Patents

Literature

37results about How to "Improve jetting stability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

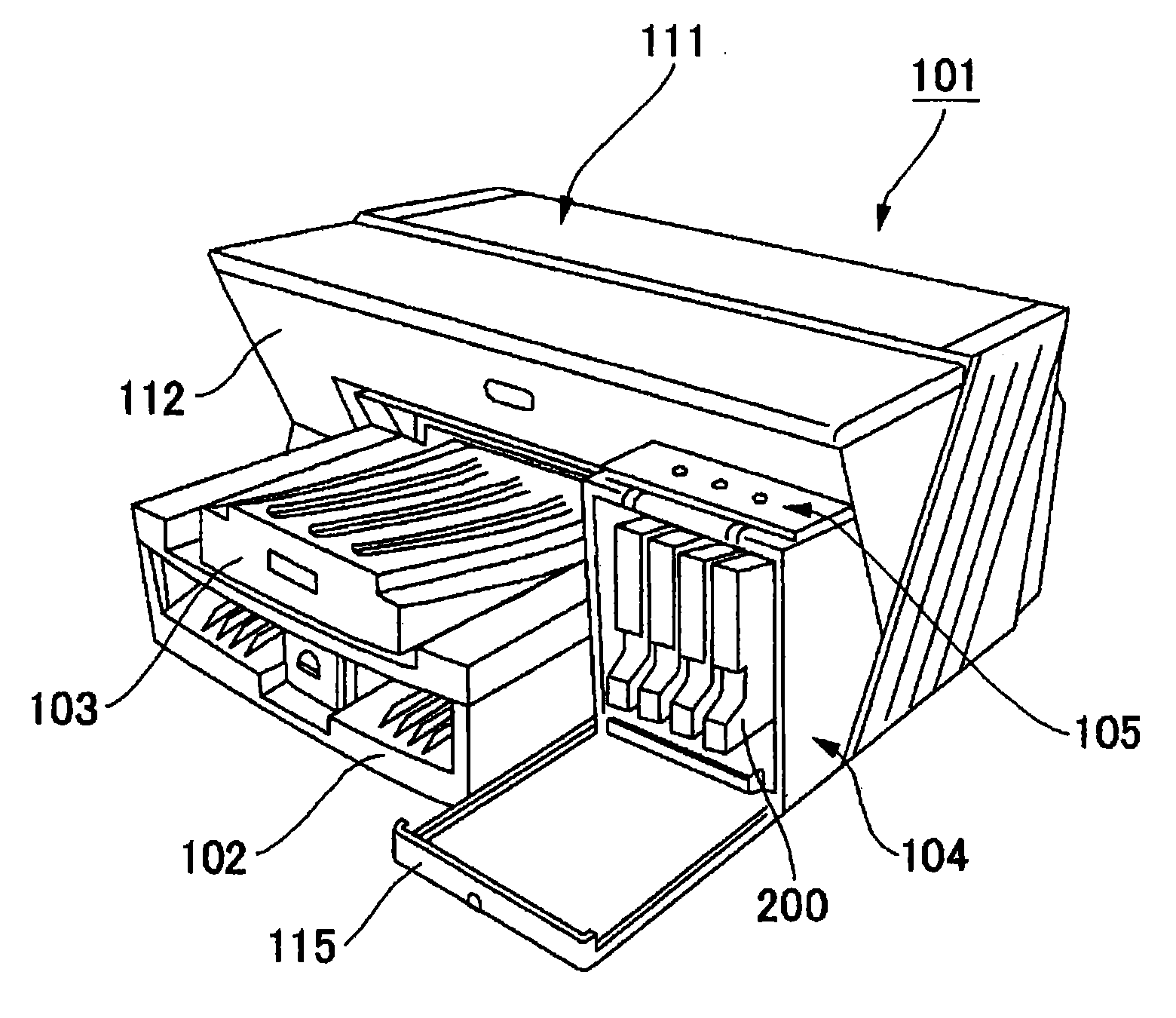

Refill ink and ink cartridge

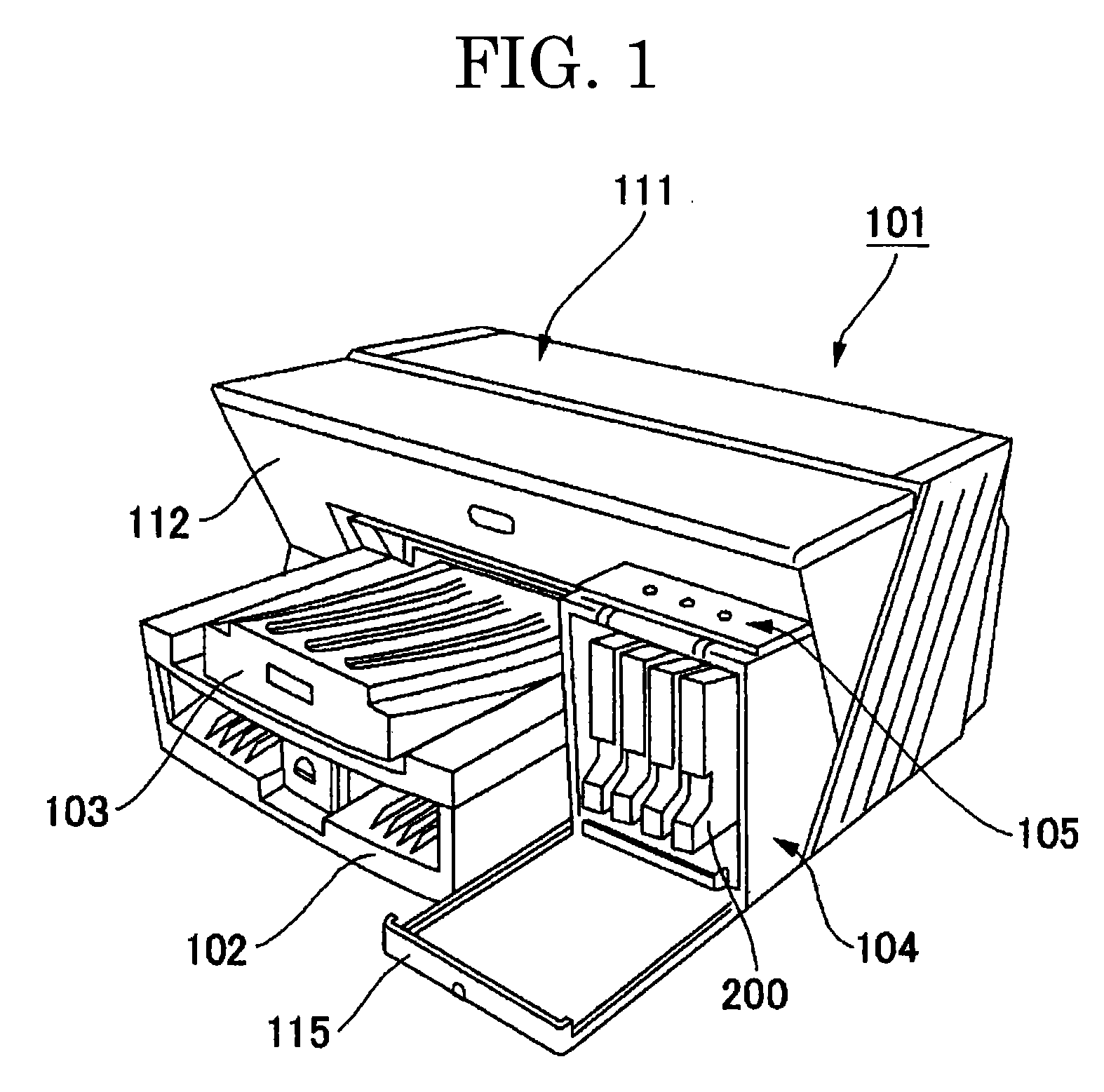

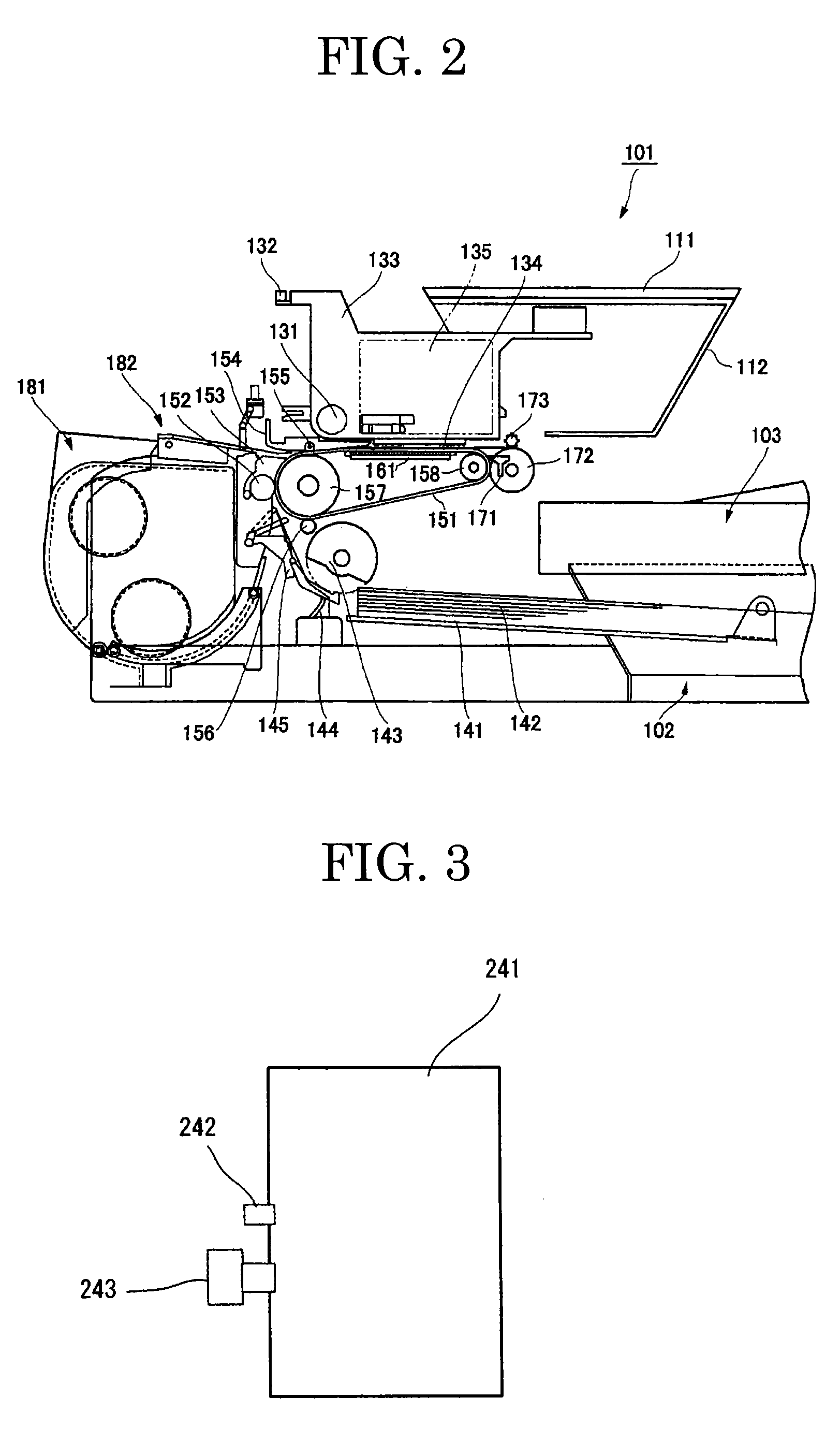

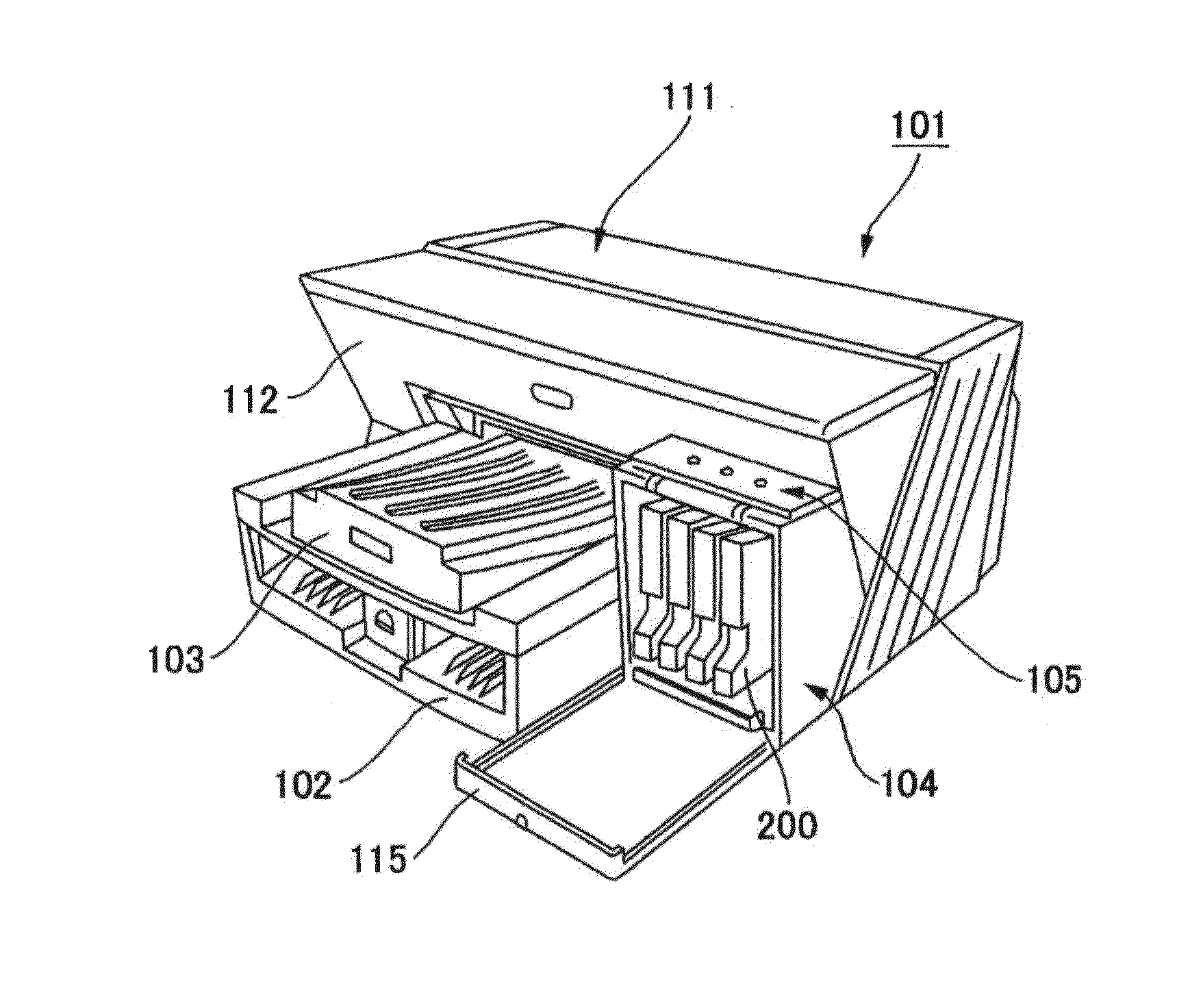

InactiveUS20100020142A1Improve jetting stabilityGood storage stabilityDuplicating/marking methodsInksEngineeringWetting

A refill ink with which a used ink cartridge is to be refilled, including: a colorant, a wetting agent, and a surfactant, wherein in a mixed ink formed by mixing a residual ink remaining in the used ink cartridge and the refill ink at a volume ratio (residual ink:refill ink) of 1:1, the number A of coarse particles of 0.5 μm or greater in diameter measured immediately after the mixing and the number B of coarse particles of 0.5 μm or greater in diameter measured after the mixed ink has been left to stand at 25° C. and at RH of 50% for 24 hours satisfy the relationship B / A≦2.

Owner:RICOH KK

Ink composition

ActiveUS20150105504A1Good dispersionImprovement ingredientsInksEmulsion paintsPolymer scienceOrganic chemistry

Disclosed is an aqueous ink composition including between 1 and 40 weight % of a water dispersible resin, between 0.5 and 15 weight % of a colorant, between 20 and 80 weight % of water and between 1 and 30 weight % of an acetal cosolvent, wherein all amounts are relative to the total ink composition. The ink composition may further include between 15 and 75 weight % of a dispersion stabilizing cosolvent.

Owner:OCE TECH

Ink for inkjet recording, ink set for inkjet recording, ink media set for inkjet recording, ink cartridge, inkjet recording method, and inkjet recording apparatus

InactiveCN101365761AImprove printing qualityHigh glossDuplicating/marking methodsInksWater dispersibleOrganic solvent

To provide an ink for inkjet recording containing water, water-soluble organic solvent, water-dispersible resin, fluorochemical surfactant or derivative thereof, and coloring agent containing pigment, wherein the ink has a surface tension of 20-35 mN / n and viscosity of 5 mPas or more at 25 DEG C, total amount of the water-dispersible resin and the coloring agent in the ink is 5-40% by mass, and mass ratio A / B of the water-dispersible resin A to the coloring agent B is 0.5-4, wherein the ink is applied for a recording medium for inkjet recording containing a support containing cellulose pulp, and one or more barrier layers disposed on at least one face of the support, and wherein the barrier layer contains 30% by mass or more of inorganic pigment having refractive index of 1.5 or more, excluding aluminum hydrate, and 10% by mass or more of inorganic pigment having a refractive index of less than 1.5.

