Ink for inkjet printing and preparation method as well as zirconia film printed by ink for inkjet printing

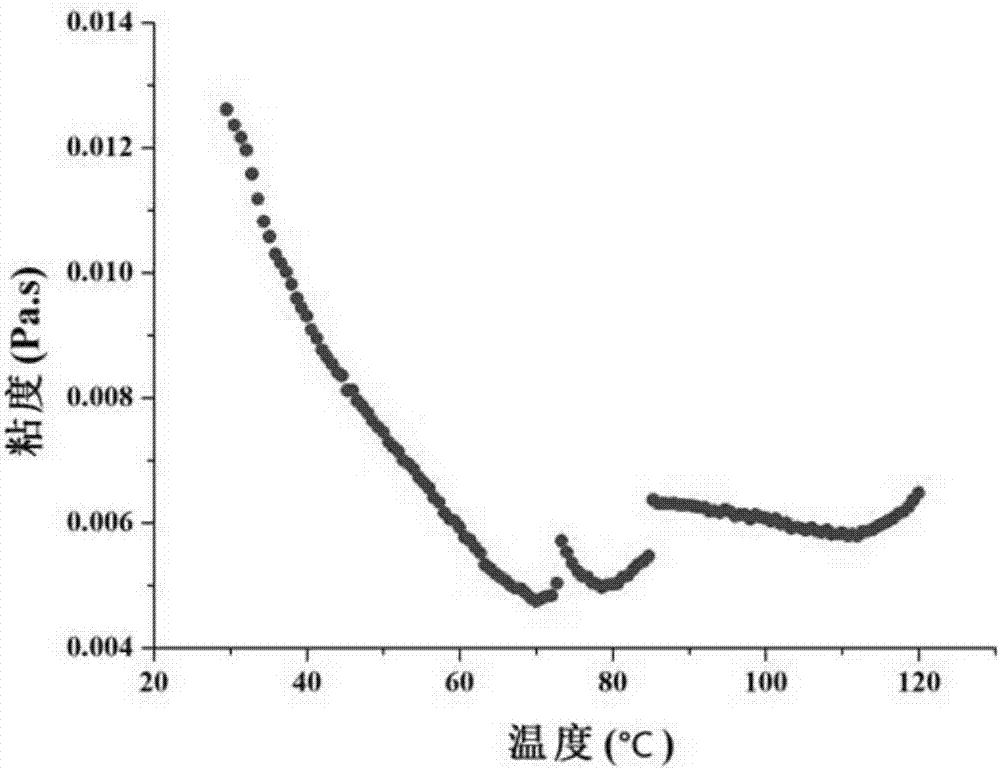

An inkjet printing, zirconia technology, applied in printing, ink, application, etc., can solve problems such as affecting the surface flatness of inkjet printing films, restricting applications, etc., to inhibit solute migration, improve surface morphology, and weaken coffee ring. effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

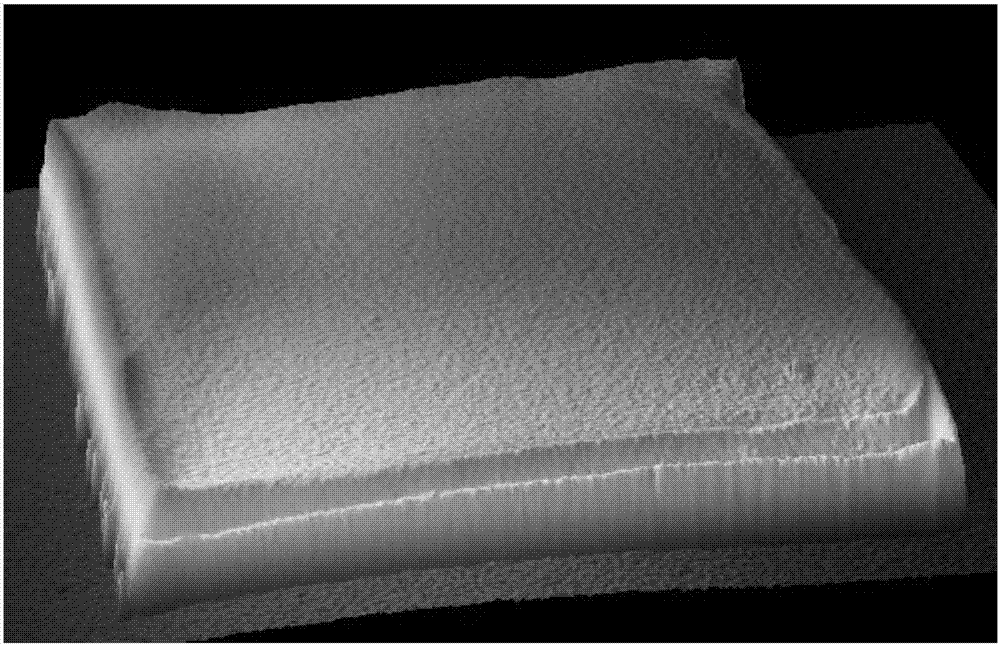

Examples

Embodiment 1

[0047] 1. Drug and reagent preparation

[0048] Raw material preparation for solution preparation: zirconium oxychloride octahydrate, analytically pure, content ≥99.0%, Shanghai Runjie Chemical Reagent Co., Ltd.; ethylene glycol methyl ether, analytically pure, content ≥99.0%, Tianjin Fuyu Fine Chemical Co., Ltd. ; polyvinylpyrrolidone (PVP) K30, Shanghai Boao Biotechnology Co., Ltd.; ethylene glycol, analytically pure, content ≥ 99.0%, Shanghai Runjie Chemical Reagent Co., Ltd.

[0049] 2. Substrate and container cleaning

[0050] Finger bottle cleaning: unscrew the bottle cap of the finger bottle to be washed, sink it into a large beaker filled with isopropanol, and put the bottle cap together. It should be noted that the bottle must be completely filled with isopropanol, and no Bubbles, then ultrasonic (53kHz) vibration for 15min, then deionized water and the same ultrasonic (53kHz) vibration for 15min. Care should be taken to avoid contacting the inner wall of the bottle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com