Cladding light filtering device for high-power optical fiber laser

A fiber laser, high-power technology, applied in the direction of cladding optical fiber, optical waveguide light guide, multi-layer core/cladding optical fiber, etc., to achieve the effect of avoiding excessive local temperature, small damage, and high filtering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

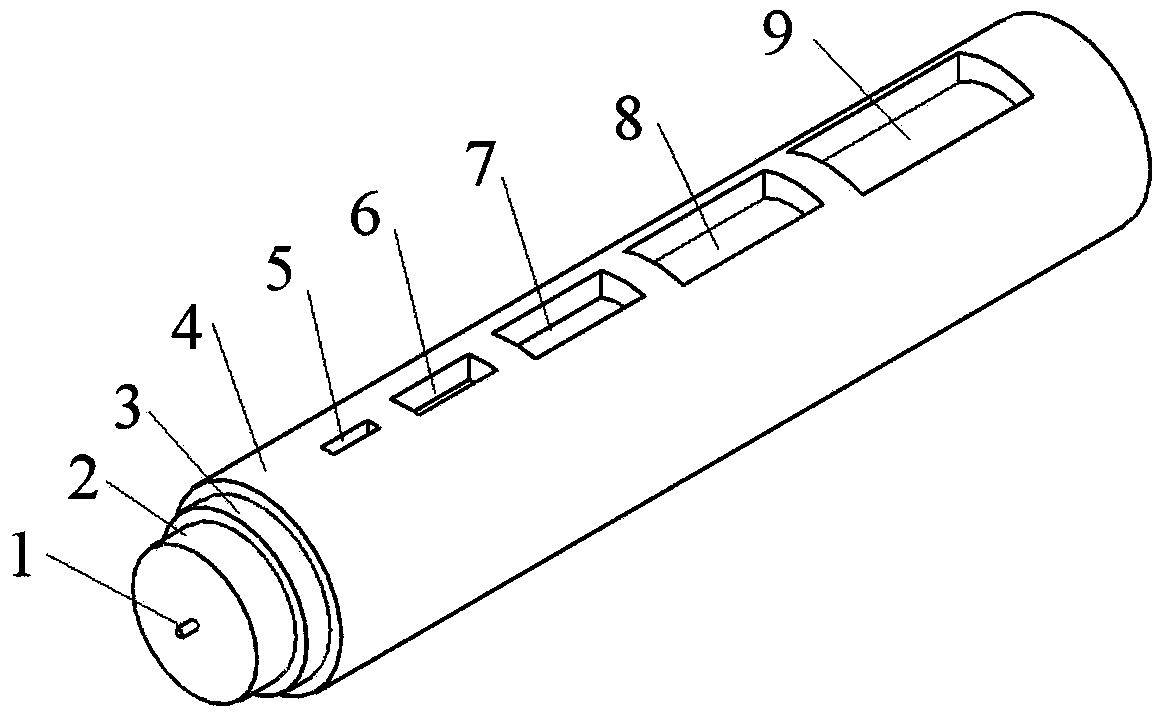

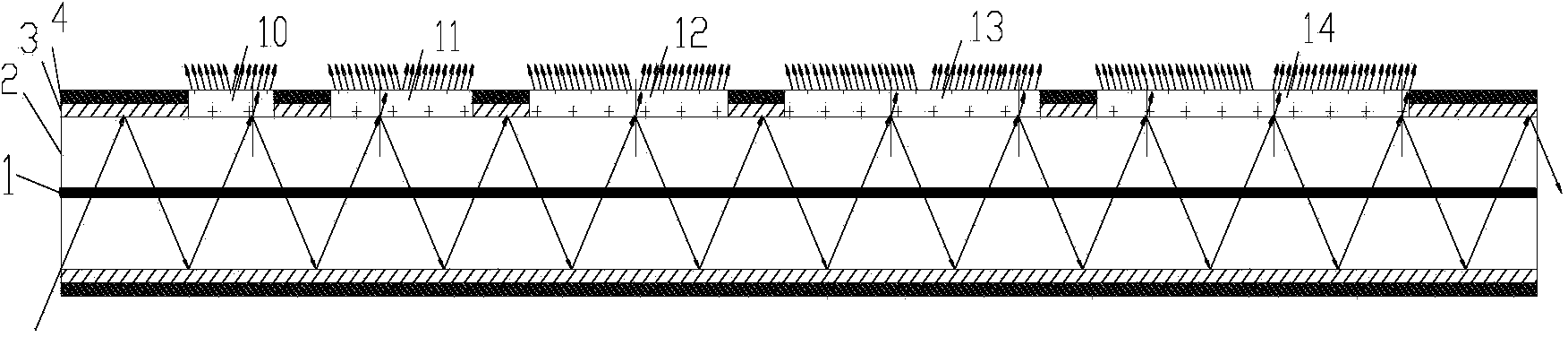

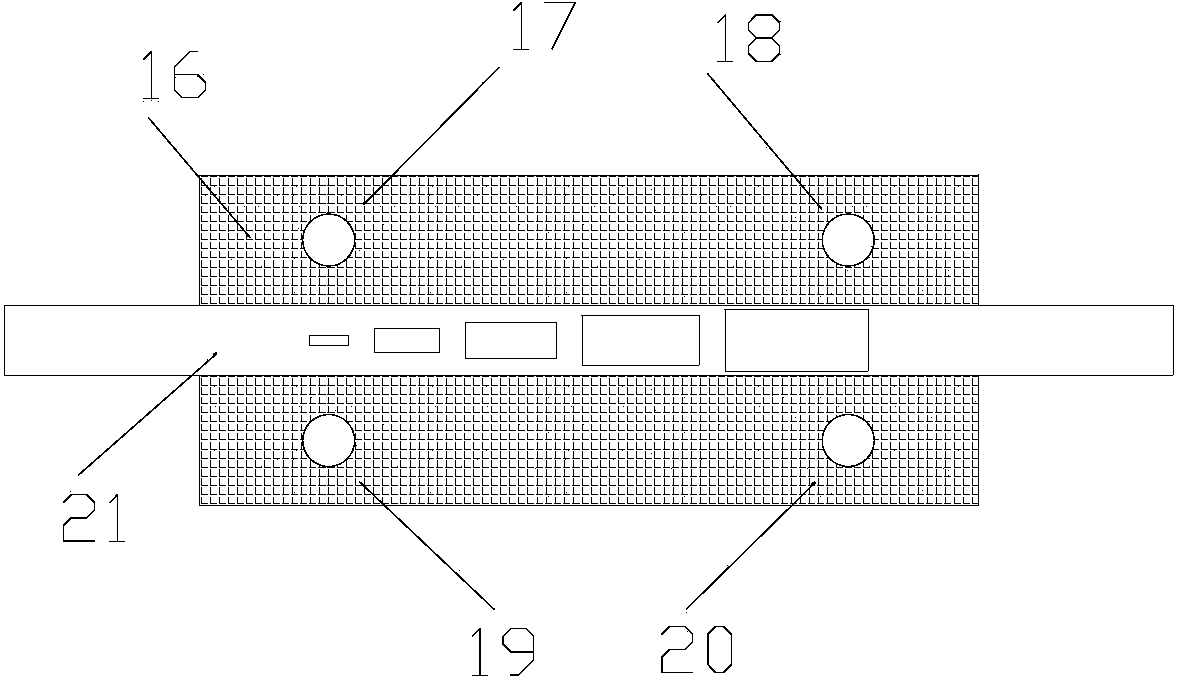

[0019] a kind of like Figure 4 The invention is shown applied to the output of a high power fiber laser to filter out unwanted cladding light. This high-power fiber laser adopts a straight cavity structure, and a high-reflection grating 24 and a low-reflection grating 25 form a necessary resonant cavity for the laser. A beam combiner 23 is used to inject the lasers output by multiple semiconductor lasers 22 into the resonant cavity. The core 1 is 20 μm, and the inner cladding 2 is 400 μm ytterbium-doped fiber, which acts as a gain medium in the cavity. 28 is the output port of the high-power fiber laser. In order to prevent the laser from reflecting on the end face, the output port has been processed with an octave. The above-mentioned cladding optical device 27 is installed at the front end of the output port, and first, the protective layer 4 and the inner cladding 3 of the optical fiber are stripped with reference to the stripping area ratio from small to large, which is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com