High-barrier bottle

A high-barrier and additive technology, applied in the chemical industry, can solve problems such as high technical requirements for equipment and difficulty in coating development, and achieve the effects of improving thermal stability, low cost, and improved performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

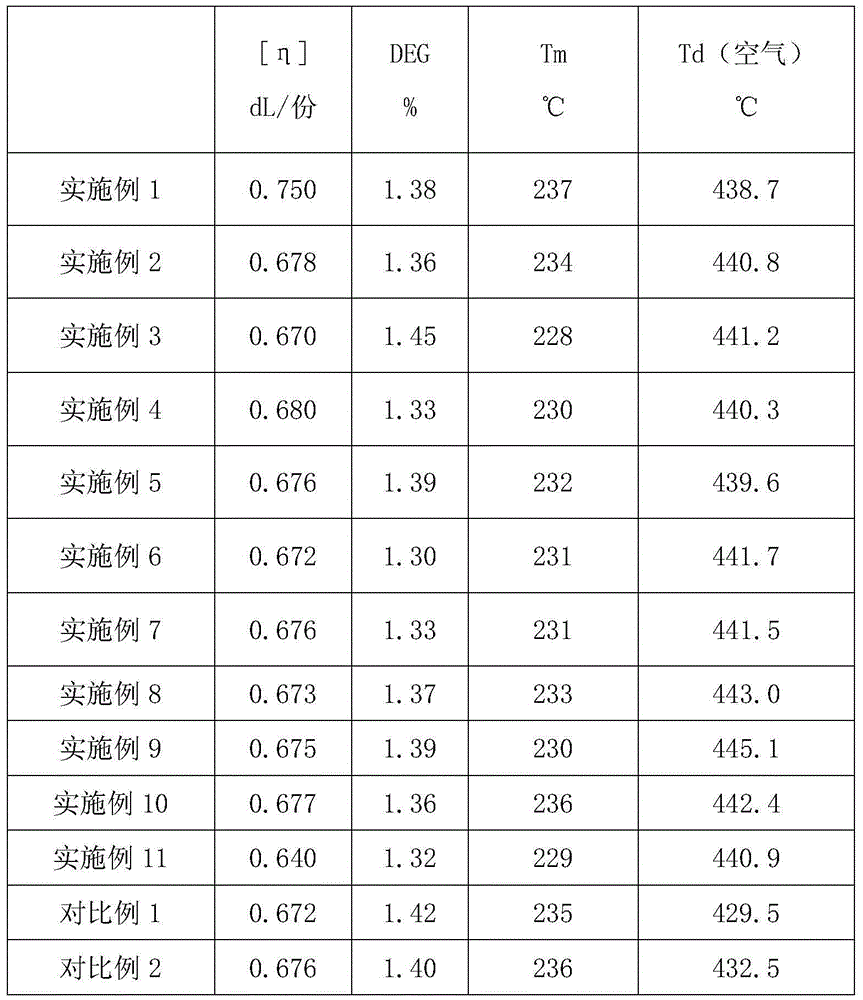

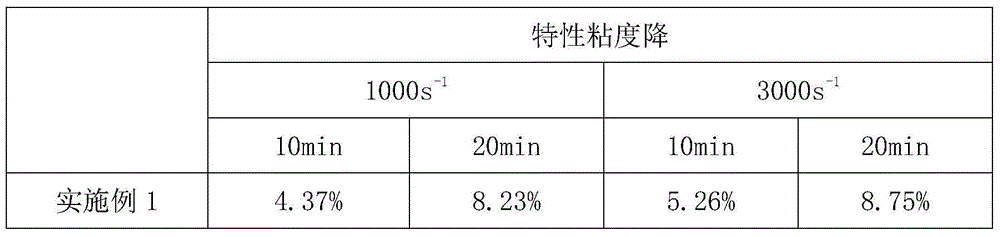

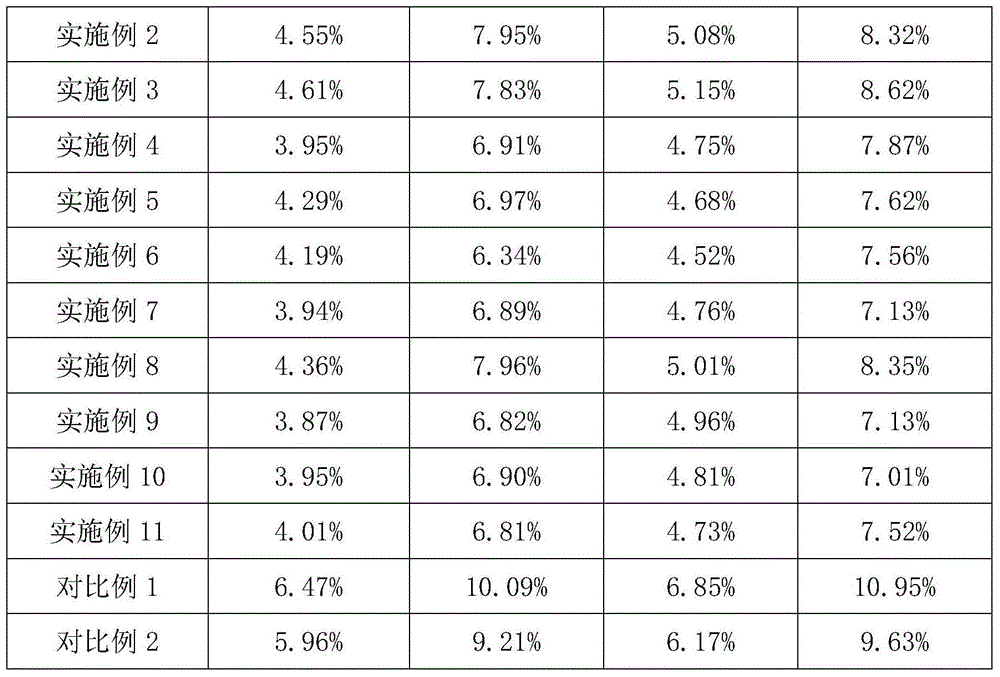

Examples

Embodiment 1

[0029] Put 100 parts of terephthalic acid, 60 parts of ethylene glycol, and 0.05 parts of antimony triacetate into a stainless steel reactor, control the reaction temperature at 235°C, and the reaction pressure at 0.25 MPa, and carry out the esterification reaction for 2 hours; after the reaction, put in PA630 with a relative viscosity of 2.0 share, 0.57 parts of L11, 0.38 parts of trimethyl phosphite, stirred for 10 minutes, then the temperature was set to 260°C, the pressure was gradually reduced to 50 Pa within 45 minutes, and the reaction was continued for 105 minutes to obtain the modified polyesteramide. The obtained modified polyamide ester is then dried and pre-crystallized to increase the viscosity to an intrinsic viscosity of 1.00dL / g to obtain a barrier material for a high barrier bottle. Example 2

Embodiment 2

