Low-migration UV flexible printing ink and preparation method thereof

A low-migration, flexographic technology, used in inks, household appliances, applications, etc., can solve problems such as entry and human hazards, and achieve the effects of reduced migration, easy cleaning, and fast curing rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

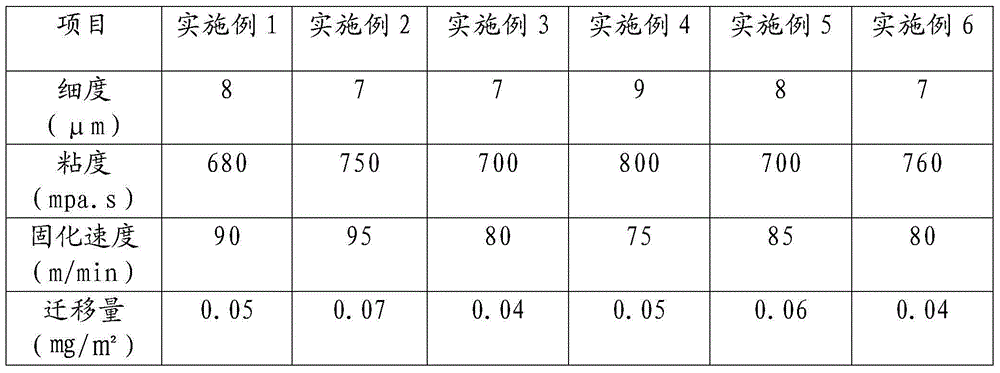

Embodiment 1

[0028] A low migration UV flexographic ink (yellow)

[0029] Composed of the following raw materials by weight percentage: EB812 10.0%, CN293 10.0%, 6353 10.0%, CN118 20.0%, NPG(PO)DA 20.0%, EB170 1.0%, Irgacure OXE01 2.0%, Irgacure754 2.0%, Omnipol TX 2.5%, C.I. Pigment Yellow 14 17.5%, RAD 2100 1.0%, BYK-168 2.0%, BYK-080 1.0%, 675 1.0%.

[0030] Its preparation method is:

[0031] (1) Weigh EB812, CN293, 6353, CN118, NPG(PO)DA, EB170, Irgacure OXE01, Irgacure754, Omnipol TX, C.I. Pigment Yellow 14, RAD 2100, BYK-168, BYK-080 and 675 according to the above ratio, Add to the dispersion container and mix to obtain the mixture;

[0032] (2) Move the mixture in step (1) to a disperser and stir evenly, and stir for 10 minutes under the condition of 800 rpm, so that the mixture is uniformly dispersed, and then ground to a fineness below 10 μm through a three-roller machine, That is, a yellow low-migration UV flexographic ink was obtained.

Embodiment 2

[0034] A low migration UV flexographic ink (red)

[0035] Composed of raw materials in the following weight percentages: EB657 8.0%, CN294 9.0%, 6351 8.0%, EB605 18.0%, TMP(PO)TA 10.0%, EB168 2.0%, Irgacure 127 1.0%, Irgacure754 2.0%, Omnipol BP 2.0%, C.I. Pigment Red 57:1 36.0%, RAD 2500 1.0%, BYK-163 1.0%, 3062 1.0%, BYK-335 1.0%.

[0036] Its preparation method is:

[0037] (1) Weigh EB657, CN294, 6351, EB605, TMP(PO)TA, EB168, Irgacure 127, Irgacure754, Omnipol BP, C.I. Pigment Red 57:1, RAD 2500, BYK-163, 3062 and BYK- 335, add in the dispersion container and mix to obtain the mixture;

[0038](2) Move the mixture in the step (1) to a disperser and stir evenly, and stir for 11 minutes under the condition of 800 rpm, so that the mixture is uniformly dispersed, and then ground to a fineness below 10 μm through a three-roller machine, That is, red low-migration UV flexographic ink was obtained.

Embodiment 3

[0040] A low migration UV flexographic ink (blue)

[0041] Composed of raw materials in the following weight percentages: EB450 6.0%, CN2203 7.0%, 6313 7.0%, EB3701 10.0%, CN386 15.0%, SR9008 3.0%, KIP150 2.0%, Omnipol TX 1.0%, C.I. Pigment Blue 15:4 46.0%, RAD 270 1.0%, BYK-345 1.0%, BYK-991 1.0%.

[0042] Its preparation method is:

[0043] (1) Weigh EB450, CN2203, 6313, EB3701, CN386, SR9008, KIP150, Omnipol TX, C.I. Pigment Blue 15:4, RAD 270, BYK-345 and BYK-991 according to the above proportions, add them into the dispersion container and mix to obtain mixture;

[0044] (2) Move the mixture in step (1) to a disperser and stir evenly, and stir for 12 minutes under the condition of 800 rpm, so that the mixture is uniformly dispersed, and then ground to a fineness below 10 μm through a three-roller machine, That is, the blue low-migration UV flexographic ink is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com