Automatic pin punching equipment

An automatic punching and punching technology, applied in needles, other household appliances, household appliances, etc., can solve the problems of low efficiency, uneven product quality, and high labor costs, and achieve the effects of low cost, simple structure and high efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

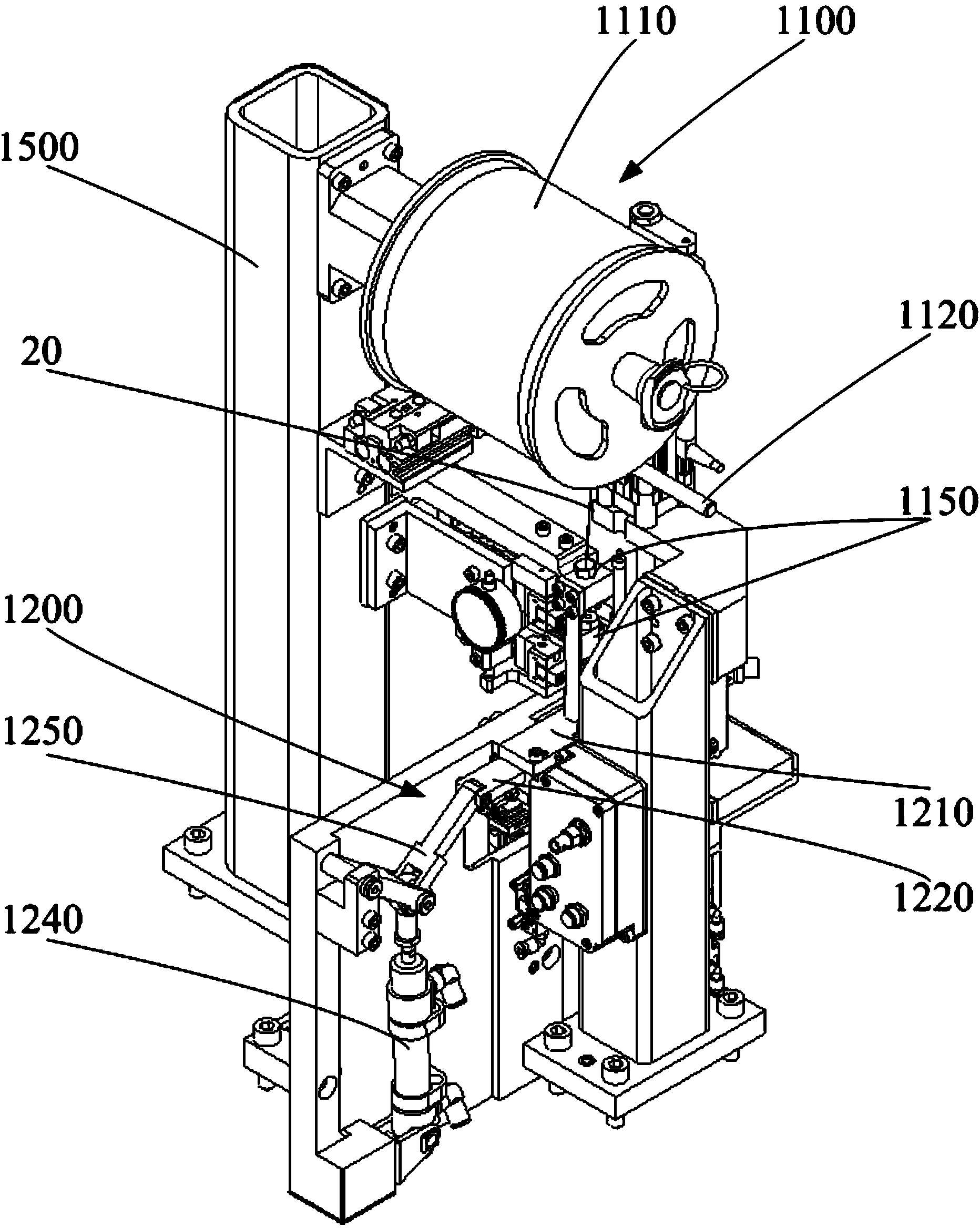

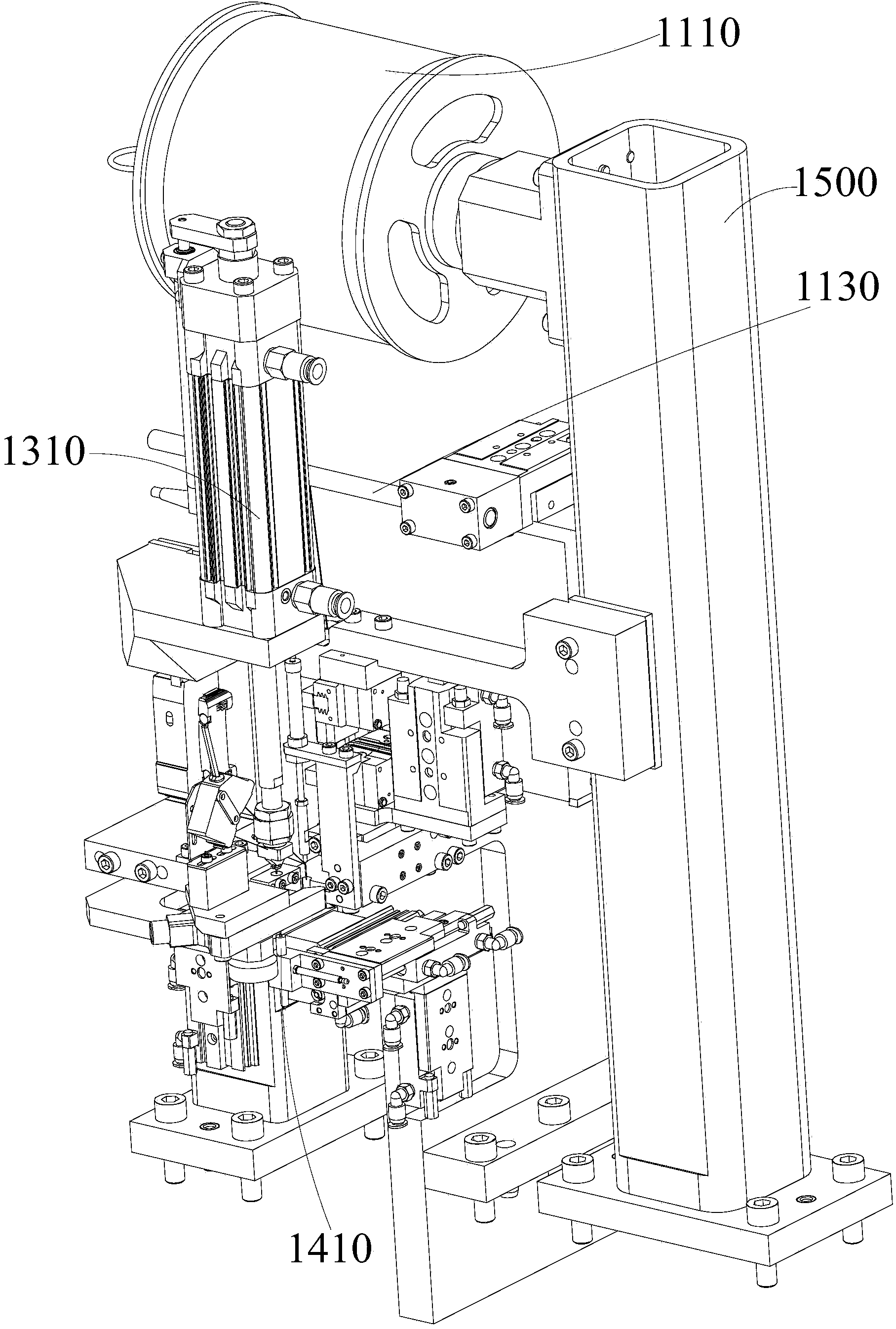

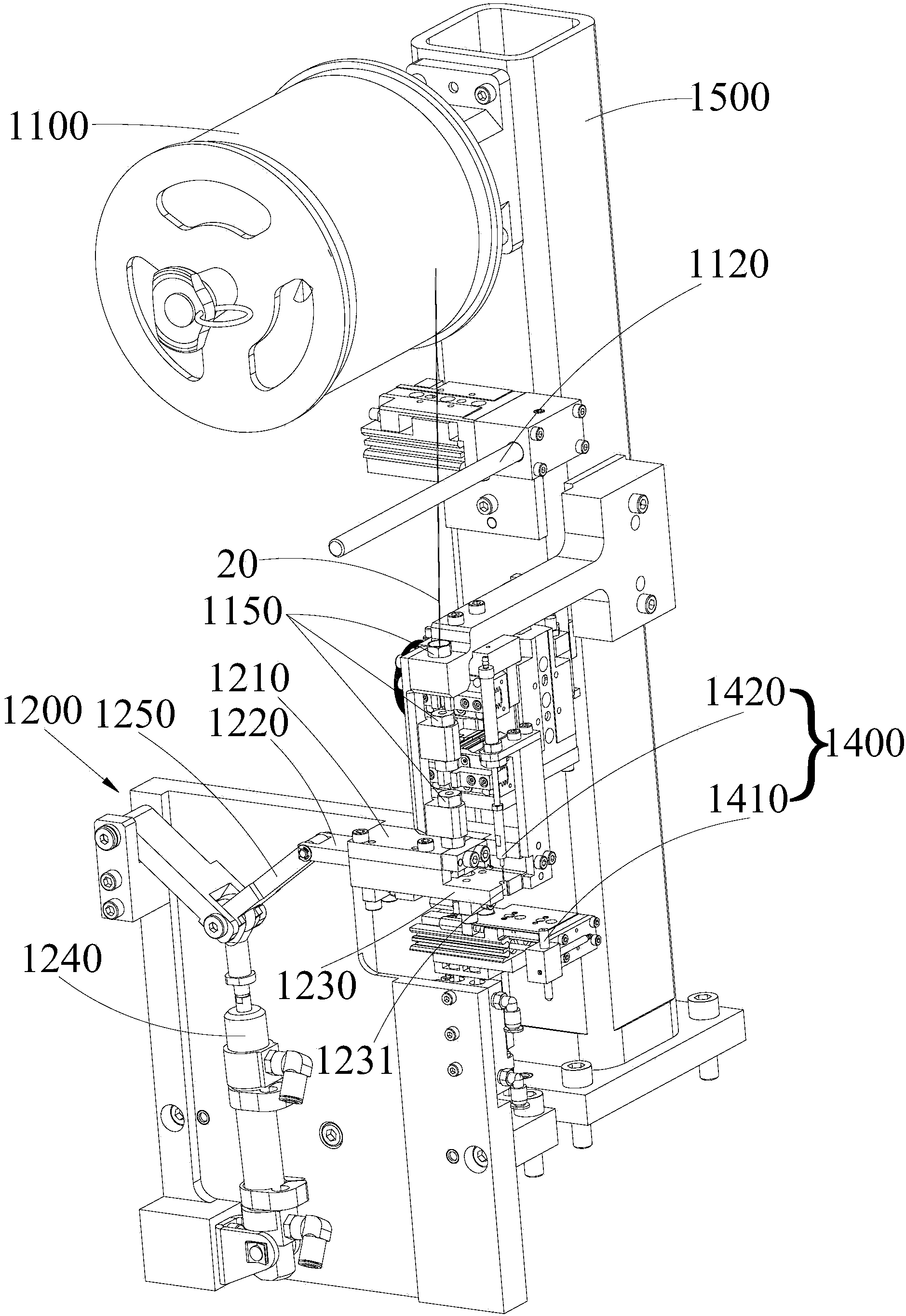

[0027] Such as Figure 1-3 as well as Figure 10 As shown, an automatic needle punching device includes a thread feeding mechanism 1100, a thread cutting mechanism 1200, a punching needle mechanism 1300 and a thread material transfer mechanism 1400, a thread feeding mechanism 1100, a thread cutting mechanism 1200, a needle punching mechanism 1300 and a thread material transfer mechanism 1400 All are arranged on the rack 1500.

[0028] Such as Figure 1-4 As shown, the wire feeding mechanism 1100 includes a wire feeding reel 1110 for conveying the metal wire 20, a tensioning rod 1120 located below the wire feeding reel 1110 and on the wire feeding path of the wire feeding reel 1110, a first wire clamp 1130 and a The second wire clamp 1140 moving axially along the metal wire 20, the first wire clamp 1130 and the second wire clamp 1140 are located below the tension rod 1120 at intervals in sequence. The first wire clamp 1130 performs a wire clamping action under the drive of a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com