Owner:RICOH KK

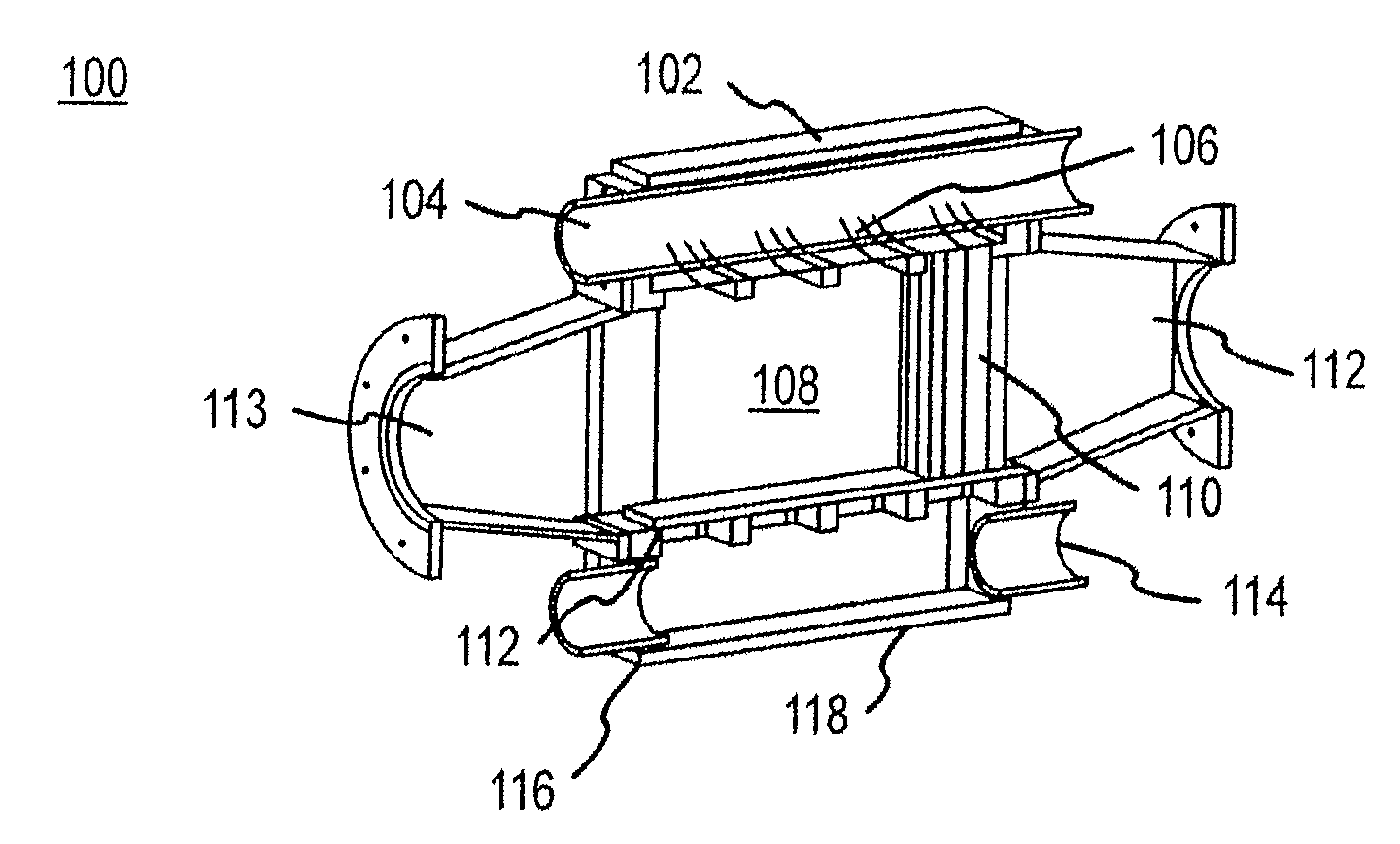

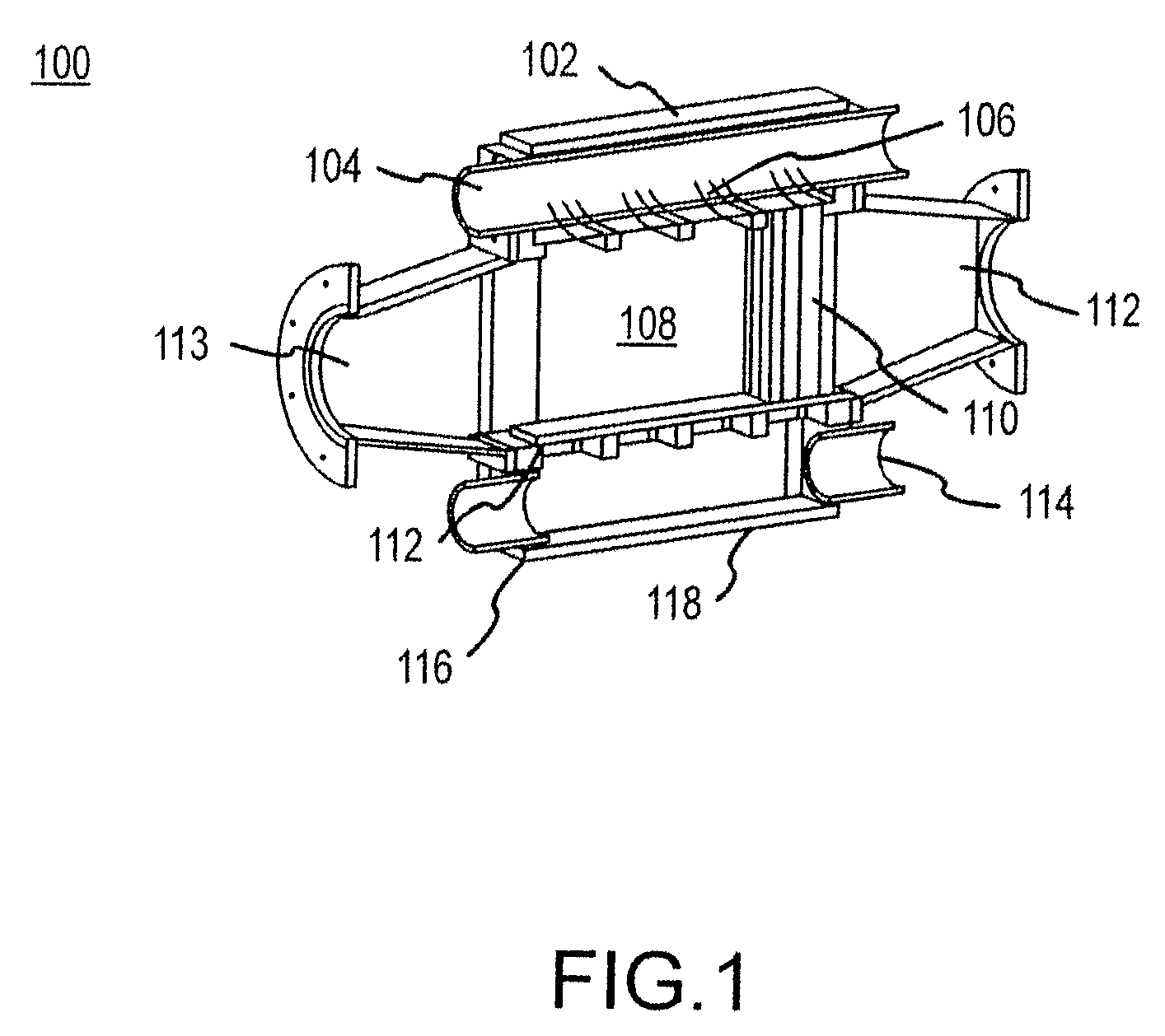

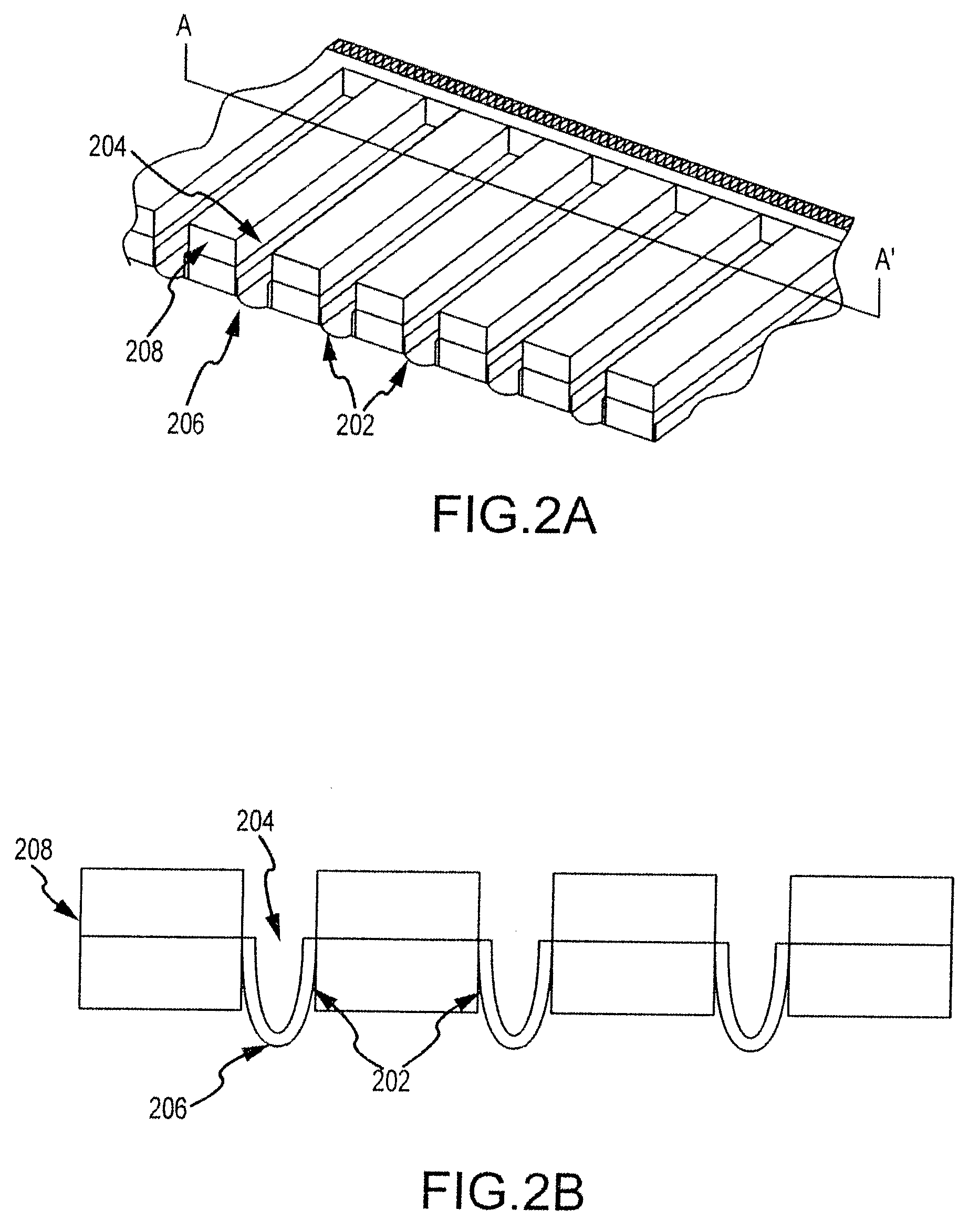

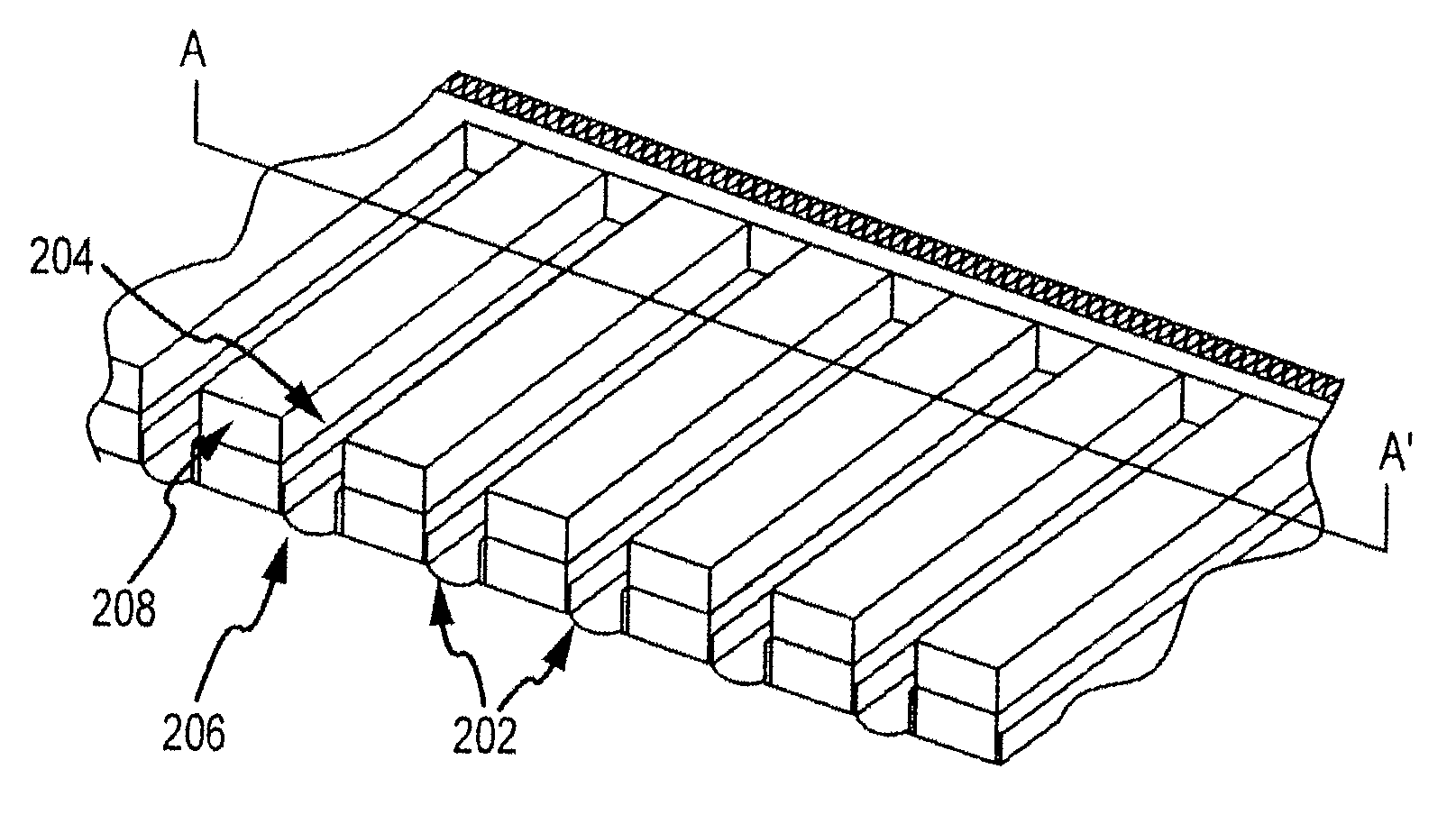

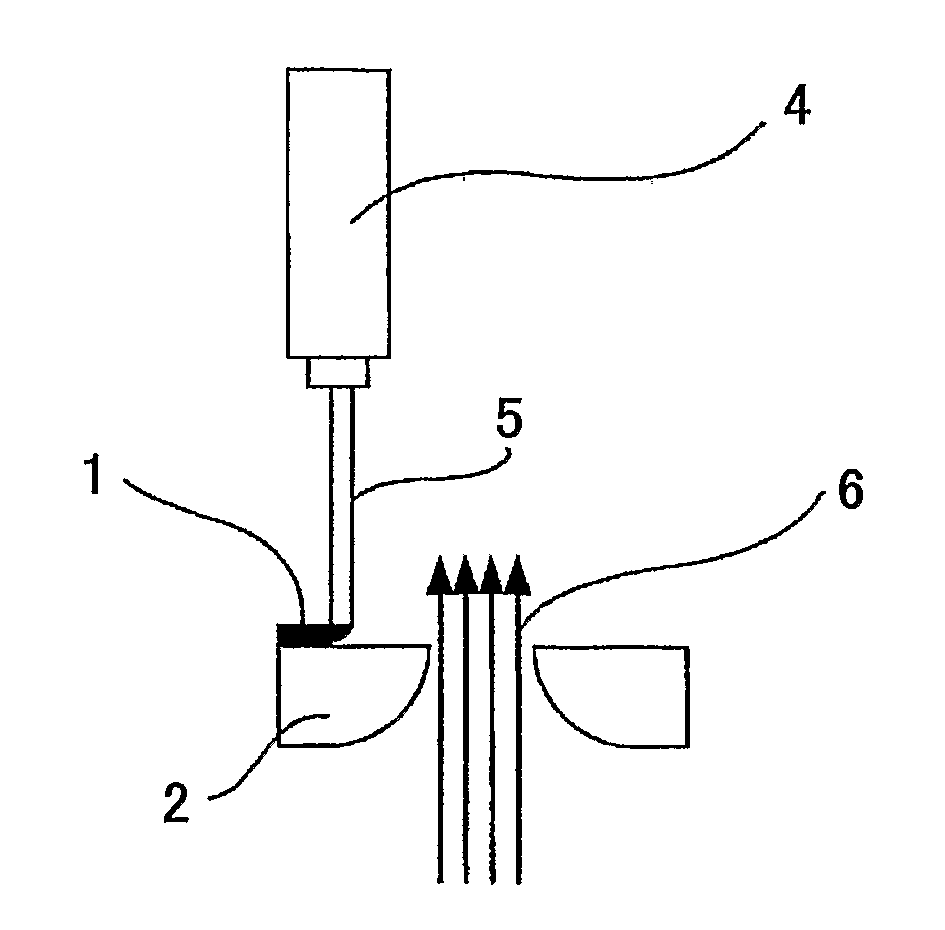

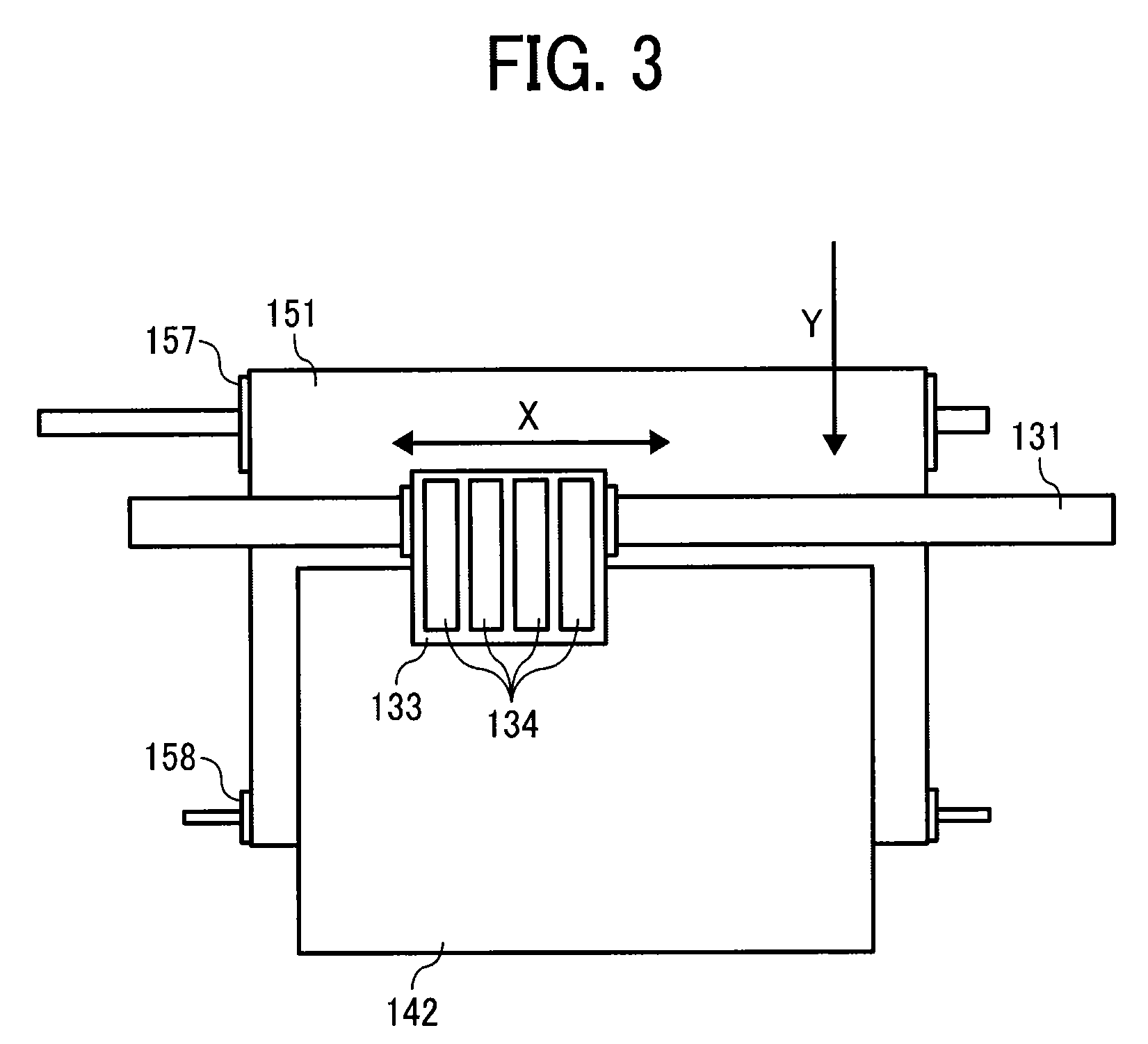

Apparatus and method thereof

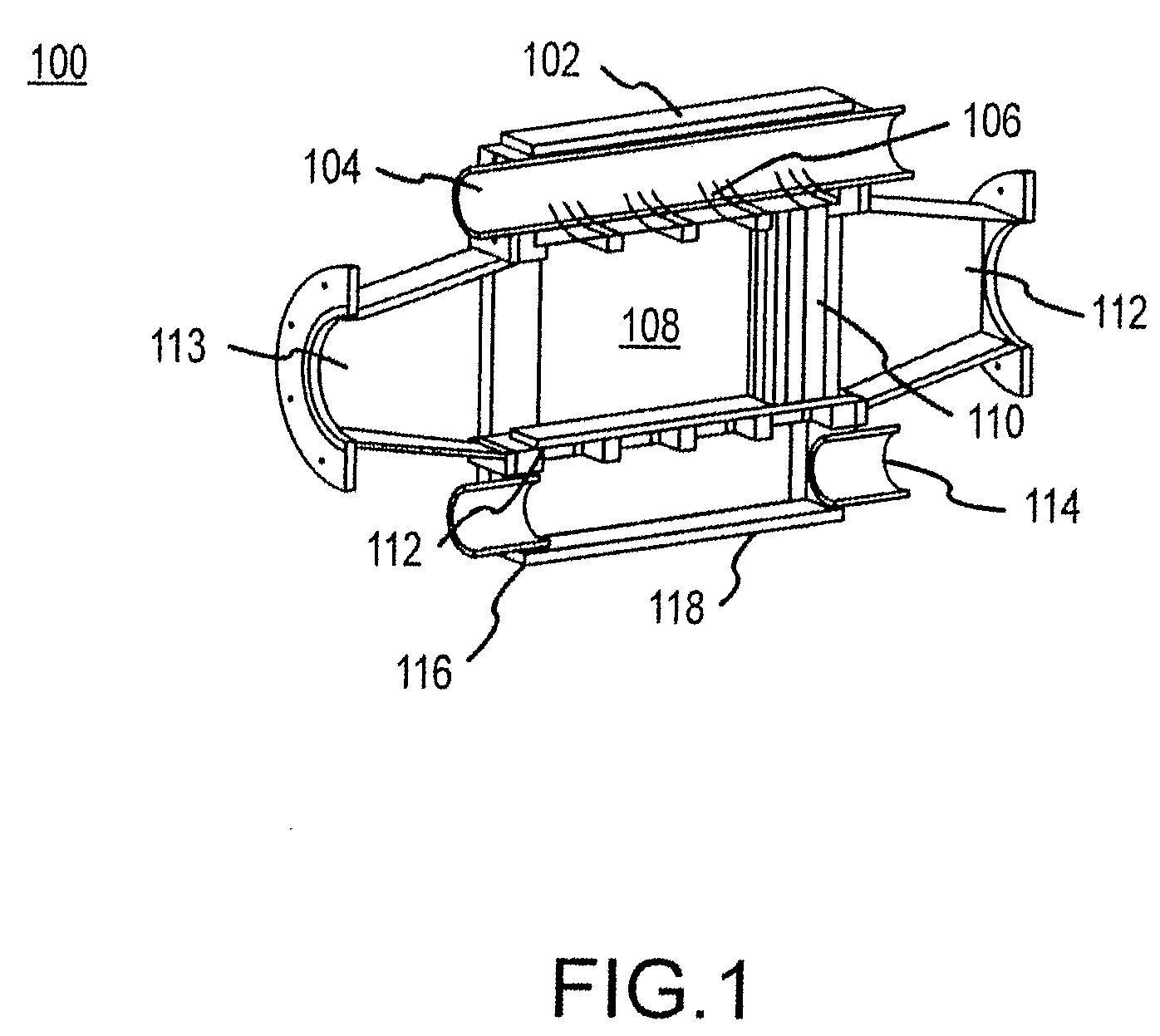

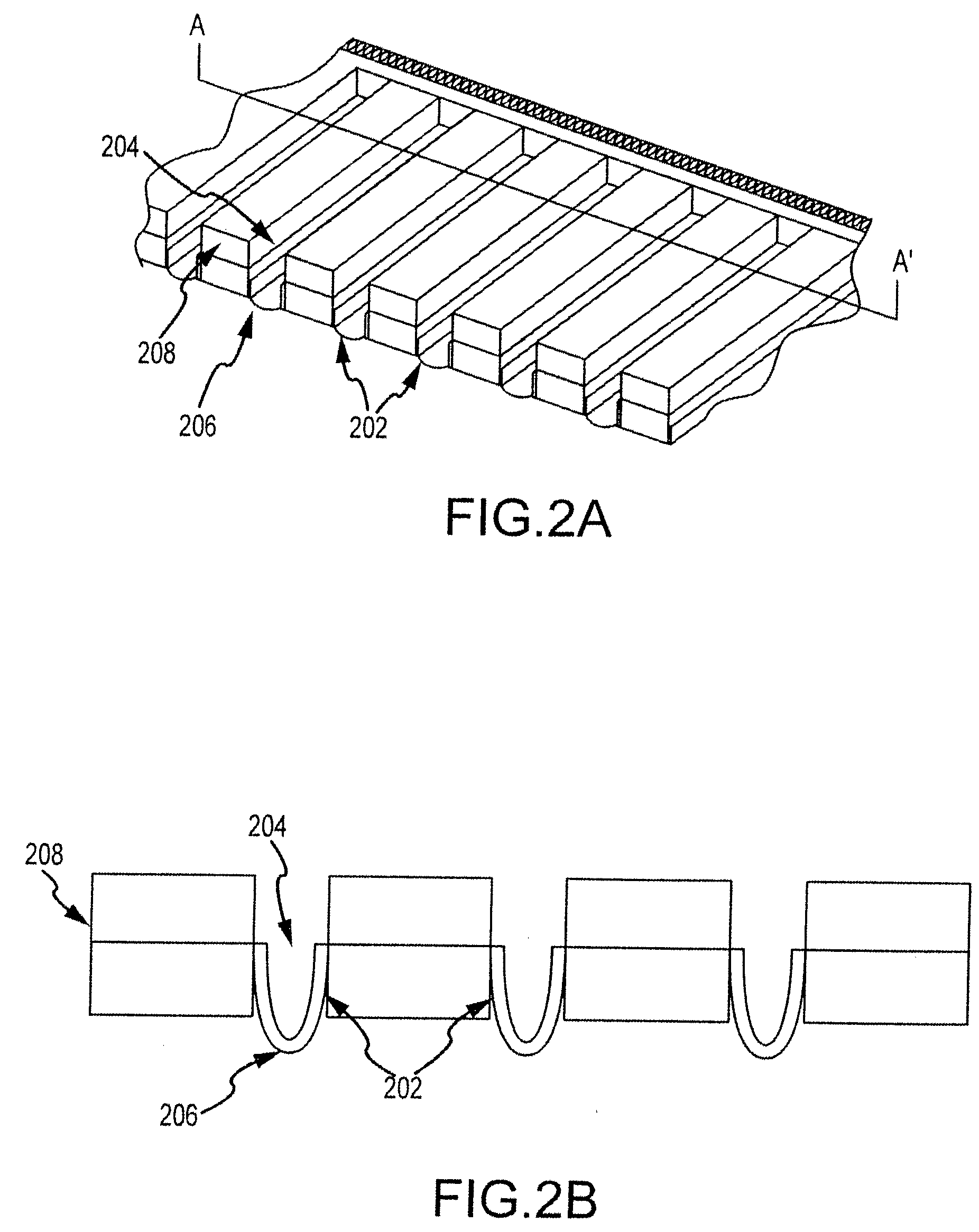

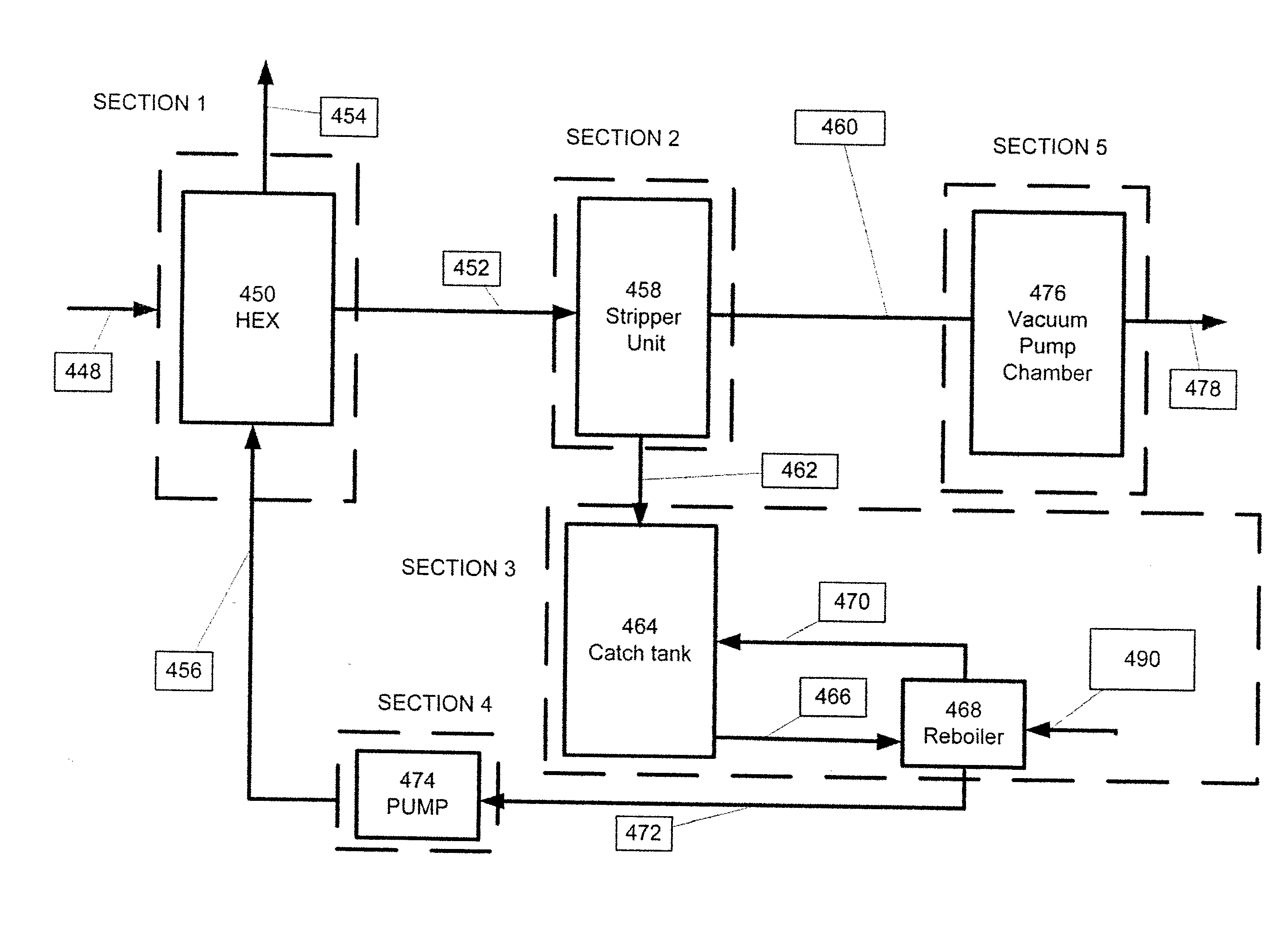

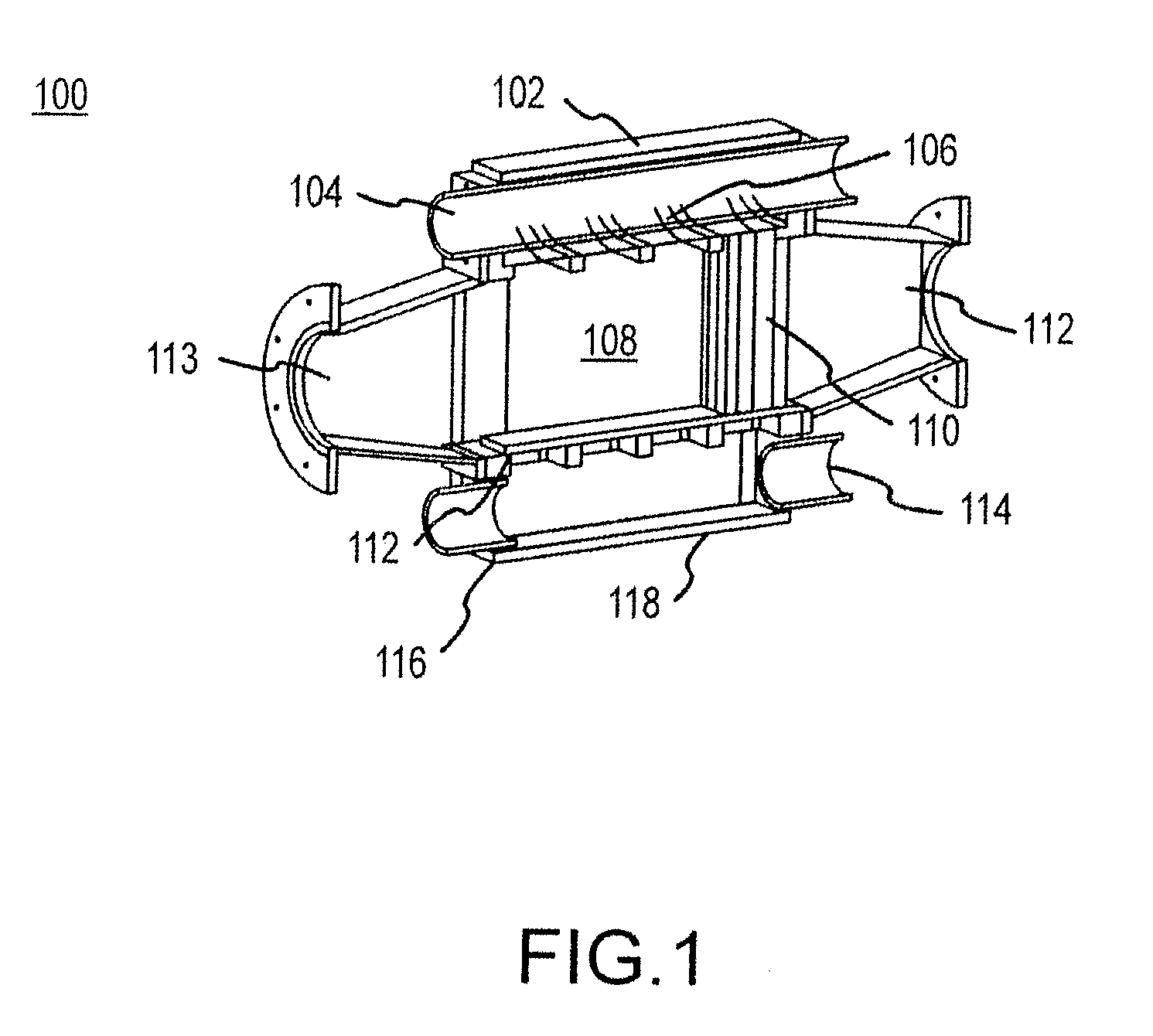

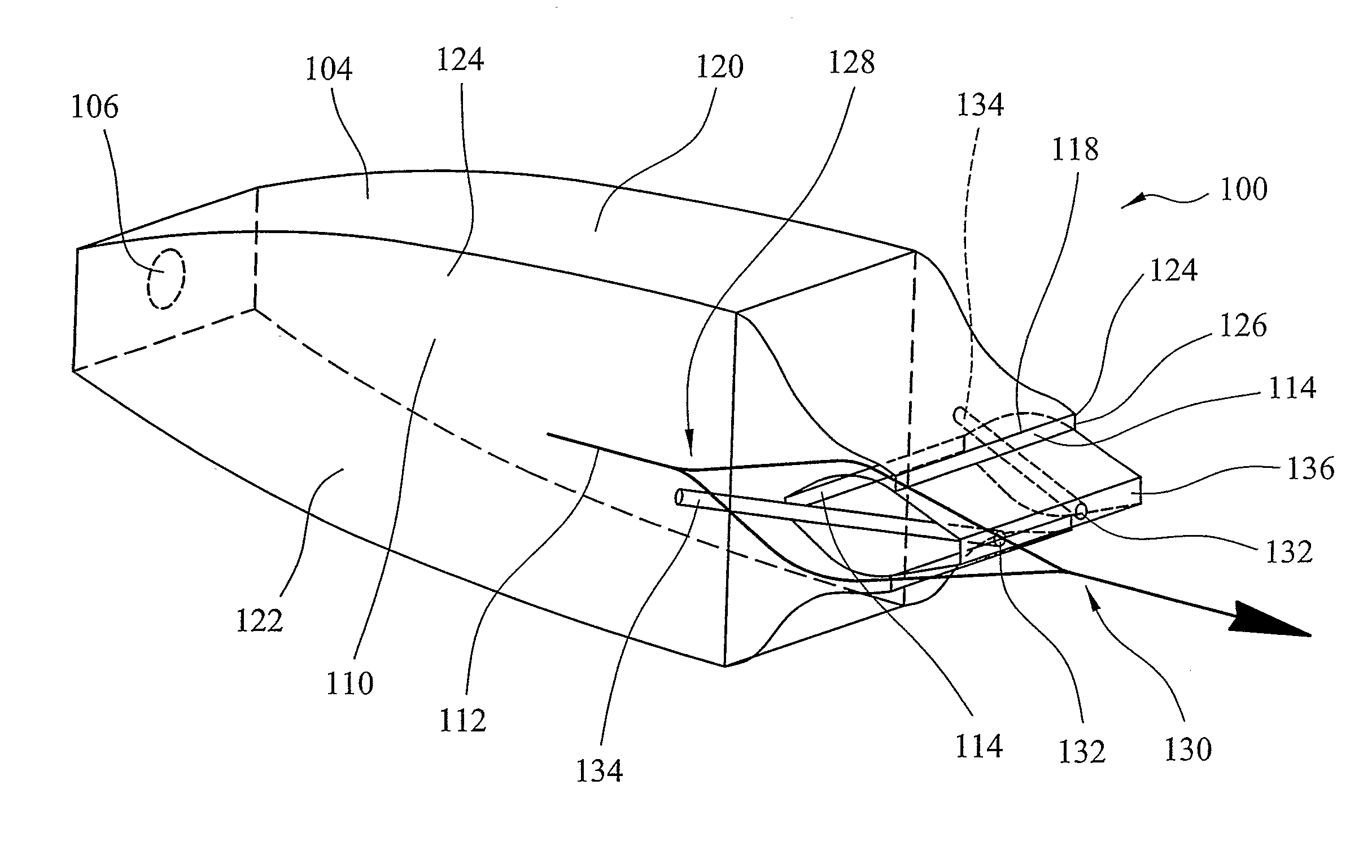

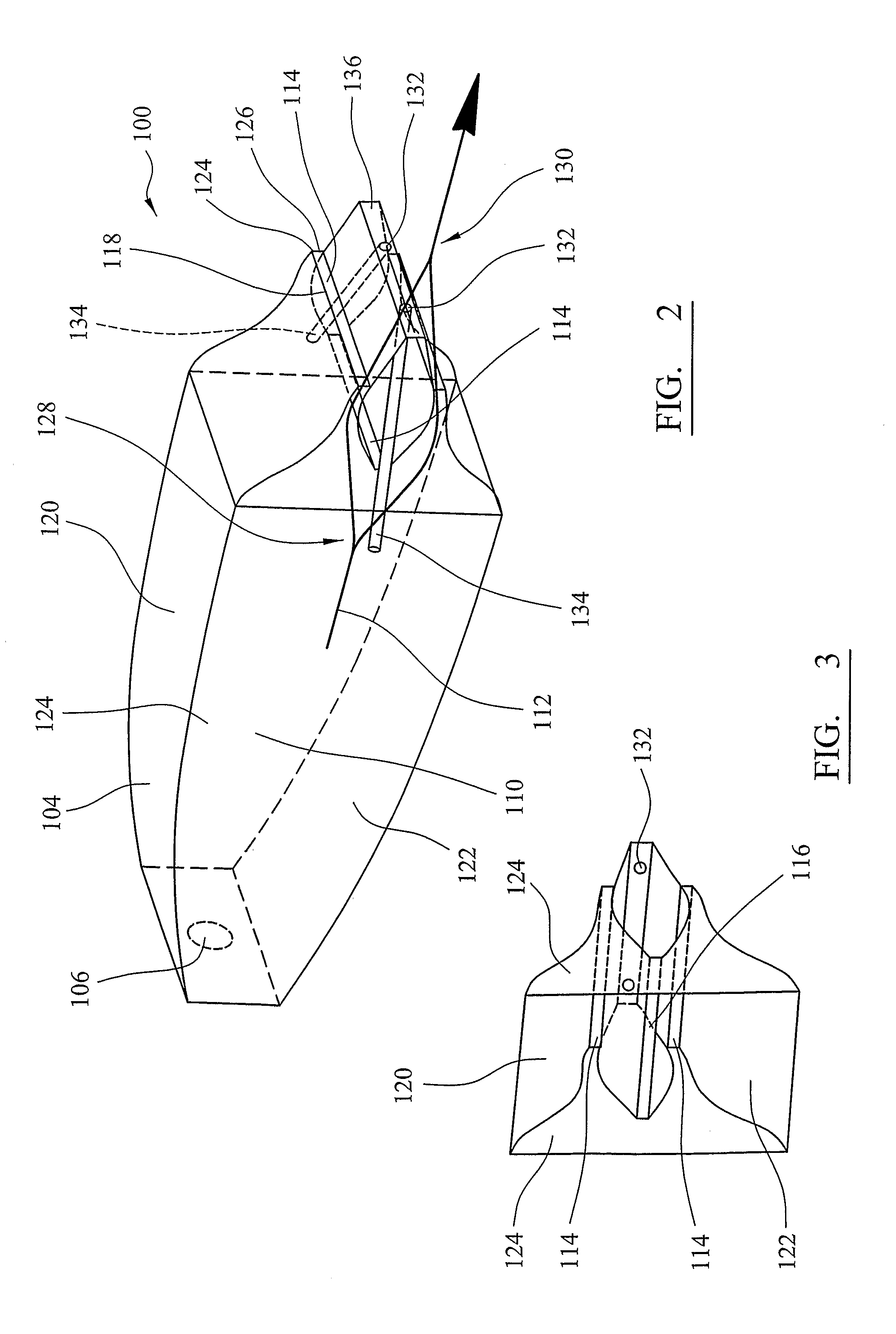

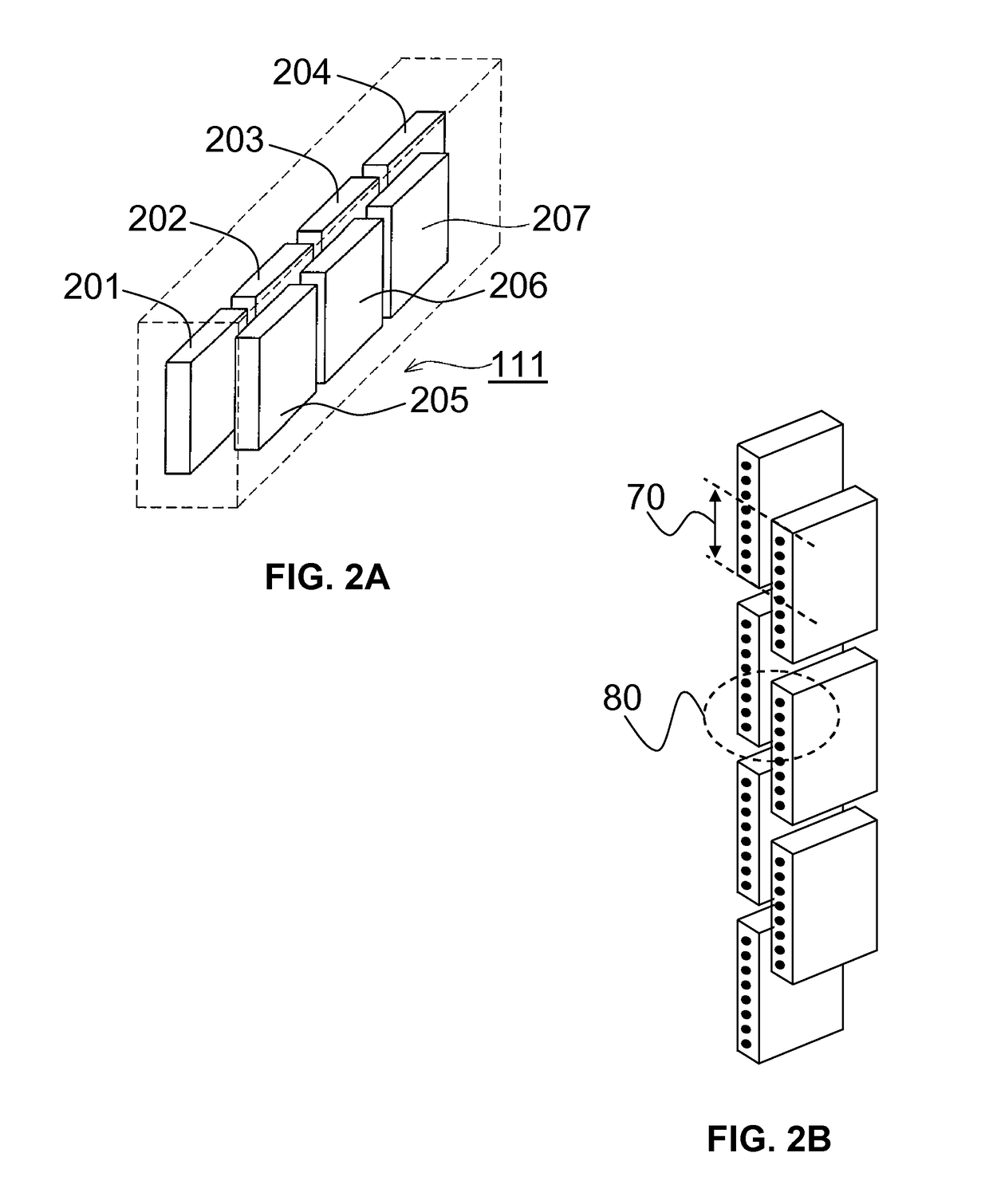

InactiveUS20110061530A1Improve jetting stabilityArea maximizationGas treatmentLaser detailsLiquid jetSpray nozzle

The invention relates to a gas liquid contactor and effluent cleaning system and method and more particularly to an array of nozzles configured to produce uniformly spaced flat liquid jets with reduced linear stability. An embodiment of the invention is directed towards a stability unit used with nozzles of a gas liquid contactor and / or an enhancer for stable jet formation, and more particularly to reducing the stability of liquid jets formed from nozzles of the gas liquid contactor. Another aspect of the invention relates to operating the apparatus at a condition that reduces the stability of liquid jets, e.g., a droplet generator apparatus. Yet another aspect of the invention relates to operation of the apparatus with an aqueous slurry. Still another aspect of the invention is directed towards to an apparatus for substantially separating at least two fluids.

Owner:NEUMANN SYST GROUP

Apparatus and method thereof

InactiveUS20110061531A1Improve jetting stabilityArea maximizationLaser detailsGas treatmentLiquid jetSpray nozzle

The invention relates to a gas liquid contactor and effluent cleaning system and method and more particularly to an array of nozzles configured to produce uniformly spaced flat liquid jets with reduced linear stability. An embodiment of the invention is directed towards a stability unit used with nozzles of a gas liquid contactor and / or an enhancer for stable jet formation, and more particularly to reducing the stability of liquid jets formed from nozzles of the gas liquid contactor. Another aspect of the invention relates to operating the apparatus at a condition that reduces the stability of liquid jets, e.g., a droplet generator apparatus. Yet another aspect of the invention relates to operation of the apparatus with an aqueous slurry. Still another aspect of the invention is directed towards to an apparatus for substantially separating at least two fluids.

Owner:NEUMANN SYST GROUP

Apparatus and method thereof

InactiveUS20110072968A1Improve jetting stabilityArea maximizationLaser detailsLiquid degasificationLiquid jetSpray nozzle

