Ultralight down feather shifting preventing down jacket with two-layer basting through structure and sewing process

An anti-running down and down jacket technology, which is applied in the field of clothing production, can solve the problems of heavy down jackets, cumbersome production, and affect the design effect, and achieve an efficient anti-running down effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to deepen the understanding of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

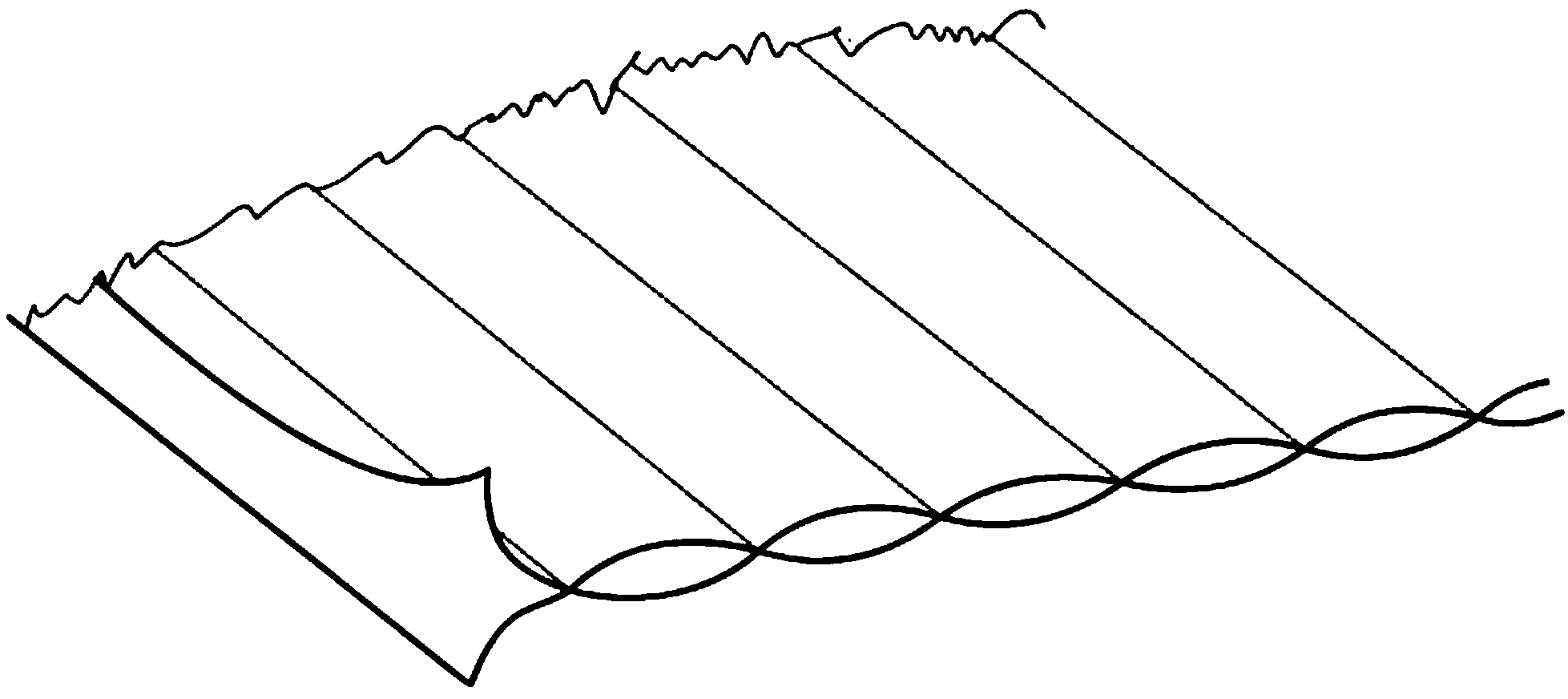

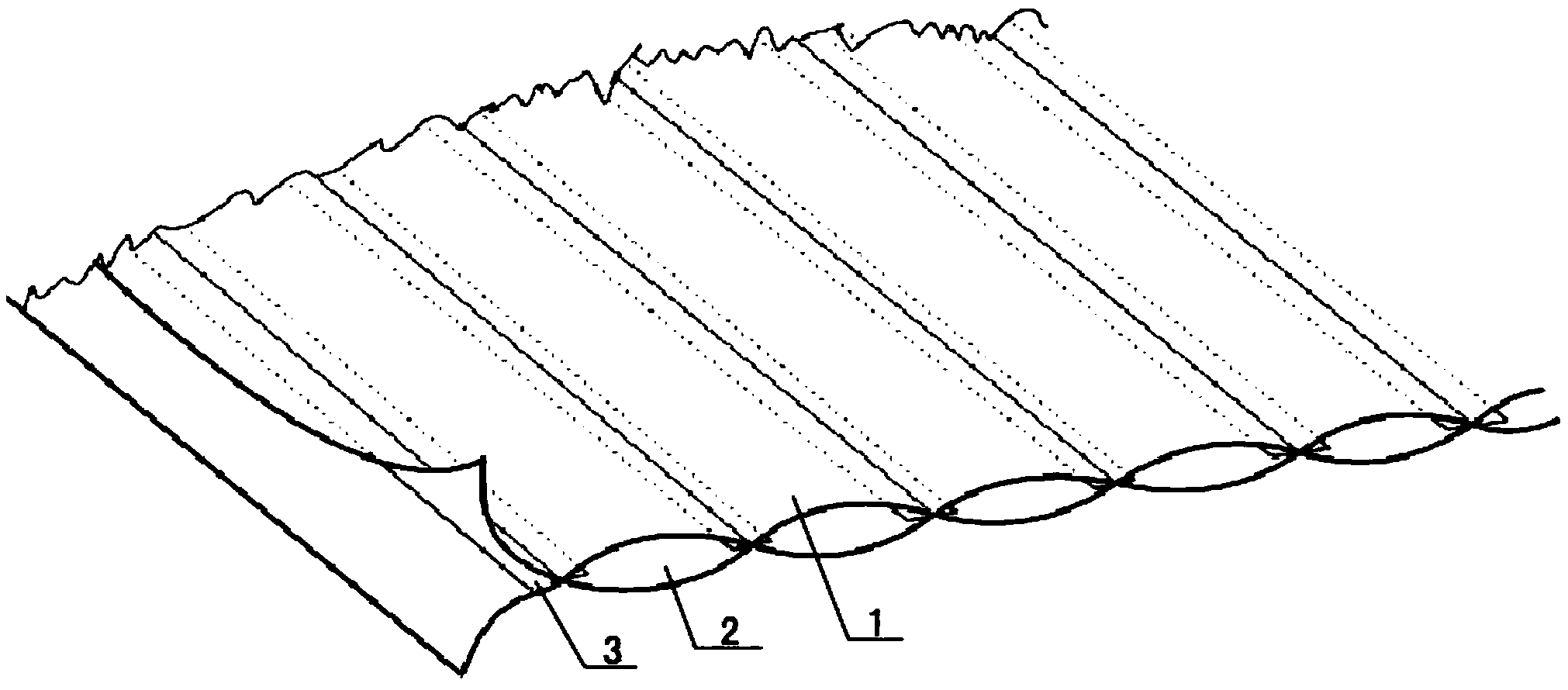

[0019] An ultra-light fleece-proof down jacket with a two-layer interlocking structure, comprising a fabric, a lining and down, and an anti-down strip 3 is provided at the stitching line between the fabric 1 and the lining 2 .

[0020] Preferably, the width of the down-proof strip 3 is 0.8 cm, which can effectively prevent down-running effect without affecting the weight and comfort of the two-layer down jacket.

[0021] A sewing process for an ultra-light fleece-proof down jacket with a two-layer layered structure, comprising the following steps:

[0022] S1. Cut the fabric and lining according to the requ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com