Multifunctional lace crochet machine

A crochet machine, multi-functional technology, applied in crochet, textile and papermaking, knitting and other directions, can solve the problems of unfavorable traditional crochet machine competition, prolonged production time, low automation level, etc., to achieve rich functions and operation failure rate. Small, productive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The preferred embodiments of the present invention will be described in further detail in conjunction with the accompanying drawings.

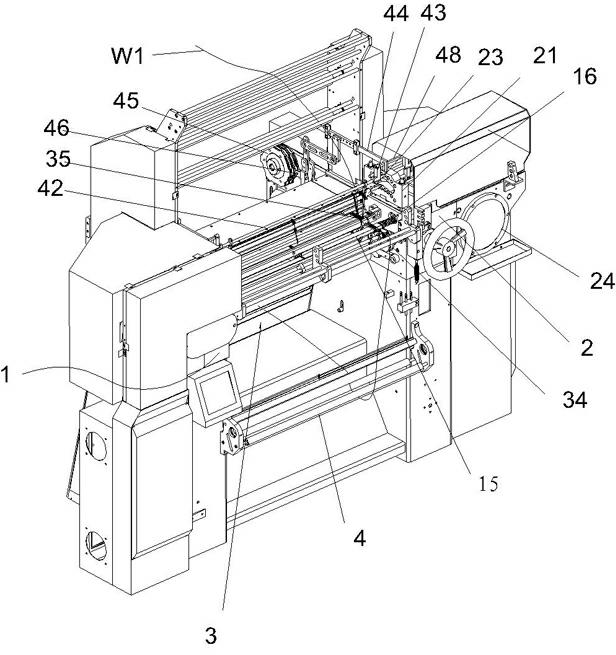

[0039] Such as figure 1 Shown, the present invention mainly comprises left box body 1, right box body 2 from frame structure, forms weaving area 3 between two box bodies, warp yarn mechanism, weft yarn mechanism, needle-out mechanism among the present invention are basically all installed in in the area. The warp yarn enters from the bottom of the weaving area 3, and is introduced into the weaving area 3 after passing through the guide roller 4, while the weft yarn is guided into the weaving area 3 from above the weaving area 3, and is woven with the warp thread.

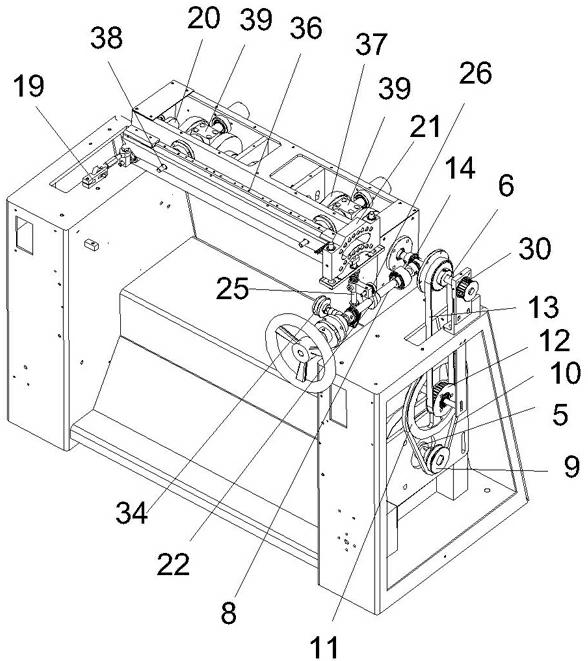

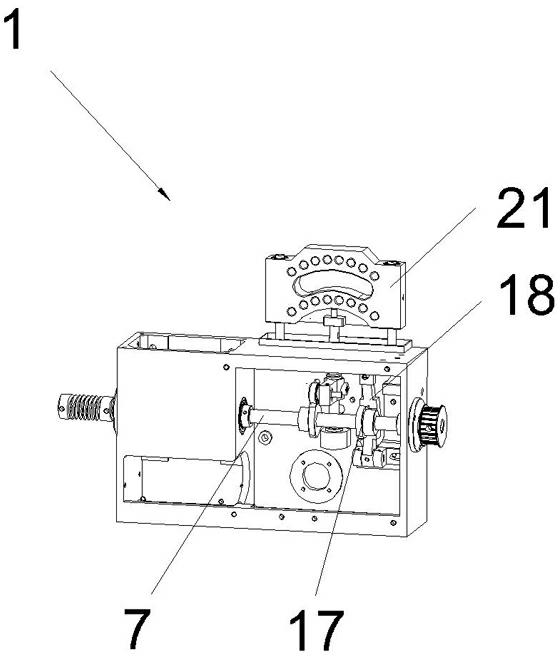

[0040] Such as figure 2 , image 3 As shown, the power transmission device in the present invention mainly includes a motor 5, a large cam main shaft 6, a left case main shaft 7, and a right case main shaft 8. Big cam main shaft 6 becomes parallel state with braiding are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com