The invention relates to a gas liquid contactor and effluent cleaning system and method and more particularly to an array of nozzles configured to produce uniformly spaced flat liquid jets with reduced linear stability. An embodiment of the invention is directed towards a stability unit used with nozzles of a gas liquid contactor and / or an enhancer for stable jet formation, and more particularly to reducing the stability of liquid jets formed from nozzles of the gas liquid contactor. Another aspect of the invention relates to operating the apparatus at a condition that reduces the stability of liquid jets, e.g., a droplet generator apparatus. Yet another aspect of the invention relates to operation of the apparatus with an aqueous slurry. Still another aspect of the invention is directed towards to an apparatus for substantially separating at least two fluids.

Owner:NEUMANN SYST GROUP

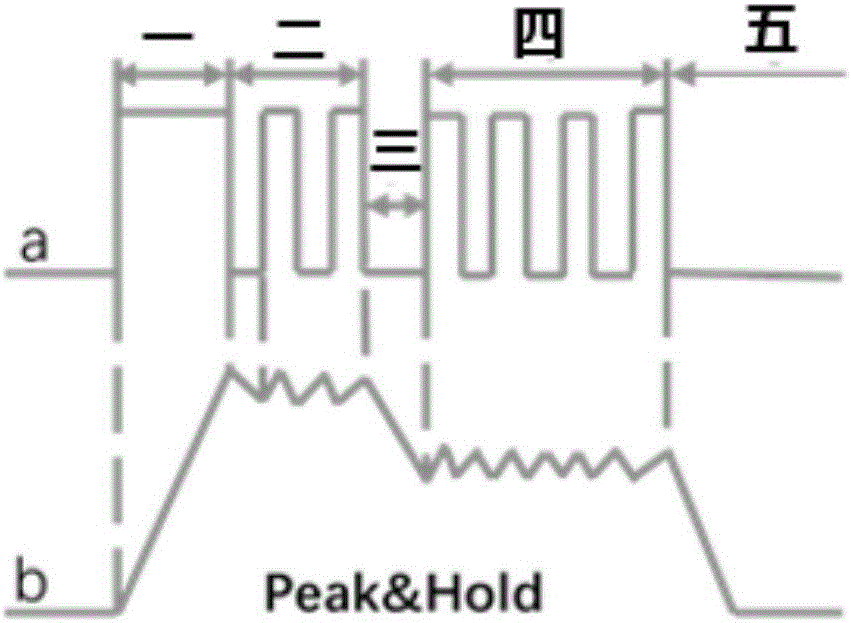

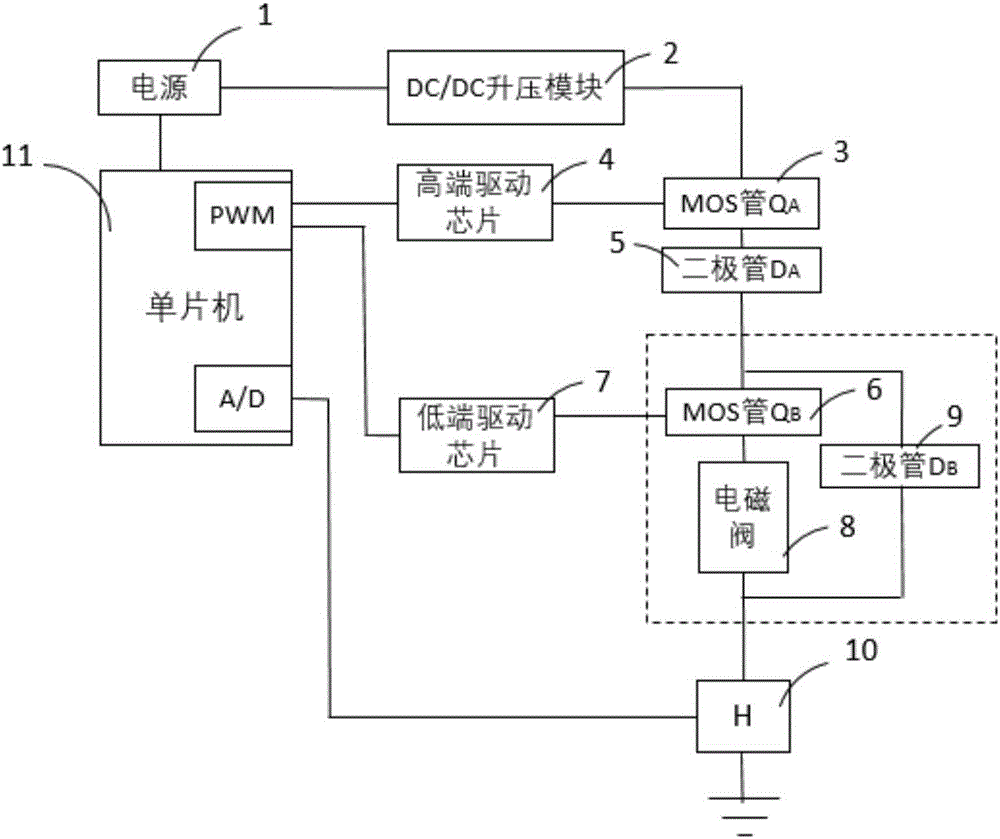

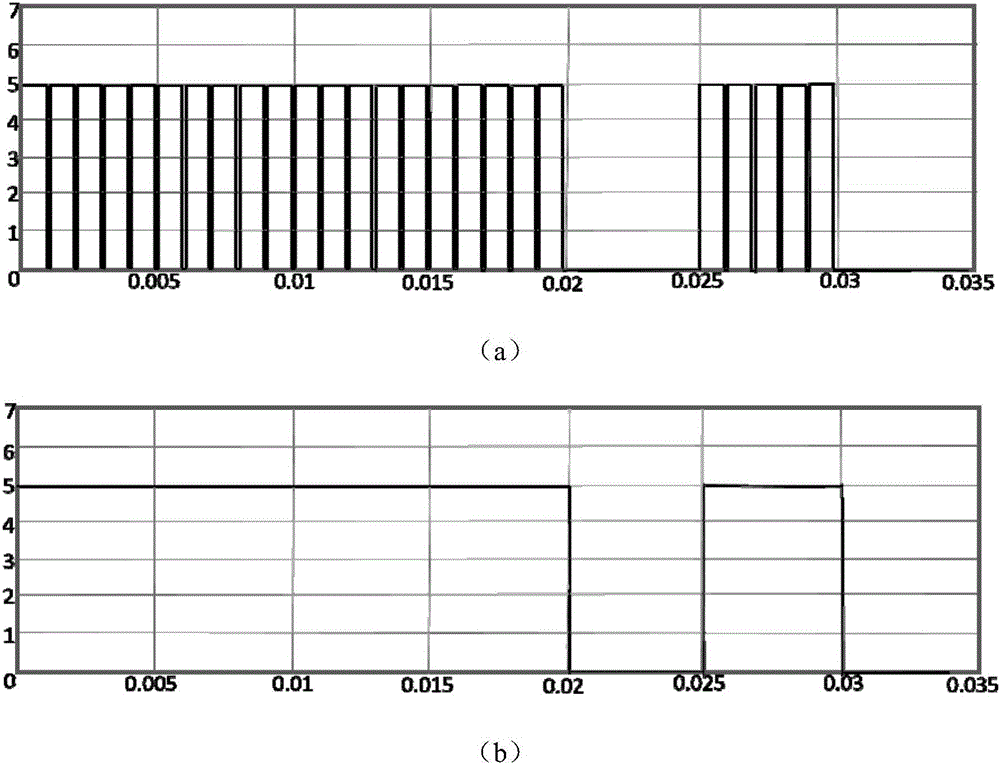

Electromagnetic valve driving circuit of electronic unit pump, and control method thereof

InactiveCN106838432AFast shutdownOpen quicklyProgramme controlOperating means/releasing devices for valvesControl signalCurrent sensor

The invention discloses an electromagnetic valve driving circuit of an electronic unit pump and a control method thereof, and belongs to the technical field of engine electronic control. The driving circuit comprises a power source, a DC / DC boosting module, a MOS tube QA, a high-end driving chip, a diode DA, a MOS tube QB, a low-end driving chip, an electromagnetic valve, a diode DB, a hall current sensor and a single chip; the MOS tube QA is controlled under a high-end control signal output by the PWM module of the single chip, and matched with a current feedback signal output by the single chip PWM module, so as to modulate the circuit driving voltage; the MOS tube QB is controlled by a low-end control signal output by the single chip PWM module, so as to control the circuit on-off, set up a follow current loop and realize rapid flow discharge. The driving circuit applies the hall current sensor, and has the advantages of few response times, small temperature drift, good output linearity and high durability, and others; the driving circuit matched control method can reduce the on-off frequency of the MOS tube QA, and reduce the circuit working noise.

Owner:JIANGSU UNIV

Ink composition, ink set and image forming method

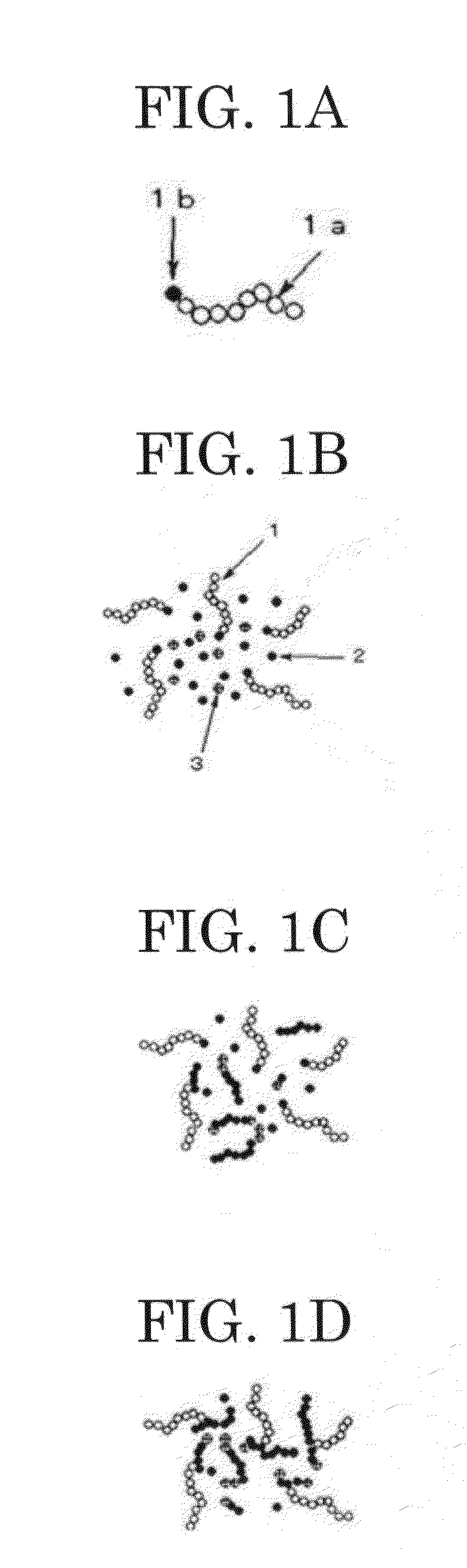

InactiveUS20130250002A1Improve jetting stabilityImprove stabilityMeasurement apparatus componentsInksPolymer scienceDivalent metal ions

The present invention provides an ink composition having excellent jetting stability, which contains water, a cross-liked polymer-coated pigment in which at least a portion of a surface of the pigment is covered with a cross-liked polymer, a free polymer that is not bound to the cross-liked polymer-coated pigment, and at least one divalent metal ion in an amount of from 30 ppm to 200 ppm with respect to the total mass of the ink composition, and an ink set and an image forming method using the same, which are excellent in jetting stability.

