Polymer spraying mechanism for static spinning nanofiber

A nanofiber and electrospinning technology, which is applied in fiber processing, textiles and papermaking, filament/thread forming, etc., can solve the problems of large error in polymer supply, decreased production effect, excessive injection of needles, etc. Suitable, improve quality, and stabilize spinning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

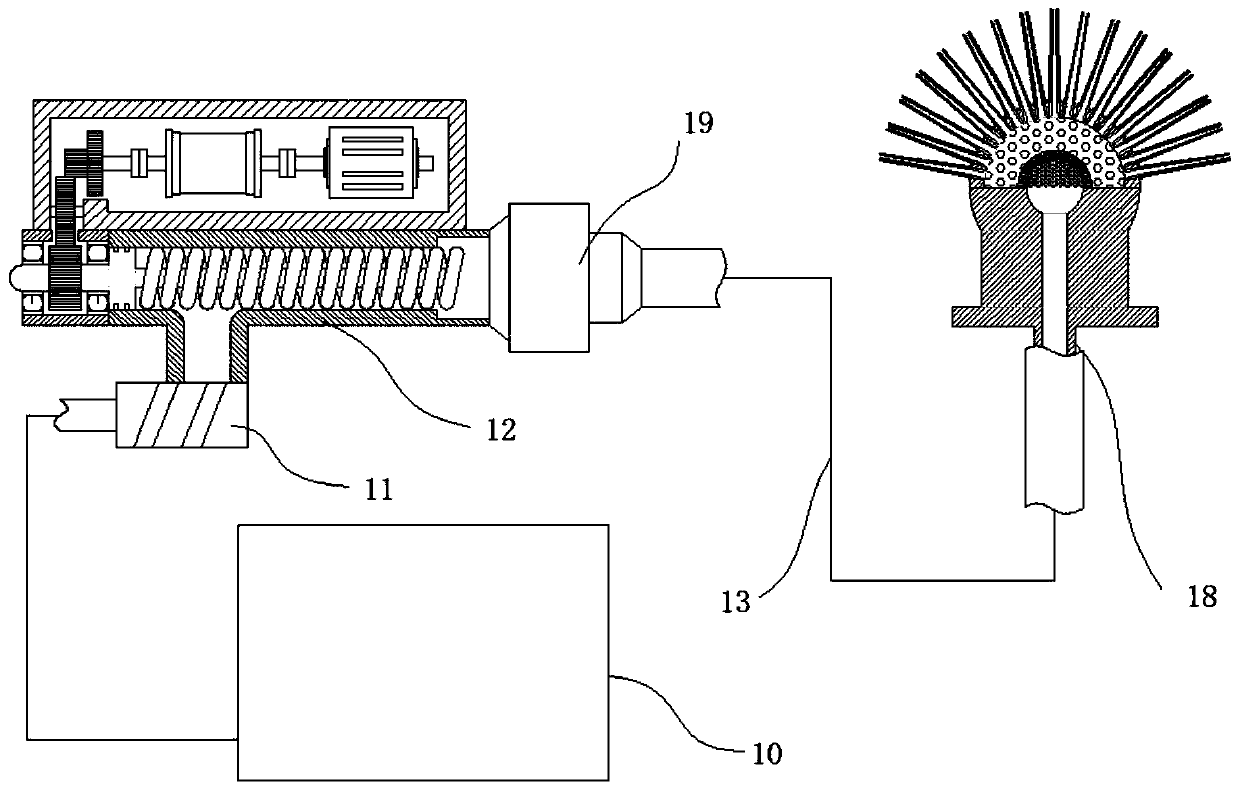

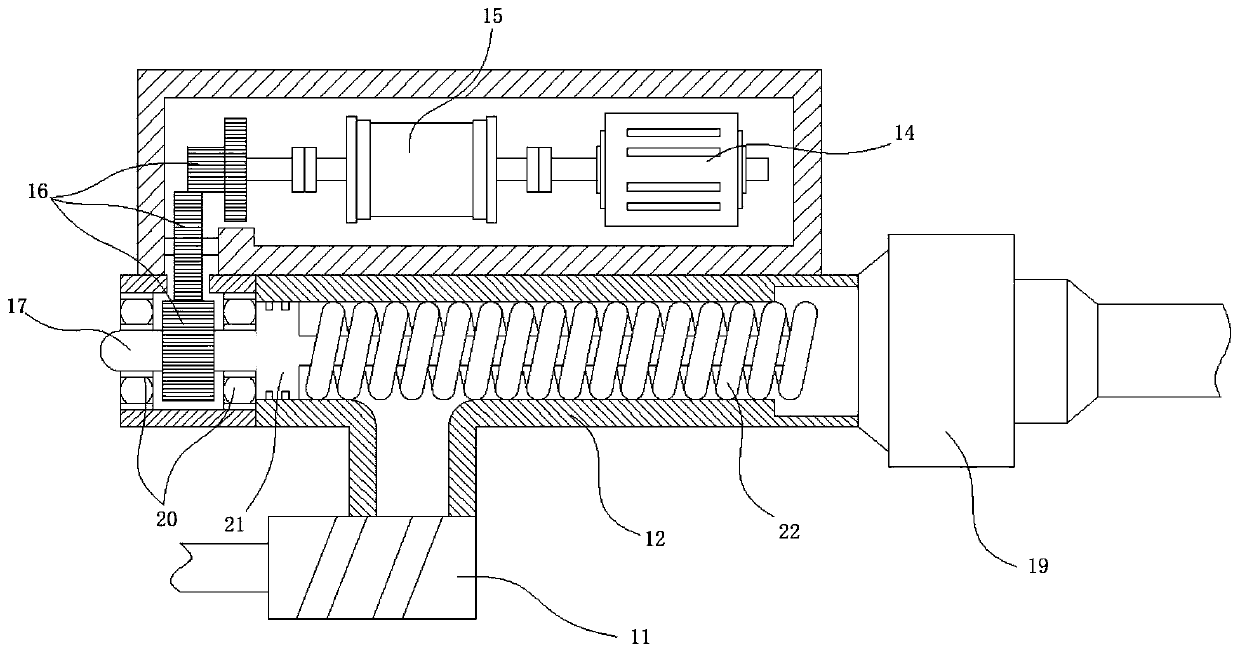

[0026] A polymer injection mechanism for electrospinning nanofibers as shown in the figure is characterized in that it includes a polymer supply mechanism and a spinning needle, and the polymer supply mechanism includes a polymer storage tank, a metering pump, and a quantitative supply tube and a polymer supply pipeline, the spinneret needle includes a nozzle body and a detachable needle unit, the polymer storage tank and the metering pump are connected through pipelines, and the quantitative supply pipeline includes a motor, a gear reducer, a gear The polymer supply mechanism is connected with the spinneret through the pipe joint and the polymer supply pipeline, and the polymer is quantitatively supplied to the spinneret.

[0027] The above-mentioned polymer injection mechanism for electrospinning nanofibers, wherein the motor is connected to a gear reducer, a gear set is connected to the transmission shaft of the gear reducer, and the shaft is driven to rotate by the gear set...

