Polymer packaging material and preparation method thereof

A packaging material and polymer technology, applied in the field of polymer packaging materials and its preparation, can solve the problems of toxic smoke, safety impact, environmental pollution, etc., and achieve improved anti-oxidation performance, high economic value, and good comprehensive performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

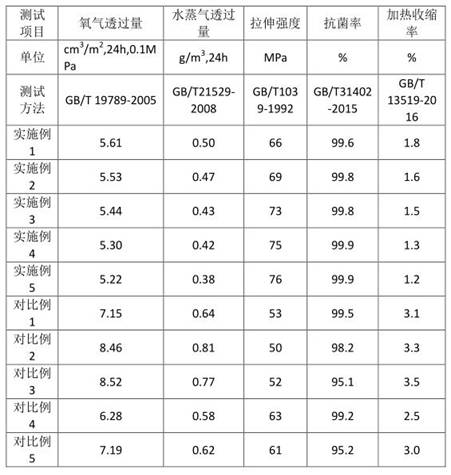

Examples

Embodiment 1

[0032] Embodiment 1 provides a kind of preparation method of polymer packaging material, is characterized in that, comprises the steps:

[0033]Step S1, preparation of the intermediate product: adding 1-p-toluenesulfonyl imidazole and permethrin into the organic solvent, stirring and reacting at 30°C for 3 hours under an oxygen atmosphere, and then removing the solvent by rotary evaporation to obtain the intermediate product;

[0034] Step S2, preparation of fluorine-containing sulfone group-modified hydroxyl-terminated hyperbranched polycarbonate: dissolve the intermediate product and hydroxyl-terminated hyperbranched polycarbonate prepared in step S1 in a high-boiling solvent, and then add 4 -Dimethylaminopyridine, 1-ethyl-(3-dimethylaminopropyl) carbodiimide hydrochloride, polymerization inhibitor, stirred and reacted at 55°C for 8 hours, after the reaction, precipitated in water filter, take the filter residue, remove by-products, unreacted small molecules and water by ro...

Embodiment 2

[0045] Embodiment 2 provides a kind of preparation method of polymer packaging material, is characterized in that, comprises the steps:

[0046] Step S1, preparation of the intermediate product: adding 1-p-toluenesulfonyl imidazole and permethrin into the organic solvent, stirring and reacting at 35°C for 4 hours under an oxygen atmosphere, and then removing the solvent by rotary evaporation to obtain the intermediate product;

[0047] Step S2, preparation of fluorine-containing sulfone group-modified hydroxyl-terminated hyperbranched polycarbonate: dissolve the intermediate product and hydroxyl-terminated hyperbranched polycarbonate prepared in step S1 in a high-boiling solvent, and then add 4 -Dimethylaminopyridine, 1-ethyl-(3-dimethylaminopropyl) carbodiimide hydrochloride, polymerization inhibitor, stirred and reacted at 58°C for 8.5 hours, after the reaction, precipitated in water filter, take the filter residue, remove by-products, unreacted small molecules and water by...

Embodiment 3

[0058] Embodiment 3 provides a kind of preparation method of polymer packaging material, is characterized in that, comprises the steps:

[0059] Step S1, preparation of intermediate product: add 1-p-toluenesulfonyl imidazole and permethrin into an organic solvent, stir and react at 40°C under an oxygen atmosphere for 4.5 hours, and then remove the solvent by rotary evaporation to obtain intermediate product;

[0060] Step S2, preparation of fluorine-containing sulfone group-modified hydroxyl-terminated hyperbranched polycarbonate: dissolve the intermediate product and hydroxyl-terminated hyperbranched polycarbonate prepared in step S1 in a high-boiling solvent, and then add 4 -Dimethylaminopyridine, 1-ethyl-(3-dimethylaminopropyl) carbodiimide hydrochloride, polymerization inhibitor, stirred and reacted at 59°C for 9 hours, after the reaction, precipitated in water filter, take the filter residue, remove by-products, unreacted small molecules and water by rotary evaporation, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com