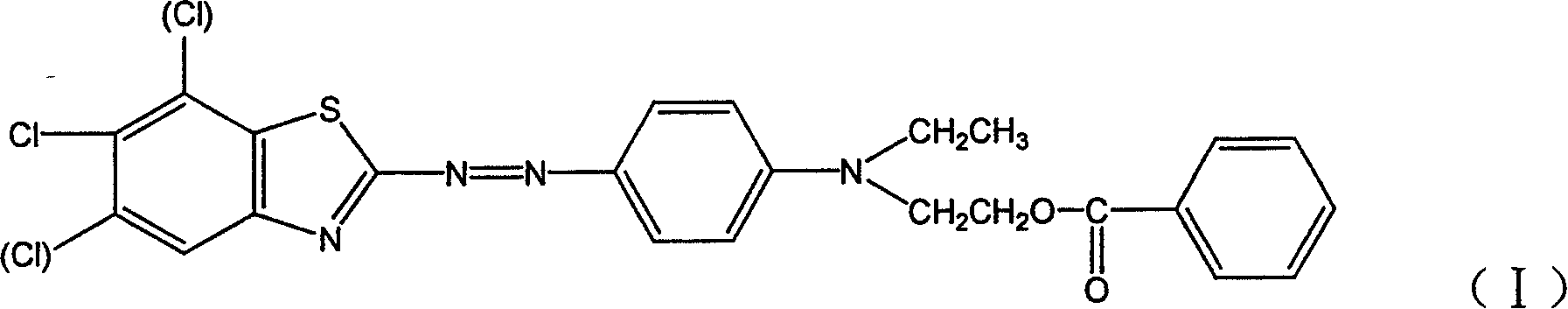

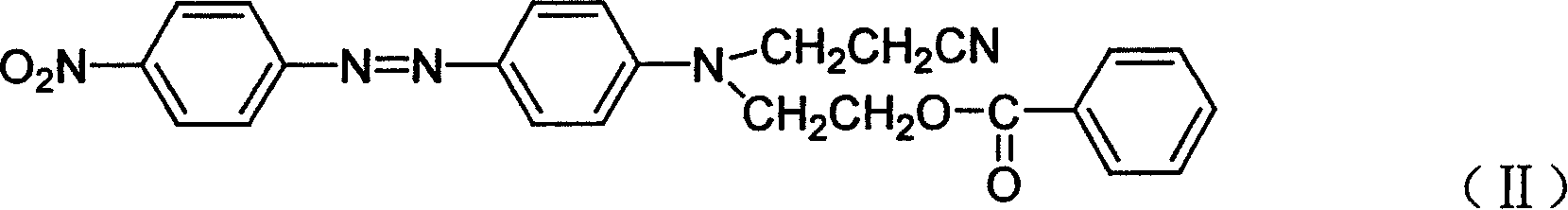

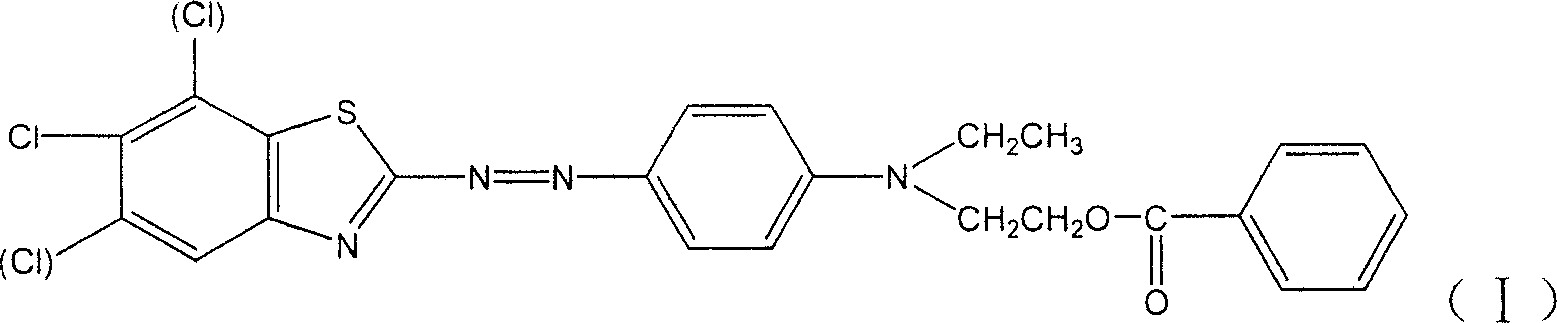

Composite disperse red dye

A technology of composite disperse and red dyes, which is applied in the field of monoazo dye compositions, can solve the problems of environmental pollution, affecting textile dyeing wet fastness, thermal migration fastness and water washing fastness, etc., and achieves washing resistance Good fastness, excellent dyeing performance, and excellent fastness performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~7

[0020] According to the metering data shown in Table 1, dye monomer A, dye monomer B, auxiliary agent (dispersant methyl naphthalene sulfonate formaldehyde condensate (MF), diffusing agent benzyl naphthalene sulfonate formaldehyde condensate (CNF) , diffusing agent naphthalenesulfonic acid formaldehyde condensate (NNO), sodium ligninsulfonate) are mixed with water, grind and disperse with a grinder, and then spray dry.

[0021] Example

Embodiment 8~11

[0023] According to the measurement data shown in Table 2, disperse red dye C (commercial dye, monomer A content 35%), C.I. disperse orange 73 (commercial dye, monomer B content 35.4%), auxiliary agent (dispersant methyl naphthalenesulfonate Acid formaldehyde condensate (MF), diffusing agent benzyl naphthalenesulfonate formaldehyde condensate (CNF), diffusing agent naphthalenesulfonic acid formaldehyde condensate (NNO)) are blended with water, grind and disperse with a grinder, and then spray dry ;

[0024] Example

Embodiment 13

[0026] Take 0.5 grams of the disperse red dyes prepared in Examples 1-12 and disperse them in 500 milliliters of water, absorb 20 milliliters and mix them with 60 milliliters of water, adjust the pH of the dyeing bath to 5 with acetic acid, heat up to 70°C and put in 2 grams of The polyester / cotton cloth is dyed, the temperature is raised from 70°C to 130°C within 30 minutes, the temperature is kept for 30 minutes, and sampling starts when it is cooled to 90°C. The national standards GB / T3921-1997, GB / T3920-1997, GB / T8427-1998, GB / T5718-1997 were used to test the color fastness to washing, rubbing, light and sublimation respectively. The test results are shown in Table 3.

[0027] Example name

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com