Silver-coating printing process for paperboard of cigarette case

A technology for cardboard and craftsmanship, applied in the field of cardboard silver-coated printing technology, can solve the problems of poor identification and exchange of anti-counterfeiting information, easy imitation of counterfeiting molecules, and comparison of anti-counterfeiting technologies of manufacturers, and achieves increased anti-counterfeiting effect, easy identification, Strong adhesion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described in detail below in conjunction with the embodiments, so that those skilled in the art can implement it with reference to the description.

[0031] A paperboard silver-coated printing process for cigarette cases, including the following steps:

[0032] 1) The gravure printing plate is engraved by laser, and the depth of the plate is between 30 μm and 35 μm; the opening width of the gravure printing plate is controlled between 60 μm and 100 μm, and the gravure printing dot density is 3-5.

[0033] 2) Prepare gravure silver ink;

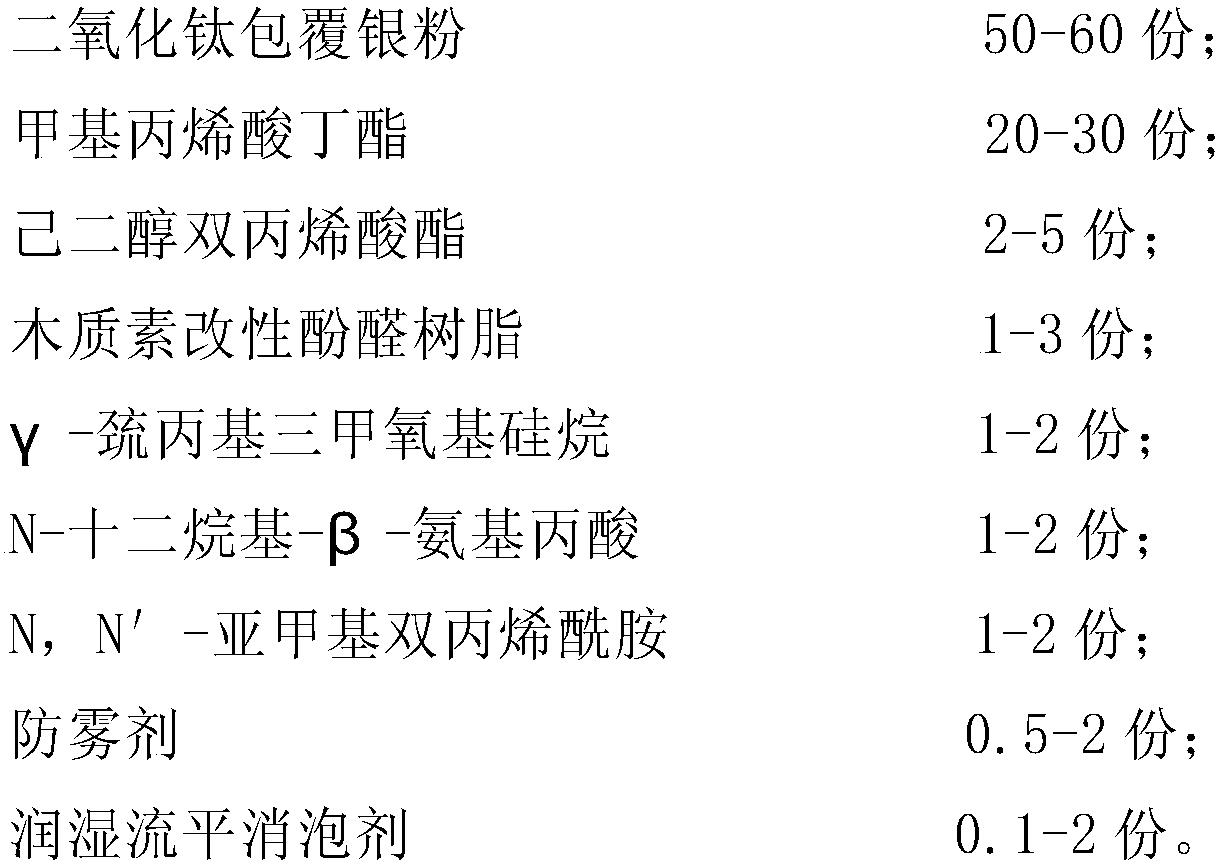

