Barrier coating and high-barrier composite material applied in barrier coating

A composite material and barrier coating technology, applied in the field of packaging materials, can solve the problems of difficult waste disposal and recycling, and achieve the effect of easy recycling, easy recycling, and accelerated curing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-3

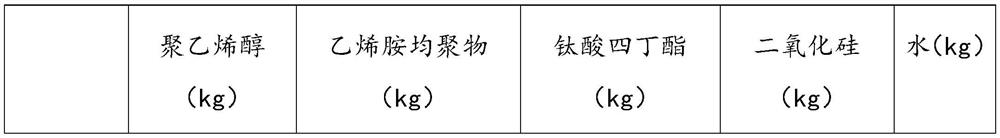

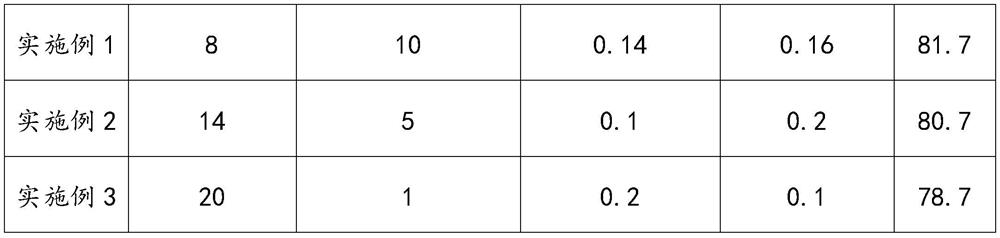

[0031] Examples 1-3 relate to a barrier coating, and its components are specifically shown in Table 1.

[0032] The barrier coating is prepared according to the following steps:

[0033] Weigh the required pure water and polyvinyl alcohol in proportion, add polyvinyl alcohol into the pure water, add it while stirring, then put it in a drying room at 40°C, bake for more than 12 hours, take it out and stir, and then add vinylamine homopolymer in proportion compound, tetrabutyl titanate, silicon dioxide, and add it while stirring to obtain a coating solution.

[0034] Table 1. The component formula table of the barrier coating of each embodiment

[0035]

[0036]

Embodiment 4

[0038] This embodiment relates to a high-barrier composite material. The high-barrier composite material includes an inner film layer, a barrier coating layer, and a surface printing layer arranged sequentially from inside to outside.

[0039] Wherein, the inner film layer is a polyethylene layer. Specifically, the inner film layer is prepared by blending polyethylene materials. Based on the total mass of the inner film layer, the inner film layer includes the following raw materials in mass percentages: low-density polyethylene Ethylene 50-70%, linear low density polyethylene 20-30%, polyolefin elastomer 15-20%, metallocene polyethylene 5-10%.

[0040] Wherein, as an option, in order to make the inner film layer have a color, some color masterbatches can be appropriately added in the middle layer of the inner film layer. The color of the color masterbatches can be selected according to specific needs, and the amount of the color masterbatches is 5-10wt%.

[0041] Low density ...

Embodiment 5

[0064] This embodiment relates to a high-barrier composite material. Compared with Embodiment 4, this embodiment differs in that:

[0065] In this embodiment, the coating provided in Embodiment 1 is used as the barrier coating.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com