Porous film for bag-constituting member and bag-constituting member for disposable body warmer

A technology of porous film and bag body, which is applied in the field of bag body components for kairo, can solve the problems of broken bags, heat sealing strength (reduced sealing strength, difficult to achieve high-speed production, etc., and achieves improved heat resistance, Excellent low-temperature heat-sealability and improved productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

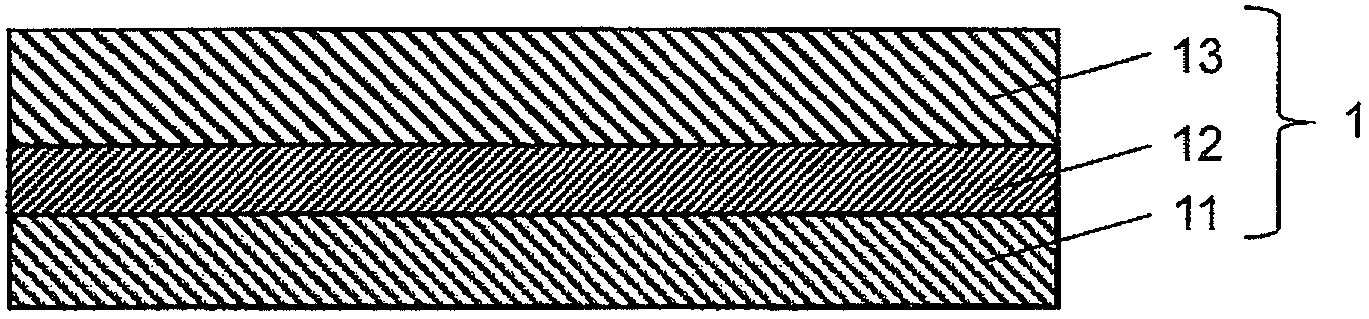

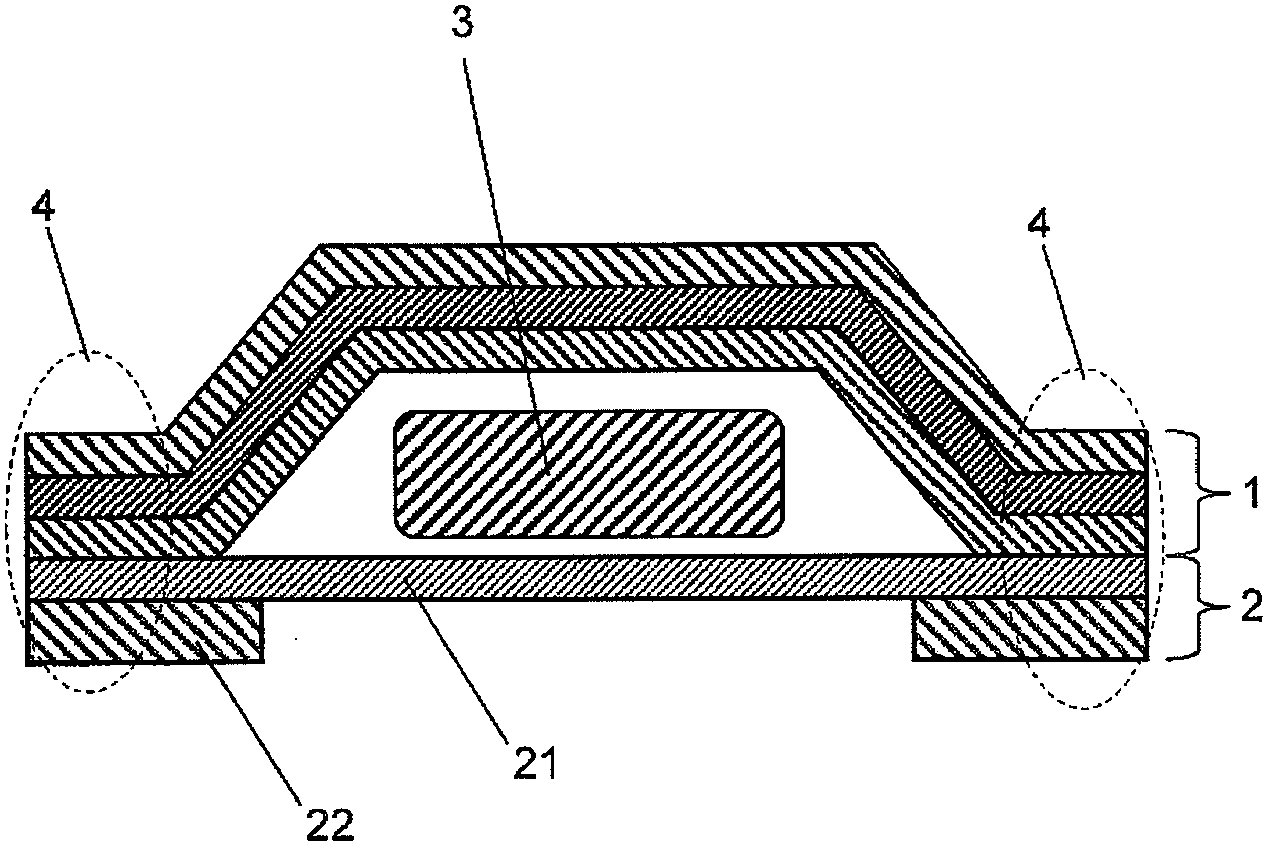

[0127] As a polymer component, 100 parts by weight of linear low-density polyethylene (metallocene LLDPE-(a)) (MFR (190°C): 3.8 (g / 10min), density: 0.918 g / cm 3 , Vicat softening point: 101°C), 30 parts by weight of ethylene-α-olefin copolymer (ethylene-α-olefin copolymer-(d)) (MFR (190°C): 3.6 (g / 10min), density: 0.870g / cm 3 , Vicat softening point: 40°C), 10 parts by weight of high molecular weight ethylene polymer (high molecular weight ethylene homopolymer) with a weight average molecular weight of 320,000 (MFR (190°C): 0.08 (g / 10min), density: 0.958 g / cm 3 ), and 130 parts by weight of calcium carbonate (inorganic particles) with an average particle size of 1.1 μm, 0.5 parts by weight of calcium stearate and 0.8 parts by weight of antioxidant were melted and kneaded at 200 ° C to obtain a mixed raw material.

[0128] The mixed raw materials were melt-extruded at 210° C. with a single-screw extruder to produce an unstretched film. Then, the unstretched film was stretche...

Embodiment 2

[0131] As shown in Table 2, change metallocene LLDPE-(a) to metallocene LLDPE-(b) (MFR (190°C): 3.8 (g / 10min), density: 0.924g / cm 3 , Vicat softening point: 106°C), except that the calcium stearate was changed to 1.5 parts by weight, and the antioxidant was changed to 1 part by weight, except that, the same operation as in Example 1 was performed to produce a porous film and a bag constituting member.

Embodiment 3

[0133] As shown in Table 2, change the high molecular weight ethylene copolymer into a high molecular weight ethylene-propylene copolymer with a weight average molecular weight of 790,000 (MFR (190°C): 43 (g / 10 minutes), density: 0.930 g / cm 3 ), except that the calcium stearate was changed to 1.5 parts by weight, and the antioxidant was changed to 1 part by weight. In the same manner as in Example 1, a porous film and a bag constituting member were produced.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com