Printing method of side face of ceramic substrate and printing device

A technology of ceramic substrates and printing methods, applied in printing devices, printing, printing machines, etc., can solve problems such as high cost, poor consistency, and slow speed, and achieve the effects of high alignment accuracy and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

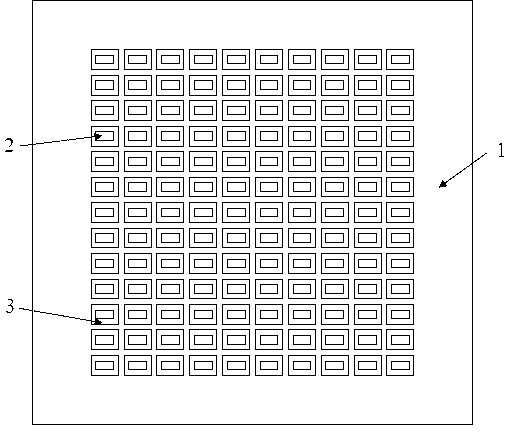

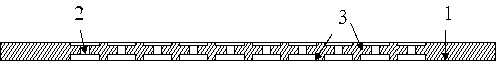

[0036] 1. Machining: combined with overlooking figure 1 and section figure 2 , the metal plate 1 is processed into a metal frame with several cavities 2 by machining, and then a step cavity 3 is processed around the cavities 2 on both sides of the metal plate;

[0037] 2. Glue compounding: mix Dow Corning glue and curing powder according to a certain ratio, and stir evenly;

[0038] 3. Pouring: Seal one side of the metal frame with plastic, place it flat on the workbench, pour the prepared glue into the cavity, so that the height of the glue is slightly higher than the height of the frame;

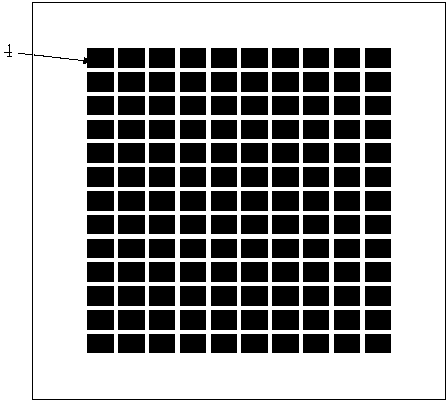

[0039] 4. Curing: combining image 3 , use negative pressure to discharge the gas in the colloid, let it stand for a period of time to cure naturally, remove the colloid higher than the height of the frame after curing, and the flat colloid 4 in the cavity afte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com