Cake wax of bobbin winder

A technology of wax plate and bobbin car, which is applied in the direction of conveying filamentous materials, thin material processing, transportation and packaging, etc. It can solve the problems of inflexible wax plate rotation and disconnection faults, so as to prevent disconnection faults and single route , The effect of solving the disconnection fault

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] In order to deepen the understanding of the present invention, the present invention will be further described below in conjunction with examples and specific implementation methods. These examples are only used to explain the present invention, and do not constitute a limitation to the scope of explanation of the present invention.

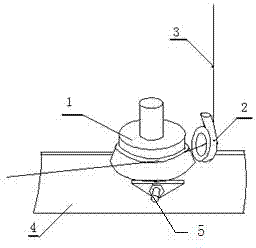

[0012] Such as figure 1 , 2 As shown, the present invention is a wax tray for a barrel making car, comprising a wax tray 1 and a mounting frame 4, the wax tray 1 is fixedly mounted on the mounting frame 4, and a guide ring is also fixedly installed on the mounting frame 4 2. The yarn 3 passes through the wax plate 1 and the guide ring 2 in sequence, so as to ensure that the yarn runs smoothly when entering the bobbin car, and there will be no thread breakage caused by yarn knotting. The rolling bearing 1-1 is composed of the wax plate body 1-2, the rolling bearing 1-1 is fixed on the mounting frame 4 through the fixed shaft 5 fixed on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com