Aluminum-plastic film for packaging lithium battery and preparation method of aluminum-plastic film

A technology for aluminum-plastic film and packaging, applied in the field of aluminum-plastic film, can solve the problems of poor heat-sealing performance of polypropylene material, failure of battery packaging, easy decomposition of electrolyte, etc., so as to improve the resistance to electrolyte and hydrolysis. , Improve corrosion resistance, improve the effect of low temperature heat sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

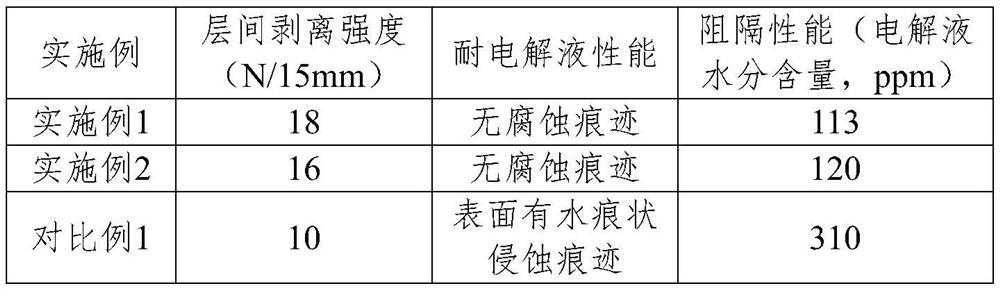

Embodiment 1

[0031] An aluminum-plastic film for lithium battery packaging, comprising a composite layer of outermost polyethylene terephthalate and nylon, a polyurethane bonding layer, an aluminum alloy foil layer, a polyolefin bonding layer and a polypropylene composite layer. Among them, in the outermost layer composite film, the mass ratio of nylon and polyethylene terephthalate is 3.5:1, in the middle layer aluminum alloy foil, the iron content in the aluminum alloy is 2%, and the polypropylene composite layer is Three-layer co-extruded composite film, the middle layer is ultra-high molecular weight polyethylene toughened polypropylene, the mass percentage of ultra-high molecular weight polyethylene is 15%, the outer layer is co-polypropylene filled with silica, and the silica The content is 3.5%, the inner layer is polypropylene copolymer, and the mass ratio of outer layer, middle layer and inner layer material is 2:4:1. In the aluminum-plastic film, the thickness of the nylon compos...

Embodiment 2

[0039] An aluminum-plastic film for lithium battery packaging, comprising a composite layer of outermost polyethylene terephthalate and nylon, a polyurethane bonding layer, an aluminum alloy foil layer, a polyolefin bonding layer and a polypropylene composite layer. Among them, in the outermost layer composite film, the mass ratio of nylon and polyethylene terephthalate is 4.5:1, in the middle layer aluminum alloy foil, the iron content in the aluminum alloy is 5%, and the polypropylene composite layer is Three-layer co-extruded composite film, the middle layer is ultra-high molecular weight polyethylene toughened polypropylene, the mass percentage of ultra-high molecular weight polyethylene is 25%, the outer layer is alumina-filled copolymerized polypropylene, alumina The content is 4.5%, the inner layer is polypropylene copolymer, and the mass ratio of outer layer, middle layer and inner layer material is 4:4:1. In the aluminum-plastic film, the thickness of the nylon compos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com