Semi-conductor conveying device

A conveying device and semiconductor technology, which is applied to conveyor control devices, conveyor objects, transportation and packaging, etc., can solve the problems of difficult adjustment, low work efficiency, and increased production costs, so as to avoid material waste and reduce production. Cost and work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

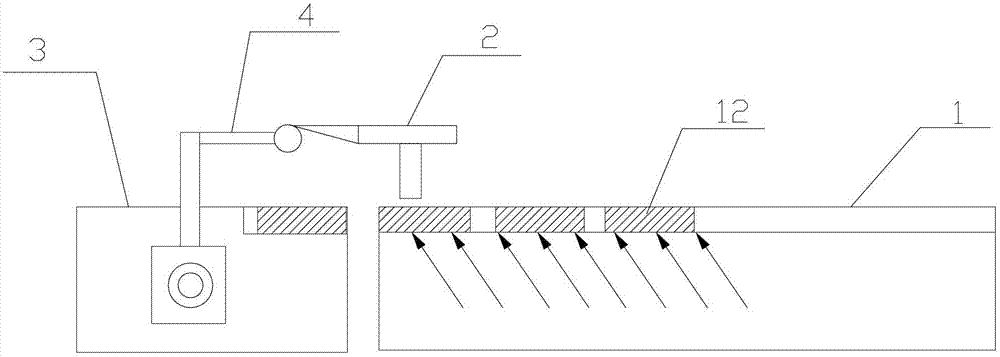

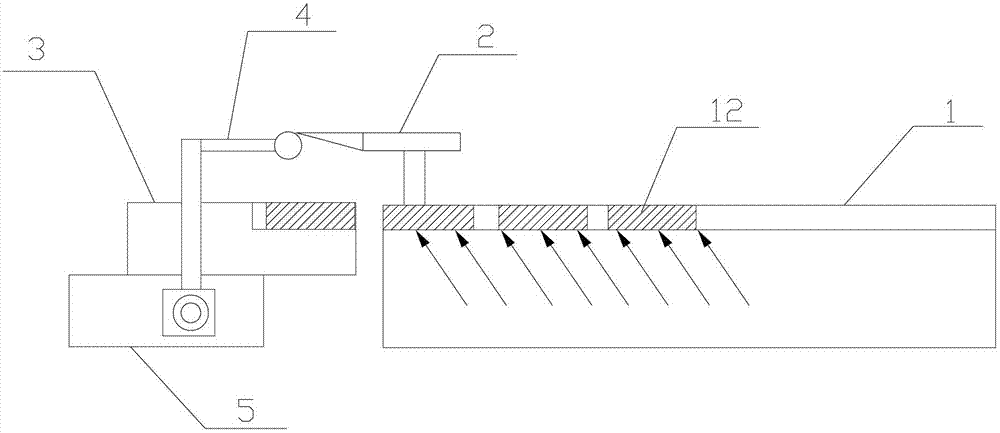

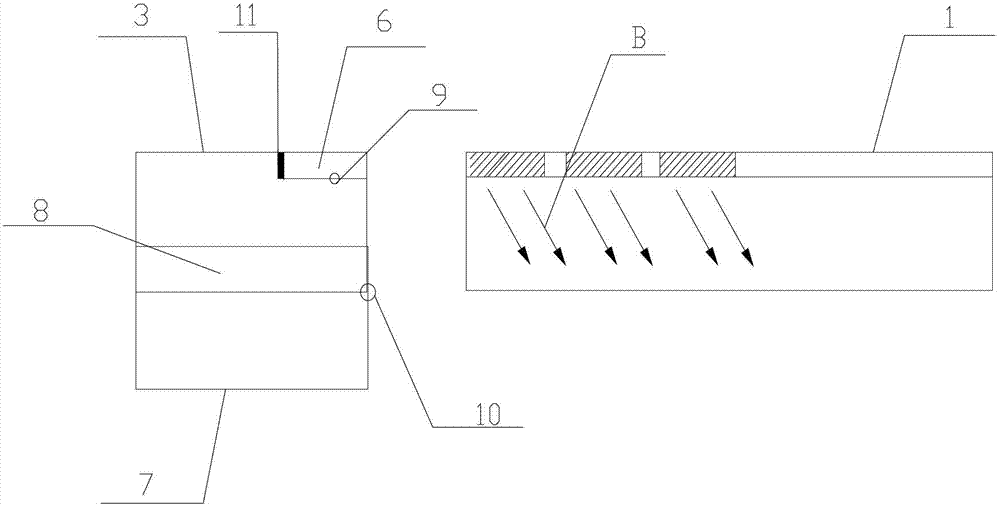

[0032] Please also see Figure 3 to Figure 5 , image 3 It is a structural schematic diagram of a semiconductor delivery device disclosed in the present invention. Figure 4 It is a structural schematic diagram of a semiconductor delivery device disclosed in the present invention when picking up semiconductors. Figure 5 It is a structural schematic diagram of a semiconductor conveying device disclosed in the present invention after picking up the semiconductor. As shown in the figure, a semiconductor conveying device is applied to a turntable test, printing and braiding machine. The conveying device includes a base 7, a conveying track 1, and a pick-up head 3 located at the output end of the conveying track 1 for receiving semiconductors. And a drive mechanism (not shown) that drives the pick-up head 3 to move back and forth on the base 7 . The driving mechanism can be a motor or an air cylinder, which drives the pick-up head to move back and forth to receive the semicondu...

Embodiment 2

[0040] The rest are the same as in Embodiment 1, except that a buffer mechanism is provided on the inner wall of the groove 6. Since the compressed air is to ensure that the semiconductor product is effectively blown into the groove, the conveying force may be relatively large, which may easily cause the semiconductor product to collide. Bad. By arranging the buffering mechanism, an effective buffering effect can be played when the semiconductor enters the groove, so as to avoid the impact damage of the semiconductor and reduce the cost.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com