Multifunctional nanometer bamboo charcoal environment-friendly printing ink, a preparing method thereof and applications of the printing ink

A nano-bamboo charcoal, multi-functional technology, applied in ink, applications, household appliances, etc., can solve the problems of high price of environmental protection ink and slow progress of environmental protection ink

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

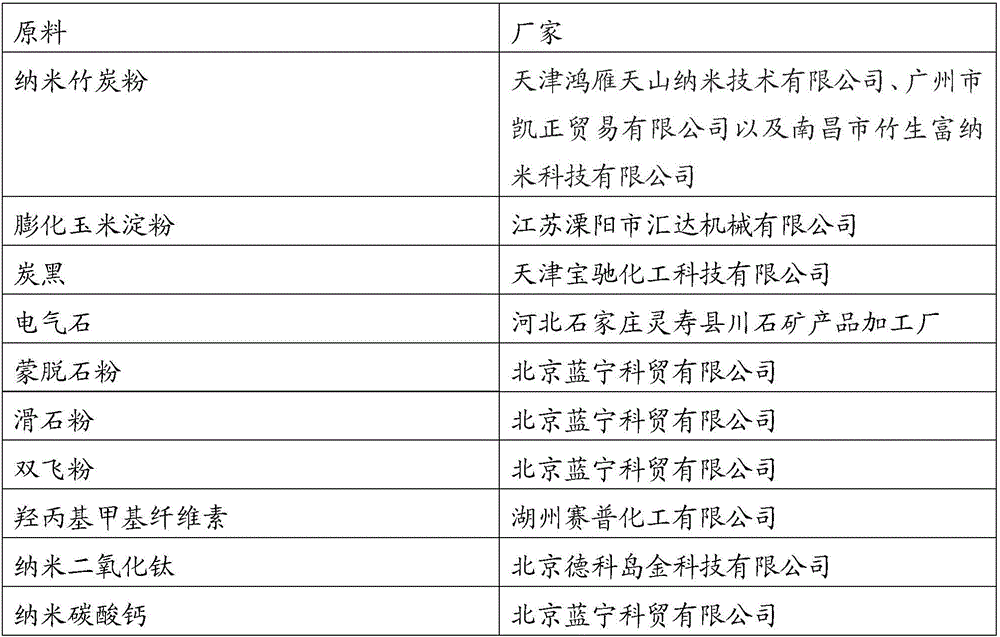

[0112] The preparation of embodiment 1 multifunctional nano bamboo charcoal environmental protection printing ink

[0113] (1) Take each component by the following weight: 10Kg of nano-bamboo charcoal powder, 5Kg of expanded cornstarch, 5Kg of carbon black, 2Kg of talc powder, 2Kg of Shuangfei powder, 2Kg of montmorillonite powder, 2Kg of nano-calcium carbonate, 2kg of tourmaline powder, and nano-titanium dioxide 1Kg, 1Kg of hydroxypropyl methylcellulose, 70Kg of purified water;

[0114] (2) Pour nano-bamboo charcoal powder, expanded cornstarch, carbon black, talcum powder, Shuangfei powder, montmorillonite powder, nano-calcium carbonate, tourmaline powder, nano-titanium dioxide, and hydroxypropyl methylcellulose into the mixer in turn, and Stir for 3 minutes each in reverse rotation, the stirring speed is 60±2r / min;

[0115] (3) First pour 1 / 2 of pure water (35Kg) into the mixer, and stir for 5 minutes each in the forward and reverse directions, and the stirring speed is 60±...

Embodiment 2

[0126] The preparation of embodiment 2 multifunctional nano bamboo charcoal environmental protection printing ink

[0127] (1) Take each component by the following weight: 12Kg of nano-bamboo charcoal powder, 7Kg of expanded cornstarch, 7Kg of carbon black, 3Kg of talc powder, 3Kg of Shuangfei powder, 3Kg of montmorillonite powder, 3Kg of nano-calcium carbonate, 2kg of tourmaline powder, and nano-titanium dioxide 2Kg, hydroxypropyl methylcellulose 2Kg, purified water 80Kg.

[0128] (2) Put nano-bamboo charcoal powder, puffed corn starch, carbon black, talcum powder, Shuangfei powder, montmorillonite powder, nano-calcium carbonate, tourmaline powder, nano-titanium dioxide, hydroxypropyl methylcellulose, purified water in turn, pour into and stir In the container, stir for 3 minutes each in forward rotation and reverse rotation, and the stirring speed is 60±2r / min;

[0129] (3) First pour 1 / 2 of pure water (40Kg) into the mixer, and stir for 5 minutes each in the forward and re...

Embodiment 3

[0140]The preparation of embodiment 3 multifunctional nano bamboo charcoal environmental protection printing ink

[0141] (1) Take each component by the following weight: 15Kg of nano-bamboo charcoal powder, 10Kg of expanded cornstarch, 10Kg of carbon black, 5Kg of talcum powder, 5Kg of Shuangfei powder, 5Kg of montmorillonite powder, 5Kg of nano-calcium carbonate, 3kg of tourmaline powder, and nano-titanium dioxide 3Kg, hydroxypropyl methylcellulose 3Kg, purified water 85Kg.

[0142] (2) Pour nano-bamboo charcoal powder, expanded cornstarch, carbon black, talcum powder, Shuangfei powder, montmorillonite powder, nano-calcium carbonate, tourmaline powder, nano-titanium dioxide, and hydroxypropyl methylcellulose into the mixer in turn, Forward and reverse stirring for 3 minutes each, the stirring speed is 60±2r / min;

[0143] (3) First pour 1 / 2 of pure water (40Kg) into the mixer, and stir for 5 minutes each in the forward and reverse directions, and the stirring speed is 60±2r / ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com