[0030] Put 100 parts of terephthalic acid, 50 parts of ethylene glycol, and 0.05 parts of antimony triacetate into a stainless steel reactor, control the reaction temperature at 265°C, and the reaction pressure at 0.2 MPa, and carry out the esterification reaction for 2 hours; after the reaction, put in PA1110 with a relative viscosity of 2.1 part, DH201-4600.5 part and stirred for 60min, then the temperature was set to 265°C, the pressure was gradually reduced to 300Pa within 50min, and the reaction was continued for 95min to obtain the modified polyesteramide. The obtained modified polyamide ester is then dried and pre-crystallized, and the viscosity is increased to an intrinsic viscosity of 0.96dL / g to obtain a barrier material for a high barrier bottle.

Embodiment 3

[0032] Put 100 parts of terephthalic acid, 60 parts of ethylene glycol, and 0.05 parts of antimony triacetate into a stainless steel reactor, control the reaction temperature at 235°C, and the reaction pressure at 0.25 MPa, and carry out esterification reaction for 1 hour; after the reaction, put in PA620 with a relative viscosity of 2.2 share, 10.18 parts of H16, 0.09 parts of phosphorous acid, stirred for 10 minutes, then the temperature was set to 260 ° C, the pressure was gradually reduced to 50 Pa within 45 minutes, and the reaction was continued for 106 minutes to obtain the modified polyesteramide. The obtained modified polyamide ester is then dried and pre-crystallized to increase the viscosity to an intrinsic viscosity of 0.90dL / g to obtain a barrier material for a high barrier bottle.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com