Wire rewinding machine applied to aluminum wire production

A wire take-up machine and aluminum wire technology, applied in the field of wire take-up machines, can solve the problems of complex structure of the wire take-up machine, mixed thickness of finished products, large space occupation, etc., to achieve easy movement, stable wire take-up, and extended use The effect of longevity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

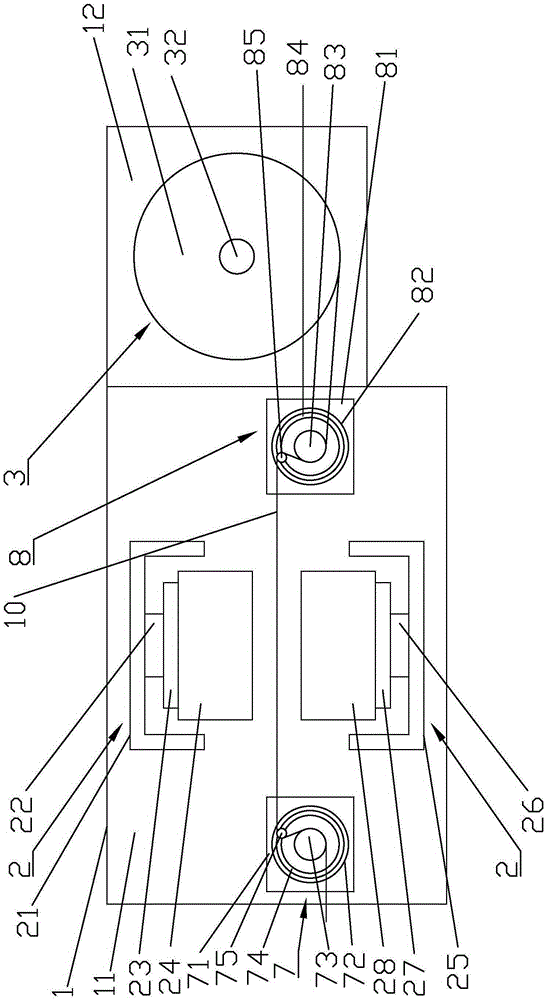

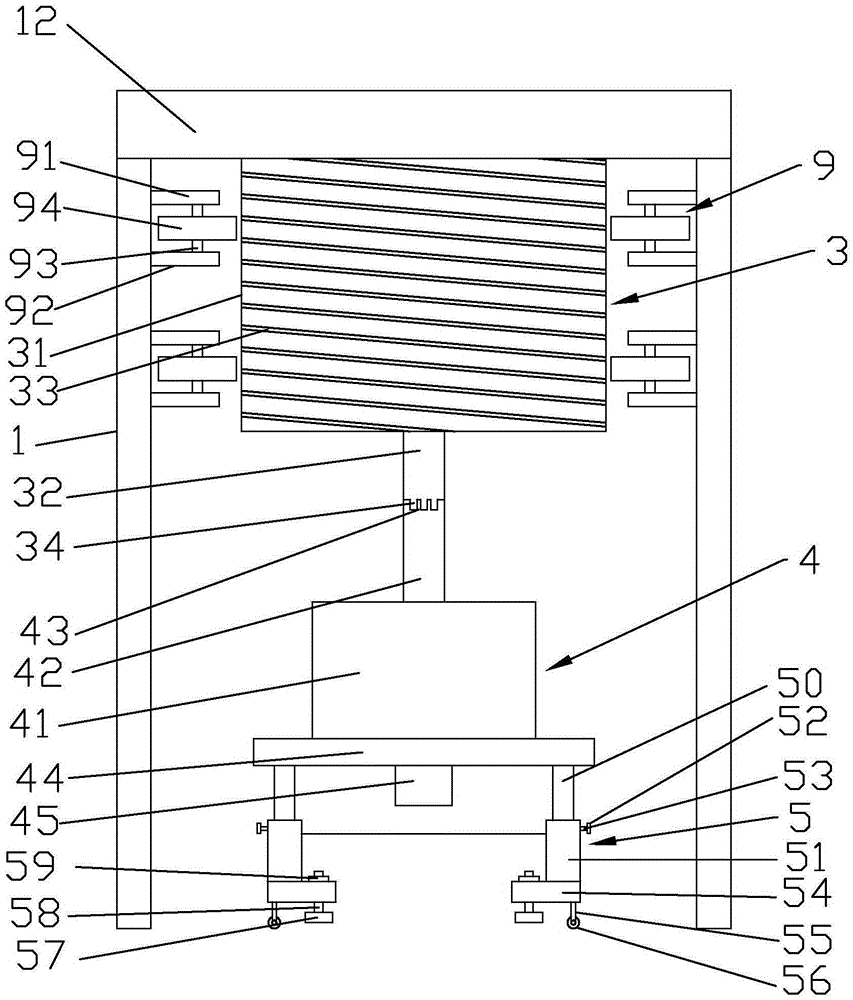

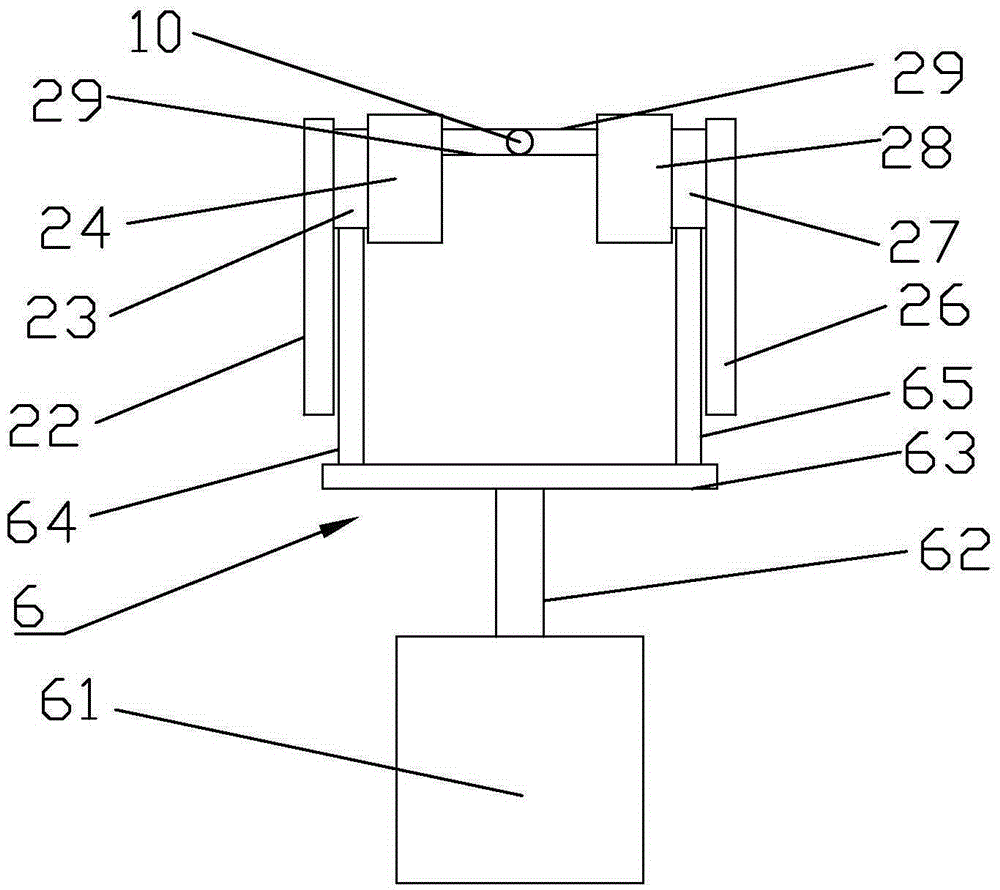

[0032] like Figure 1 to Figure 7 As shown, a wire take-up machine applied to aluminum wire production includes a frame 1 and a wire take-up trolley 4. The frame 1 is provided with a detection platform 11 and a winding platform 12. The detection platform 11 is connected to the winding platform 12. The take-up trolley 4 is provided below the wire platform 12 . A detection device 2 is provided on the detection platform 11 , and a winding device 3 is provided on the winding platform 12 . First, the detection device 2 is used to detect the thickness of the aluminum wire 10 to prevent the aluminum wire 10 of uneven thickness, knotting or twisting into a group from being wound up on the take-up reel 41, and then the aluminum wire 10 is quickly wound by the winding device 3. Wind up on the take-up reel 41 well, and finally pass the take-up trolley 4 to store the aluminum wire 10 that has been rewound.

[0033] Detecting device 2 comprises detection frame, and detection frame is pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com