Owner:FUJIFILM CORP

Recording Method and Printed Matter

InactiveUS20090033704A1Improve jetting stabilityEliminate the effects ofDuplicating/marking methodsInksPhysicsRelative humidity

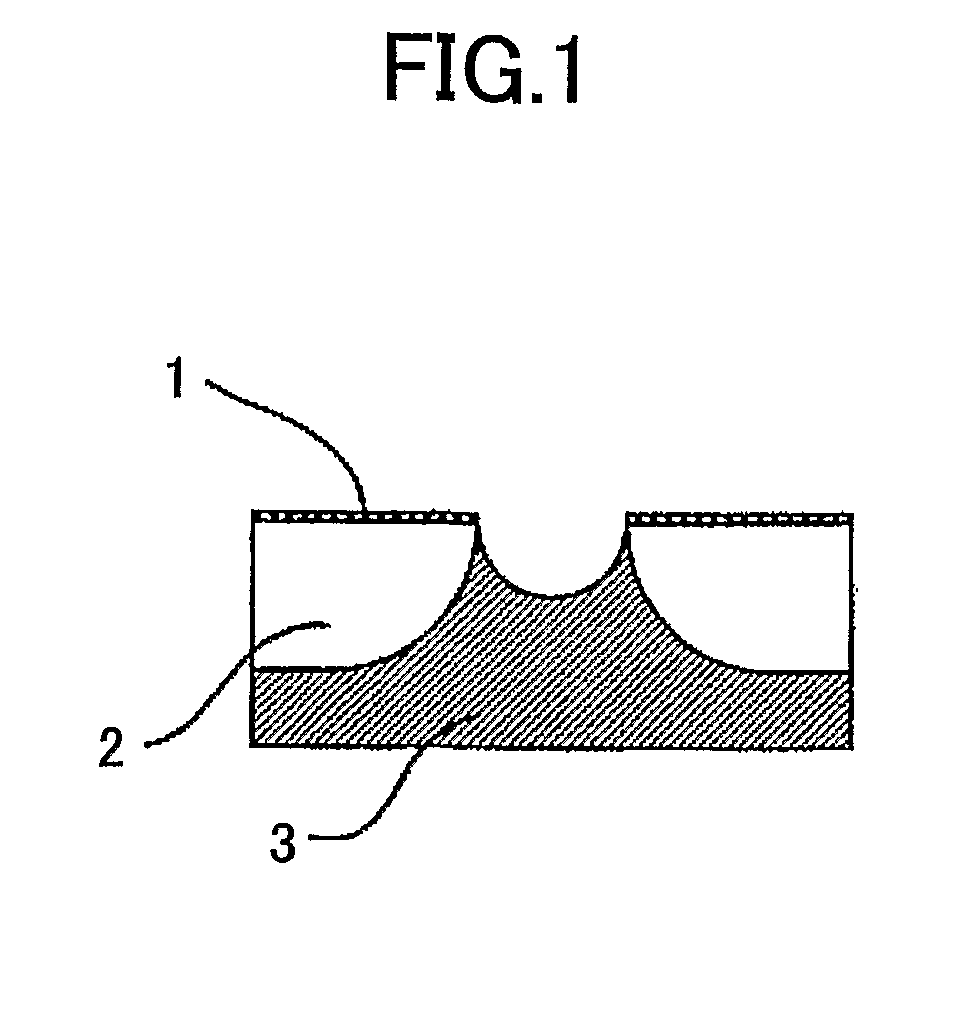

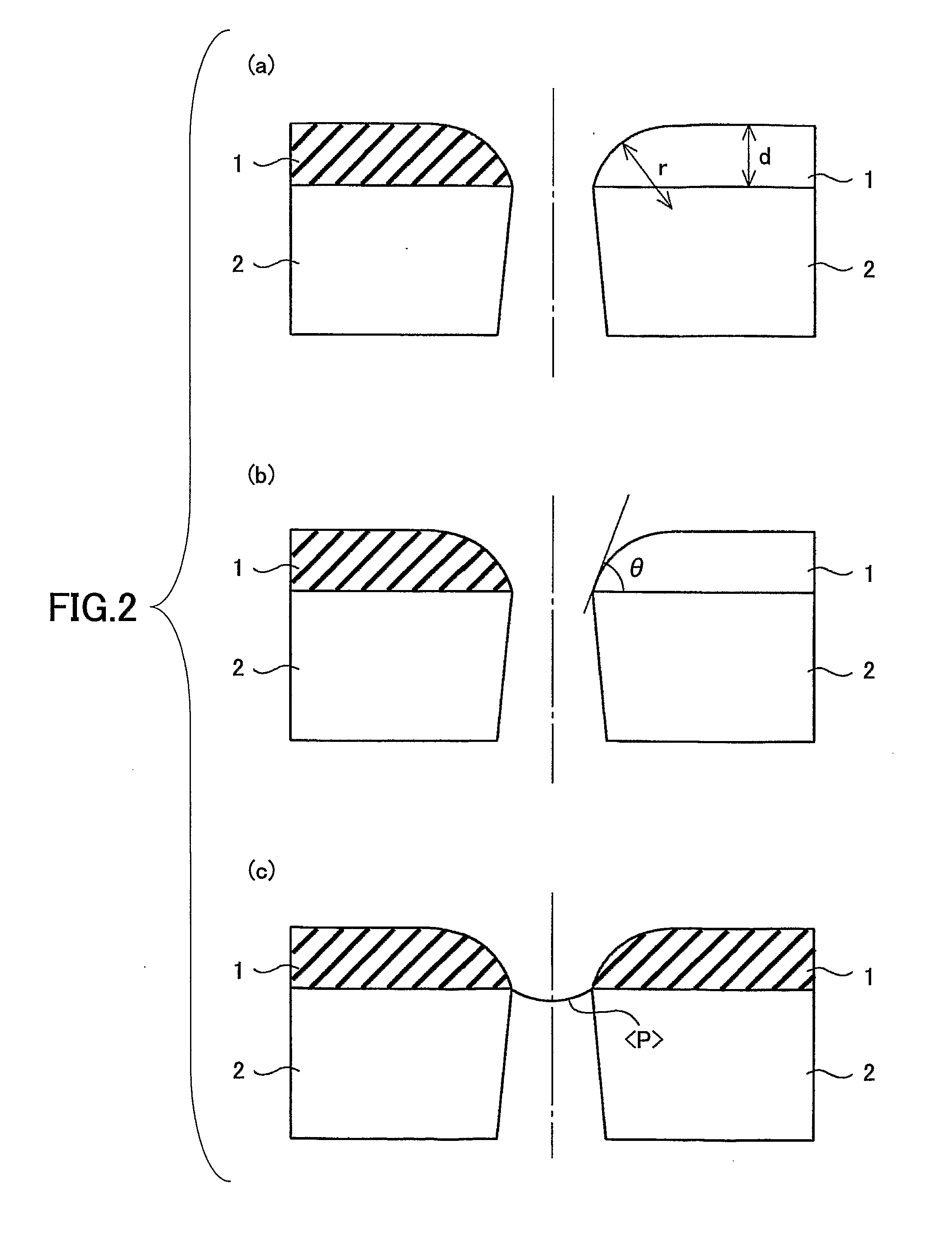

A recording method with an ink ejected by an ink jet head, in which an ink repellent layer is formed on a surface of a nozzle plate of the ink jet head so that an opening portion for liquid ejections is established, the ink jet head being formed such that a cross-sectional area for the opening portion neighborhood of the ink repellent layer in a plane which is perpendicular to a centerline of the opening portion grows big sequentially as the cross-sectional area is further separated from the surface of the base material nozzle plate, wherein the amount of the ink transferred onto a recording medium during a contact time of 100 ms measured by a dynamic scanning absorptometer with environmental conditions of temperature 23° C. and relative humidity 50% RH is between 4 and 15 ml / m2, and the amount of the ink transferred onto the recording medium during a contact time of 400 ms measured by the dynamic scanning absorptometer with the environmental conditions of temperature 23° C. and relative humidity 50% RH is between 7 and 20 ml / m2.

Owner:RICOH KK

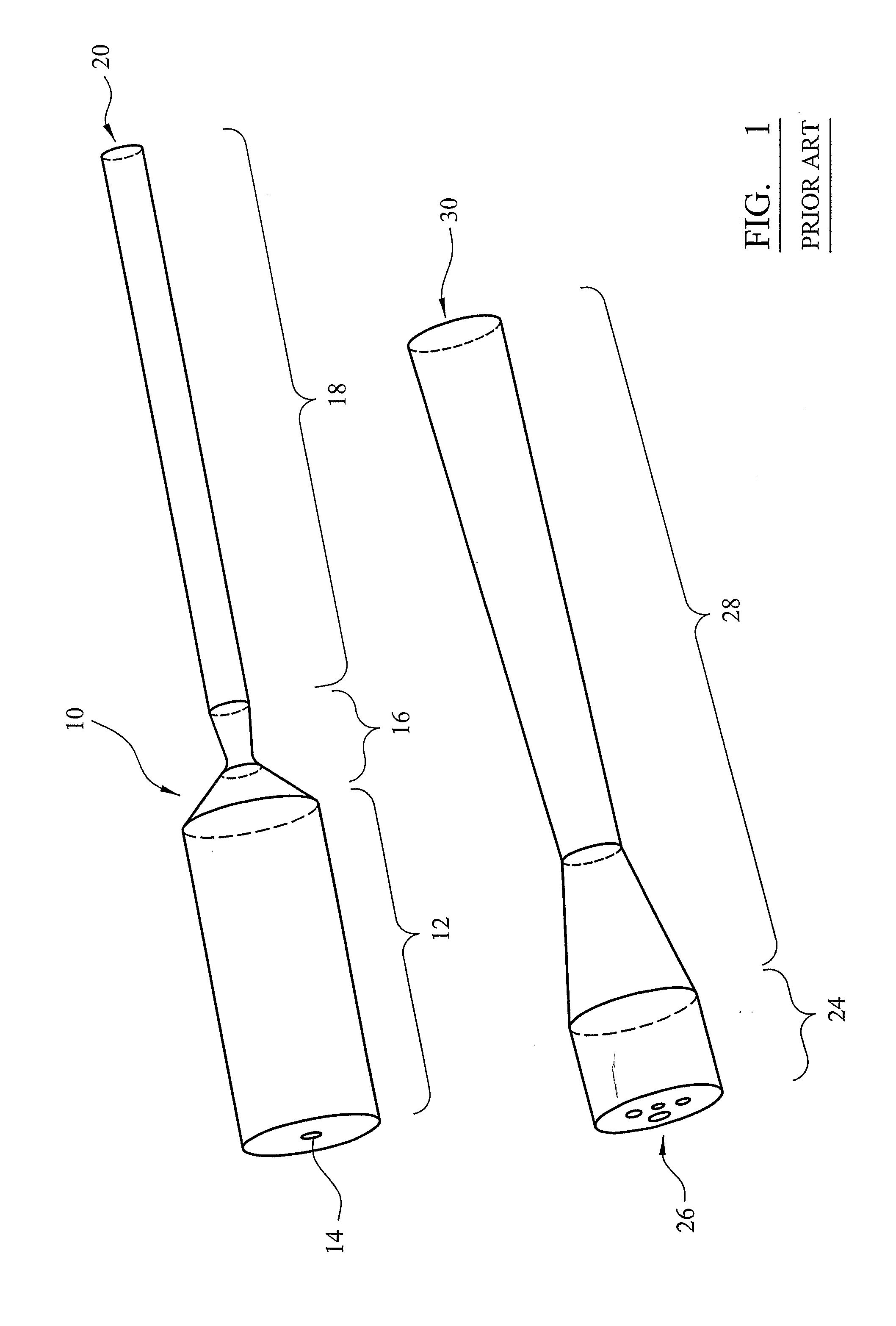

Nozzle For A Thermal Spray Gun And Method Of Thermal Spraying

ActiveUS20120082797A1Reducing loss of energy/temperatureImprove jetting stabilityMolten spray coatingSpray nozzlesThermal sprayingCombustion chamber

A nozzle for a thermal spray gun and a method of thermal spraying are disclosed. The nozzle has a combustion chamber within which fuel is burned to produce a stream of combustion gases. The streams of heated gases exit through a pair of linear exhausts which are located on either side of an aerospike. The streams converge outside the nozzle and powdered coating material is introduced into the converging streams immediately downstream of the aerospike. The coating material is heated and accelerated before impacting on a substrate to be coated.

Owner:MONITOR COATINGS

Inkjet recording ink, inkjet recording ink set, and ink cartridge

ActiveUS8646891B2Reduced stabilityWell formedMeasurement apparatus componentsInksActive agentOrganosolv

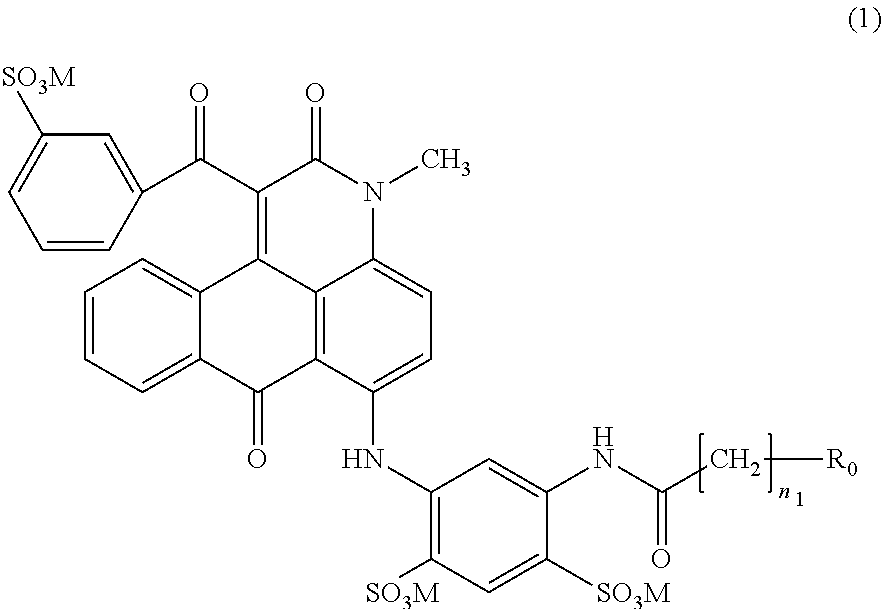

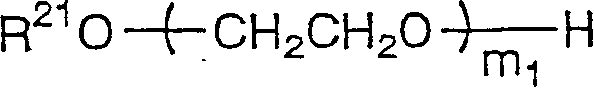

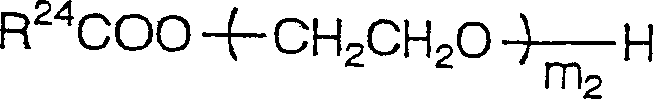

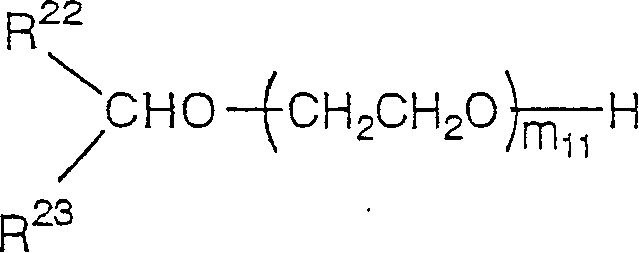

An inkjet recording ink, including: a pigment; a water-soluble organic solvent; a surfactant; a polyether-modified silicone oil; a dispersing agent represented by the following General Formula (1) or (2); and water, wherein the water-soluble organic solvent contains: glycerin as a first water-soluble organic solvent; and a second water-soluble organic solvent, wherein the second water-soluble organic solvent is dipropylene glycol, 1,3-butanediol, 3-methyl-1,3-butanediol, 1,5-pentanediol, 1,6-hexanadiol, or any combination thereof, and wherein a mass ratio of the first water-soluble organic solvent:the second water-soluble organic solvent is 1:0.75 to 1:2.25,where R1 represents a C1-C20 alkyl group, an allyl group or an aralkyl group, L is an integer of 0 to 7, and n is an integer of 20 to 200,where m is an integer of 1 or greater.

Owner:RICOH KK

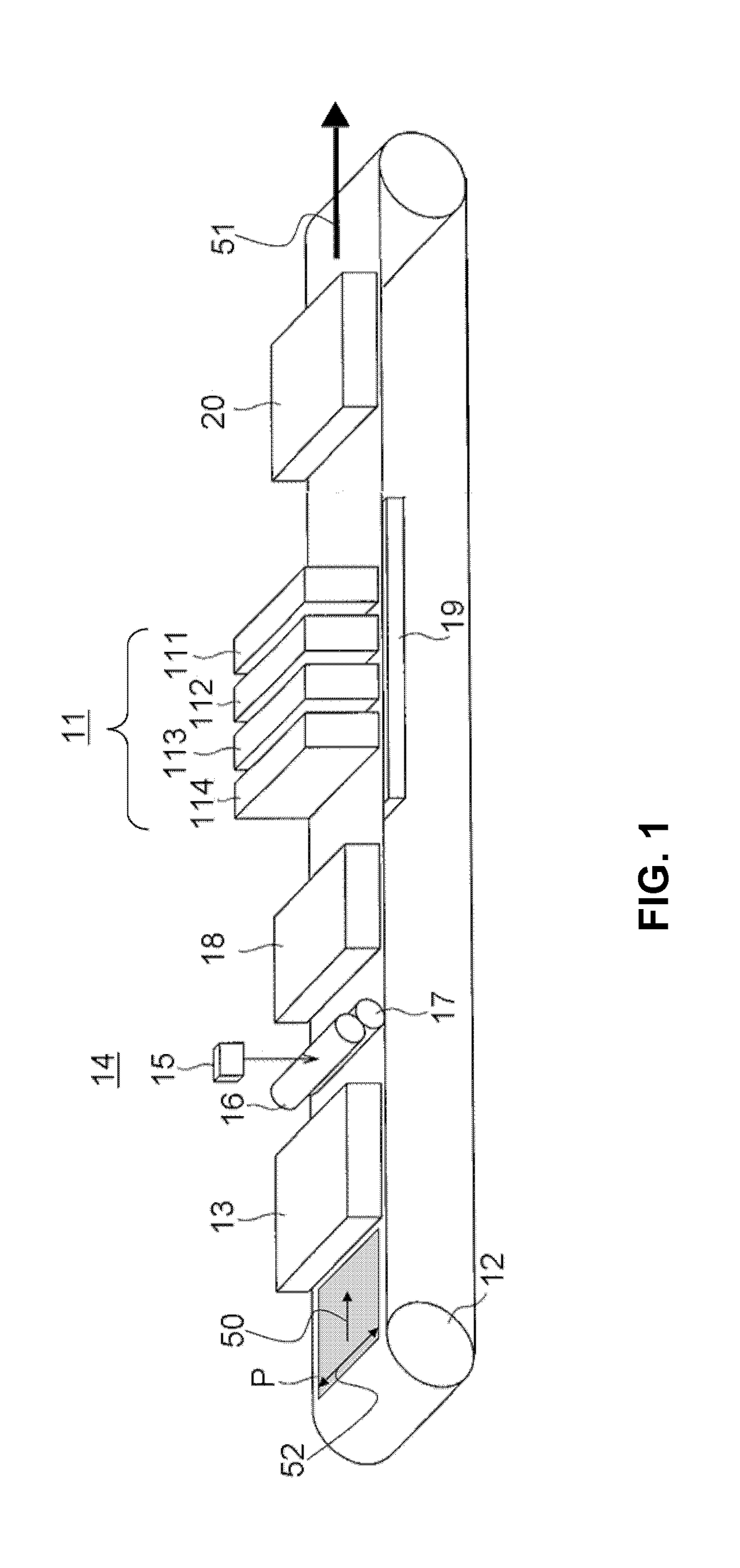

Inkjet ink set, inkjet recording device, and inkjet recording method

InactiveUS20130202862A1Simple processHigh-resolution imageMeasurement apparatus componentsDecorative surface effectsEmulsionAcrylic resin

An inkjet ink set containing a first pigment ink and a second pigment ink. The first pigment ink includes an anionic self-emulsification ether polyurethane, and the second pigment ink includes a styrene acrylic resin emulsion.

