Green ink for ink jet printing

An inkjet printing and ink technology, applied in the field of green water-based pigment ink, can solve the problems of unsuitable high-precision, high-speed inkjet printing nozzles, unsuitable for new ink formulation systems, etc., and achieve good jetting stability and dispersion stability. Maintain good, fast results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

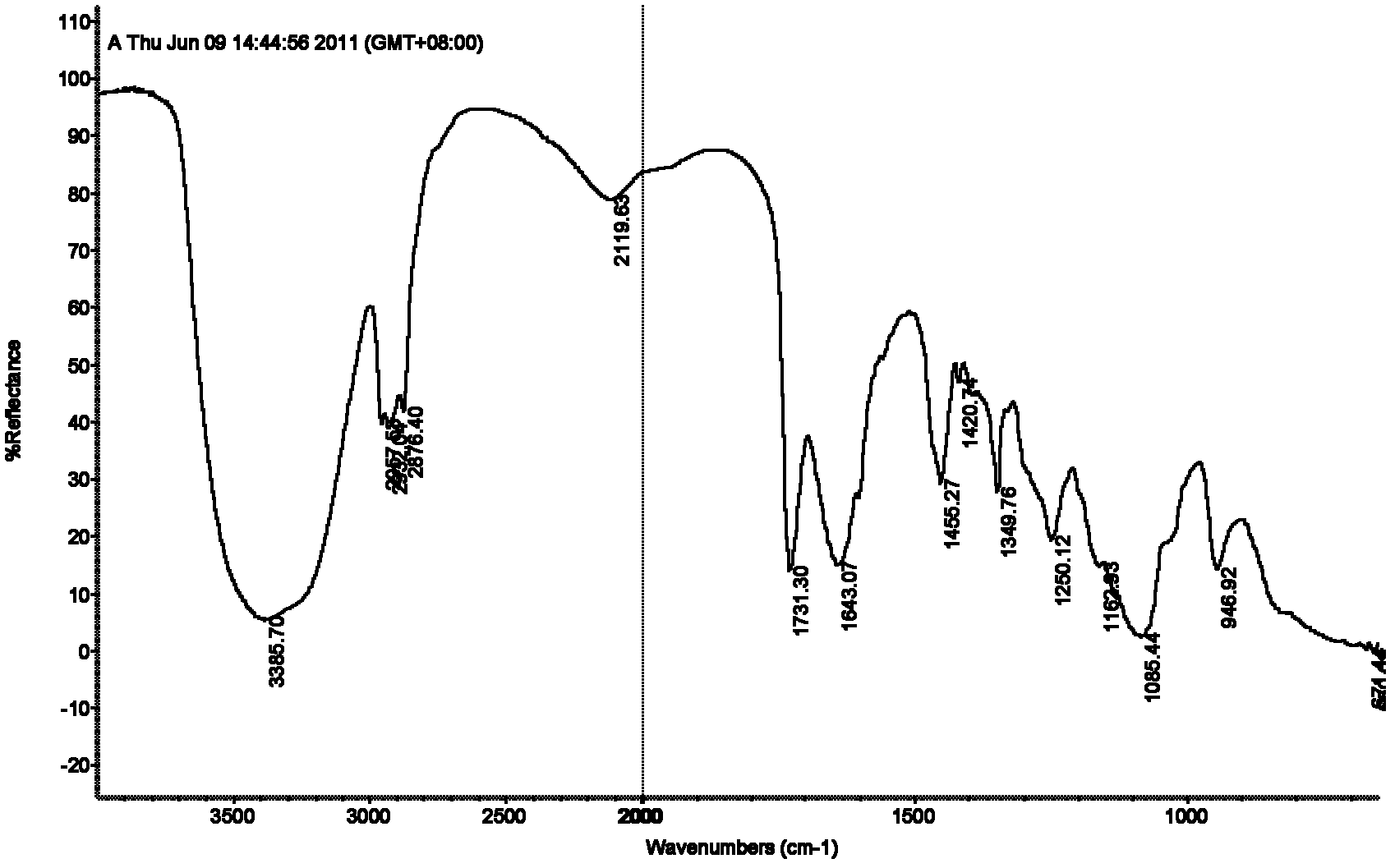

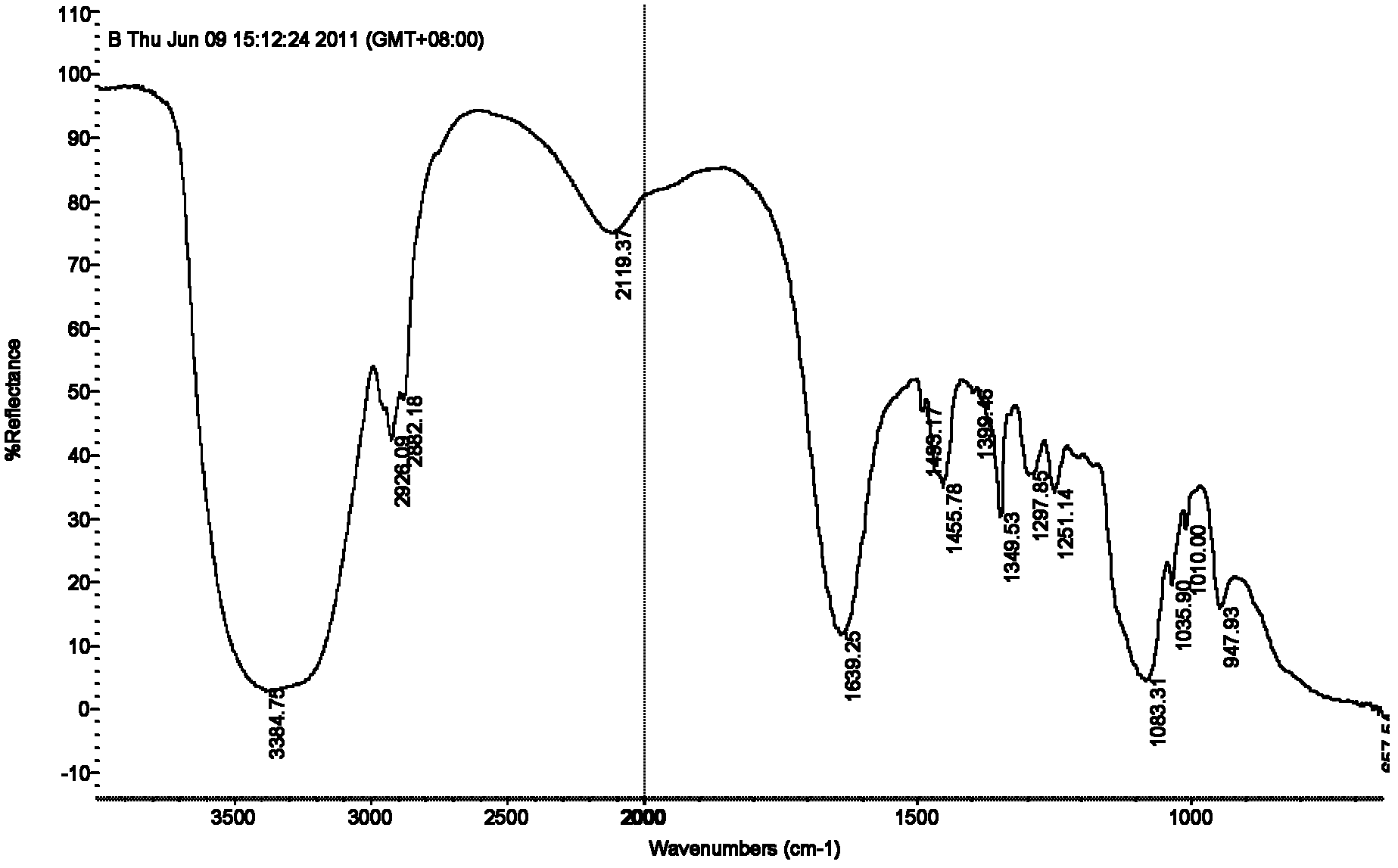

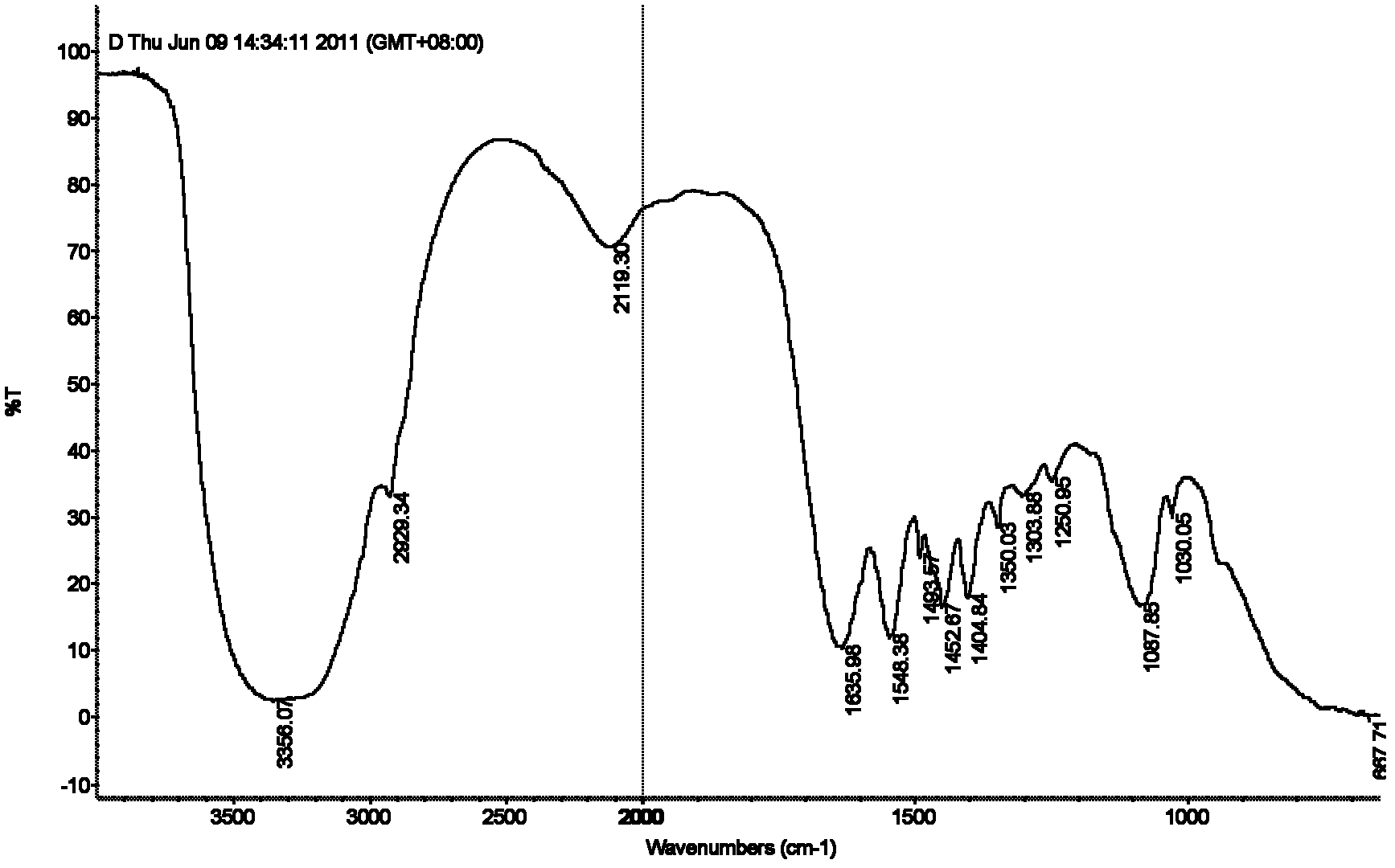

Image

Examples

Embodiment 1

[0054] Mix 12 parts of C.I. Pigment Green 36, 13 parts of dispersant Jeffesperse X3204 and 75 parts of deionized water with a high-speed shear mixer to obtain a shear dispersion, and then grind and disperse the above shear dispersion with a grinder for 2 hours , to obtain dispersion A.

