Broom automatic knitting machine

A knitting machine and automatic technology, which is applied to sewing machine components, textiles, papermaking, sewing equipment, etc., can solve the problems of high cost and low efficiency of manual sewing brooms, etc., and achieve increased production, reasonable structure settings, and uniform arc routing Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below in conjunction with specific example and accompanying drawing, the present invention is described in further detail:

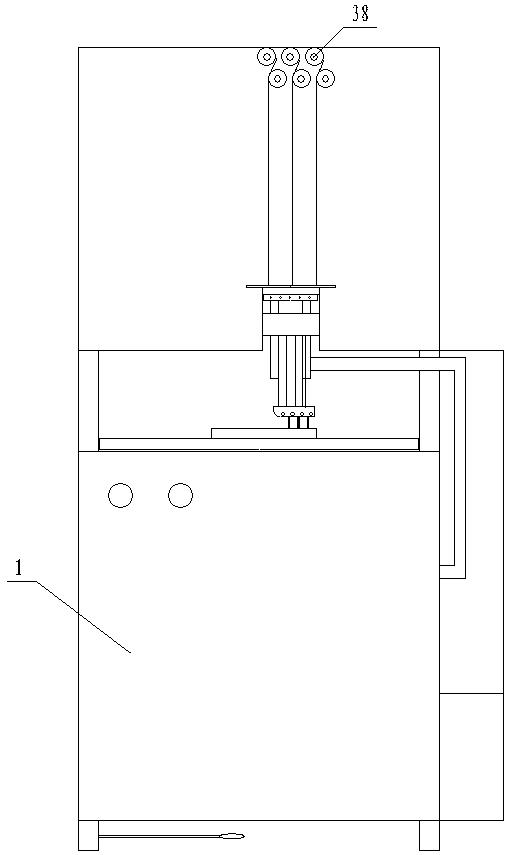

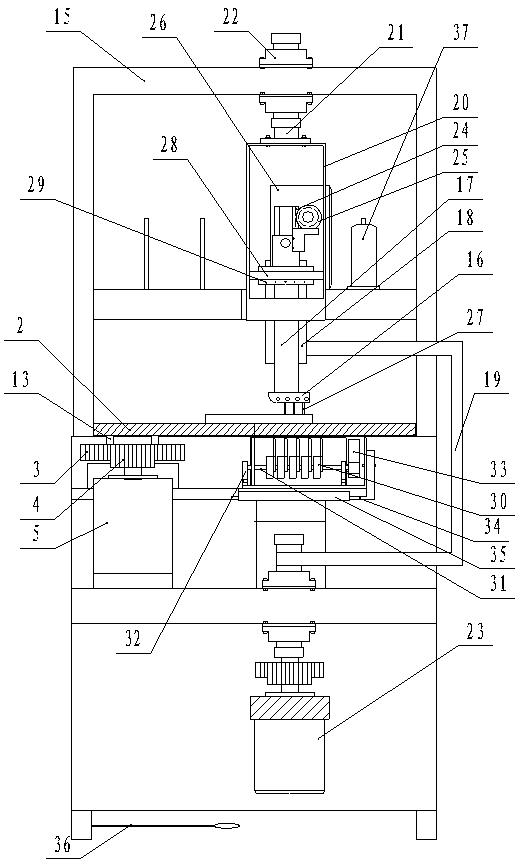

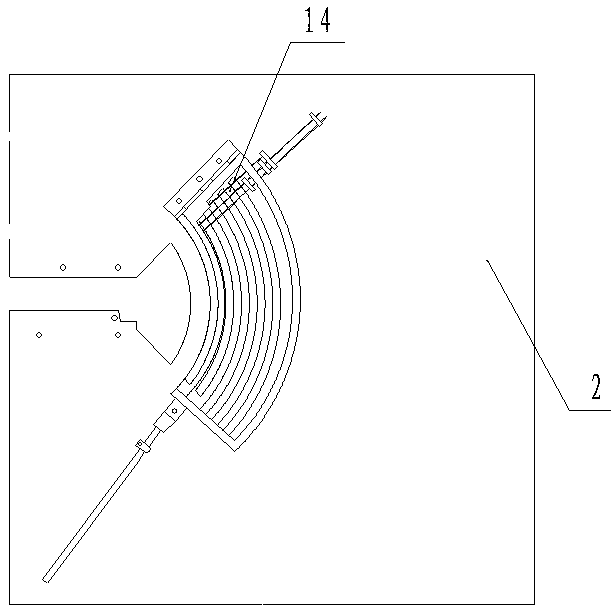

[0021] Such as figure 1 and figure 2 The embodiment shown has a cabinet 1, which is provided with a sewing board 2 that can rotate horizontally, and the bottom of the sewing board 2 is fixed on the first gear 3 by screws 13, the first gear 3 and the second gear 4 meshing, the second gear 4 is driven by the first motor 5; as image 3 and Figure 4 As shown, the middle part of the sewing plate 2 has five parallel arc sewing openings 6, one end of the arc sewing opening along the length direction is hinged with an arc pressure ring 7 on the sewing plate 2, and the other end of the arc pressure ring is hinged with a lock A tight rod 11 is provided with a locking hook 12 for fixing the locking rod on the sewing plate 2; two spacer bars 8 are inserted in the axial interval at the outer end of the outermost arc-shaped sewing mouth, and the two spacer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com