Multifunctional double-twisting machine

A two-for-one twister and multi-functional technology, applied in spinning machines, continuous winding spinning machines, textiles and papermaking, etc., can solve problems such as increased yarn wear, affecting yarn quality, and many operators. Achieve the effects of small equipment occupation, reduced equipment investment, and high braking sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

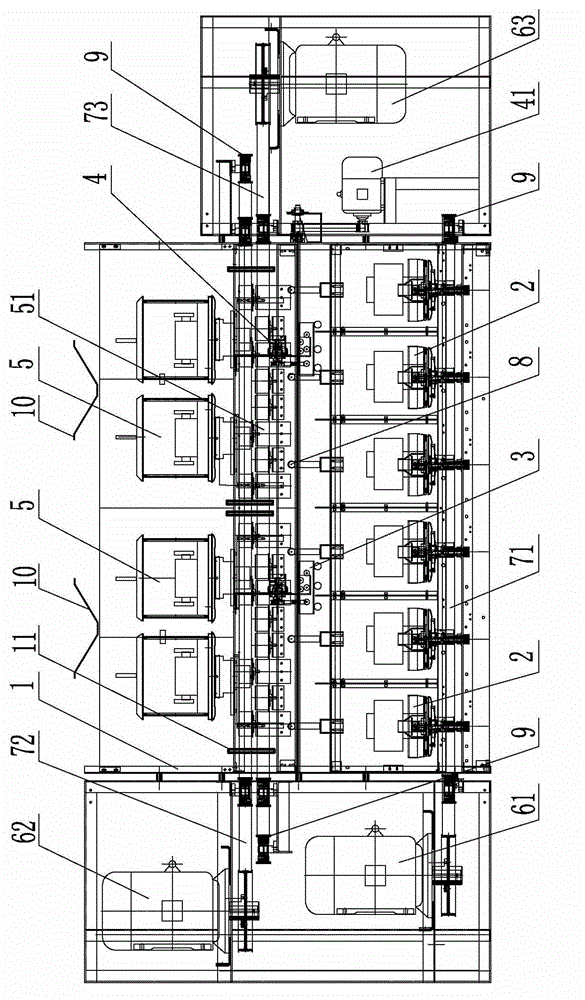

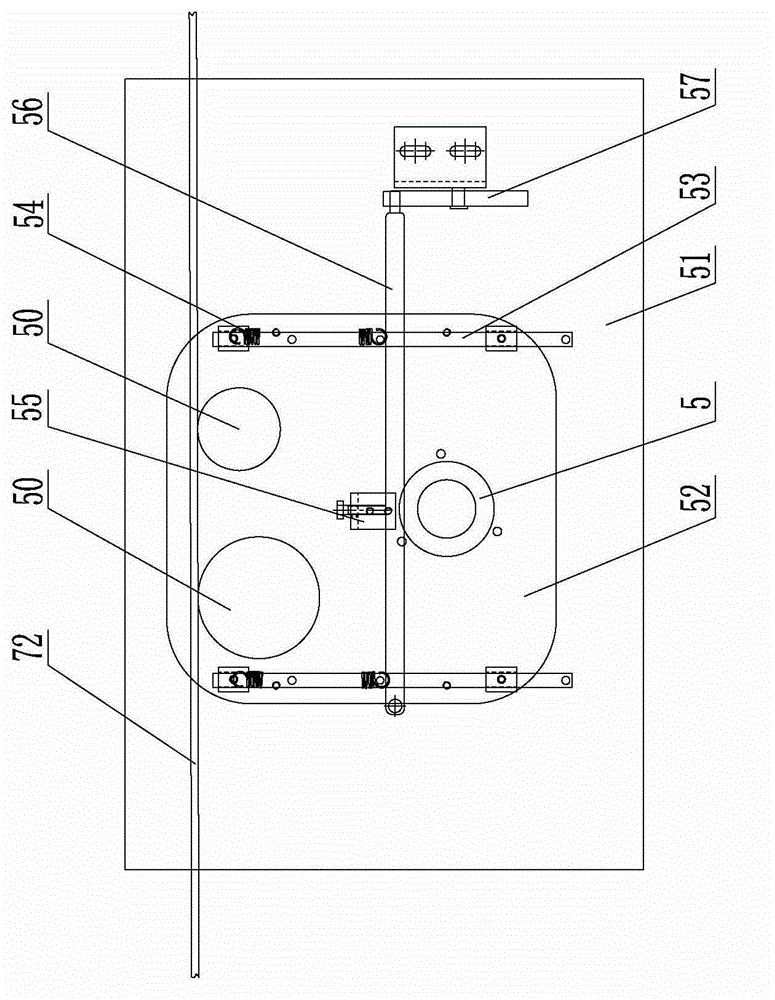

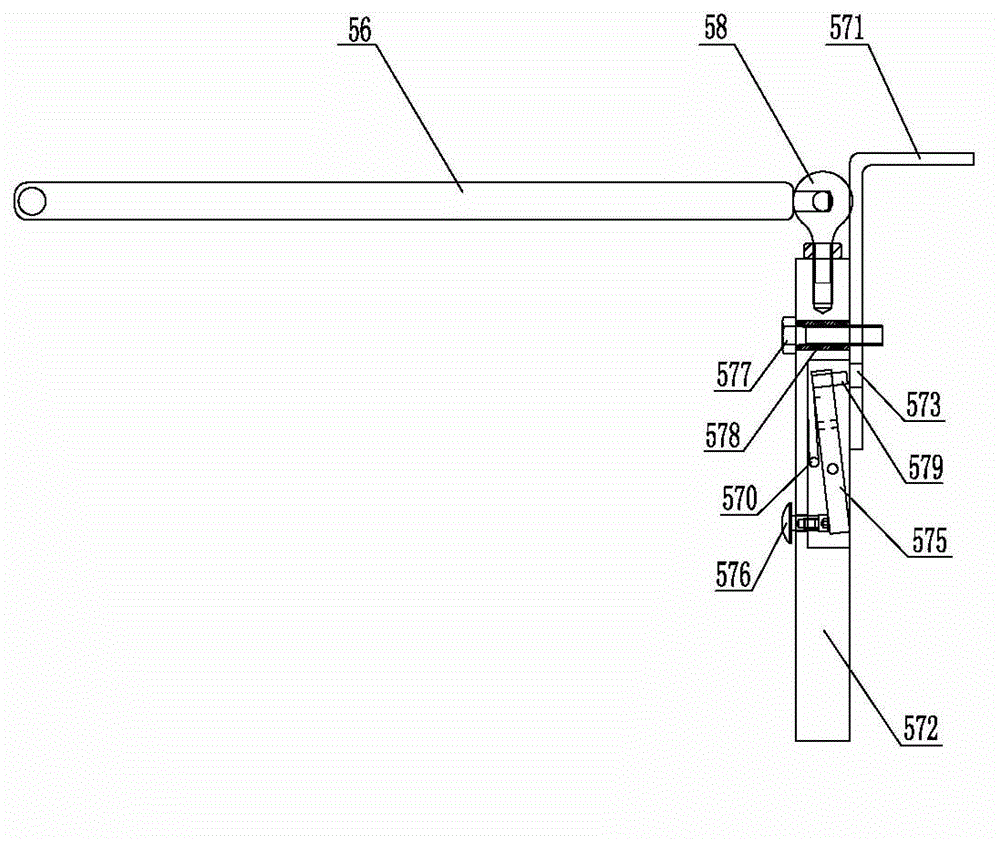

[0036] Please refer to the attached figure 1 to attach Figure 12 Shown, the present invention is a kind of multifunctional two-for-one twisting machine, and it consists of a frame 1 and several primary twisting spindles 2, yarn converging devices 3, overfeeding mechanisms 4 and several Several parts such as double-twisting spindle 5 are assembled.

[0037] Wherein, at least two primary twisting spindles 2 form a group, and are matched with a double twisting spindle 5. In this embodiment, three primary twisting spindles 2 are used as a group, so that the three strands of yarn can be initially added respectively. Twisting, the yarn after primary twisting enters the yarn concentrating device 3 for plying, and then feeds into the double twisting spindle 5 through the overfeeding mechanism 4, and finally passes through the double twisting spindle 5 to add double twisting and then is wound into shape.

[0038] The plurality of primary twisting spindles 2 are driven by a first mot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com