[0055] Mix 4 parts of 2-pyrrolone, 12 parts of glycerol, 4 parts of diethylene glycol n-butyl ether, 1 part of Surfynol465, 0.5 parts of BYK348, 1 part of Joncryl 67, 0.2 parts of sodium hydroxide and 52.3 parts of deionized water, Obtain an ink solution.

[0056] Add the prepared ink solution dropwise to 25 parts of the above-mentioned dispersion liquid A, mix evenly, and filter through a filter with a pore size of 0.5 micron to obtain a green water-based pigment ink.

Embodiment 2

[0058] Mix 4 parts of 2-pyrrolone, 12 parts of glycerol, 4 parts of diethylene glycol n-butyl ether, 1 part of BYK348, 1 part of Joncryl 67, 0.2 parts of sodium hydroxide and 52.3 parts of deionized water to obtain an ink solution.

[0059] The prepared ink solution was added dropwise to 25 parts of the dispersion liquid A prepared in Example 1, and after mixing evenly, it was filtered with a filter with a pore size of 0.5 micron to obtain a green water-based pigment ink.

Embodiment 3

[0061] Mix 12 parts of C.I. Pigment Green 7, 13 parts of dispersant Jeffesperse X3204 and 75 parts of deionized water with a high-speed shear mixer to obtain a shear dispersion, and then grind and disperse the above shear dispersion with a grinder for 2 hours , to obtain dispersion B.

[0062] Mix 4 parts of 2-pyrrolone, 12 parts of glycerin, 4 parts of diethylene glycol n-butyl ether, 1 part of BYK348, 1 part of Joncryl 67, 0.2 parts of sodium hydroxide and 52.8 parts of deionized water to obtain an ink solution.

[0063] Add the prepared ink solution dropwise to 25 parts of the above-mentioned dispersion liquid B, mix evenly, and filter through a filter with a pore size of 0.5 micron to obtain a green water-based pigment ink.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com