Hole type oil nozzle for controlling low-oil-amount spraying stability of commercial vehicle diesel engine

A diesel engine and small oil volume technology, which is applied to fuel injection devices, mechanical equipment, engine components, etc., to achieve the effects of increasing injection pressure, reducing HC and soot emissions, and reducing impact force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to have a clearer understanding of the technical features, purposes and effects of the invention, the specific implementation of the present invention will now be described with reference to the accompanying drawings. The accompanying drawings are only used to illustrate the present invention, and do not represent the actual structure and true proportion of the present invention.

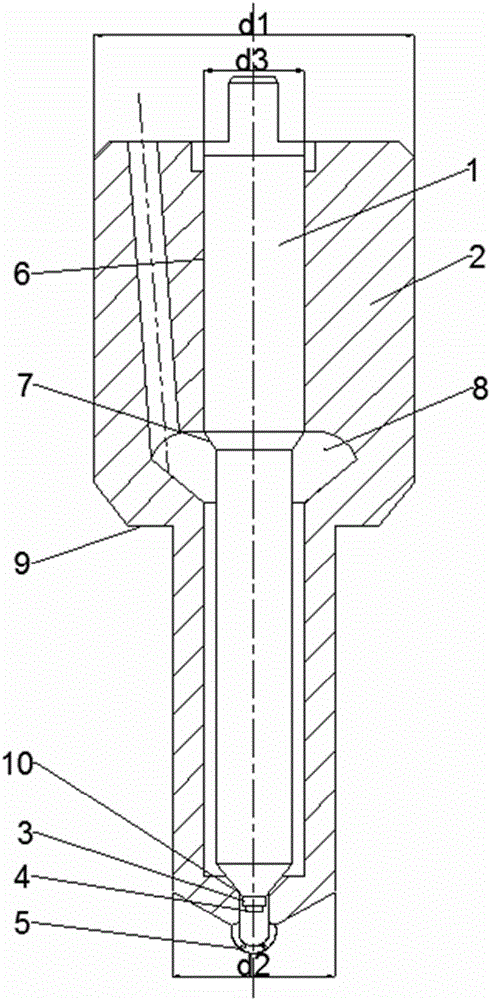

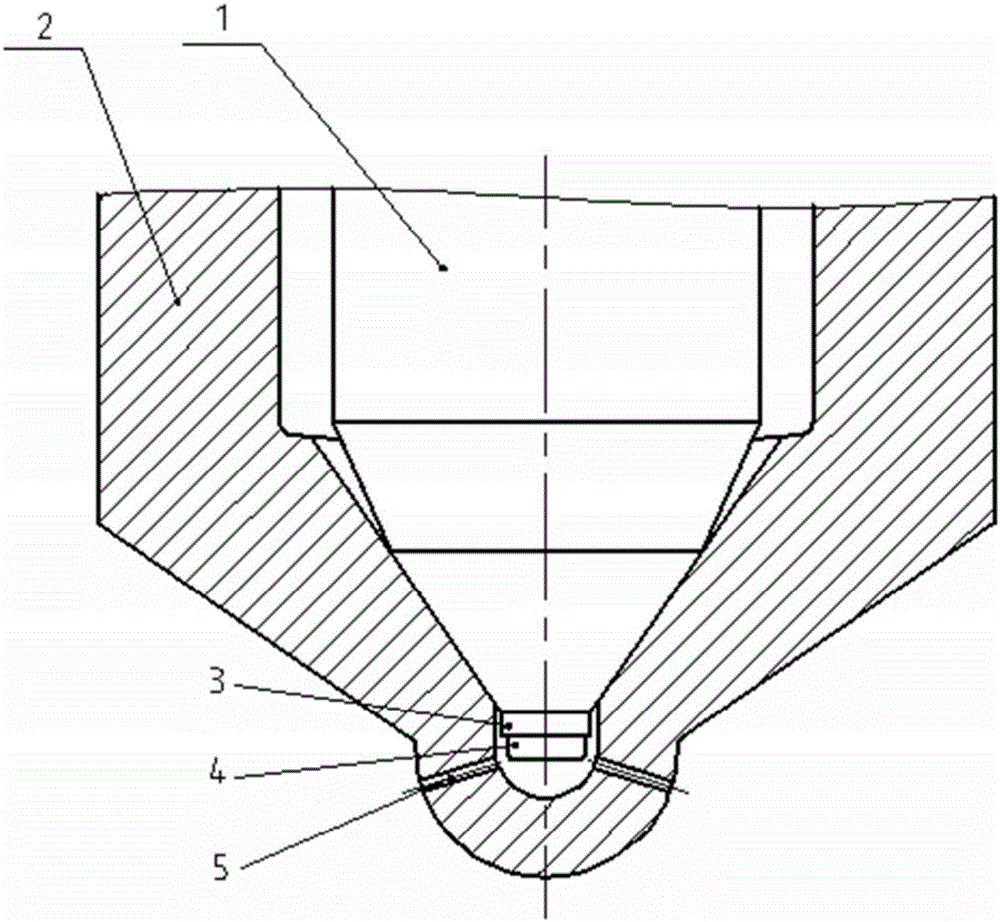

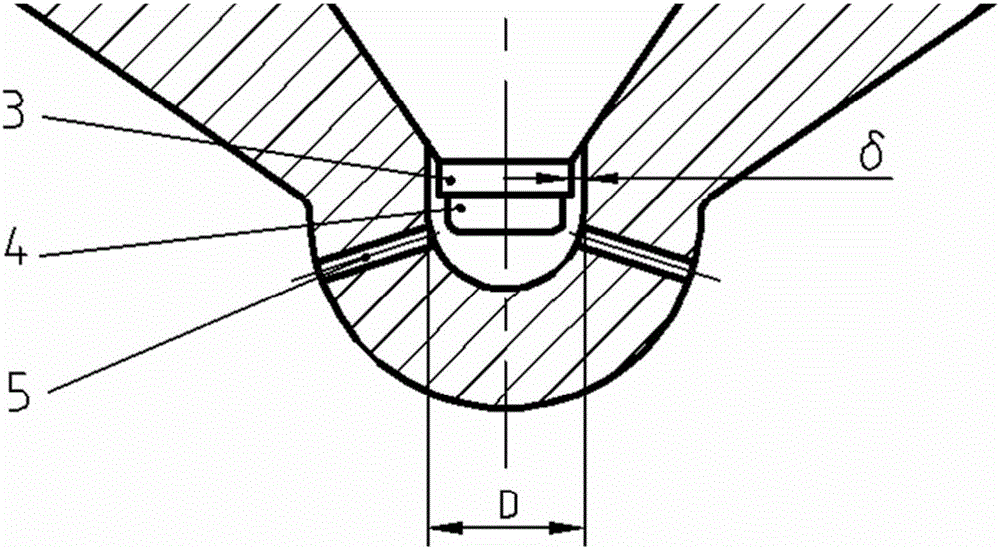

[0026] The implementation of the present invention takes a commercial vehicle diesel engine supporting a hole-type fuel injector as an example. In order to control the injection stability of the commercial vehicle diesel engine with a small amount of fuel, the structure of the fuel injector is designed as follows: Figure 1-4 structure shown. The needle valve of the injector is a rod-shaped cylindrical entity, and the needle valve body is a cavity-shaped entity. The needle valve is assembled in the needle valve body. The outer diameter d2 of the lower part of the needle valve body is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com