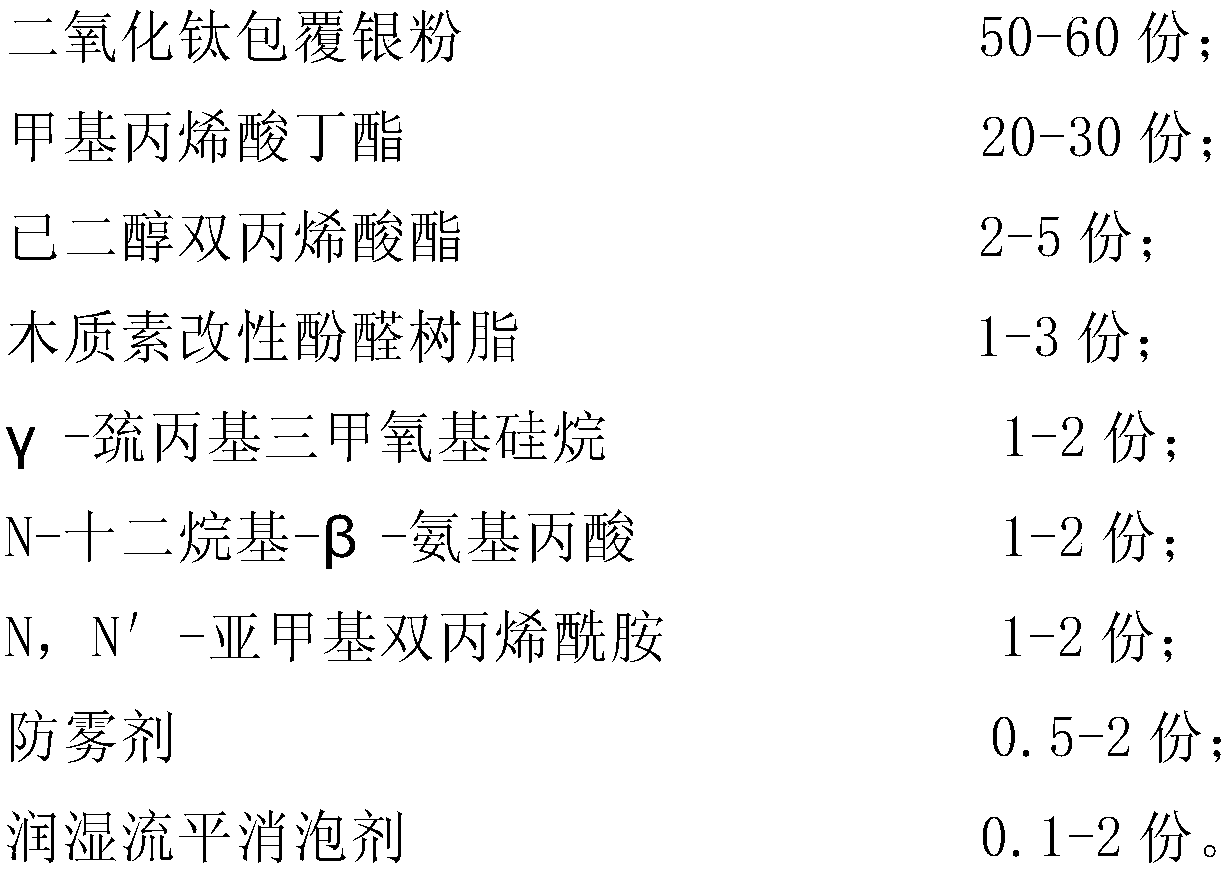

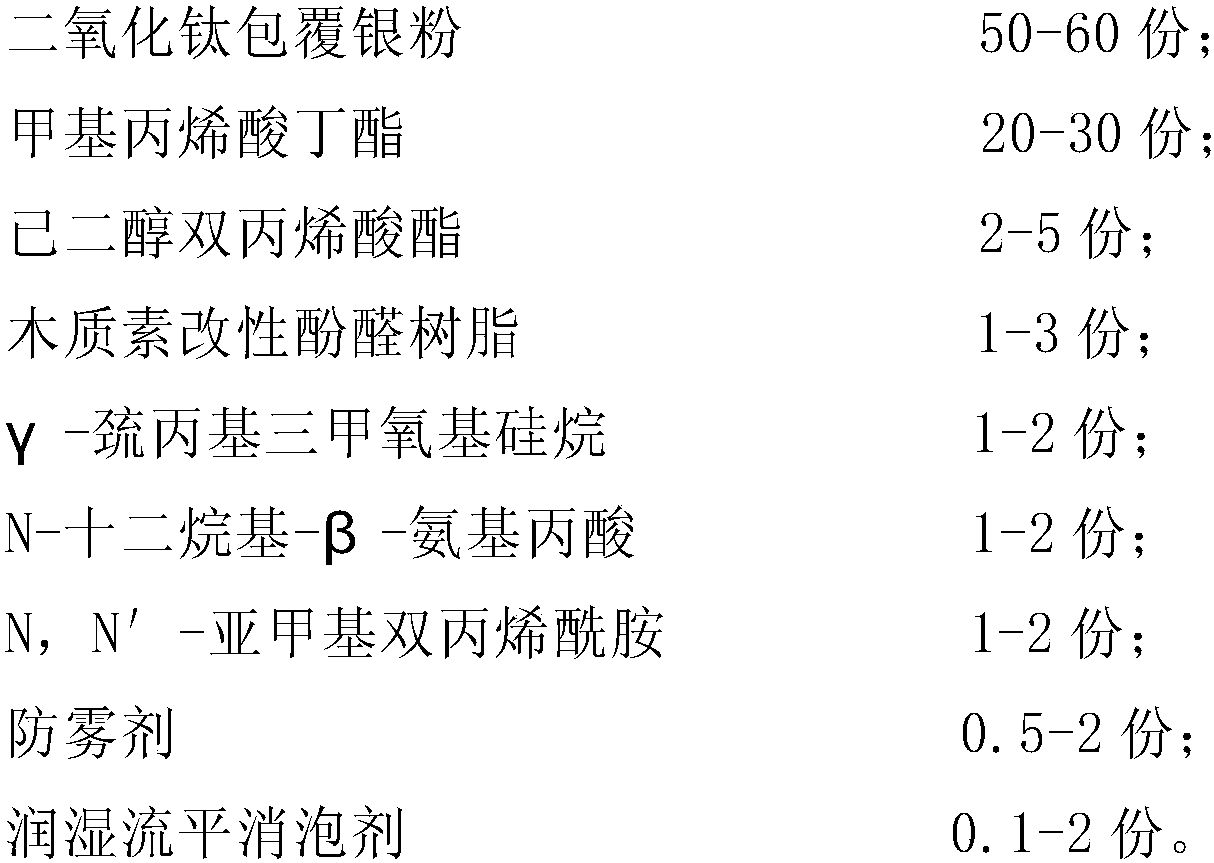

[0034] Wherein, the gravure silver ink comprises the following components by weight:

[0035]

[0036] Wherein, the viscosity of the hexanediol diacrylate is 3000-5000, the viscosity of the lignin-modified phenolic resin is 10000-30000, and the particle size of the hexanediol diacrylate and the lignin-modified phenolic resin is much smaller than that of titanium dioxide The particle size of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com