Improved drawing oil and preparation method thereof

A technology of wire drawing oil and sheep oil, which is applied in the petroleum industry, lubricating compositions, etc., can solve the problems that the lubricating effect is difficult to meet the requirements of the wire drawing and drawing process, the cleaning and chip removal is difficult, and the waste liquid is difficult to degrade, so as to achieve clean dispersion Enhanced performance, good wire drawing effect, and comprehensive performance improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

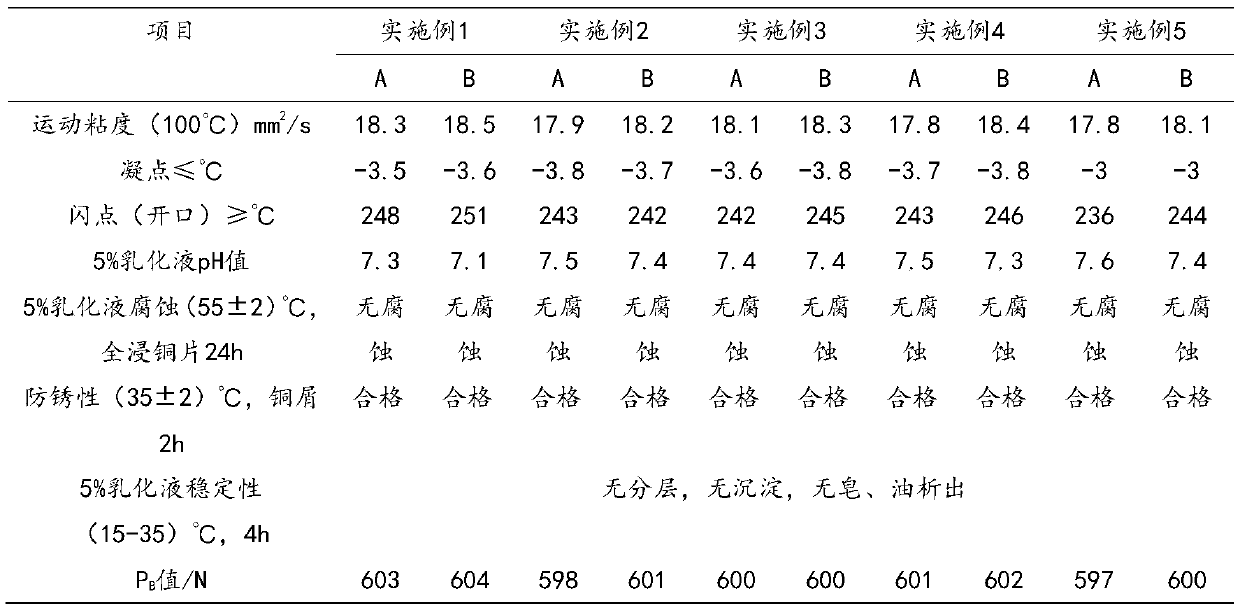

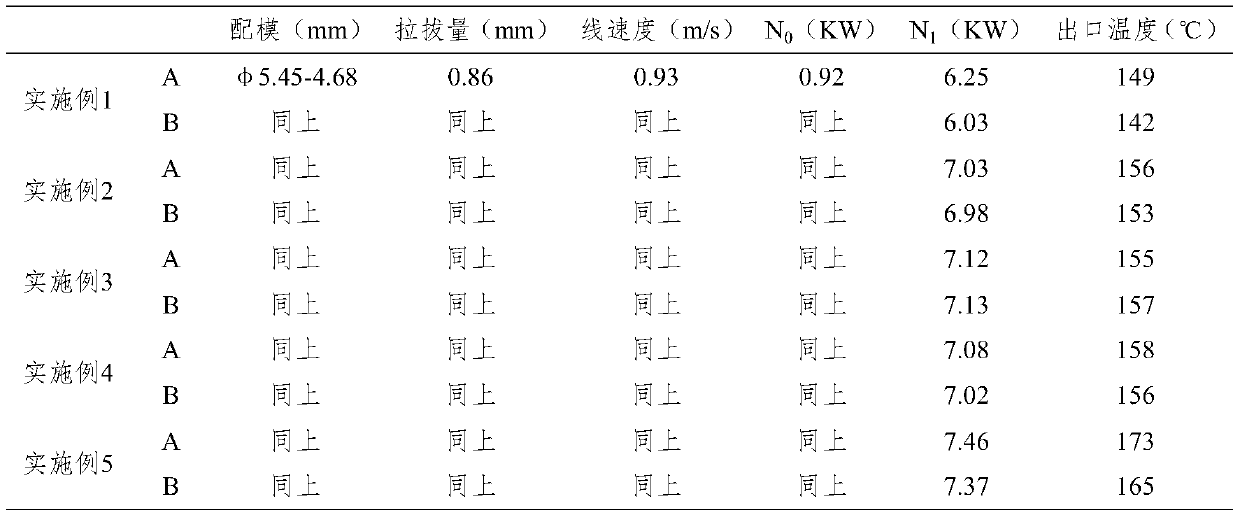

Examples

Embodiment 1

[0013] Improved drawing oil, prepared by weight (kg) of the following raw materials: epoxy soybean oil 78, microcrystalline wax 13, lanolin 7,2-octyldodecanol 2, triethanolamine borate 2, Dodecyl trimethyl ammonium chloride 1.5, stearyl alcohol polyoxyethylene ether 9, propylene glycol phenyl ether 0.5, polyoxyethylene rosin acid ester 11, vulcanized cottonseed oil 1.3, auxiliary 4.

[0014] Preparation method 1: According to the patent No. 201410169999.2, it is mixed and formulated with a clean, friction-reducing and high-efficiency drawing oil to obtain a finished product A;

[0015] Preparation method 2: First mix the epoxy soybean oil, microcrystalline wax, and lanolin, heat to 80-90°C, at a constant temperature; then add the additives and 2-octyldodecanol, triethanolamine borate, ten Dialkyltrimethylammonium chloride, stir and mix for 25-30min at a stirring speed of 1000-1500r / min; then add other remaining materials together, continue to stir for 40-50min, and cool to room tem...

Embodiment 2

[0017] Improved drawing oil, prepared from the following raw materials by weight (kg): epoxy soybean oil 78, microcrystalline wax 13, lanolin 7,2-octyldodecanol 2, triethanolamine borate 1, Dodecyl trimethyl ammonium chloride 1, stearyl alcohol base polyoxyethylene ether 9, propylene glycol phenyl ether 0.5, polyoxyethylene rosin acid ester 11, vulcanized cottonseed oil 1, auxiliary 4.

[0018] The preparation method is the same as in Example 1.

Embodiment 3

[0020] Improved drawing oil, prepared from the following raw materials by weight (kg): epoxy soybean oil 78, microcrystalline wax 13, lanolin 7,2-octyldodecanol 2, triethanolamine borate 3, Dodecyl trimethyl ammonium chloride 2, stearyl alcohol base polyoxyethylene ether 9, propylene glycol phenyl ether 0.5, polyoxyethylene rosin acid ester 11, vulcanized cottonseed oil 2, auxiliary 4.

[0021] The preparation method is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com