Self-flushing anti-blocking waste water jar

A technology of waste water ratio and self-flushing, applied in osmosis/dialysis water/sewage treatment, functional valve type, safety valve, etc., can solve the problems of unavoidable blockage, durability defect, circuit dependence, etc. of solenoid valve, and achieve good self-control The effect of resistance and anti-blocking properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

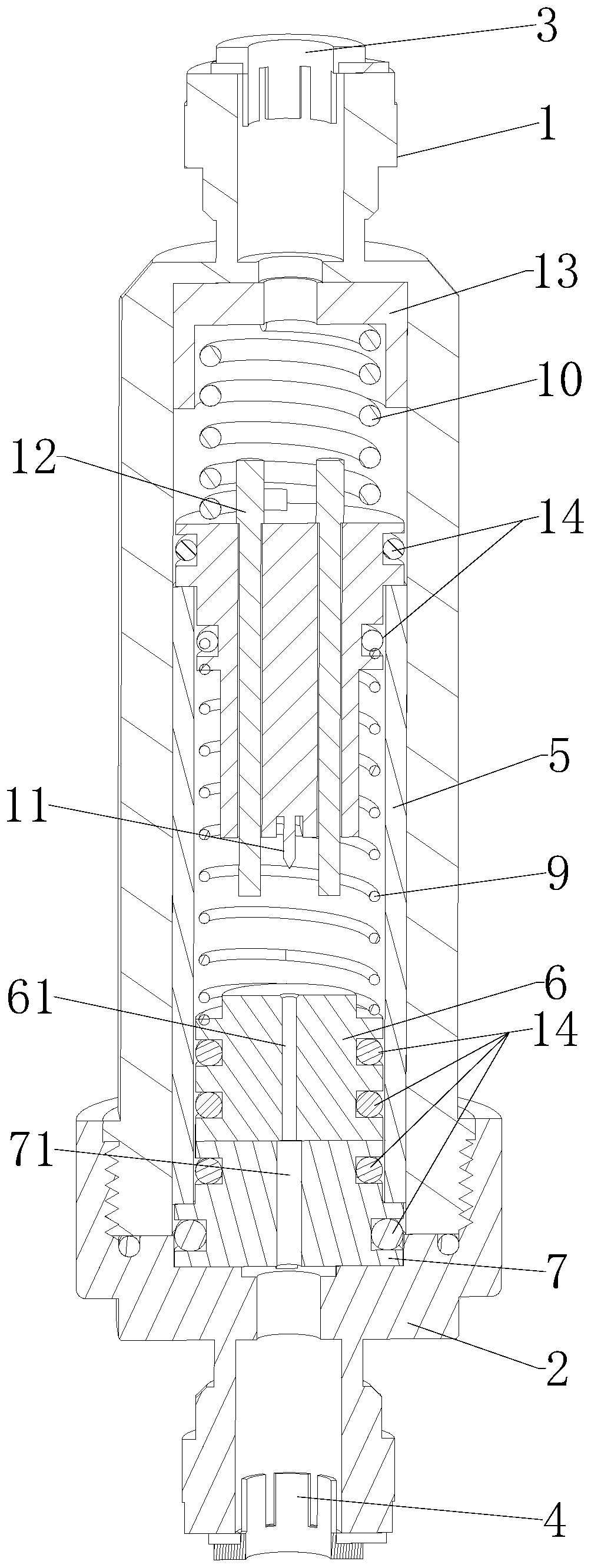

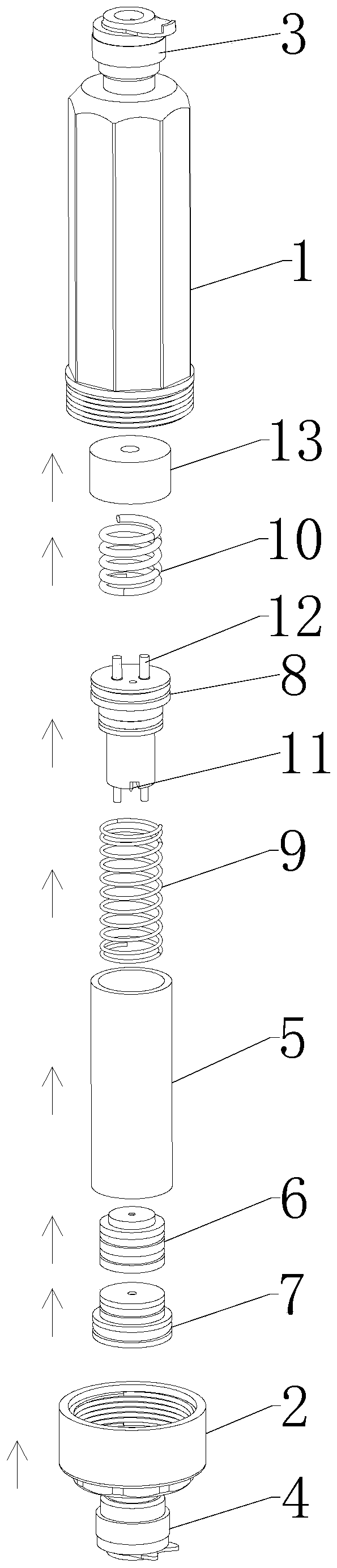

[0030] In order to understand the technical scheme of the present invention more intuitively and completely, the non-limiting feature descriptions are as follows in conjunction with the accompanying drawings of the present invention:

[0031] Such as figure 1 — Figure 5 as shown, figure 1 The middle arrow represents the direction of water flow, the ratio of self-flushing and anti-clogging waste water, including the shell 1 and the shell cap 2 arranged at the lower end of the shell 1, the upper end of the shell 1 is provided with the water outlet 3, and the lower end of the shell cap 2 is provided with the water inlet 4 , housing 1 is equipped with:

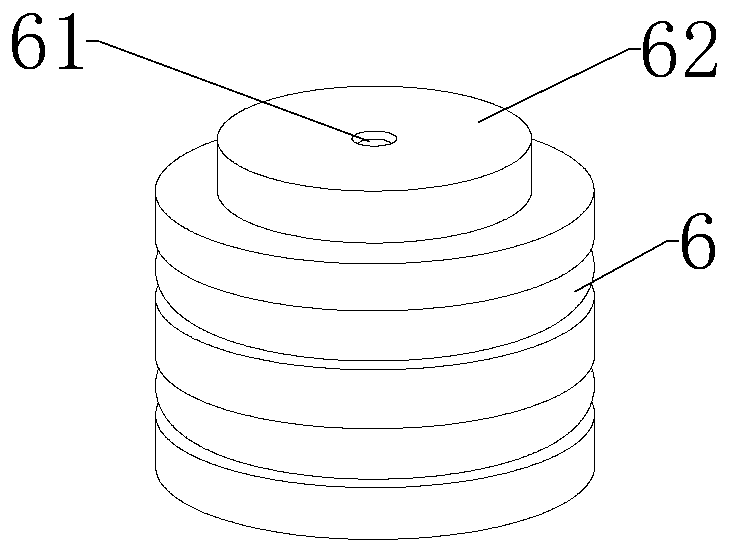

[0032] The inner tube 5 is provided with a piston 6 inside, and the piston 6 is provided with a first through hole 61 which penetrates up and down;

[0033] The lower plug 7 is arranged at the lower end of the inner tube 5, and the lower plug 7 is provided with a second through hole 71 that penetrates up and down, and the wate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com