Acrylic acid coating film and its manufacturing method

A manufacturing method and acrylic technology, applied in the field of high-transparency packaging films and coating films, can solve the problems of unsuitable high-speed packaging equipment packaging, composite materials are not easy to degrade, and the thickness of the composite layer is large, and achieve excellent packaging adaptability and excellent low temperature. Heat-sealing performance, the effect of reducing the manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

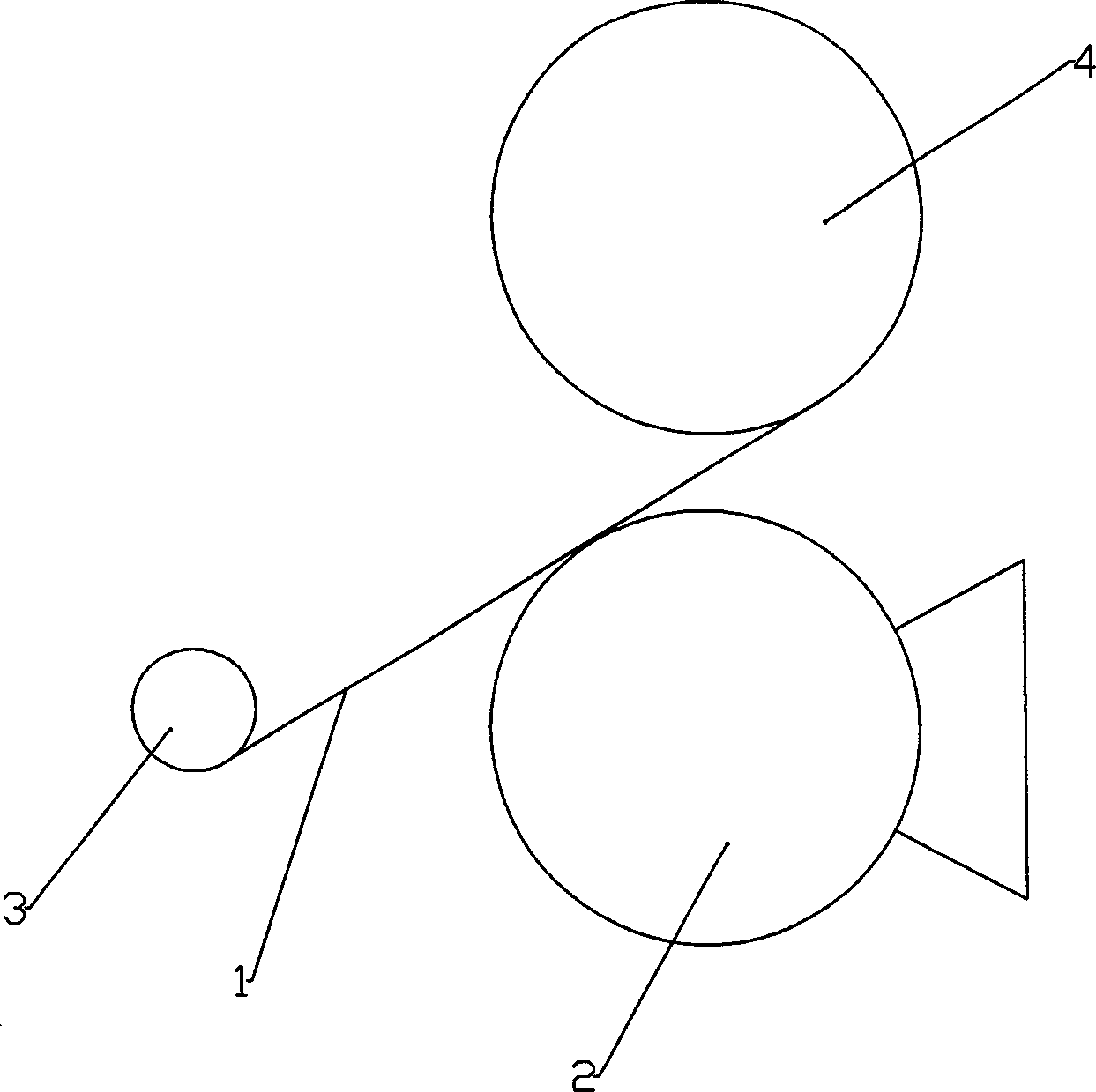

Image

Examples

Embodiment 1

[0034] The raw materials used are:

[0035] Substrate: Biaxially oriented polypropylene (BOPP), 18 μm thick.

[0036] Acrylic acid emulsion: 200kg of acrylic acid emulsion formed by copolymerization of 70% acrylic acid and 30% acrylic acid methyl obtained on the market, its solid content is 30%;

[0037] Demineralized water: self-made, 70kg;

[0038] Slip agent: commercially available palm wax slip agent 10kg;

[0039] Anti-blocking agent: commercially available silicon dioxide anti-blocking agent 1kg;

[0040] Primer: Commercially available solvent-based polyurethane.

[0041] Weigh 200kg of acrylic emulsion and add it into a stainless steel container, then add 10kg of palm wax slip agent, 1kg of silicon dioxide anti-adhesive agent and 70kg of soft water in turn while stirring, and stir well to form an acrylic paint, which will be used in the next process.

[0042] Unwind the biaxially oriented polypropylene (BOPP) base material as the base material and perform corona tre...

Embodiment 2

[0045] The raw materials used are:

[0046] Substrate layer: Biaxially oriented polypropylene (BOPP) with a thickness of 200 μm.

[0047] Acrylic acid emulsion: 300kg of acrylic acid emulsion formed by copolymerization of 10% acrylic acid and 90% acrylate methyl obtained on the market, its solid content is 16%;

[0048] Slip agent: commercially available palm wax slip agent 15kg;

[0049] Anti-blocking agent: 1.6kg of commercially available silicon dioxide anti-blocking agent;

[0050] Primer: Commercially available water-based acrylic adhesive.

[0051] Weigh 300kg of acrylic emulsion and add it into a stainless steel container, then add about 15kg of palm wax slip agent and 1.6kg of silicon dioxide anti-sticking agent in sequence while stirring, and wait for the next process after stirring evenly.

[0052] The biaxially oriented polypropylene (BOPP) substrate used as the substrate is unwound and then corona treated, and the primer is pre-coated, and the coating amount of ...

Embodiment 3

[0054] The raw materials used are:

[0055] Substrate layer: PET film with a thickness of 10 μm.

[0056] Acrylic emulsion: 100kg of acrylic emulsion copolymerized by 80% acrylic acid and 20% ethyl acrylate, with a solid content of 45%;

[0057] Palm wax slippery agent 40kg, commercially available;

[0058] Silica anti-sticking agent 10kg, commercially available;

[0059] Soft water 250kg.

[0060] Primer: solvent-based polyurethane, commercially available.

[0061] Weigh 100kg of acrylic emulsion and add it to a stainless steel container, then add about 40kg of slip agent, 10kg of anti-adhesive agent and 250kg of soft water while stirring, and stir well to form an acrylic paint for use in the next process.

[0062] Corona treatment is carried out after unwinding the PET film as the substrate; pre-coating solvent-based polyurethane primer on one side of the substrate, and the coating amount is 0.8g / m 2 , and then evenly transfer the acrylic paint to the substrate film coa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com