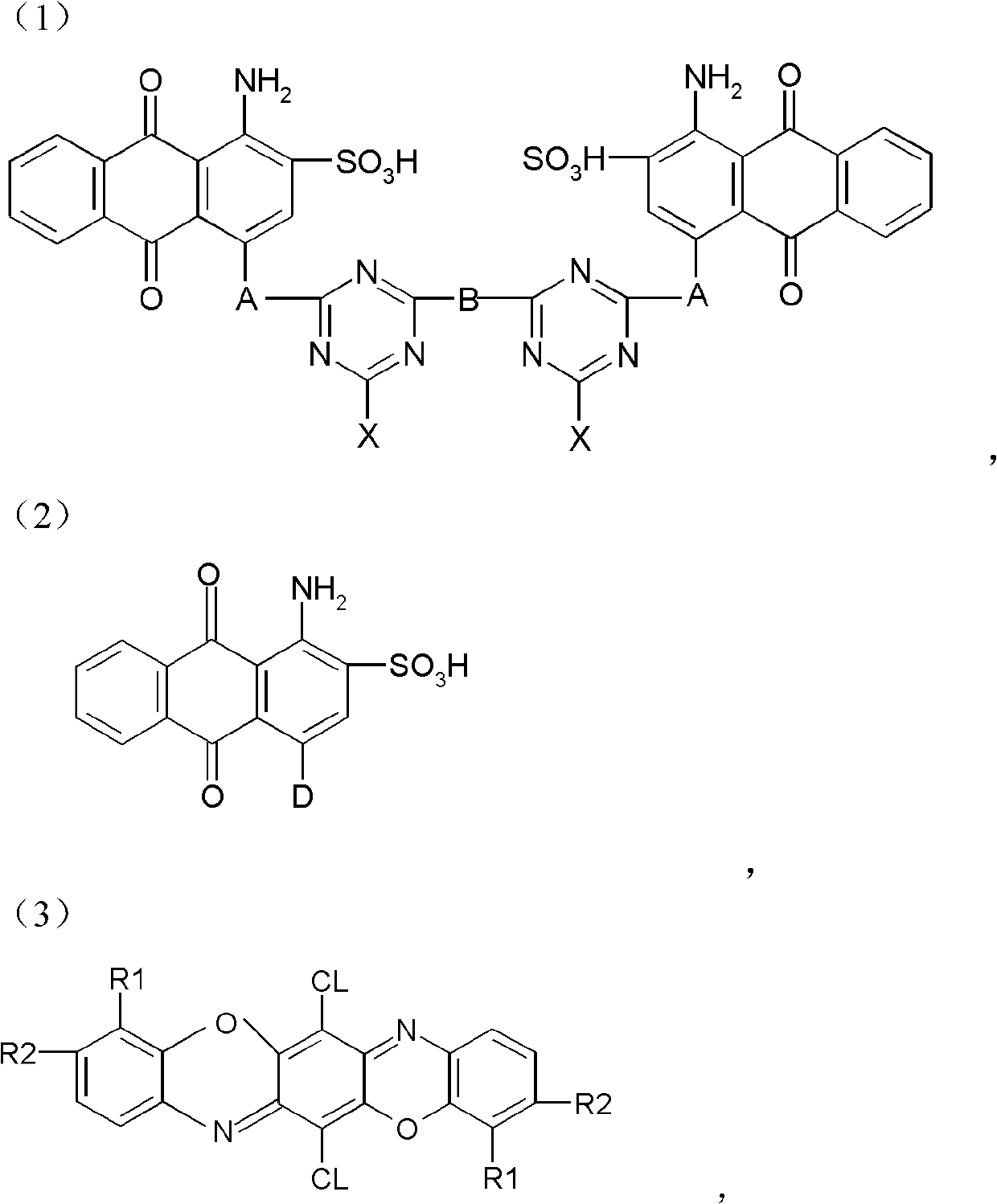

Blue active dye mixture and preparation and application thereof

A technology of reactive dyes and mixtures, applied in the field of dyes, can solve the problem that the combined properties of reactive dyes cannot meet the needs, etc., and achieve the effect of good comprehensive fastness characteristics.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0083] Embodiment 1, preparation of formula (1) dyestuff:

