Numerical control firecracker binding and firecracker barrel tail blocking machine

A technology of tail machine and nose machine, which is used in fireworks, offensive equipment, weapon types, etc., can solve the problems of inaccurate positioning, high labor intensity, and many waste barrels.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

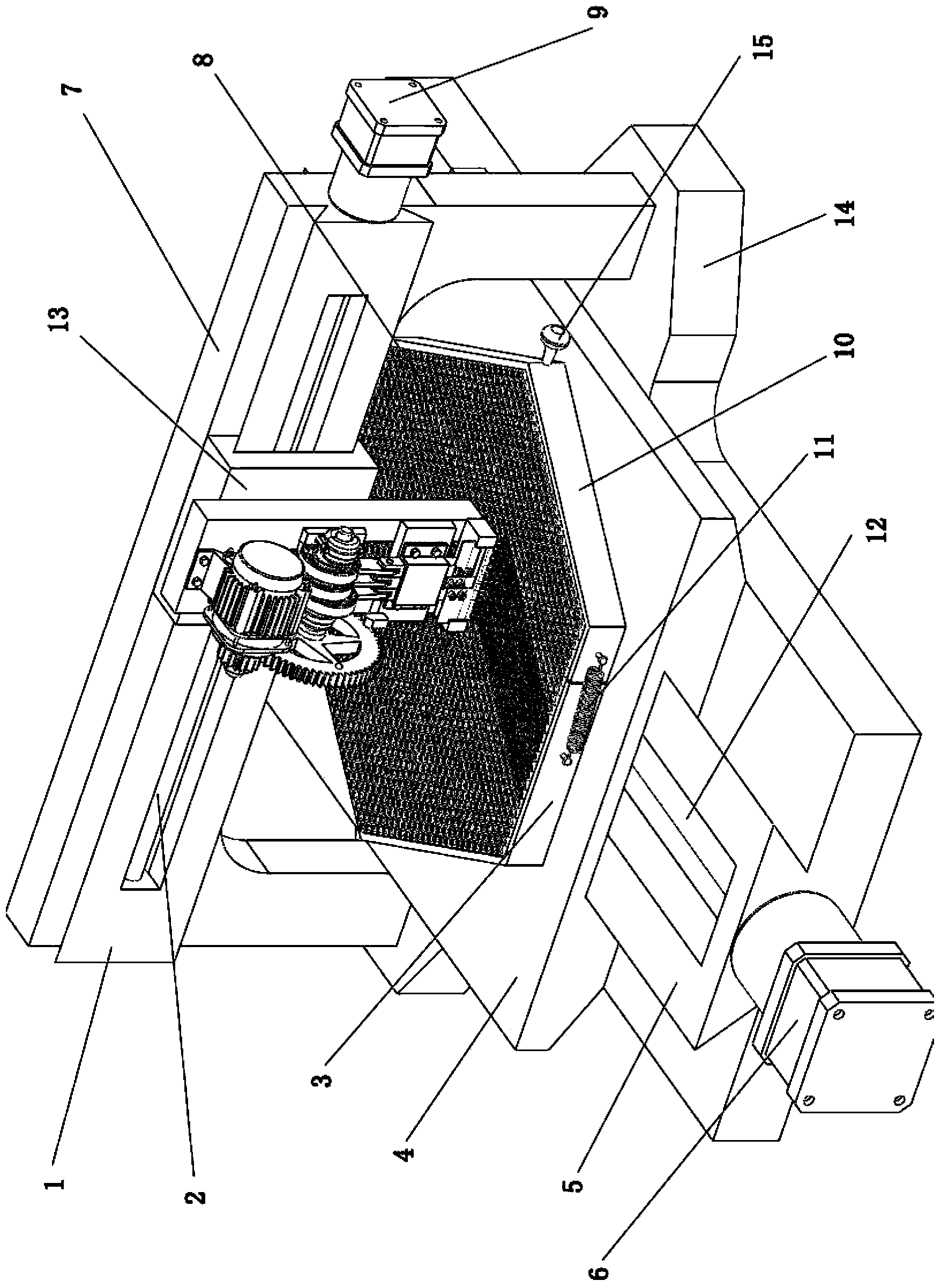

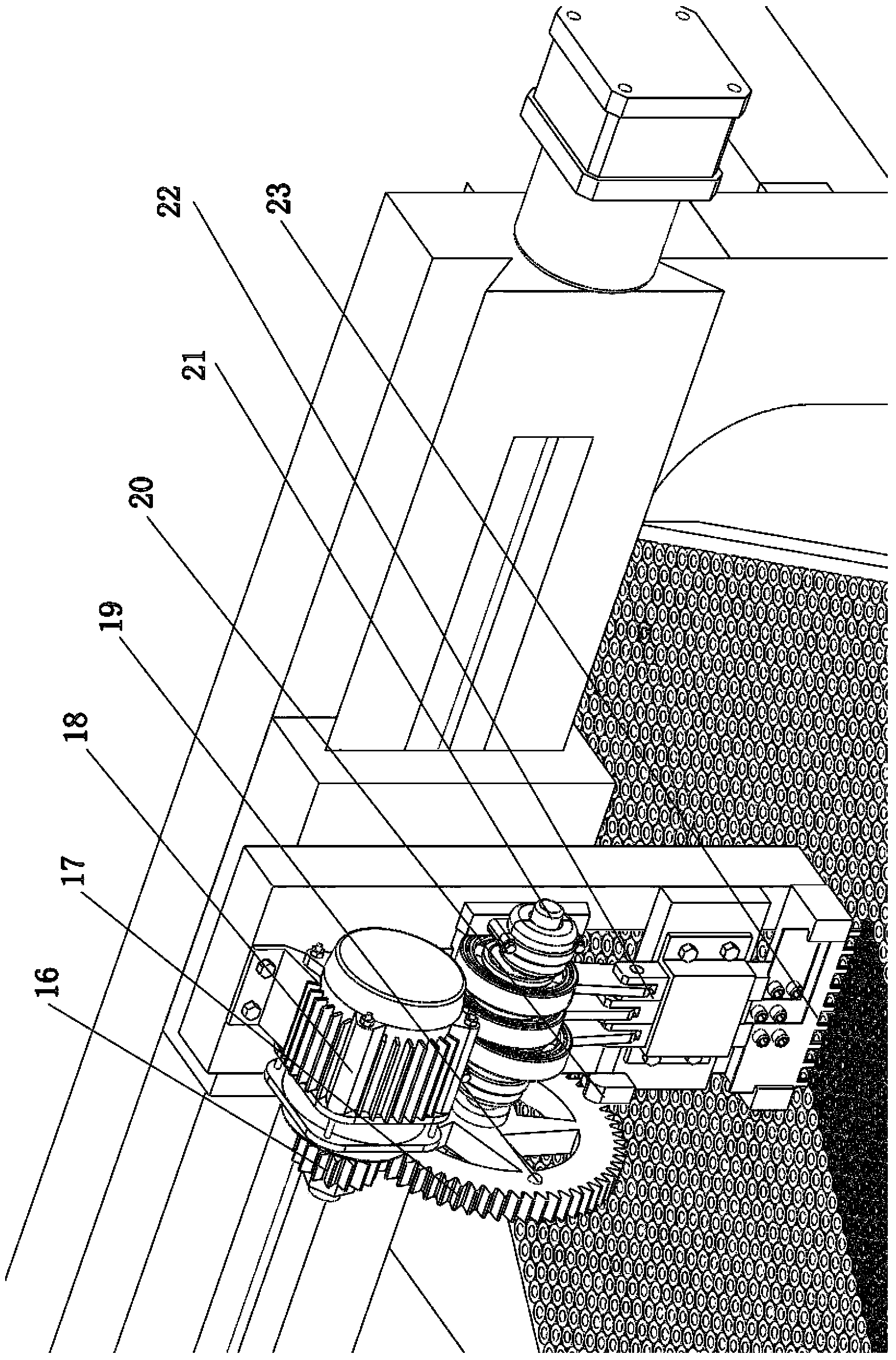

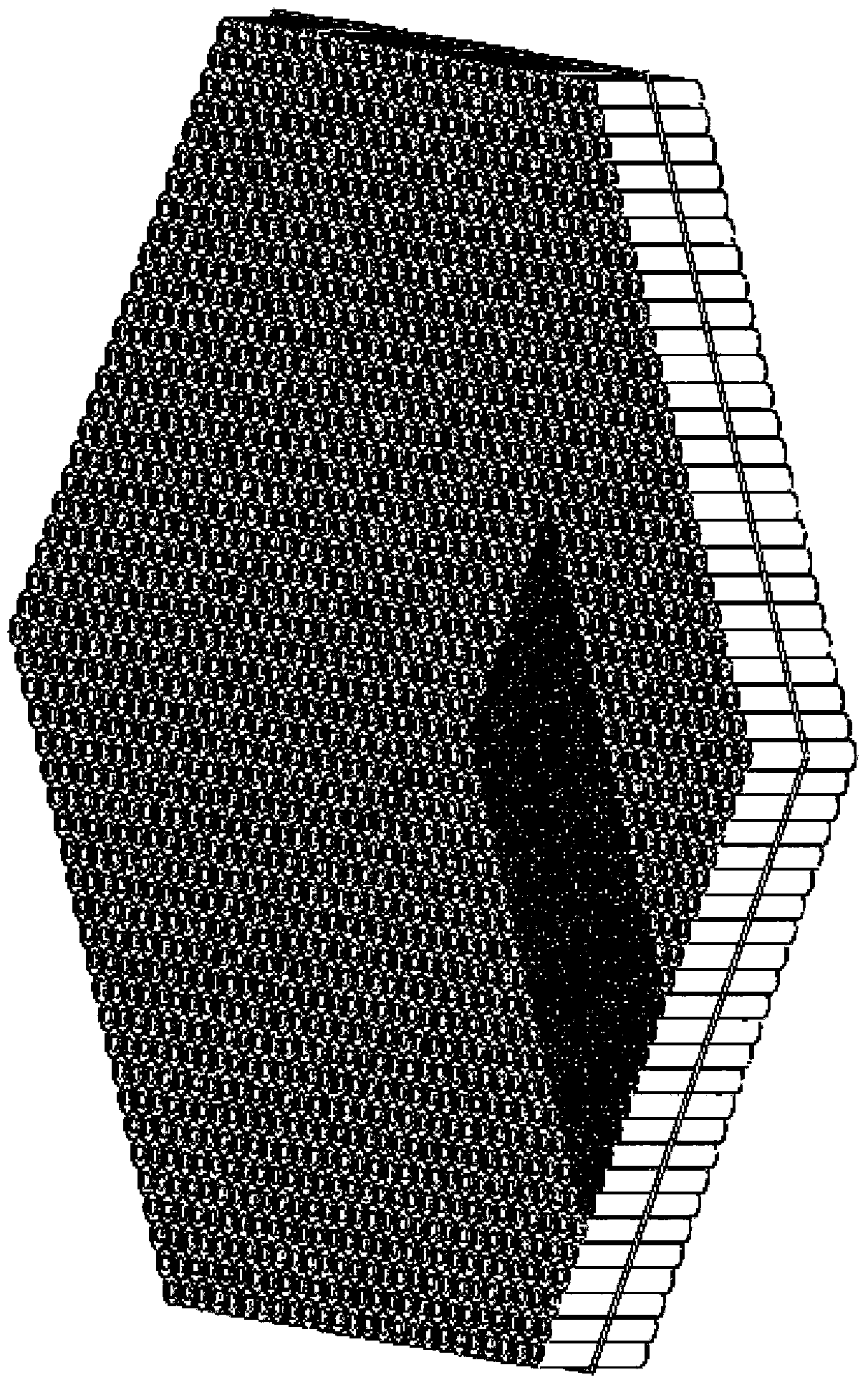

[0009] In order to overcome the disadvantages of the existing manual disc gun tailing machine that the labor intensity is high and the manual feeding and positioning is inaccurate, which easily causes many waste gun barrels. Some technical measures have been taken in this plan: use mechanical power (electric motor) to replace manual power, and use numerical control automatic feed to replace manual manual feed. The numerical control automatic feeding is to fix the clamping disc gun on the longitudinal sliding table, and install the electric tailing machine head on the horizontal sliding table. Control the synchronous movement of the vertical sliding table and the horizontal sliding table through a single board computer, so that the tailing needle is aligned with each row of gun barrels, so as to realize the automatic feeding of CNC. Concrete scheme is: motor is installed on the manual tailing machine head and is used for driving manual tailing machine head work, makes it become...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com