Constant-tension control method for diamond line cutting machine

A control method and diamond wire technology, applied to controllers with specific characteristics, electric controllers, manufacturing tools, etc., can solve problems such as large tension fluctuations, unsatisfactory control effects, and unbalanced wire tension, so as to avoid errors Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

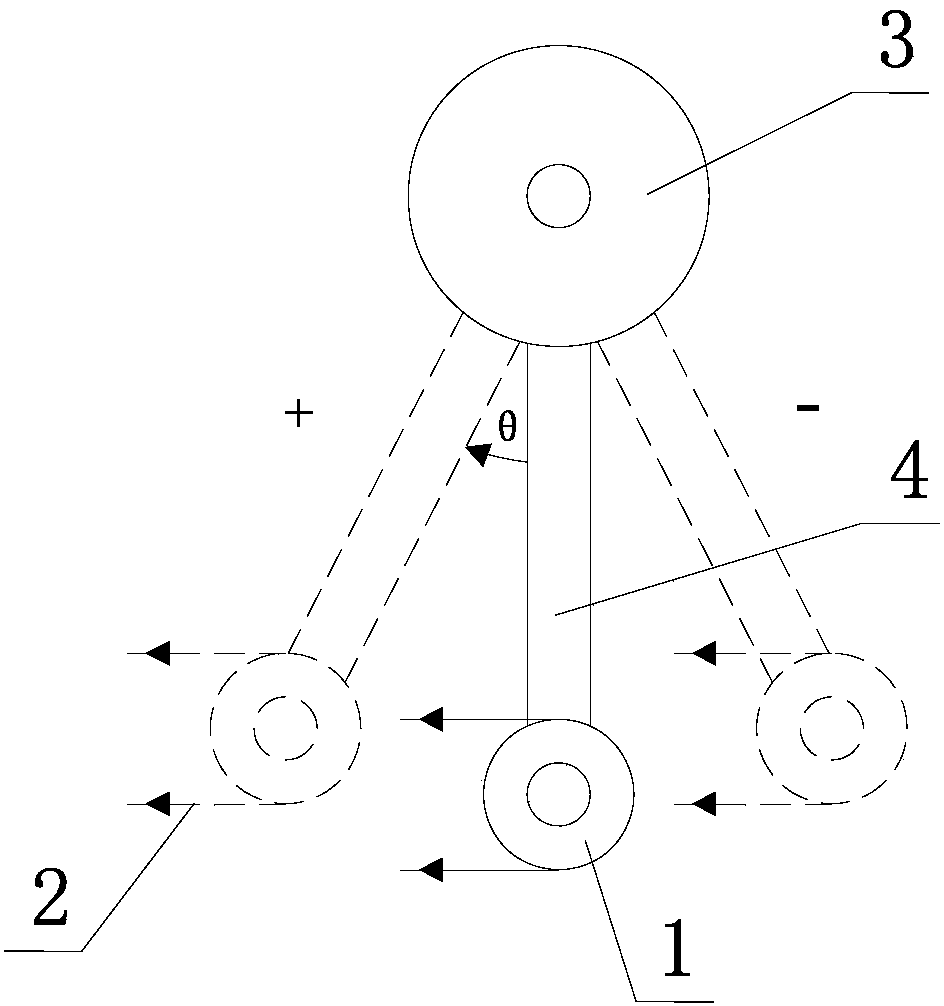

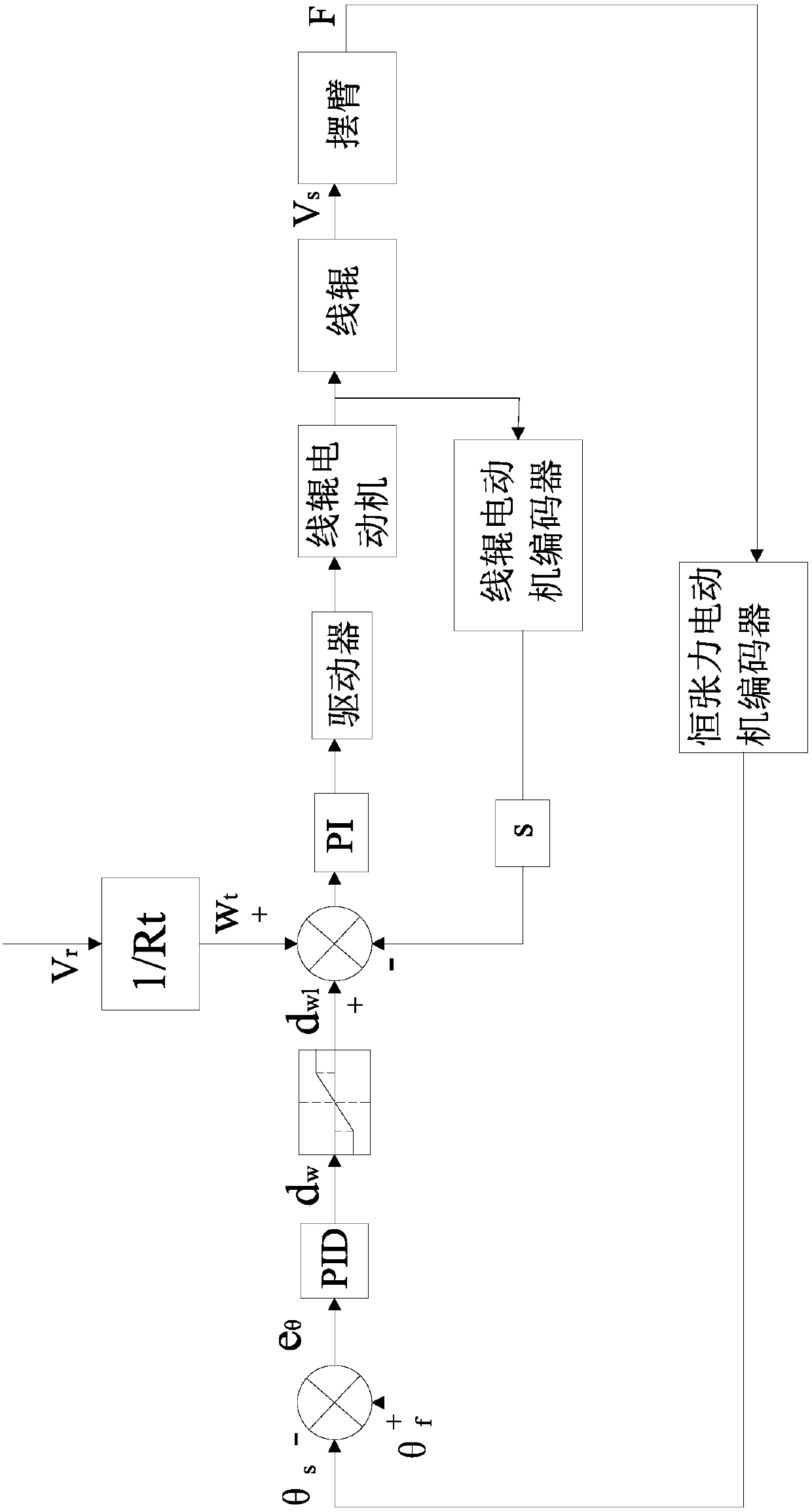

[0039] Such as figure 1 , figure 2 As shown, the constant tension control method of the diamond wire cutting machine of the present invention has the following steps.

[0040] a. When the tension of the diamond wire 2 on the swing guide wheel 1 is equal to the set tension provided by the constant tension motor 3, the swing arm 4 is located on the reference line, and the swing angle of the swing arm 4 at this moment is the set swing angle θ s ; Generally, the swing arm 4 hangs vertically as the reference line.

[0041] And the actual swing angle θ of the swing arm 4 during wiring f Subtract the set swing angle θ s The value of the pendulum angle errorе θ ; while the above actual swing angle θ f is measured by the encoder of the constant tension motor 3 and fed back to the PID controller.

[0042] When the direction in which the swing arm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com