Owner:RICOH KK

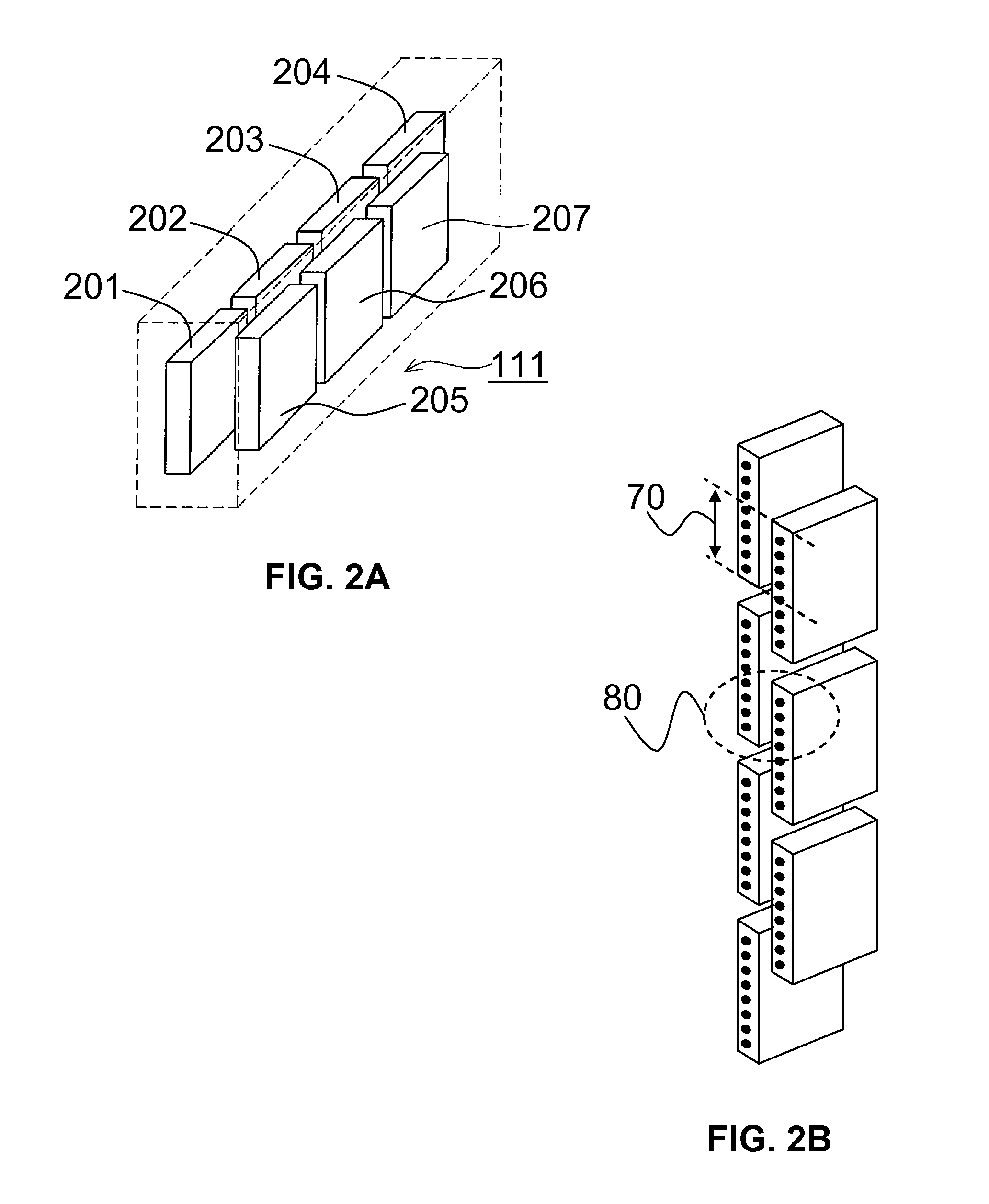

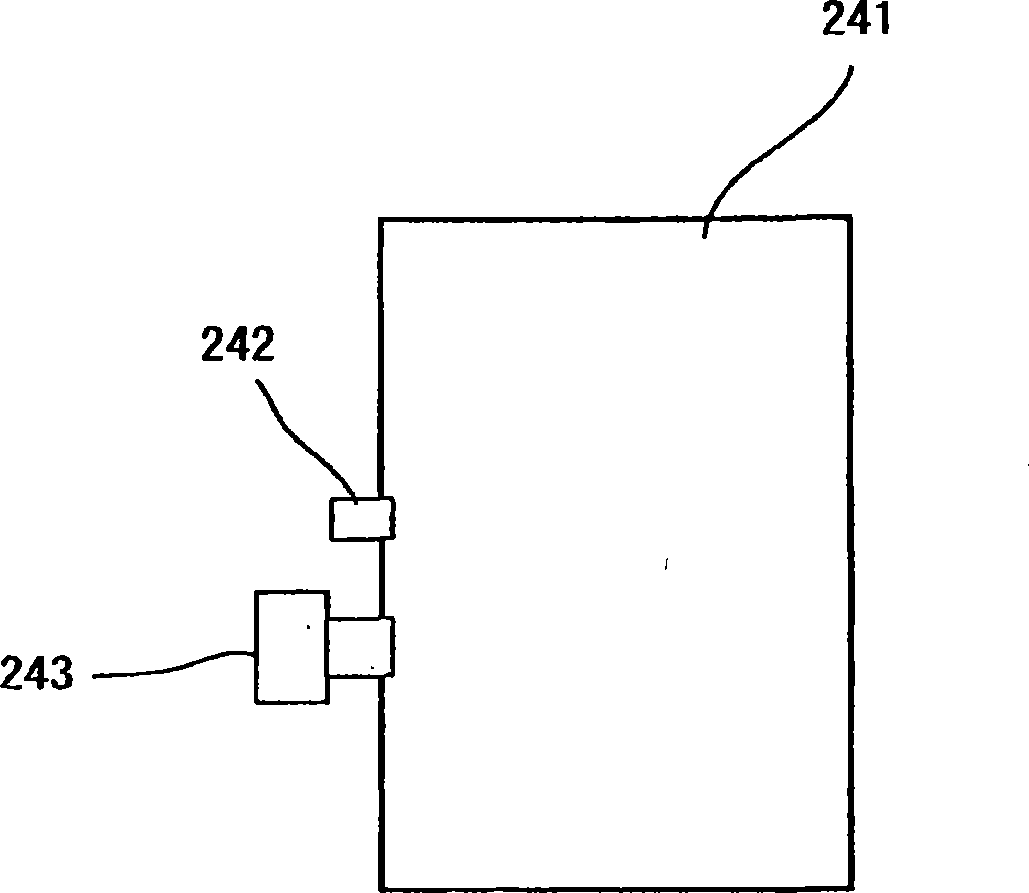

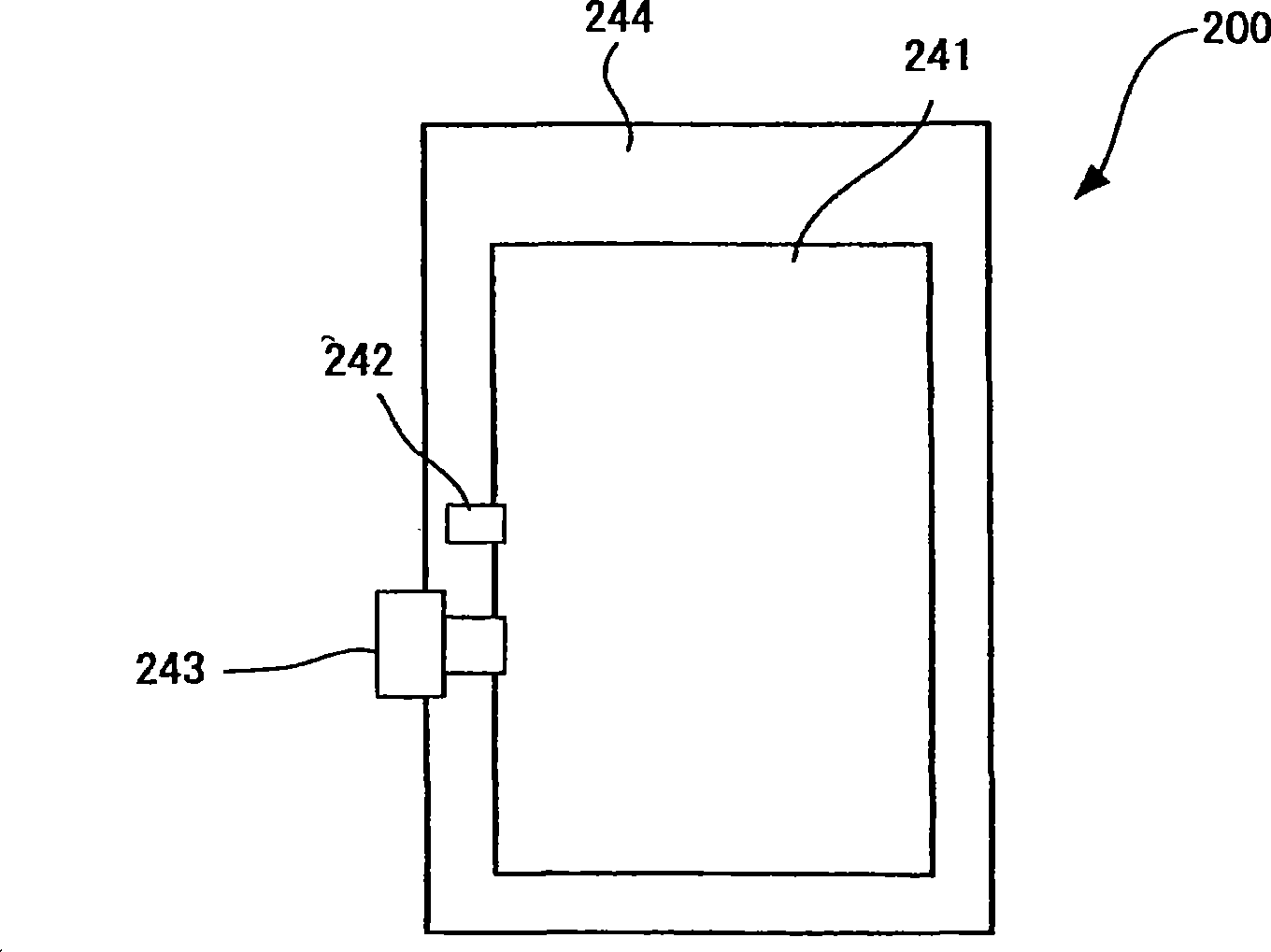

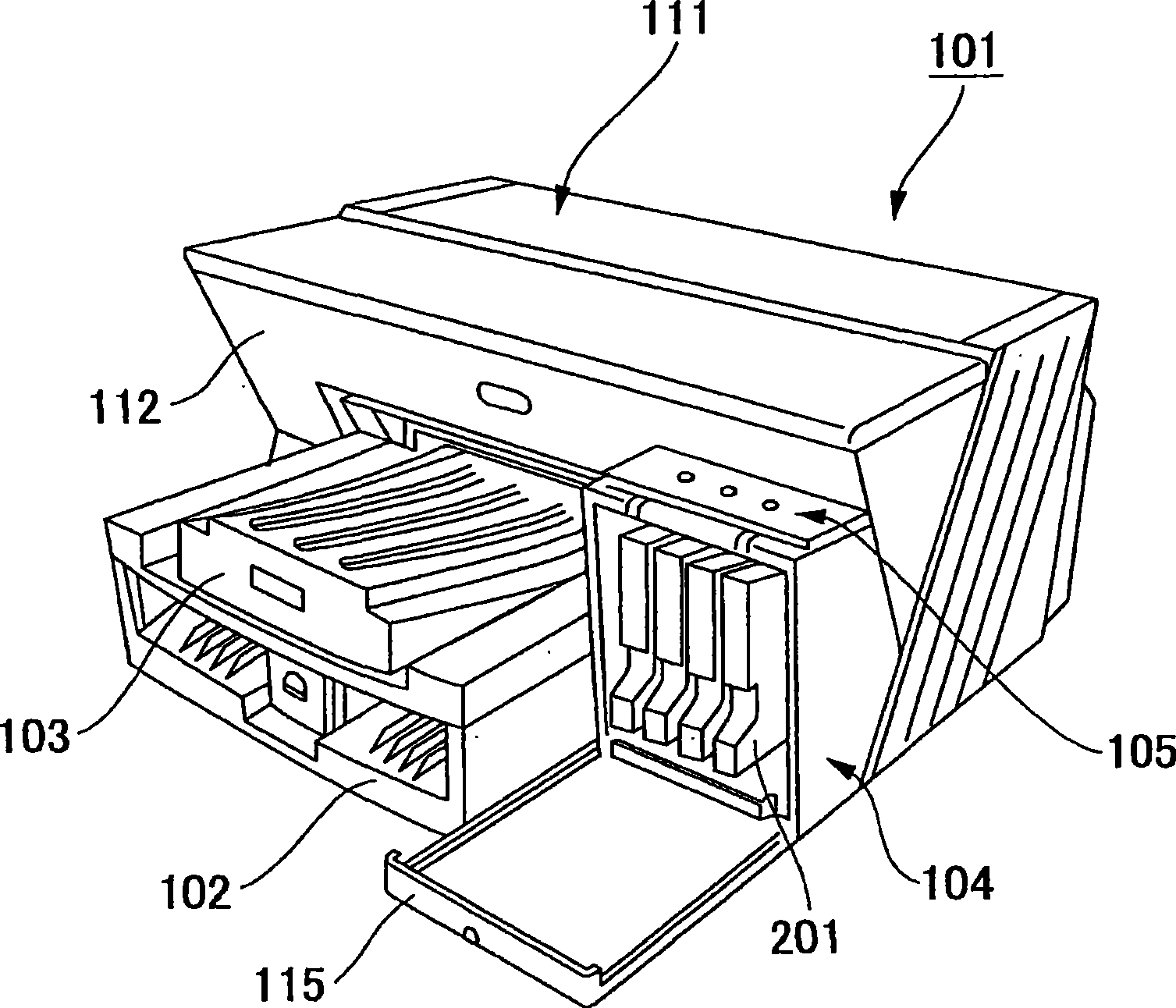

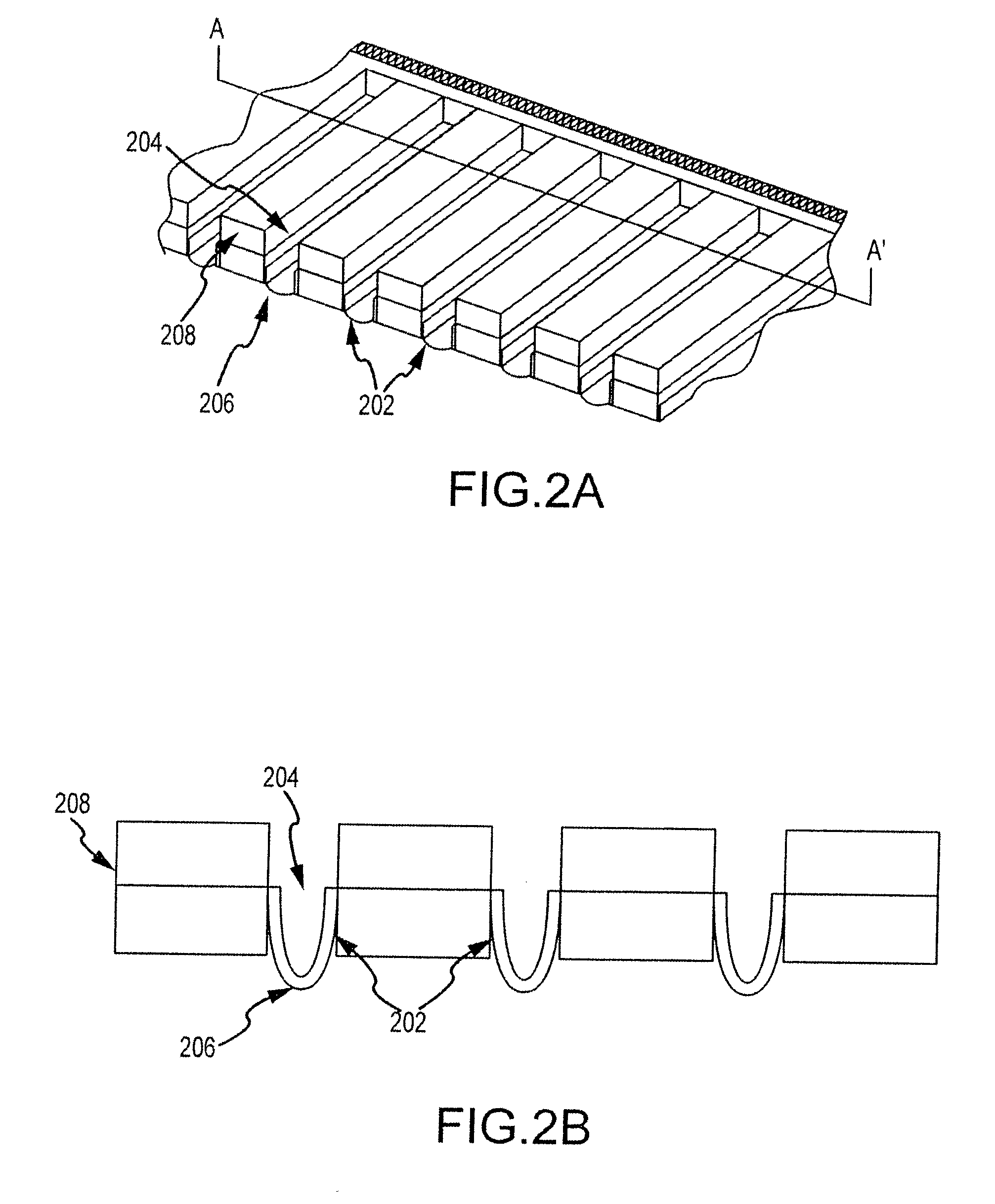

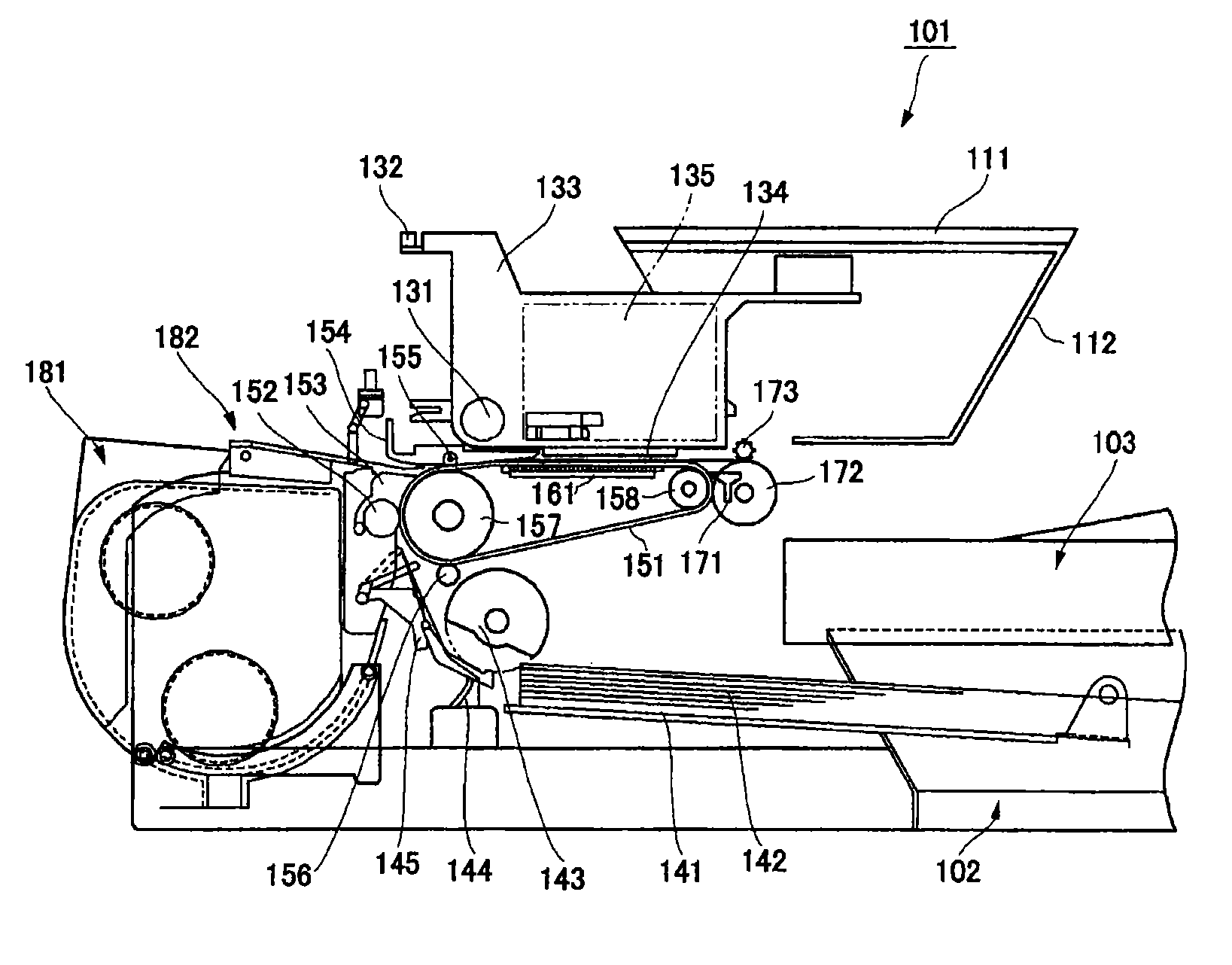

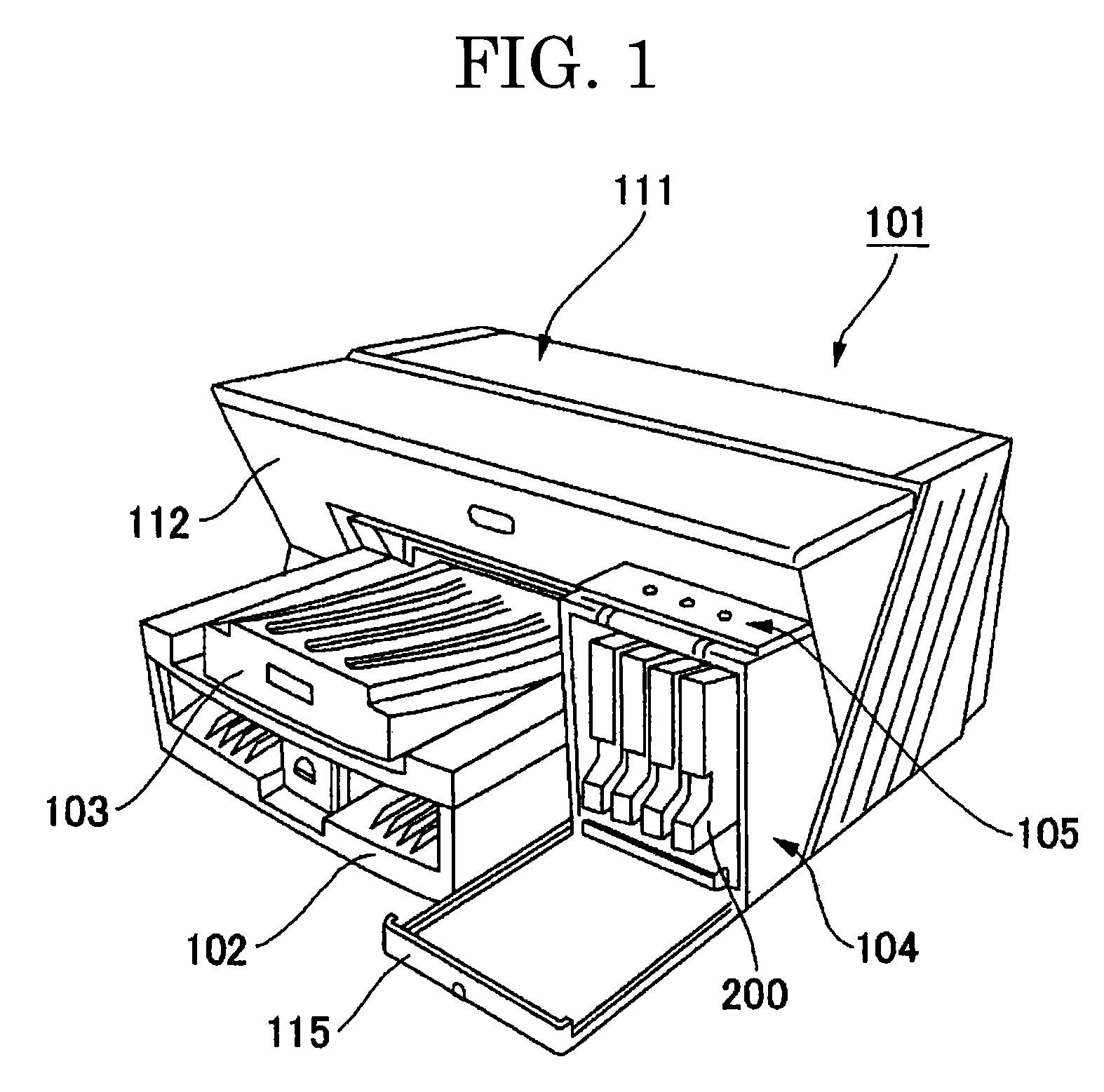

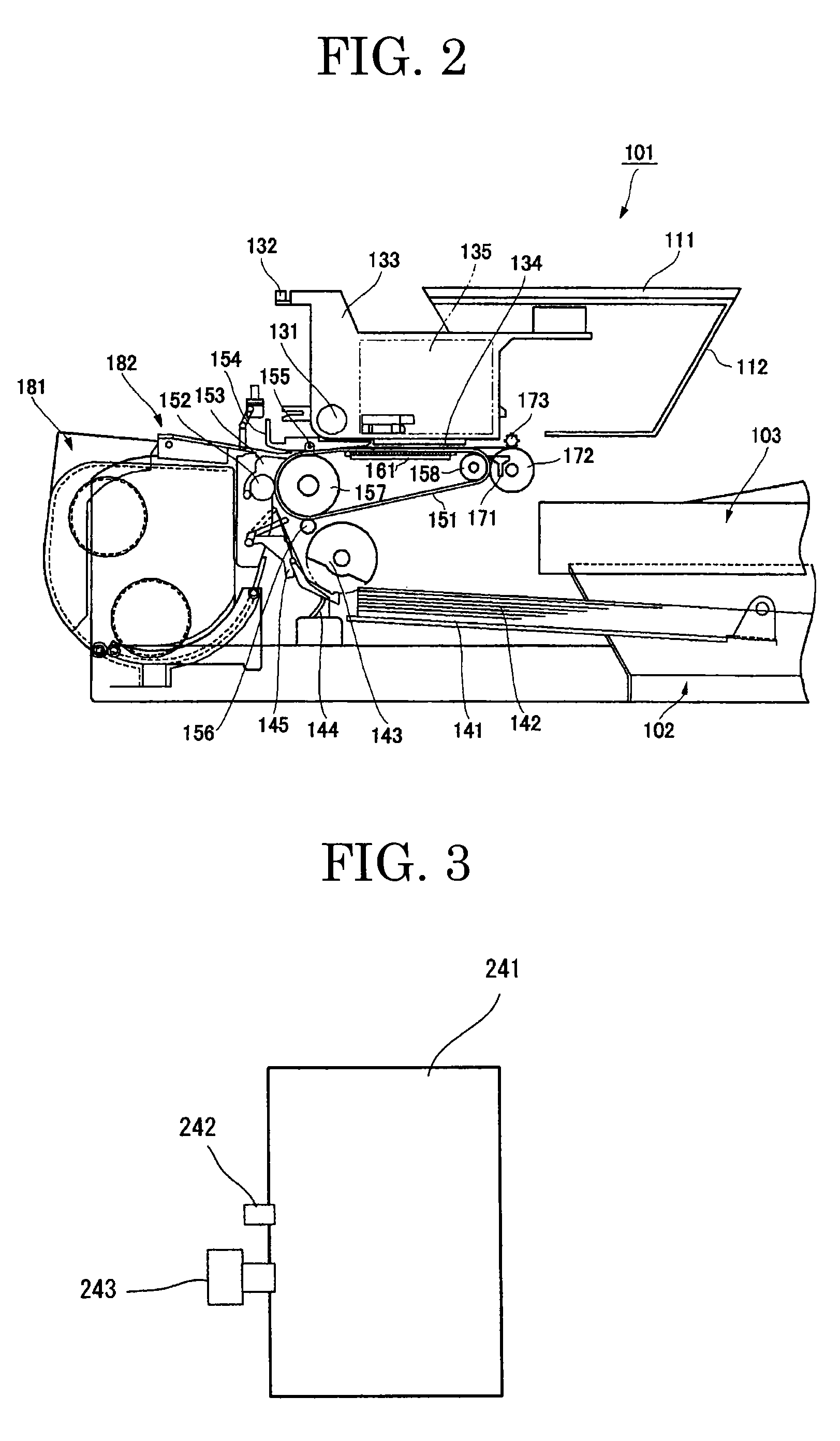

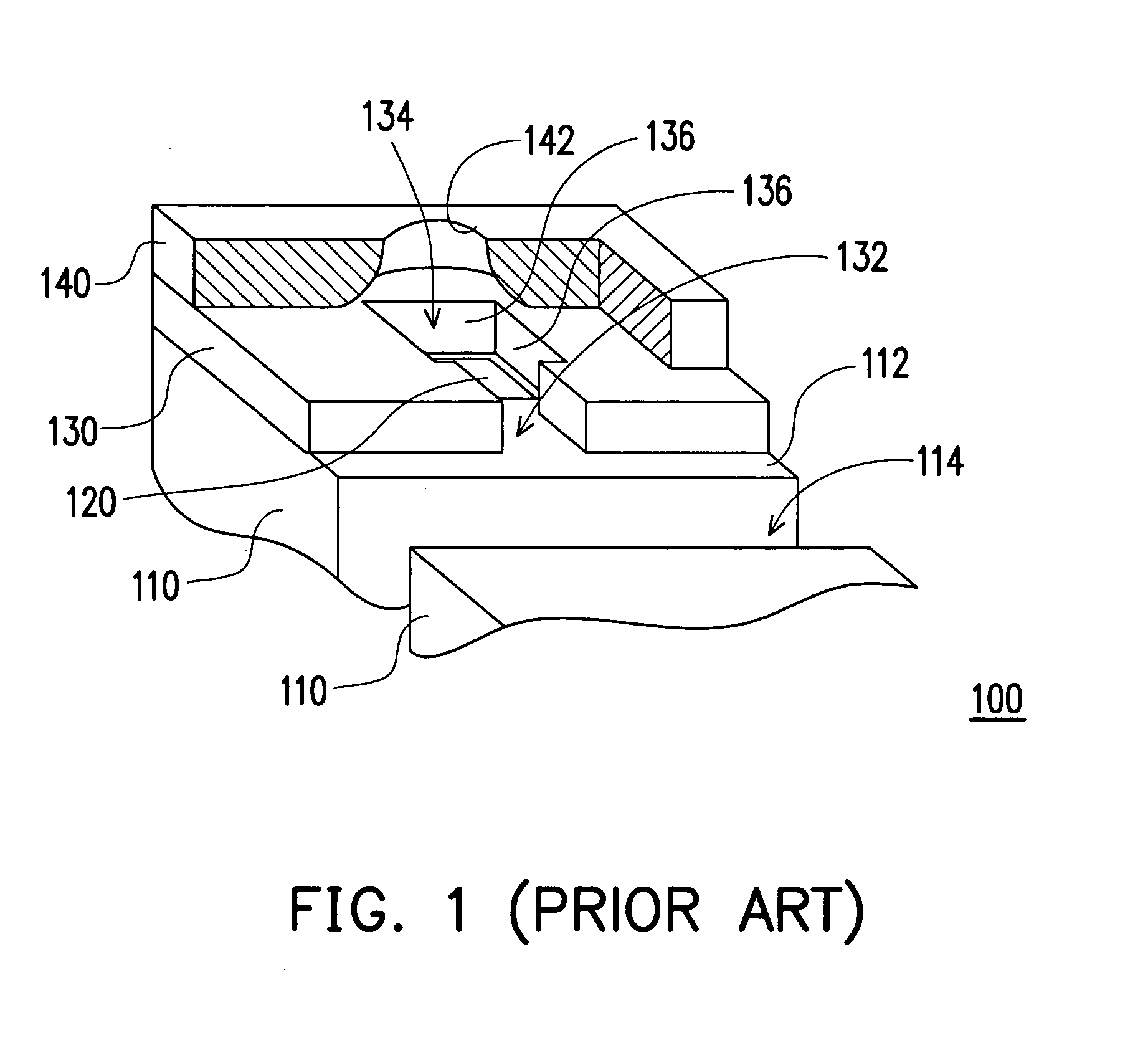

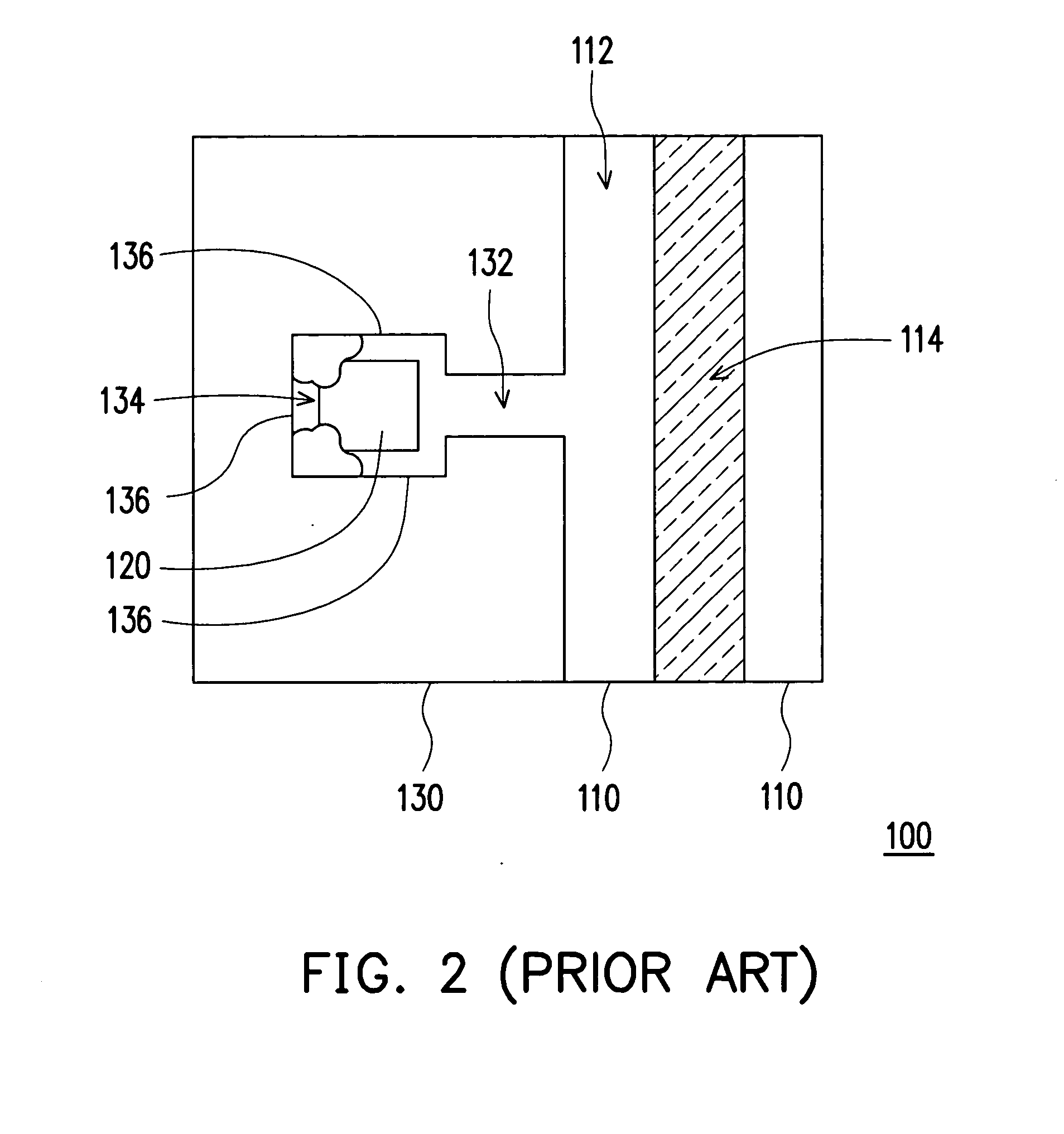

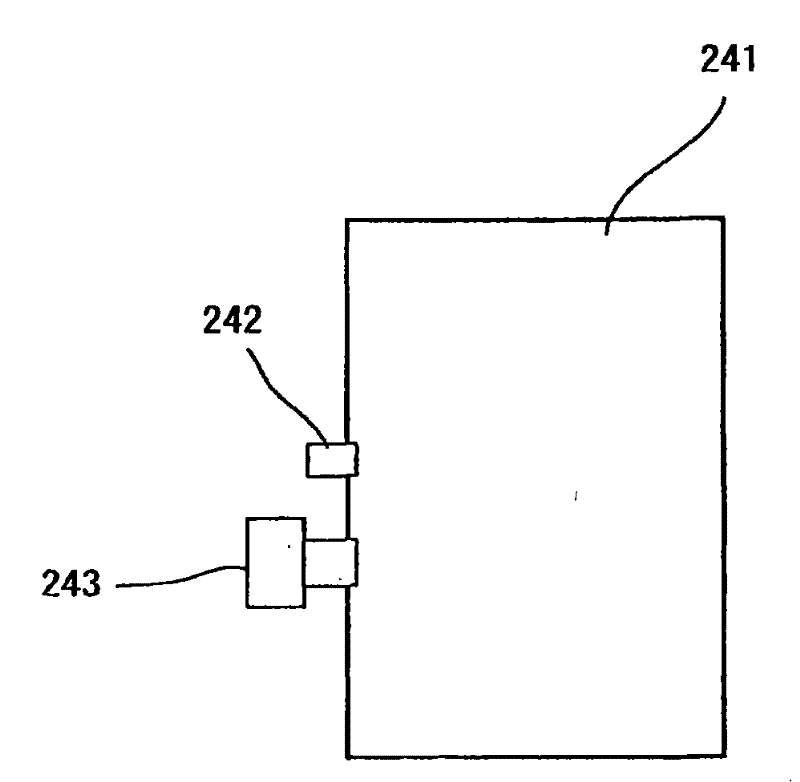

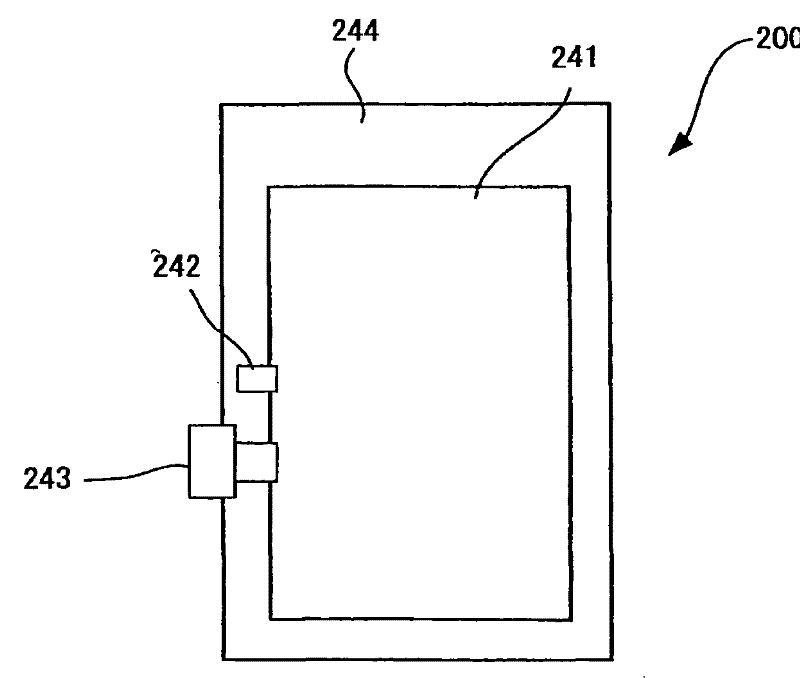

Inkjet print head

An inkjet print head comprising an ink chip, at least a heater, a chamber layer and a nozzle plate is provided. The heater and the chamber layer are formed on the surface of the ink chip. The chamber layer has at least an ink channel and at least an ink chamber. The ink chamber exposes the heater and connects to a reservoir through the ink channel. The ink chamber has a plurality of chamber walls. At least one of the chamber walls has a first area and a second area. The first area corresponds to the heater. The first area and the second area have a distance offset for forming at least a collecting room. The nozzle plate is positioned over the chamber layer. The nozzle plate has at least a nozzle positioned above the heater. By forming the collecting room, air bubbles and / or impurities within the ink can be collected after an ink-jetting operation.

