Residual heat recycling device

A waste heat recovery and heat collecting tube technology, which is used in waste heat treatment, transportation and packaging, lighting and heating equipment, etc., can solve the problems of blocking smoke, inconvenient operation, and reduced adsorption performance of the filter, saving energy, simple and convenient operation. , Improve the efficiency of cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The following is further described in detail through specific implementation methods:

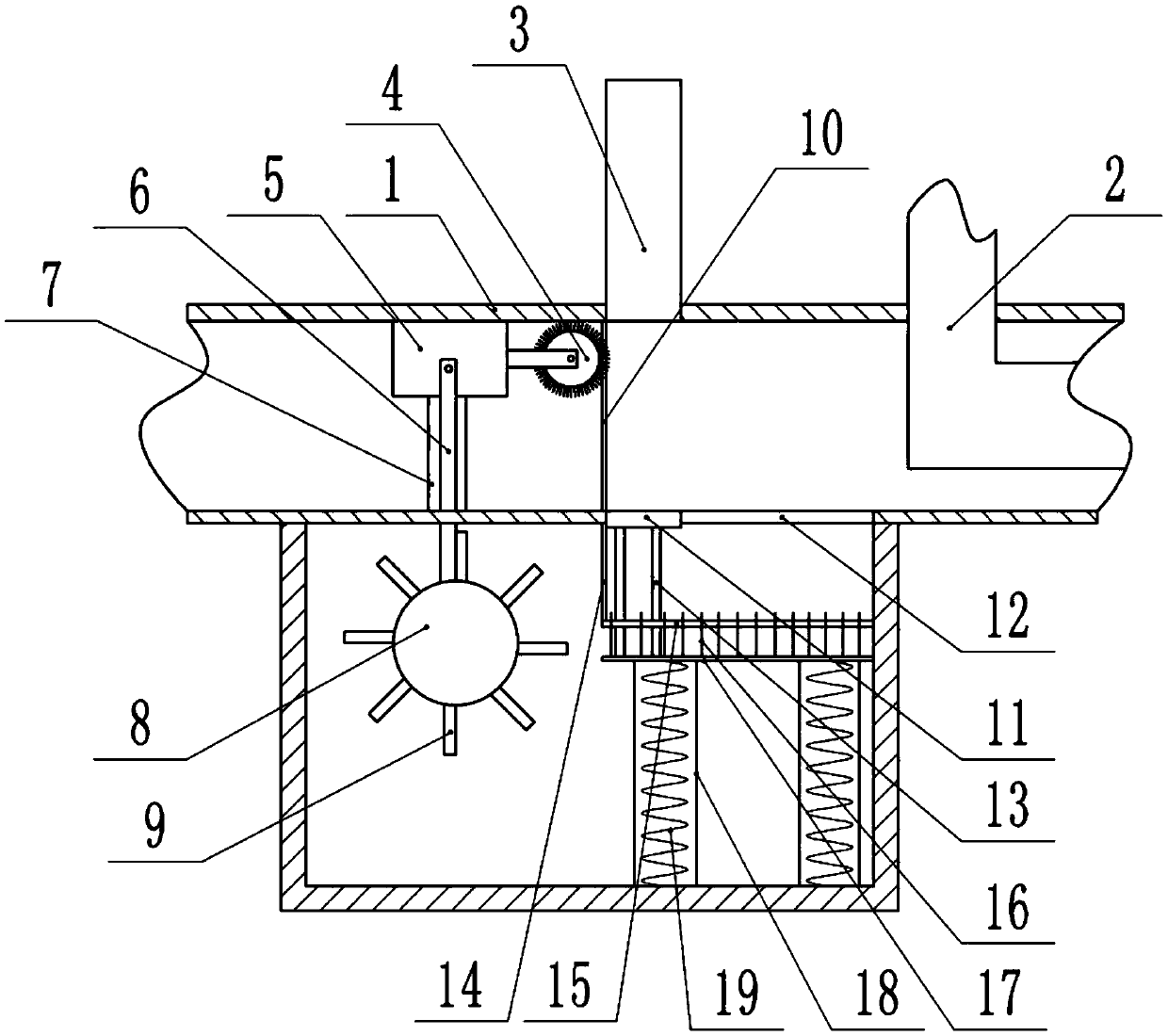

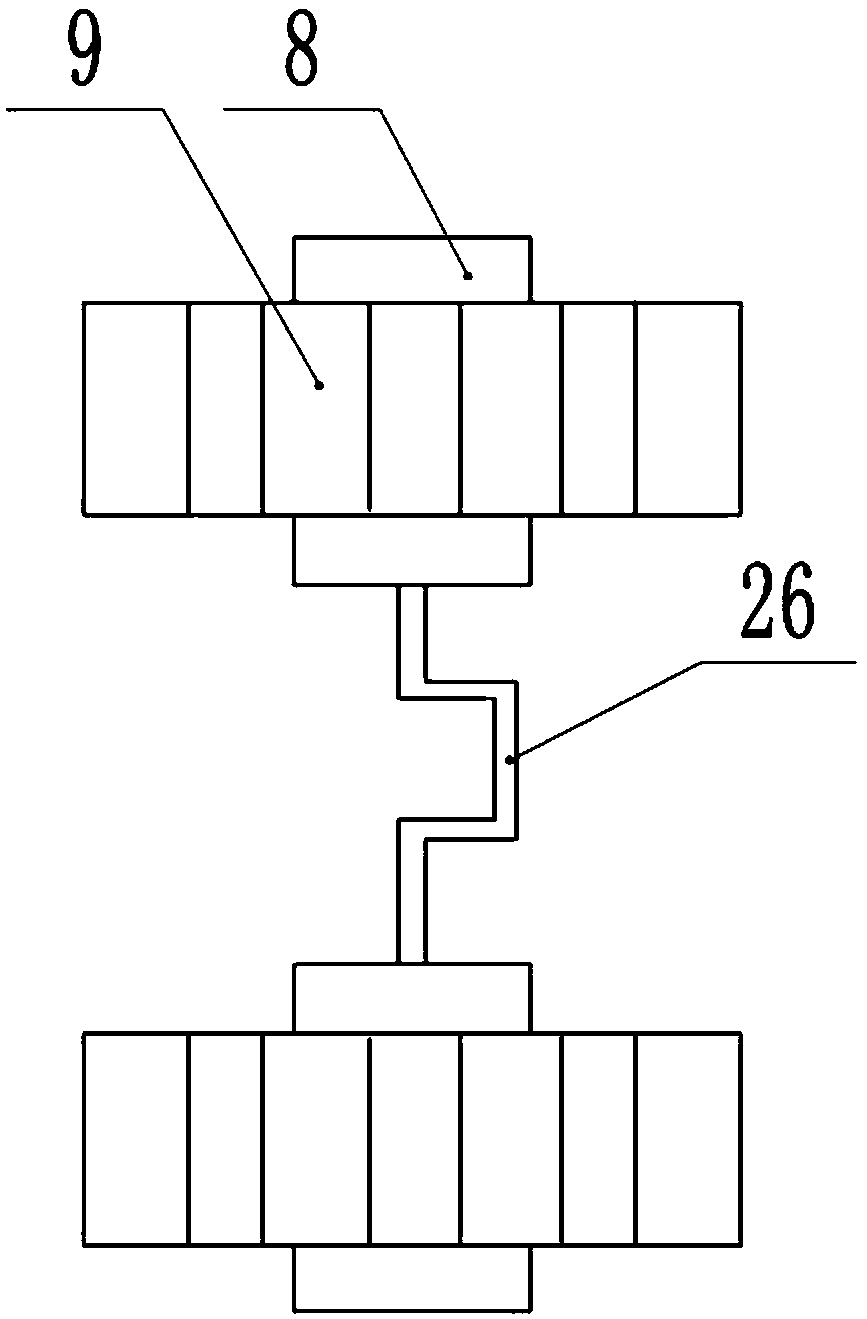

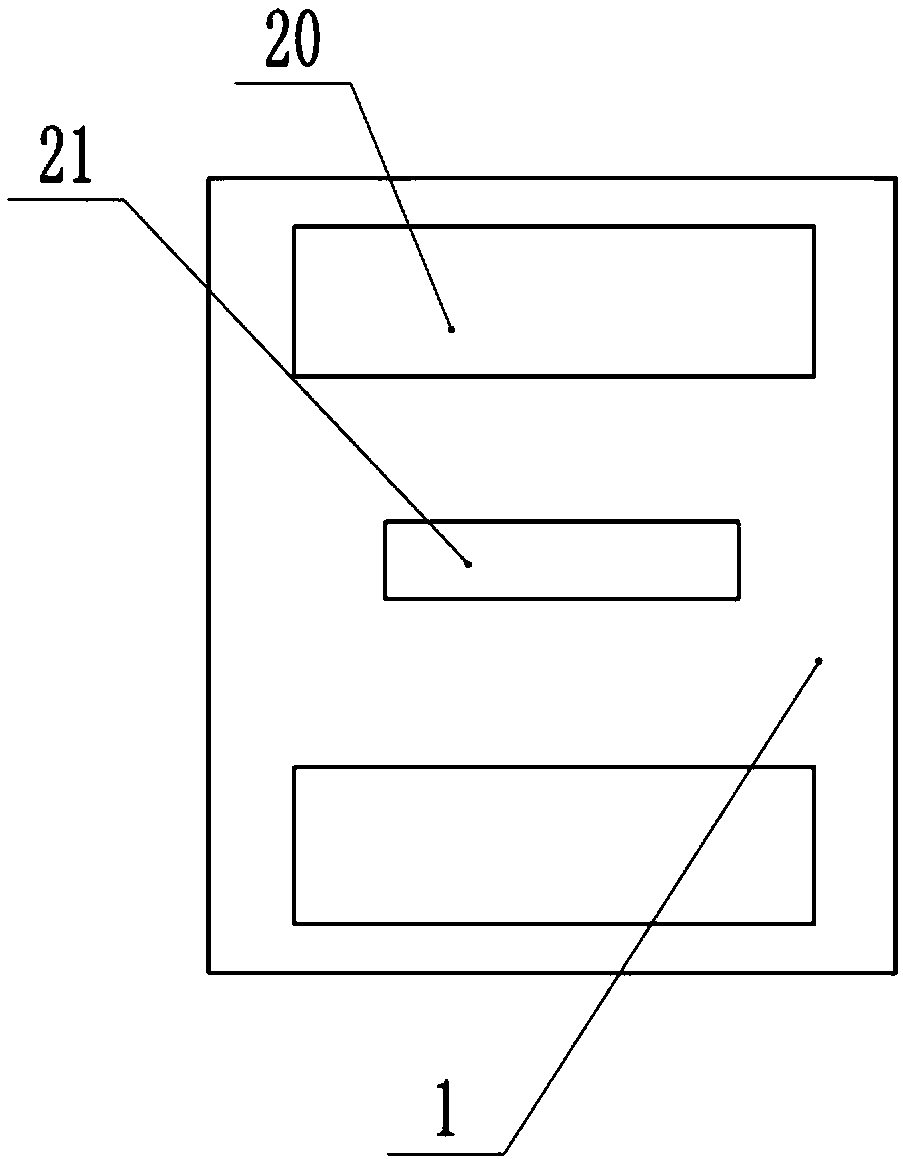

[0028] The reference signs in the accompanying drawings of the specification include: smoke exhaust pipe 1, heat collecting pipe 2, baffle plate 3, cleaning roller 4, slider 5, connecting rod 6, chute 7, rotating roller 8, fan blade 9, main filter screen 10. Press plate 11, air outlet 12, vertical rod 13, fixed plate 14, secondary filter screen 15, plugging needle 16, slide plate 17, telescopic tube 18, pressure spring 19, air inlet 20, connecting rod hole 21, through hole 22, Mesh 23, one-way door 24, torsion spring 25, crankshaft 26.

[0029] The embodiment is basically as attached Figure 1-Figure 5 Shown: the waste heat recycling device, including the exhaust pipe 1 and the heat collecting pipe 2, the heat collecting pipe 2 is located inside the smoke exhaust pipe 1, and the main filter screen 10 located on the left side of the heat collecting pipe 2 is installed in the smoke ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com