Small soy sauce fermentation tank

A fermenter and soy sauce technology, applied in bioreactor/fermenter combination, specific-purpose bioreactor/fermenter, biochemical instruments, etc., can solve the problem of inaccurate temperature detection, improve accuracy and speed up , the effect of enhancing controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

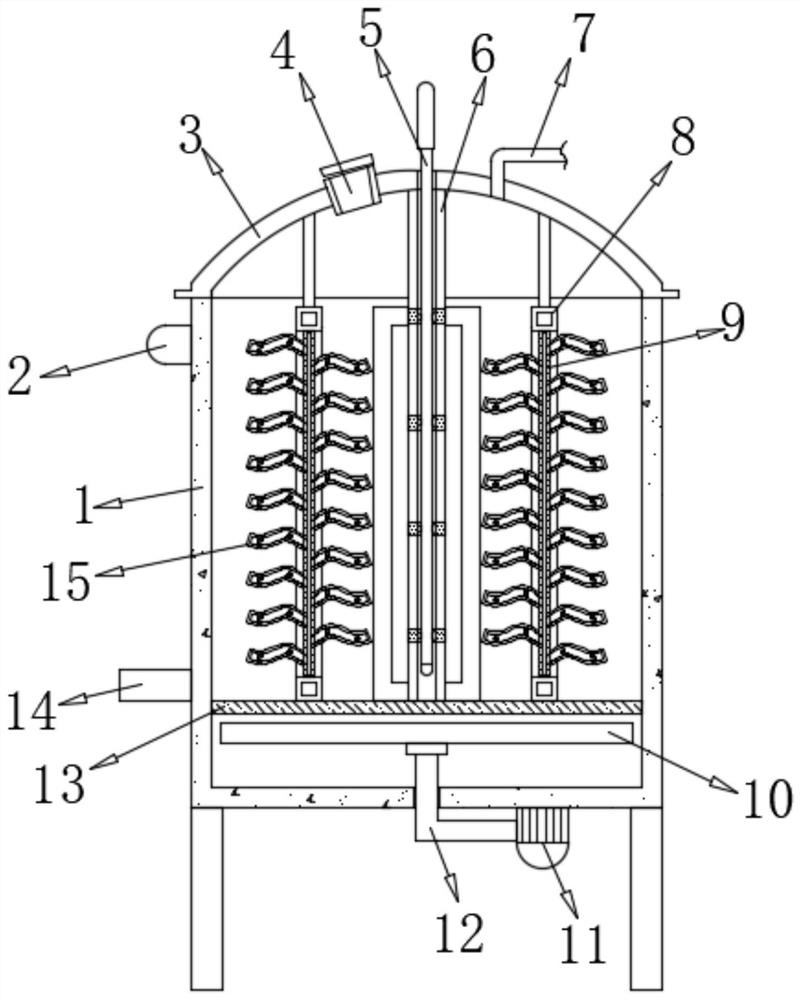

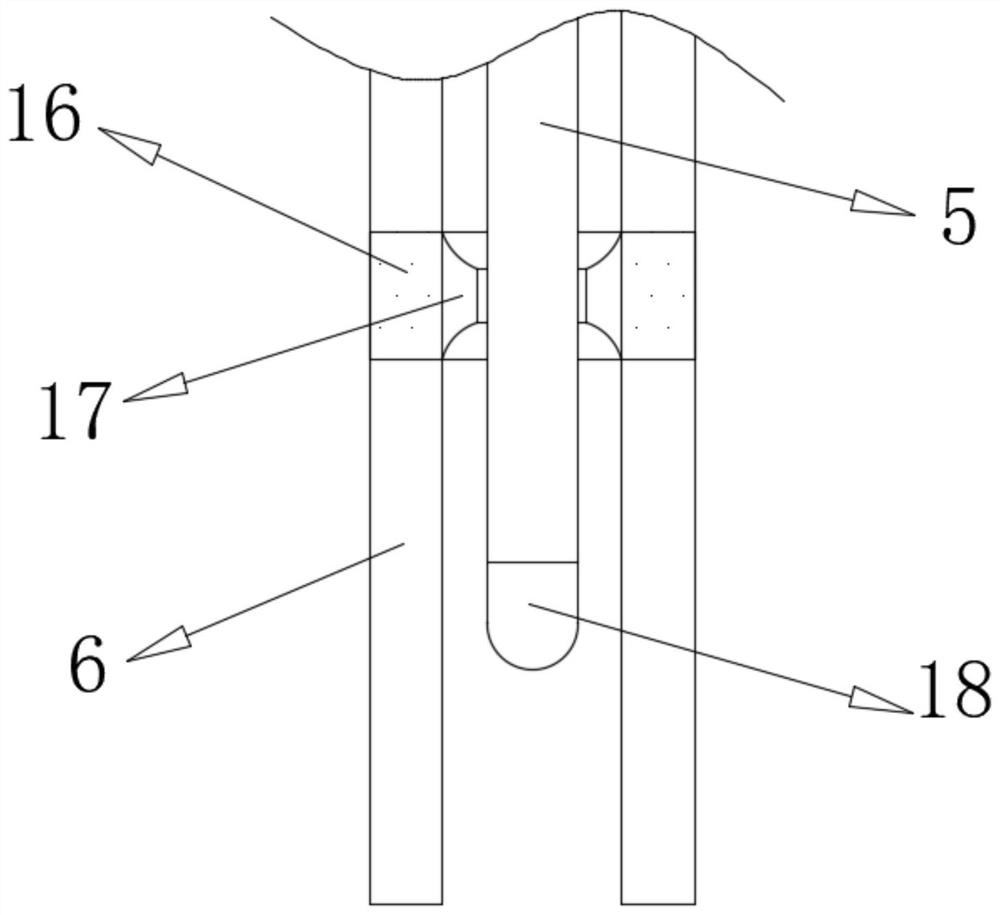

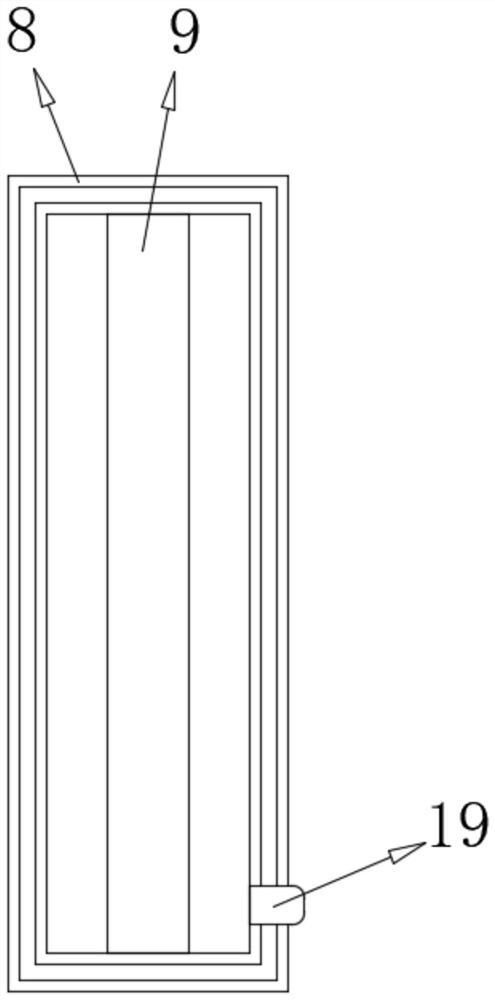

[0029] refer to Figure 1-5 , a small soy sauce fermentation tank, comprising a tank body 1, the top of the tank body 1 is connected with a top cover 3 by fastening bolts, and the bottom of the inner wall of the tank body 1 is connected with a sieve plate 13 by fastening bolts, and the sieve plate 13 A distributor 10 is provided at the bottom, and an air inlet pipe 12 is provided at the bottom of the distributor 10, a slag outlet 14 is plugged into one side of the outer wall of the tank body 1, and a feed inlet 4 is provided on one side of the top outer wall of the top cover 3, The top outer wall of the top cover 3 is plugged with an air outlet pipe 7, and the top inner wall of the top cover 3 is connected with two fixed rods 6 by fastening bolts, and the two fixed rods 6 are connected with evenly distributed spacer rings 16 by fastening bolts , the circumferential inner wall of the limit ring 16 is connected with a scraper ring 17 by fastening bolts, the top of the top cover ...

Embodiment 2

[0038] refer to Image 6 , a warp knitting machine pulling and winding device for weaving plastic nets. Compared with Embodiment 1, the bottom of the inner wall of the tank body 1 is provided with a limited groove, and both sides of the distributor 10 pass through tight The fixed bolts are connected to the limit block, and the outer diameter of the limit block is compatible with the inner diameter of the limit groove. Both sides of the outer wall of the bottom of the tank body 1 are connected with drive motors 22 by fastening bolts, and the output of the two drive motors 22 The shafts are all connected with drive gears 21 by fastening bolts, and the circumference of the bottom of the distributor 10 is connected with a gear ring 23 by fastening bolts, and the circumferences of the two drive gears 21 and the peripheral outer walls of the gear ring 23 mesh with each other.

[0039] Working principle: When in use, the gear ring 23 and the distributor 10 can be driven to rotate by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com