Owner:INT UNITED TECH

Jet fuel additive concentrate composition and fuel composition and methods thereof

InactiveUS20050274063A1Improve jetting stabilityReduce depositionLiquid carbonaceous fuelsFuel additivesSolventJet fuel

A jet fuel additive concentrate composition comprises a solvent and a combination of components. A fuel composition and methods to improve thermal stability of a jet fuel and to reduce deposits in a jet engine include the jet fuel additive concentrate composition. The improvement in the thermal stability of a jet fuel is synergistic when the combination of components includes a cold-flow improving composition.

Owner:THE LUBRIZOL CORP

Water-based ink set for ink-jet recording, ink-jet recording method, and ink-jet recording apparatus

ActiveUS20120081452A1Increase brightnessGood colorMonoazo dyesDuplicating/marking methodsWater basedOrganic solvent

A water-based ink set for ink jet recording, includes: a water-based black ink which contains a black colorant, water, and a water-soluble organic solvent, the black colorant containing self-dispersible carbon black; and a water-based magenta ink which contains a magenta colorant, water, and a water-soluble organic solvent, the magenta colorant containing a dye represented by the general formula (1); wherein the water-soluble organic solvent includes a penetrant of which amount is 0.5% by weight to 3.5% by weight of the water-based magenta ink.

Owner:BROTHER KOGYO KK

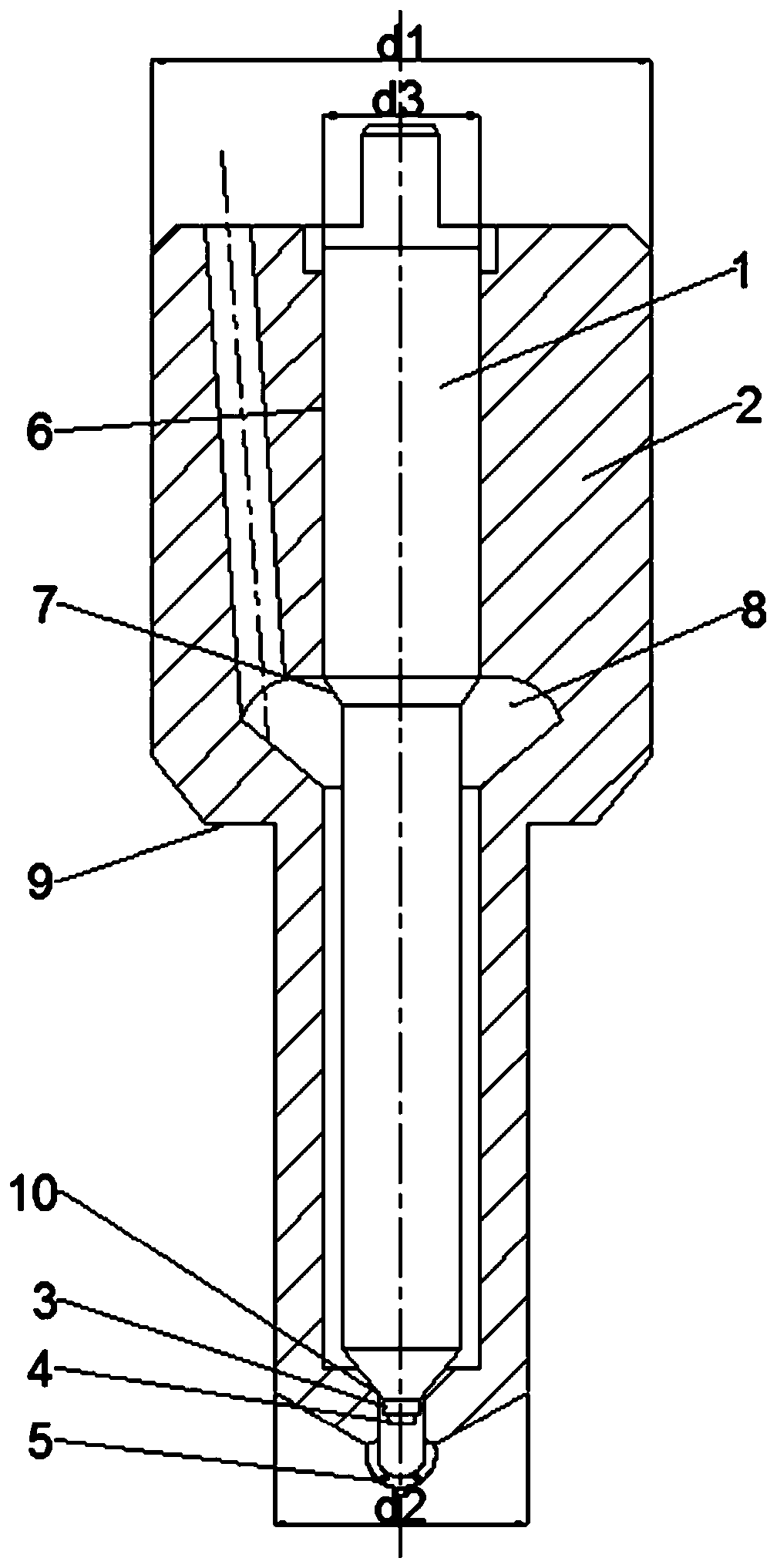

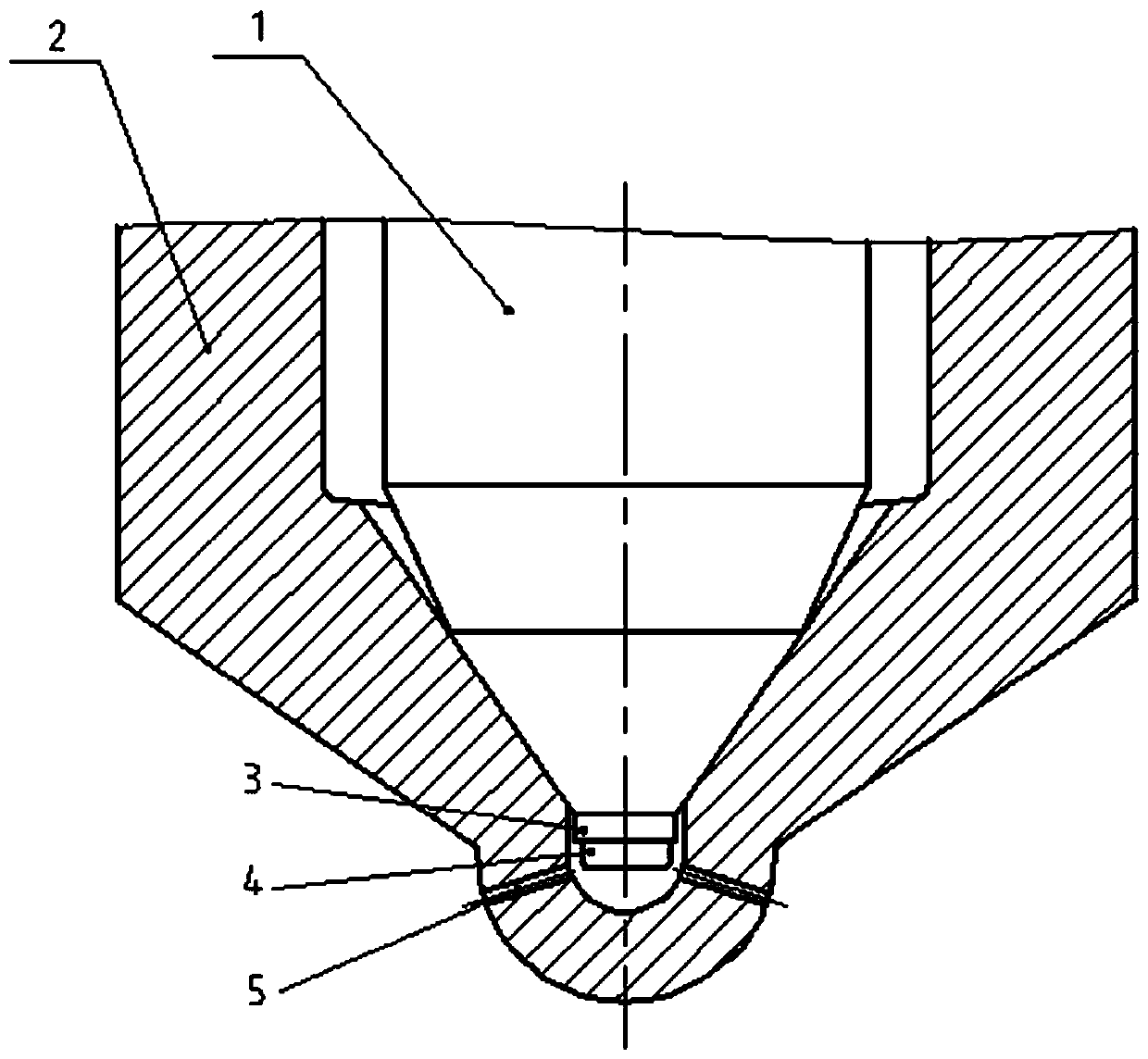

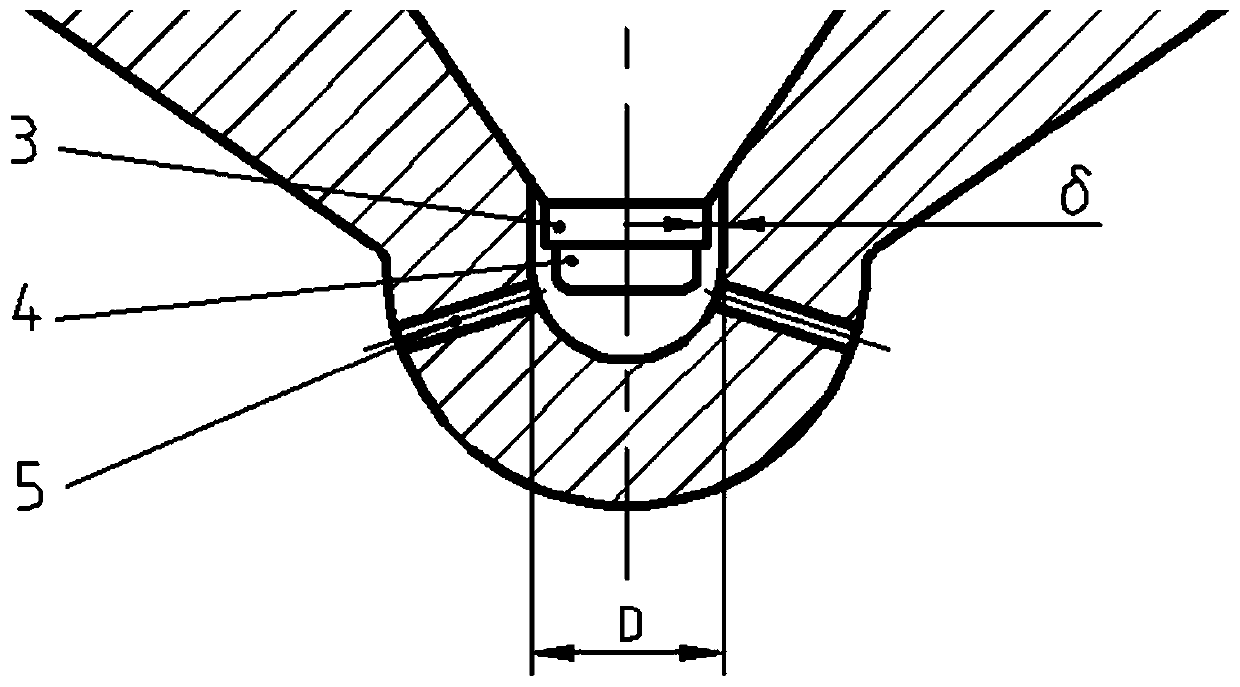

Hole type oil nozzle for controlling low-oil-amount spraying stability of commercial vehicle diesel engine

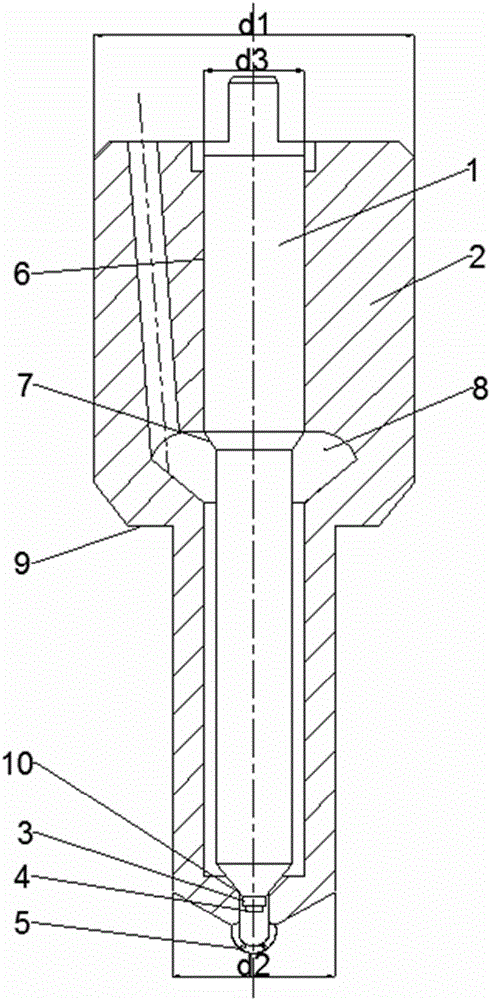

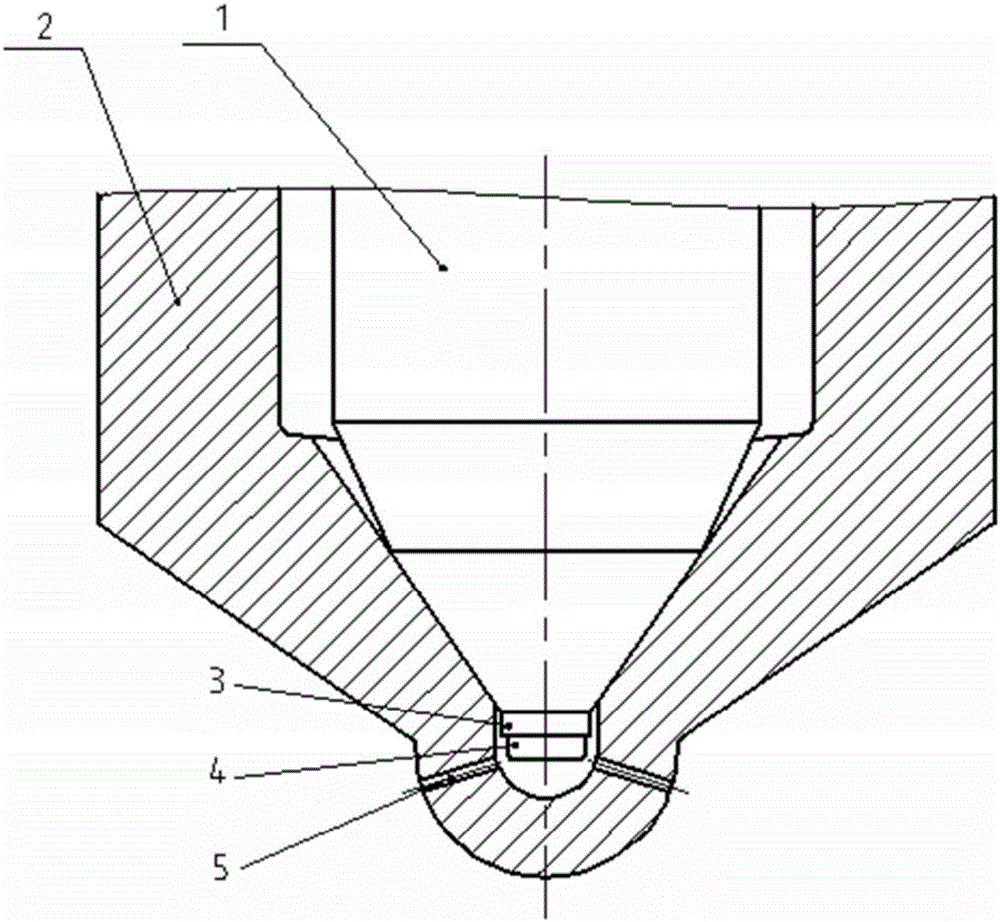

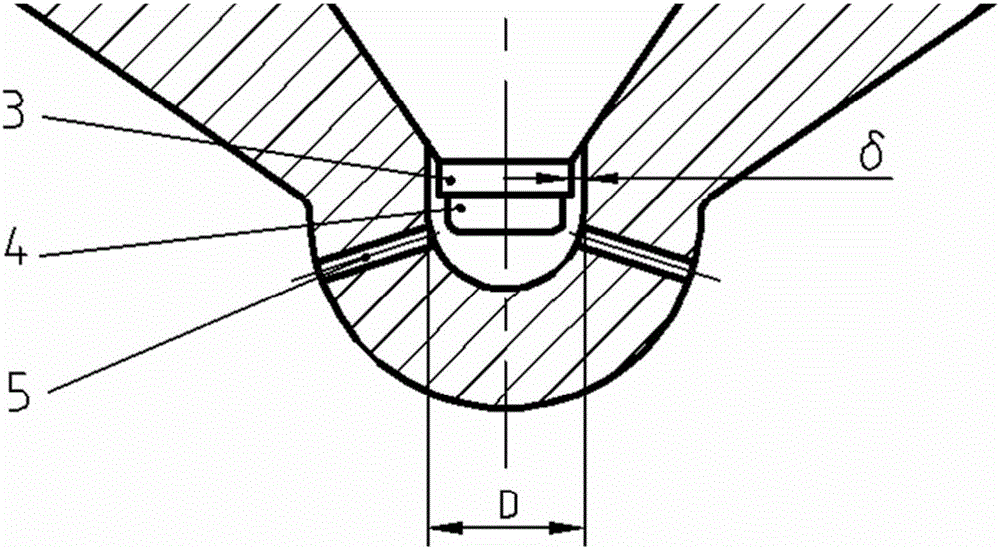

InactiveCN106762303AHigh working reliabilityExtended service lifeFuel injection apparatusMachines/enginesEngineeringFuel oil

The invention discloses a hole type oil nozzle for controlling low-oil-amount spraying stability of a commercial vehicle diesel engine. The hole type oil nozzle comprises a needle valve and a needle valve body, the head of the needle valve is composed of two stairs, the height of the first stair is 0.2-0.8 time the maximum lift range of the needle valve, and the diameter of the first stair is slightly larger than that of the second stair; in the small needle valve lift range, the annular circulating sectional area of fuel oil between the head of the needle valve and the needle valve body in a pressure chamber is decreased to be smaller than the spraying hole area, and then precise control over small-flow fuel oil spraying is achieved; the inner diameter of the upper portion of the needle valve body is the same as the outer diameter of the needle valve and is in clearance fit with the outer diameter of the needle valve, and then an axial sealing surface for high-pressure fuel oil is formed; an oil nozzle sealing conical surface used for controlling high-pressure fuel oil spraying is formed by a conical body arranged on the lower portion of the needle valve body and a boss arranged on the head of the needle valve; the outer diameter d2 of the lower portion of the needle valve body of the oil nozzle ranges from 11 mm to 13 mm. According to the hole type oil nozzle, the low-oil-amount fuel oil flowing performance of the oil nozzle and the low-oil-amount spraying stability are improved while the spraying reliability and power performance under the condition of the high circulating oil supply amount are guaranteed.

Owner:JIANGSU UNIV

Ink composition and method of ink-jet recording

InactiveCN1628156AImprove jetting stabilityExcellent toneDuplicating/marking methodsInksImaging qualityAqueous medium

Owner:FUJIFILM CORP

Inkjet recording ink, inkjet recording ink set, and ink cartridge

ActiveUS20130258007A1Improve ink in jetting stabilityPrevent nozzle cloggingInksPrintingOrganic solventWater soluble

An inkjet recording ink, including: a pigment; a water-soluble organic solvent; a surfactant; a polyether-modified silicone oil; a dispersing agent represented by the following General Formula (1) or (2); and water, wherein the water-soluble organic solvent contains: glycerin as a first water-soluble organic solvent; and a second water-soluble organic solvent, wherein the second water-soluble organic solvent is dipropylene glycol, 1,3-butanediol, 3-methyl-1,3-butanediol, 1,5-pentanediol, 1,6-hexanadiol, or any combination thereof, and wherein a mass ratio of the first water-soluble organic solvent:the second water-soluble organic solvent is 1:0.75 to 1:2.25,where R1 represents a C1-C20 alkyl group, an allyl group or an aralkyl group, L is an integer of 0 to 7, and n is an integer of 20 to 200,where m is an integer of 1 or greater.

Owner:RICOH KK

Inkjet recording ink, ink cartridge, and inkjet recording method

ActiveUS20130242013A1Improve jetting stabilityHigh image densityMeasurement apparatus componentsInksPolymer scienceMicroparticle

An inkjet recording ink, including: water; a wetting agent; a colorant; and polymer microparticles, wherein the polymer microparticles are each a copolymer of a monomer represented by the following structural formula (1) or the following general formula (2), a monomer represented by the following general formula (3), and a macromonomer represented by the following general formula (4):where “R1” is an alkyl group having 1 to 4 carbon atoms,where “Rs” are independently an alkyl group having 1 to 4 carbon atoms,where “l” is the number of repeating units, and an integer of 1 to 100.

