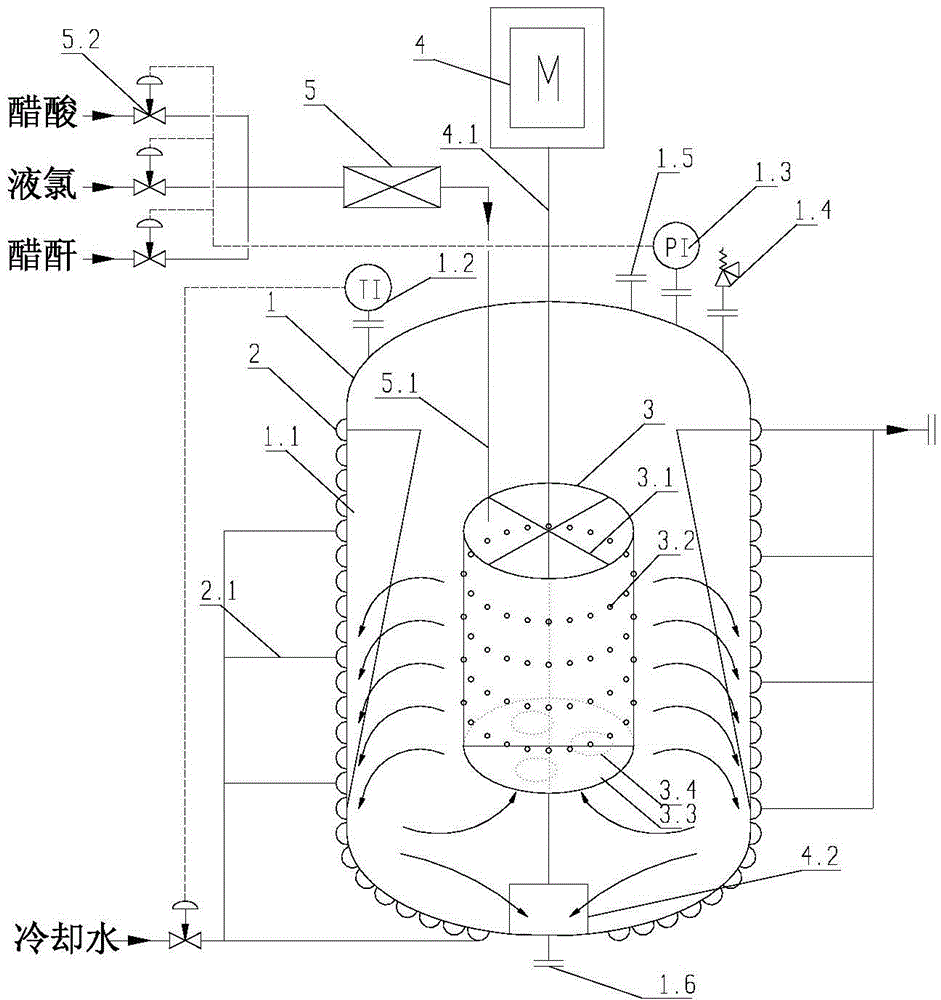

[0027] A production method and reactor for chloroacetic acid.

[0028] The volume of the chlorination reactor is 1m 3 , there are 4 inverted triangular baffles on the inner wall, and the volume of the supergravity bucket is 0.2m 3 , add acetic acid in the chlorination reactor, add the acetic anhydride that is equivalent to 5% of acetic acid quality, add liquid chlorine quality and be 1.4 times of acetic acid quality, maintain reaction temperature to be 180 ℃, reaction pressure is 6bar, chlorination reaction process is in 500g gravity It is completed in the field, and after the reaction is completed, the product is separated and purified according to the continuous production process, and 99.3% of the chloroacetic acid product is obtained. The unit volume processing capacity of the reactor is 3.2 times that of the existing reactor.

Embodiment 2

[0030] A production method and reactor for chloroacetic acid.

[0031] The volume of the chlorination reactor is 1m 3 , there are 6 inverted triangular baffles on the inner wall, and the volume of the supergravity bucket is 0.3m 3 , add acetic acid in the chlorination reactor, add the acetic anhydride that is equivalent to 6.5% of acetic acid quality, add liquid chlorine quality and be 1.3 times of acetic acid quality, maintain reaction temperature to be 200 ℃, reaction pressure is 8bar, chlorination reaction process is in 800g gravity It is completed in the field, and after the reaction is completed, the product is separated and purified according to the continuous production process, and 99.4% of the chloroacetic acid product is obtained. The unit volume processing capacity of the reactor is 4.5 times that of the existing reactor.

Embodiment 3

[0033] A production method and reactor for chloroacetic acid.

[0034] Chlorination reactor volume is 2m 3 , there are 8 inverted triangular baffles on the inner wall, and the volume of the supergravity bucket is 0.3m 3 , add acetic acid in the chlorination reactor, add the acetic anhydride that is equivalent to 6% of acetic acid quality, add liquid chlorine quality and be 1.8 times of acetic acid quality, maintain reaction temperature to be 230 ℃, reaction pressure is 5bar, chlorination reaction process is in 700g gravity It is completed in the field, and after the reaction is completed, the product is separated and purified according to the continuous production process, and 99.0% of the chloroacetic acid product is obtained. The unit volume processing capacity of the reactor is 4.7 times that of the existing reactor.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com