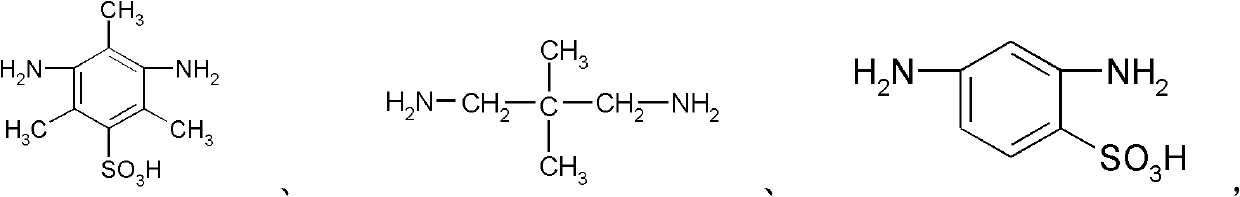

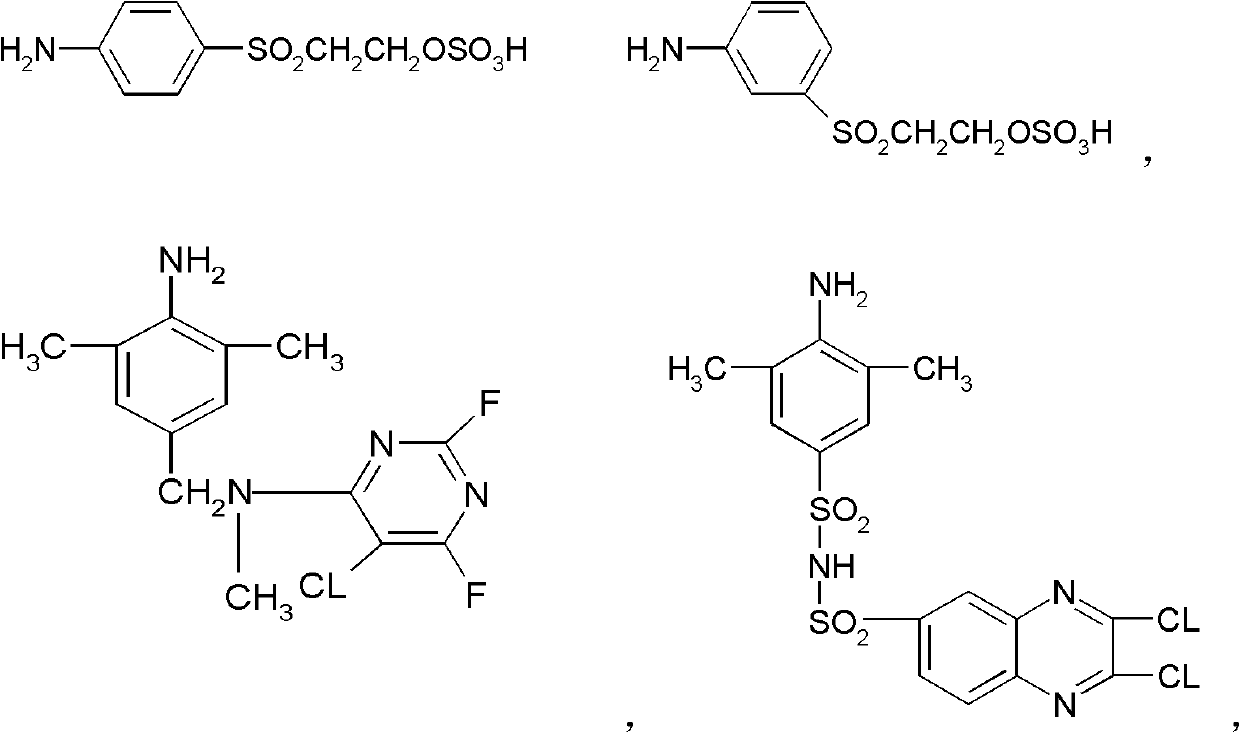

[0084] After beating 40.41 parts of bromacine (compound of formula (4)) in an appropriate amount of water for 1 hour, add 23 parts of 3.5-diamino2.4.6-trimethylbenzenesulfonic acid (compound of formula (A-1)), Then add 2.9 parts of cuprous chloride and 4.6 parts of sodium sulfite, raise the temperature to 60°C, adjust the pH to 8 with soda ash, perform condensation reaction for 4 hours, refine with diatomaceous earth for 2-3 times, then acidify and salt out (add 15 parts by volume percentage) % sodium chloride carries out salting-out; Add hydrochloric acid and adjust pH=1 (carry out acid-outing), filter after 2 hours, filter cake adds appropriate amount of water to dissolve, obtains a kind of blue dye parent solution, and 13.5 parts of cyanuric fluorine ( The compound of formula (6)) is added dropwise into the blue dye matrix solution to undergo condensation reaction, the process control is below T=10°C, pH=3.5-8.0, t...

Embodiment 2

[0086] Embodiment 2, preparation of formula (1) dyestuff:

[0087] After beating 40.4 parts of bromonic acid (compound of formula (4)) in an appropriate amount of water for 1 hour, add 23 parts of 3.5-diamino2.4.6-trimethylbenzenesulfonic acid (formula (A-1)) compound, add 2.9 cuprous chloride and 4.6 parts of sodium sulfite, heat up to 60°C, adjust pH=8 with soda ash, condense for 4 hours, refine for 2-3 times, acidify, salt out (add 15% sodium chloride by volume percentage for salting out Add hydrochloric acid to adjust pH=1 to carry out acid analysis), filter after 2 hours, add appropriate amount of water to dissolve the filter cake to obtain a blue dye matrix, add the blue dye matrix solution to 18.45 parts of fully ice-ground cyanurea in 30 minutes Condensation reaction occurs in the acid chloride (compound of formula (6)), control T=10°C, pH=3.5, maintain the reaction for 4 hours, and finally add 2.5 parts of ethylenediamine (compound of formula (7)) to the system to mai...

Embodiment 3

[0089] Embodiment 3, preparation of formula (1) dyestuff:

[0090] After beating 40.41 parts of bromacine (compound of formula (4)) in an appropriate amount of water for 1 hour, add 23 parts of 3.5-diamino2.4.6-trimethylbenzenesulfonic acid (compound of formula (A-1)), Then add 2.9 parts of cuprous chloride and 4.6 parts of sodium sulfite, raise the temperature to 60°C, adjust the pH to 8 with soda ash, perform condensation reaction for 4 hours, refine with diatomaceous earth for 2-3 times, then acidify and salt out (add 15 parts by volume percentage) % sodium chloride carries out salting-out; Add hydrochloric acid and adjust pH=1 (carry out acid-outing), filter after 2 hours, filter cake adds appropriate amount of water to dissolve, obtains a kind of blue dye parent solution, and 13.5 parts of cyanuric fluorine ( The compound of formula (6)) is added dropwise into the blue dye parent solution to undergo condensation reaction, the process control is below T=10°C, pH=3.5-8.0, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com