Owner:RICOH KK

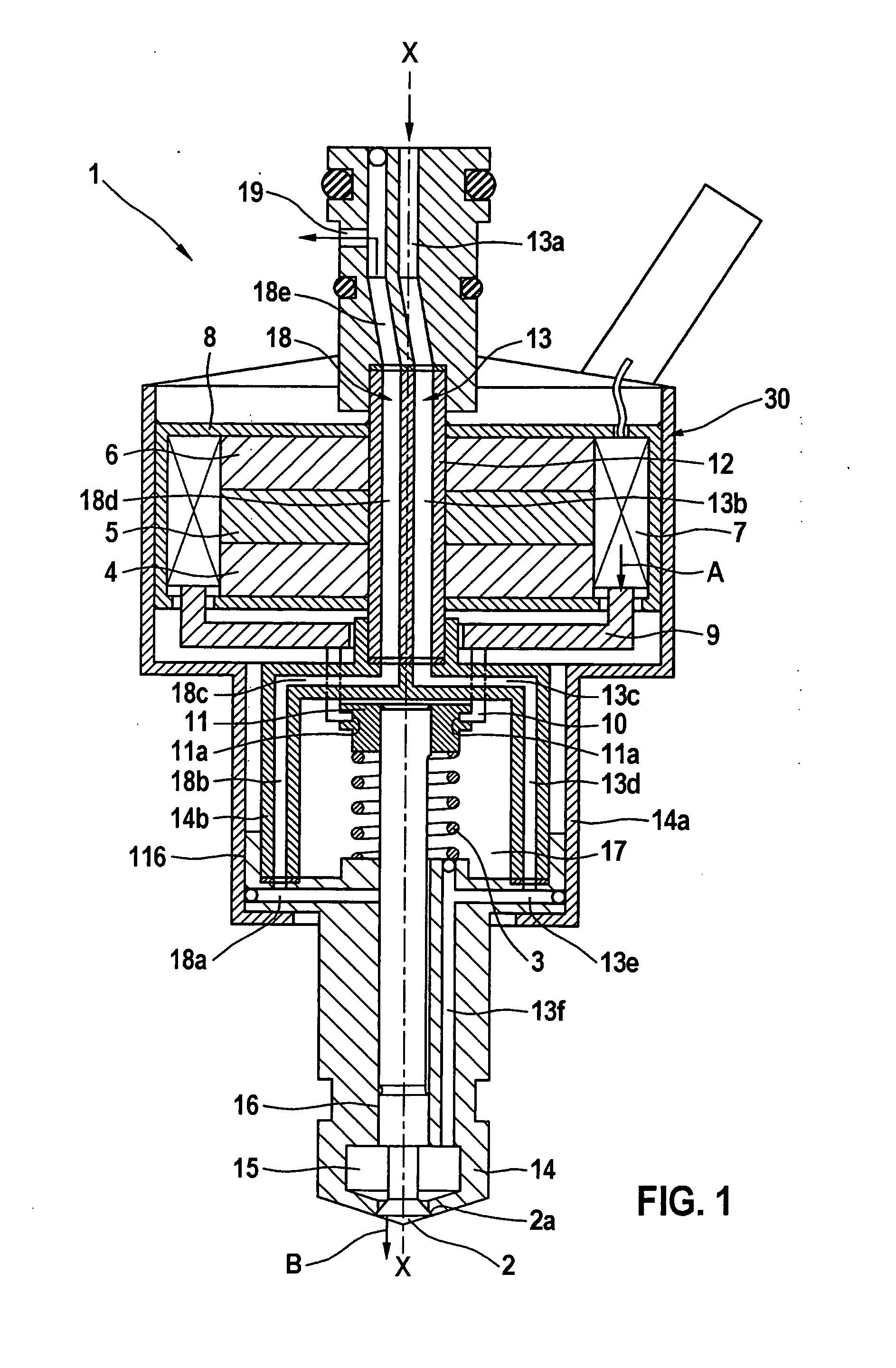

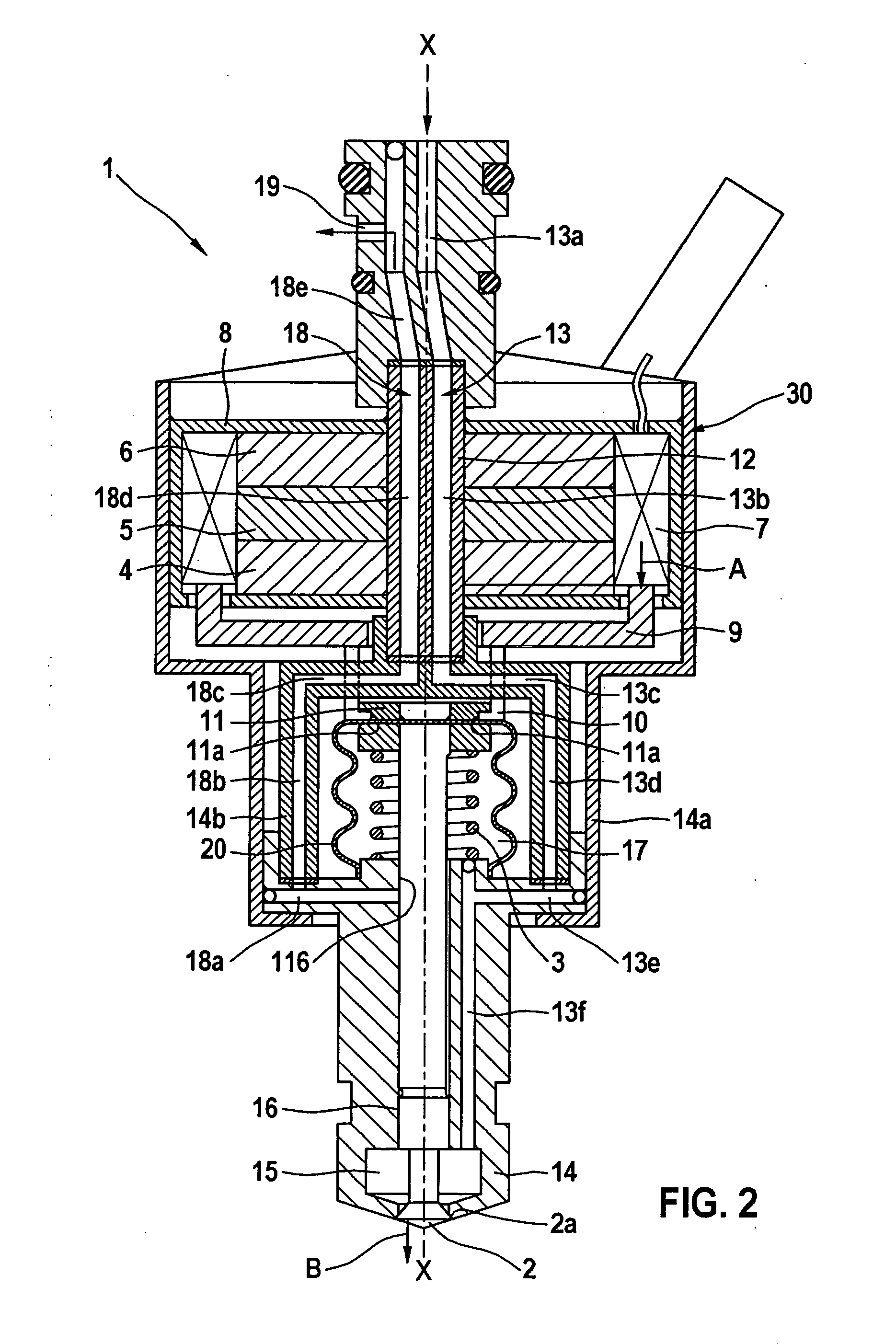

Device for injecting fuel

InactiveUS20120000994A1Short switching timeImprove jetting stabilityMachines/enginesFuel injecting pumpsEngineeringActuator

A device for injecting pressurized fuel includes an electrodynamic actuator having a movably situated coil, an outwardly opening needle which opens and closes a cross section on a valve seat, a connecting device which connects the needle to the movably situated coil, a pressure chamber which is situated at the needle upstream from the valve seat and contains pressurized fuel, a low-pressure chamber from which, fuel is dischargeable, and a gap seal which is provided at an outer peripheral region of the needle, the gap seal (16) providing a connection between the pressure chamber and the low-pressure chamber.

Owner:ROBERT BOSCH GMBH

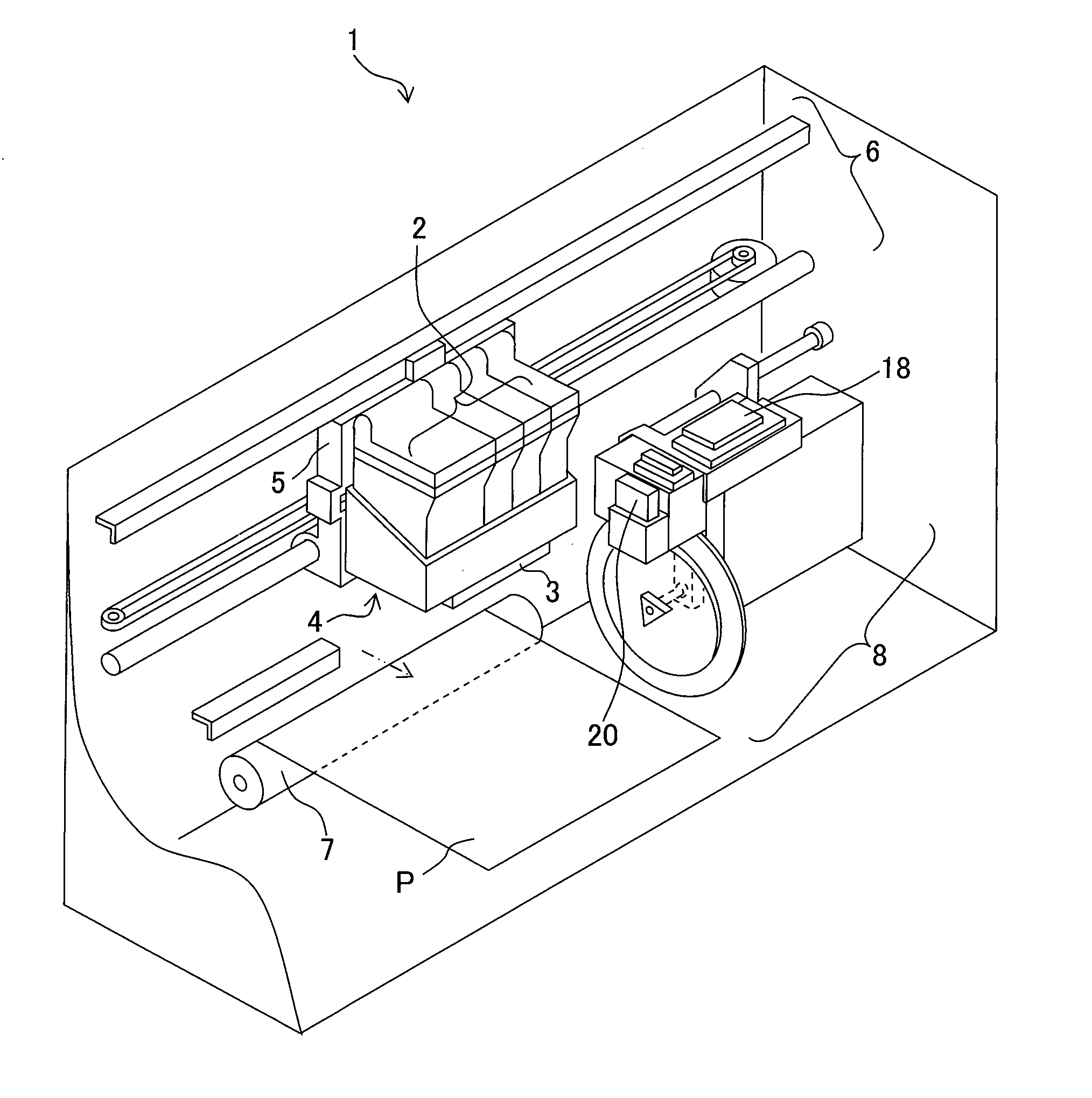

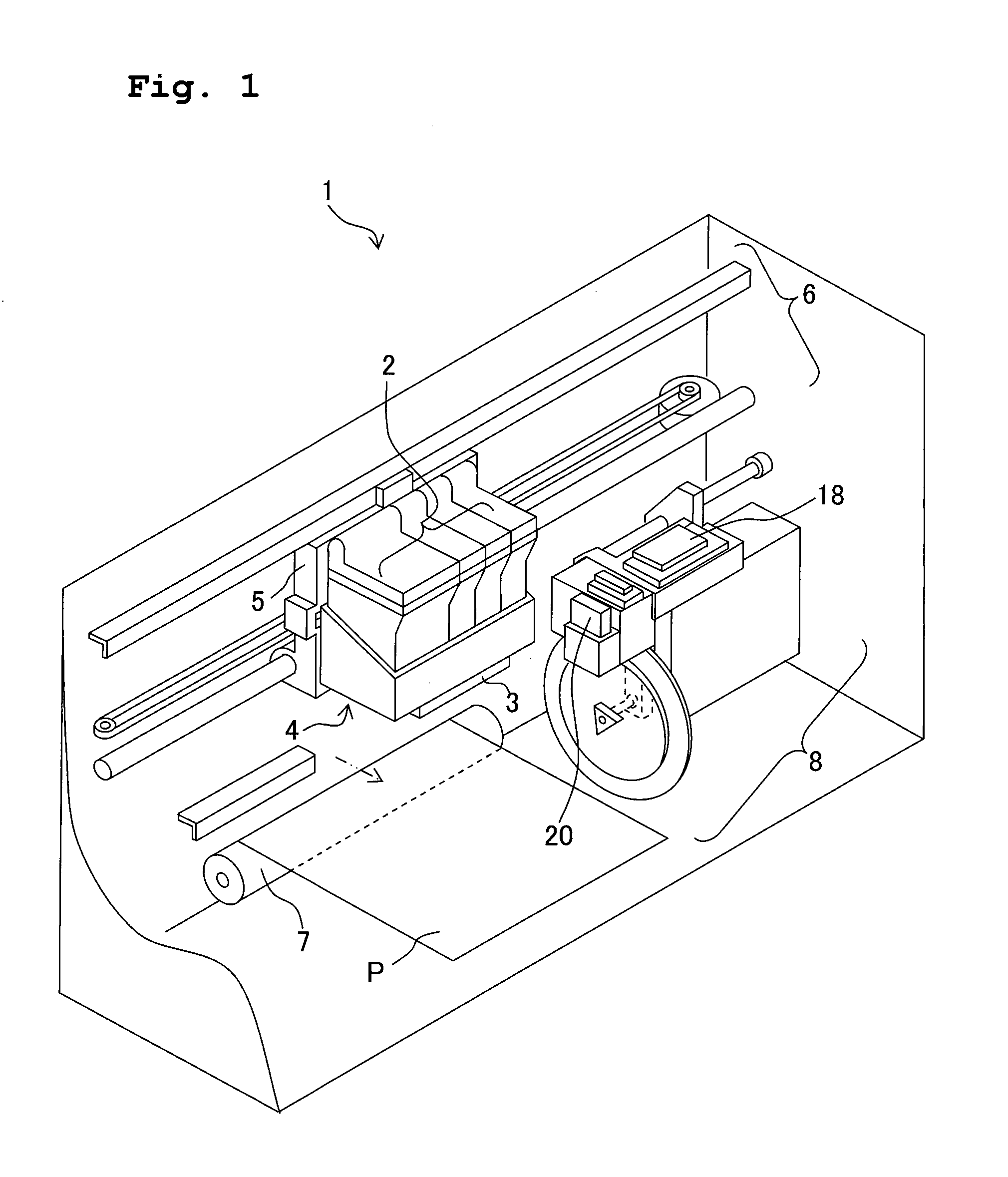

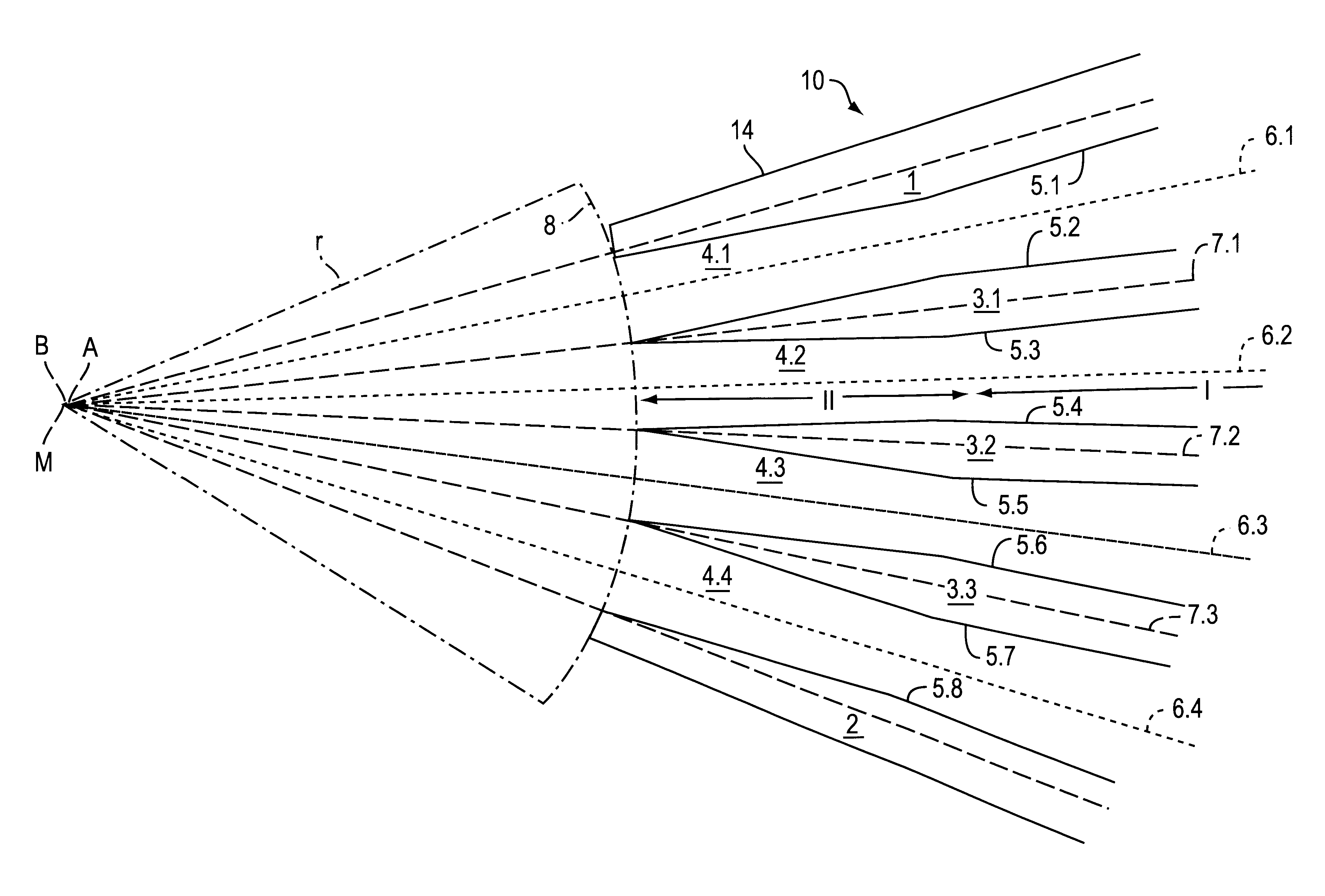

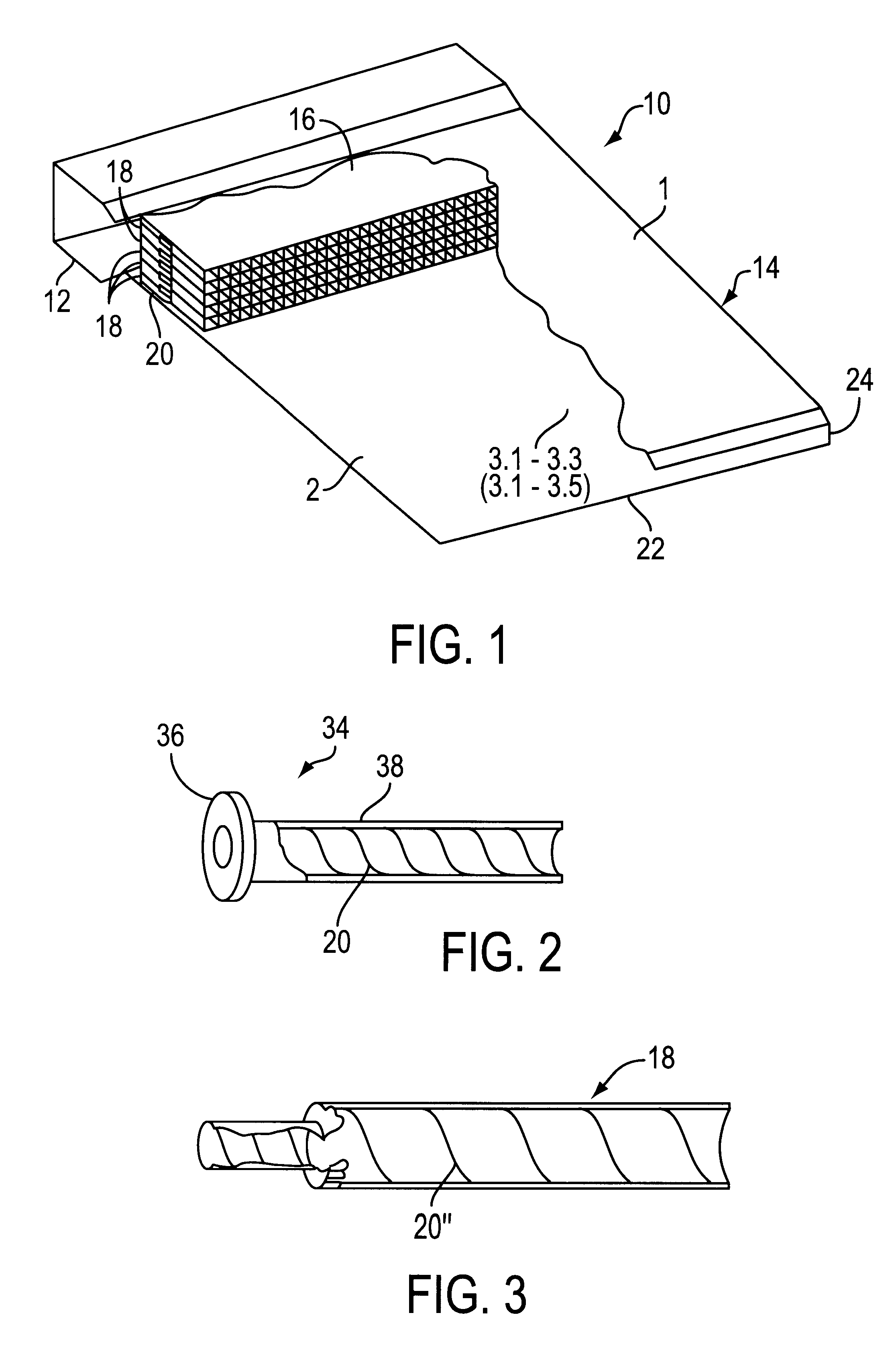

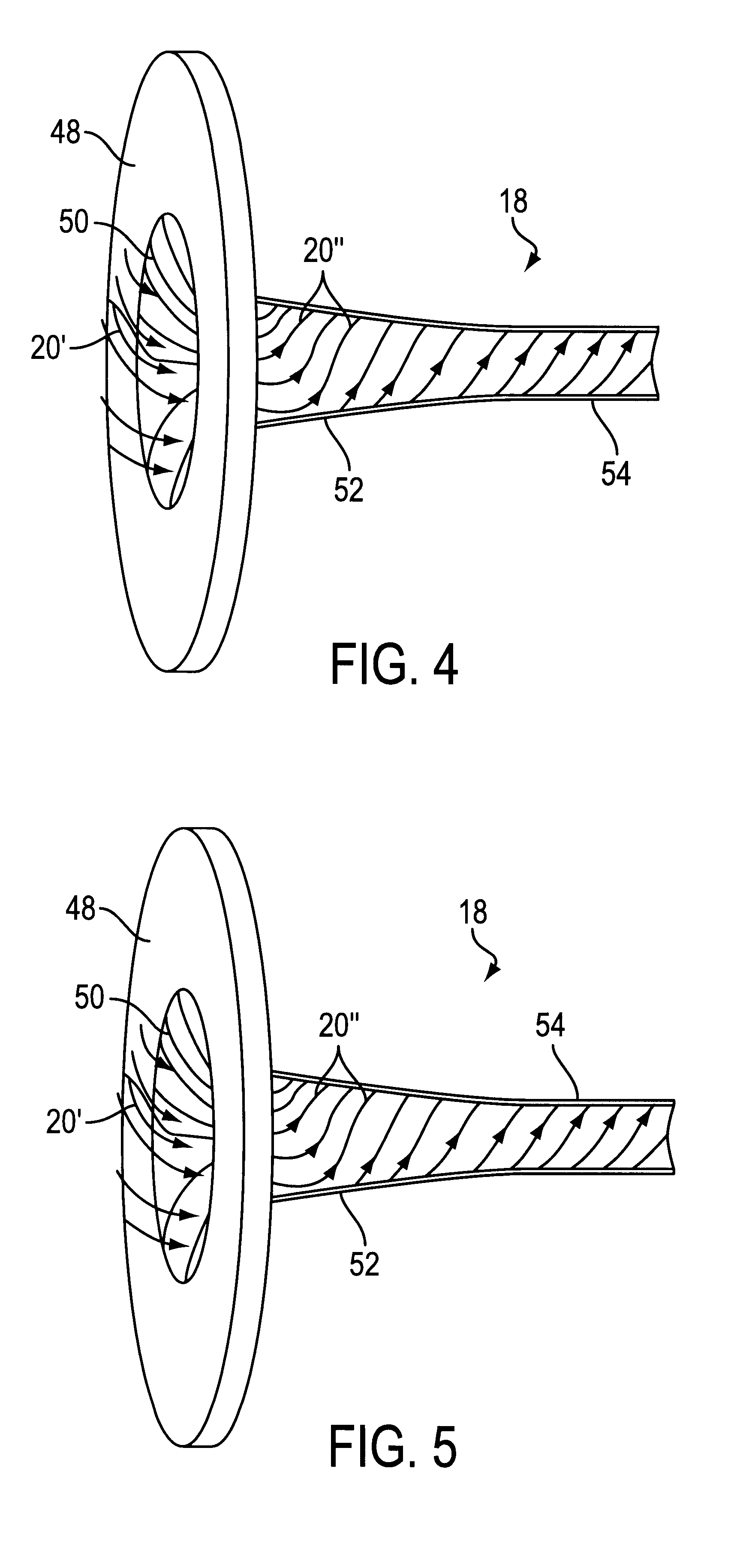

Stock inlet

Stock inlet of a paper machine that includes at least one stock suspension supply, a diffusor block having a plurality of tubular elements, dividing elements which extend across a width of the machine, and a stock inlet aperture having a top wall and a bottom wall. The dividing elements are located between the top wall and the bottom wall, so that a plurality of suspension conduits are formed, which extend across the width of the machine. Further, the stock inlet aperture is positioned one of adjacent one wire and between two wires. The suspension conduits include a first region and a second region disposed downstream of the first region, with respect to a stock flow direction. The first region is formed by flat boundary surfaces which extend across the width of the machine and converge in the stock flow direction, and each of the dividing elements has a sharper convergence of surfaces in the second region than in the first region. The plurality of tubular elements are associated with a turbulence generating element to produce secondary turbulence currents in partial suspension flows conveyed through the plurality of tubular elements. In this way, the secondary turbulence currents overlap a primary current of each partial suspension flow, and all of the dividing elements have a contour and an arrangement so that the second region for each suspension conduit is of equal length and has an identical cross sectional course.

Owner:VOITH PATENT GMBH

Ink composition

Disclosed is an aqueous ink composition including between 1 and 40 weight % of a water dispersible resin, between 0.5 and 15 weight % of a colorant, between 20 and 80 weight % of water and between 1 and 30 weight % of an acetal cosolvent, wherein all amounts are relative to the total ink composition. The ink composition may further include between 15 and 75 weight % of a dispersion stabilizing cosolvent.

Owner:OCE TECH

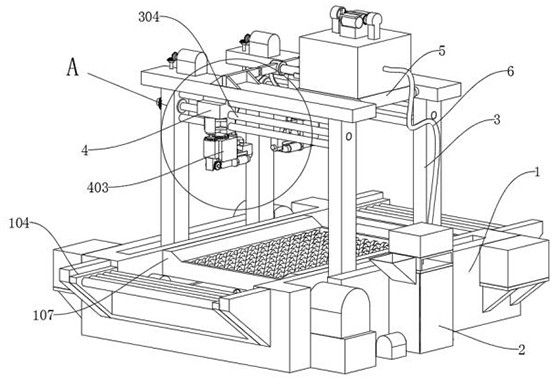

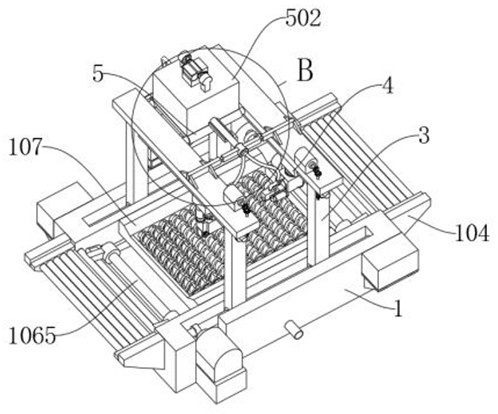

Anti-clogging clarifier injection device for glass manufacturing

ActiveCN113663847BImprove adaptabilityEasy to sprayGlass furnace apparatusSpraying apparatusElectric machineryStructural engineering

The invention discloses an anti-clogging clarifying agent spraying device for glass manufacturing, which relates to the technical field of production and manufacturing auxiliary devices, in order to solve the problem that the existing device can only spray one place, and the user can only move the glass to adjust the spraying position ;Includes a spray carrier and a one-way carrier tube; the inner side of the top of the spray carrier is provided with an assembly loading shaft, and the inner side of the configuration carrier box is provided with a drive mixing structure; a guide column is provided between the load columns; There are telescopic pillars on the side, a storage box on the top of the top base of the load, a load-bearing convex plate on the side of the top base of the load, a transport connection tube on the side of the storage load box, and a one-way load tube on the side of the storage load box. The evenly mixed clarifying agent is transported to the interior of the storage tank, and transported to the spray joint through the transport connection tube and the shunt load tube. The angle adjustment motor drives the bearing tooth column to rotate, and drives the drive spray structure to sweep and spray the glass, so that the device can Spray the glass evenly over the entire surface.