Embodiment 2

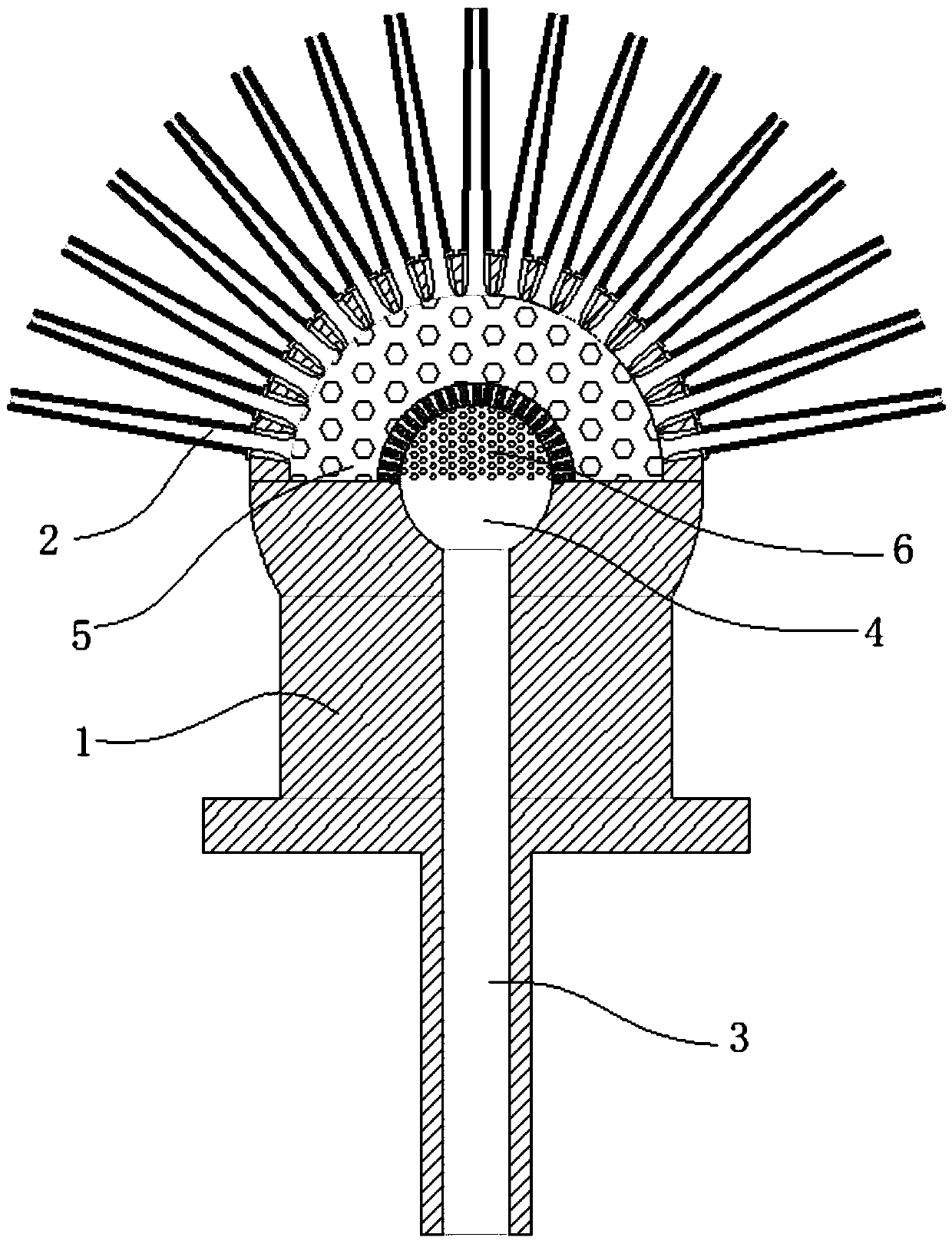

[0031] In the spinning needle of this embodiment, the nozzle tube is provided with a nozzle pipe for polymer supply, a nozzle distributor for uniform distribution of the polymer, and a nozzle inner cavity for the polymer to flow to the needle unit. The number of units is multiple, and multiple needle units are detachably and hermetically connected to the nozzle body, and are evenly distributed on the spherical end of the nozzle body;

[0032] Wherein, the nozzle pipe is a straight line pipe and communicates with the nozzle distributor. The nozzle distributor is hollow spherical, and the surface of the upper half of the spherical shape is provided with a plurality of distribution channels for polymer circulation. Holes, a plurality of the distribution through holes are evenly distributed, and communicate with the inner cavity of the nozzle, the inner cavity of the nozzle is a hemispherical cavity, and communicated with the needle unit, the pipeline of the nozzle, the distributor...

Embodiment 3

[0035] In this embodiment, the needle unit is detachably and airtightly connected to the nozzle body through plugging, clamping or threaded connection;

[0036] Wherein, the needle unit includes a connecting part and a needle tube, the needle unit is connected with the nozzle body through the connecting part, and communicates with the inner cavity of the nozzle and the needle tube, and the needle tube is a flexible tube, and a plurality of soft metal wires are embedded in it , the soft metal wire is electrically connected to the connecting part, and the nozzle body is electrically connected to the needle unit;

[0037] Wherein, the soft metal wire is one of iron wire, copper wire, silver wire or aluminum wire.

[0038]Most of the existing spinneret needles are fixed and difficult to replace. In this embodiment, the needle unit is improved, replaced by a hose, and a conductive soft metal wire is implanted inside. During the electrospinning process, the soft metal The filament ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com