Owner:徐州市威固特种玻璃有限公司

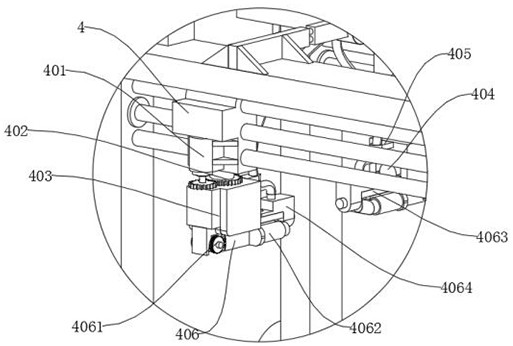

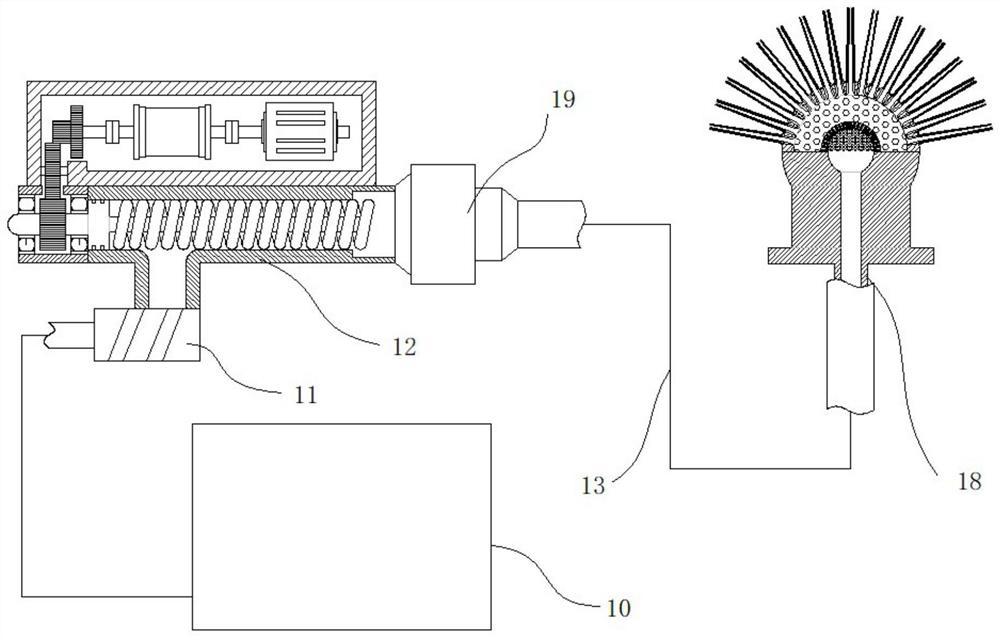

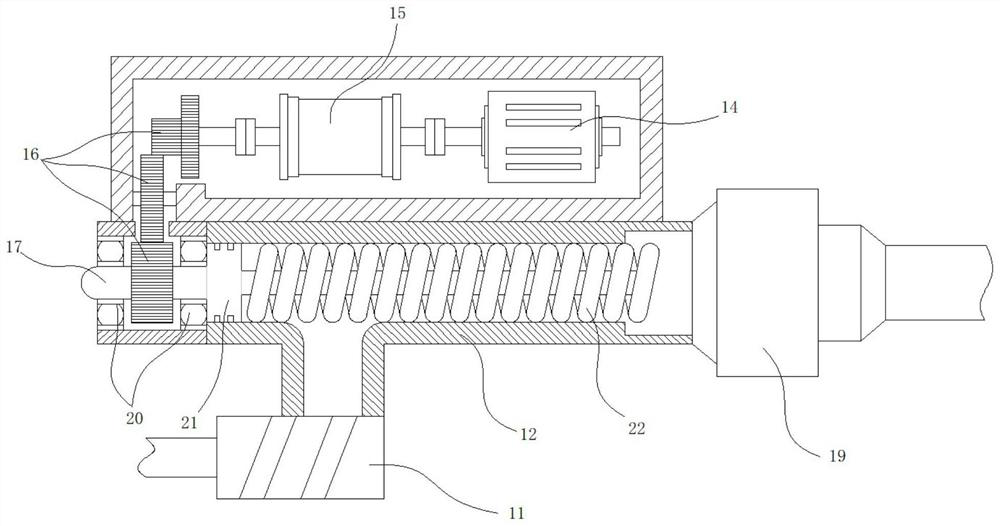

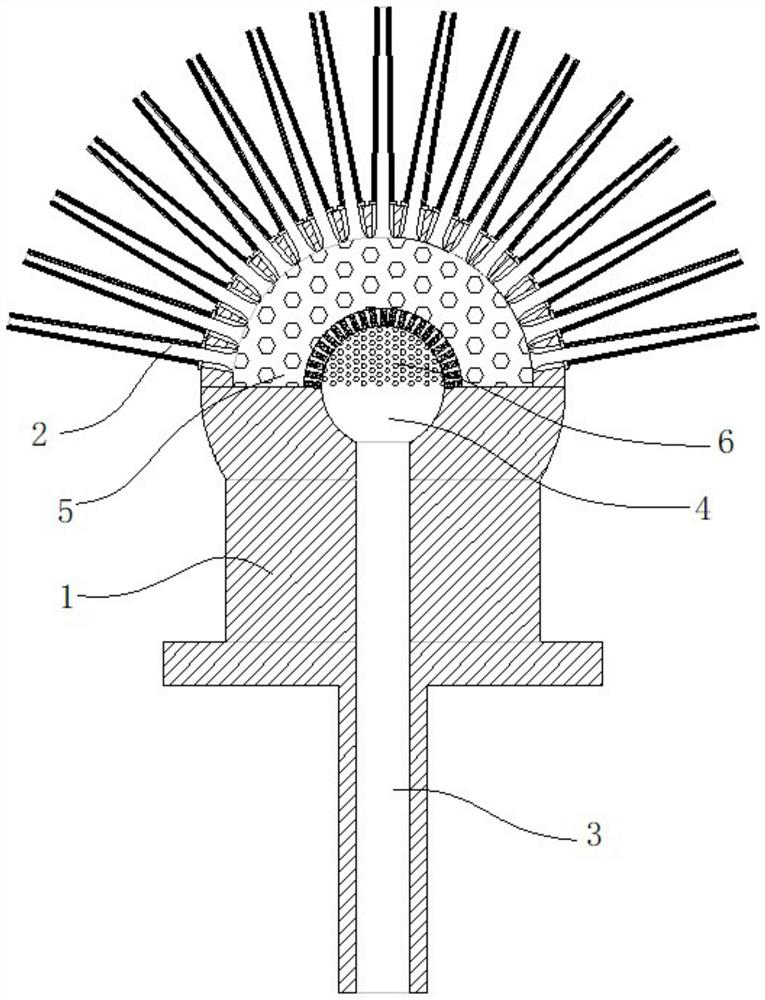

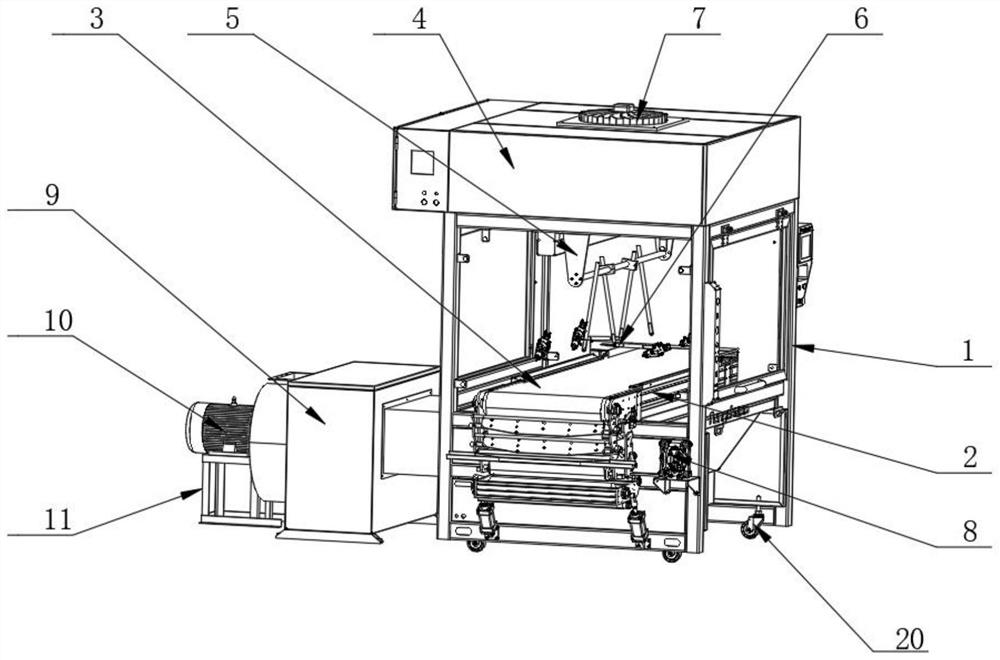

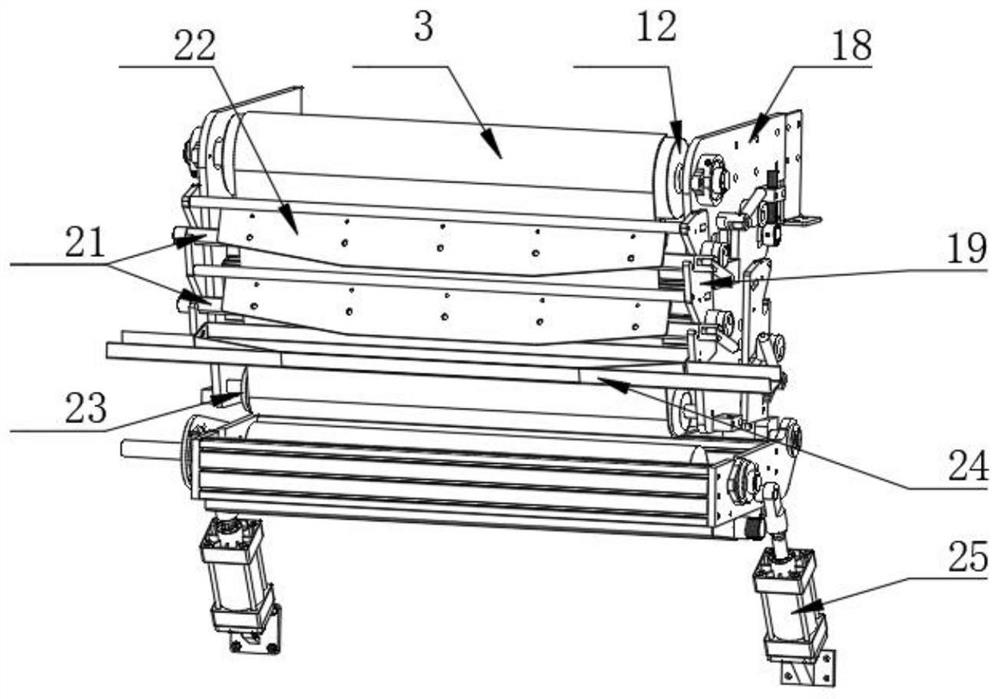

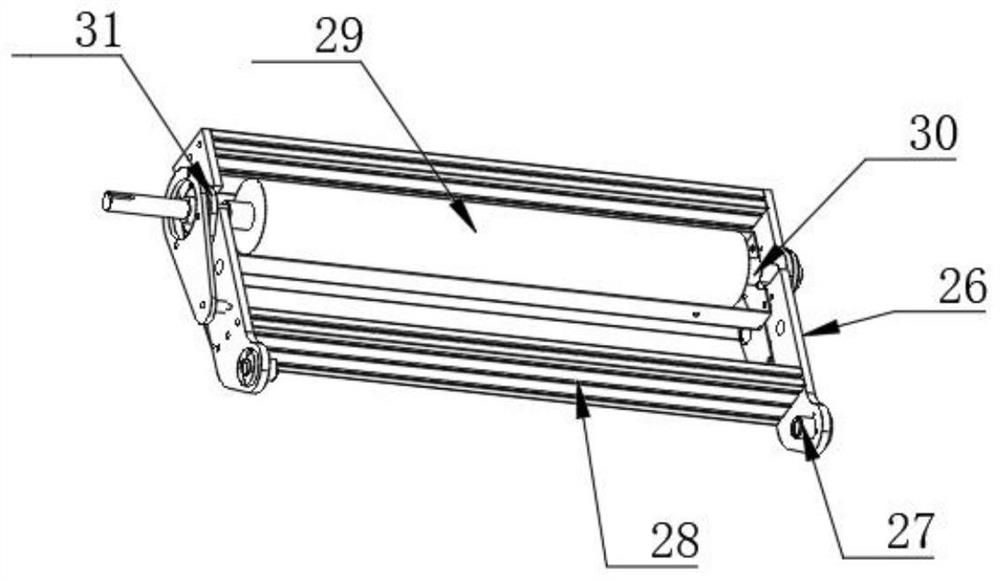

A polymer injection mechanism for electrospinning nanofibers

ActiveCN110205686BIncrease productivityPressure is easy to controlSpinning head liquid feederFilament/thread formingPolymer scienceSpinning

Owner:北京英鸿光大科技有限公司

Ink for inkjet recording, ink set for inkjet recording, ink media set for inkjet recording, ink cartridge, inkjet recording method, and inkjet recording apparatus

InactiveCN101365761BImprove printing qualityHigh glossDuplicating/marking methodsInksPolymer scienceActive agent

To provide an ink for inkjet recording containing water, water-soluble organic solvent, water-dispersible resin, fluorochemical surfactant or derivative thereof, and coloring agent containing pigment, wherein the ink has a surface tension of 20-35 mN / n and viscosity of 5 mPas or more at 25 DEG C, total amount of the water-dispersible resin and the coloring agent in the ink is 5-40% by mass, and mass ratio A / B of the water-dispersible resin A to the coloring agent B is 0.5-4, wherein the ink is applied for a recording medium for inkjet recording containing a support containing cellulose pulp, and one or more barrier layers disposed on at least one face of the support, and wherein the barrier layer contains 30% by mass or more of inorganic pigment having refractive index of 1.5 or more, excluding aluminum hydrate, and 10% by mass or more of inorganic pigment having a refractive index of less than 1.5.

Owner:RICOH KK

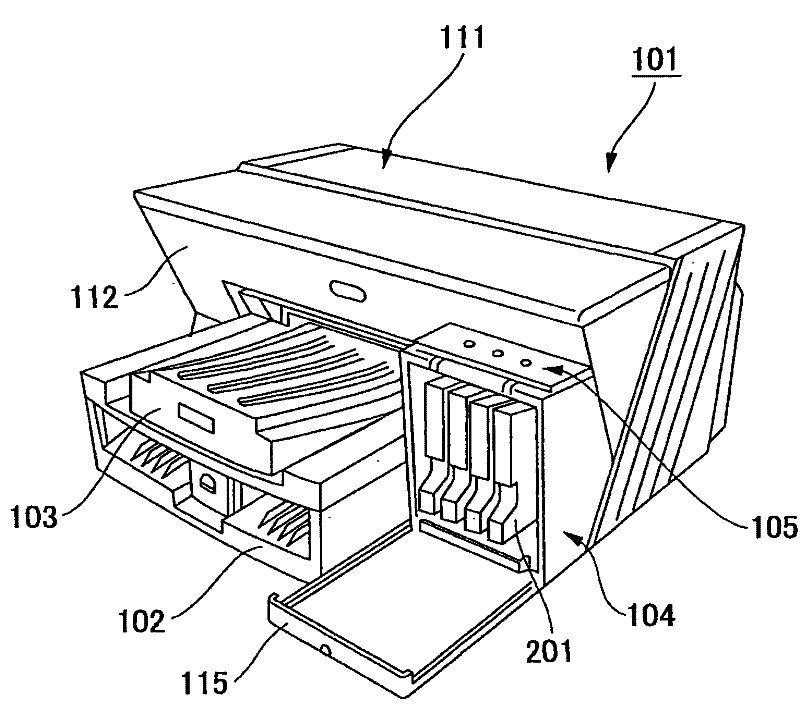

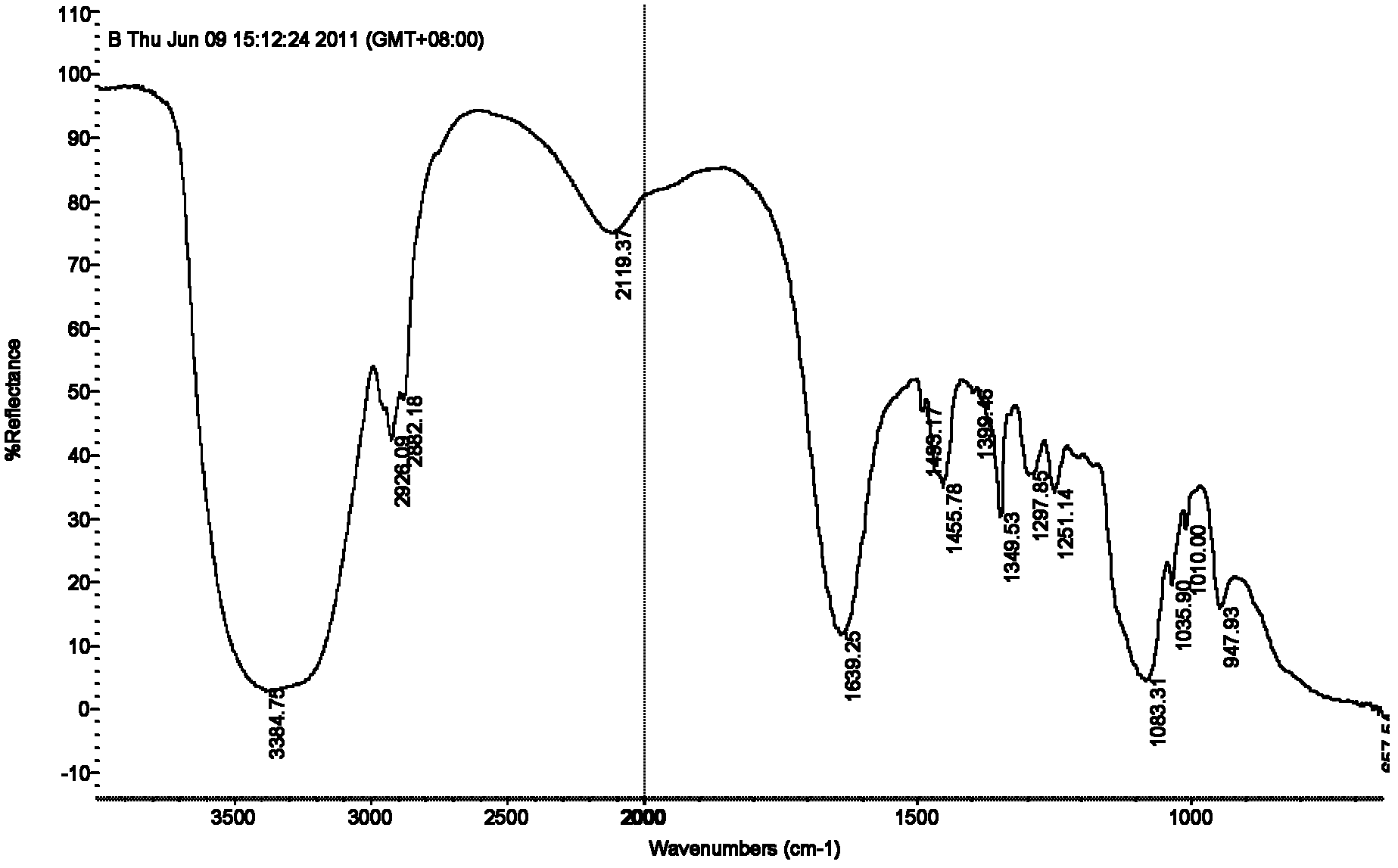

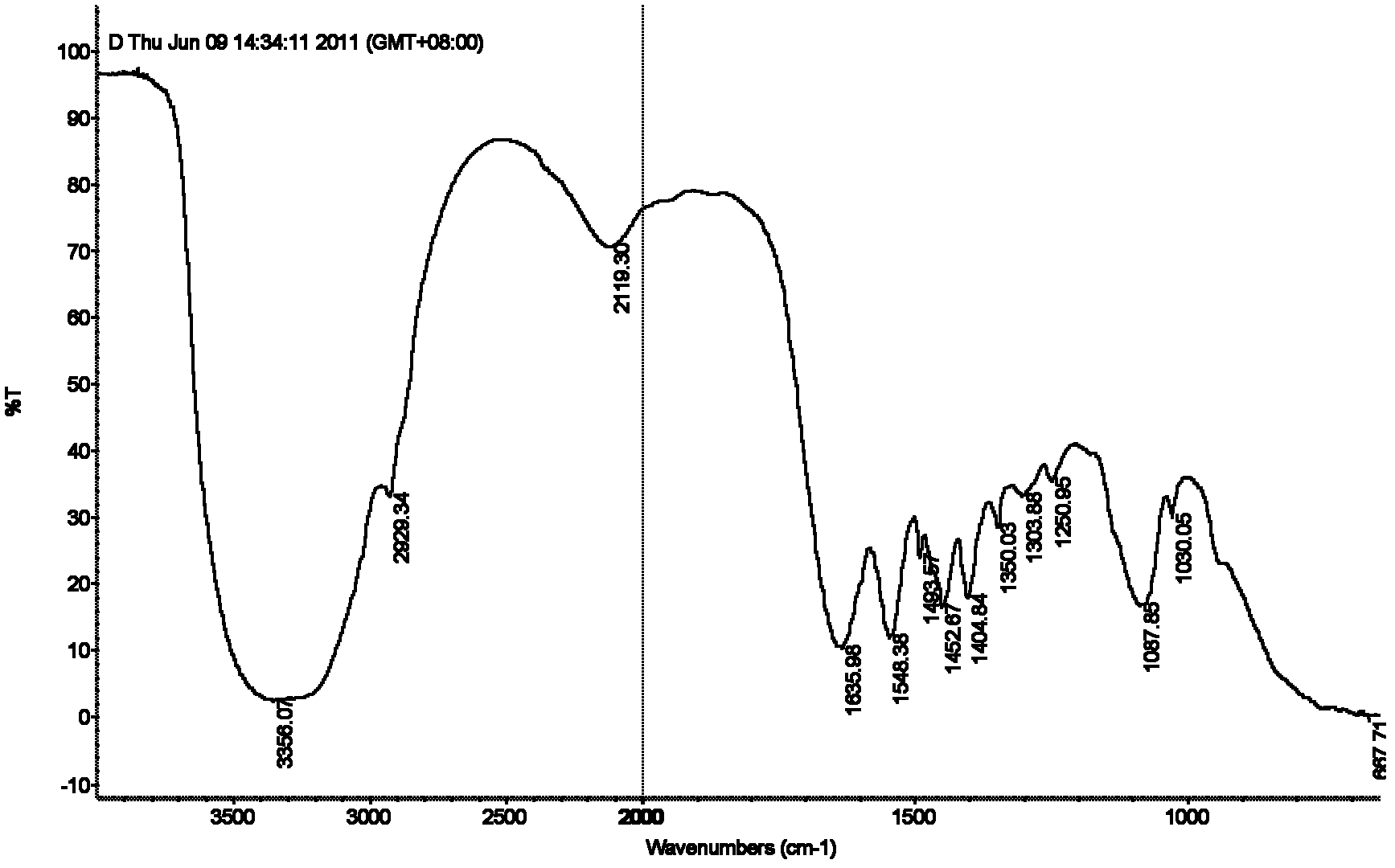

Green ink for ink jet printing

The invention relates to green ink for ink jet printing. The ink comprises a green pigment, a dispersing agent and water, wherein the green pigment is phthalocyanine green pigment; and the dispersing agent comprises one or more substances which have infrared spectrum absorption peaks in the following positions: 3300-3500 cm<-1>, 2070-2170 cm<-1>, 1590-1690 cm<-1>, 1490-1530 cm<-1>, 1436-1476 cm<-1>, 1329-1369 cm<-1>, 1277-1317 cm<-1>, 1229-1269 cm<-1>, 1163-1203cm<-1>, and 1034-1132 cm<-1>. The green ink still has good jet stability under the condition of quick ink jet printing, and has excellent dispersion stability; and compared with the ink in the prior art, the green ink is more suitable for high-precision and high-speed ink jet printing jetting heads.

Owner:天津兆阳纳米科技有限公司

Inkjet ink set, inkjet recording device, and inkjet recording method

InactiveUS8765839B2Jet stabilityEasy to storeMeasurement apparatus componentsDecorative surface effectsEmulsionAcrylic resin

Owner:RICOH KK

A hole-type fuel injector for controlling the injection stability of a commercial vehicle diesel engine with a small amount of fuel

InactiveCN106762303BHigh working reliabilityExtended service lifeFuel injection apparatusMachines/enginesFuel oilEngineering

The invention discloses a hole type oil nozzle for controlling low-oil-amount spraying stability of a commercial vehicle diesel engine. The hole type oil nozzle comprises a needle valve and a needle valve body, the head of the needle valve is composed of two stairs, the height of the first stair is 0.2-0.8 time the maximum lift range of the needle valve, and the diameter of the first stair is slightly larger than that of the second stair; in the small needle valve lift range, the annular circulating sectional area of fuel oil between the head of the needle valve and the needle valve body in a pressure chamber is decreased to be smaller than the spraying hole area, and then precise control over small-flow fuel oil spraying is achieved; the inner diameter of the upper portion of the needle valve body is the same as the outer diameter of the needle valve and is in clearance fit with the outer diameter of the needle valve, and then an axial sealing surface for high-pressure fuel oil is formed; an oil nozzle sealing conical surface used for controlling high-pressure fuel oil spraying is formed by a conical body arranged on the lower portion of the needle valve body and a boss arranged on the head of the needle valve; the outer diameter d2 of the lower portion of the needle valve body of the oil nozzle ranges from 11 mm to 13 mm. According to the hole type oil nozzle, the low-oil-amount fuel oil flowing performance of the oil nozzle and the low-oil-amount spraying stability are improved while the spraying reliability and power performance under the condition of the high circulating oil supply amount are guaranteed.

Owner:JIANGSU UNIV

Ink composition for inkjet recording, ink set, and image recording method

PendingUS20220041880A1Improve jetting stabilityIncrease graininessDuplicating/marking methodsInksWater soluble polymersImage recording

Provided is an ink composition for inkjet recording containing water, a pigment, and a water-soluble polymer having a carboxy group, in which the water-soluble polymer satisfies the following expression (1), and the ink composition for inkjet recording is used for recording an ink image on a recording medium to which a pretreatment liquid including at least one aggregating agent selected from the group consisting of acids, cationic polymers, and polyvalent metal salts is applied:230 mgKOH / g≤Σ(a×b)≤750 mgKOH / g (1)a means an acid value of the water-soluble polymer, in terms of mgKOH / g, and b means a content of the water-soluble polymer with respect to a total amount of the ink composition, in terms of % by mass.

Owner:FUJIFILM CORP

Line paint spraying machine with high recycling rate

PendingCN112827694AWill not affect processing application effectImprove recycling ratesLiquid spraying apparatusIndustrial engineeringLeather belt

The invention discloses a line paint spraying machine with high recycling rate, and particularly relates to the technical field of line paint spraying machines. The line paint spraying machine with the high recycling rate comprises a main body frame, wherein a conveying rack is arranged in the main body frame; a top support is arranged on the inner top wall of the conveying rack; four supports are arranged at the bottom end of the top support; rolling wheels are arranged at the two ends of the inner side of the conveying rack in the horizontal direction; a belt is arranged between the two rolling wheels; a scraping system is arranged outside one side of the main body frame; the scraping system comprises first side frames arranged on the two sides of one end of the main body frame; and the bottom ends of the two first side frames are in shaft connection with a cleaning assembly. According to the whole line paint spraying machine, residual paint on the belt is recycled through the arranged scraping system, so that the recycling rate of the paint is increased; and meanwhile, the cleaning effect of the structure is good due to the fact that the cleaning assembly is arranged at the bottom of the scraping system, so that the machining application effect of the line paint spraying machine is guaranteed, and the operation efficiency of the whole line paint spraying machine is improved.

Owner:昆山丰巧机械有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com