Organic EL panel

A panel and organic technology, applied in the field of wiring structure improvement, can solve problems such as anode wiring disconnection failure, and achieve the effect of suppressing disconnection, avoiding disconnection failure, and realizing large-scale

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

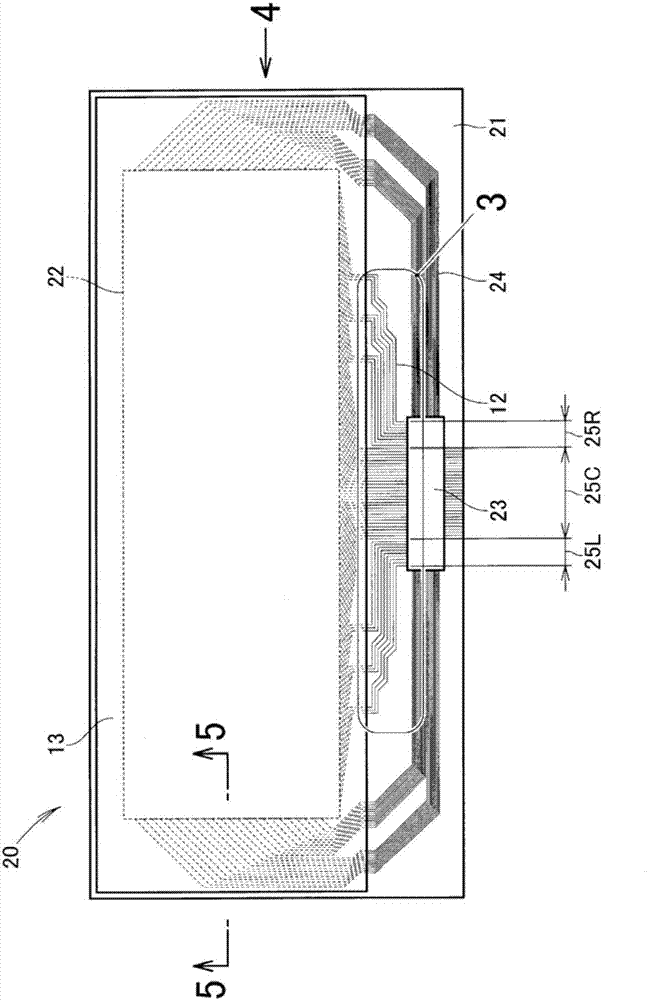

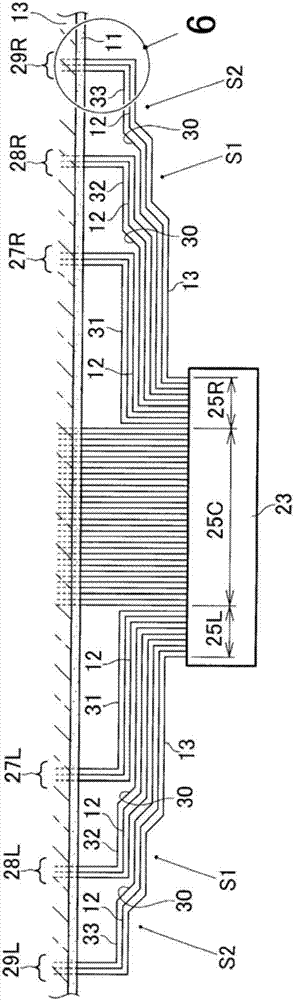

[0069] Such as figure 2 As shown in , the organic EL panel 20 is a COG-type organic EL panel, and includes: a support substrate 21, a light-emitting display portion 22 provided on the support substrate 21, and a sealing member mounted on the support substrate 21 and covering the light-emitting display portion 22. 13. A driver IC 23 provided on the support substrate 21 outside the sealing member 13 , and a plurality of anode wires 12 and a plurality of cathode wires 24 extending from the driver IC 23 to the light-emitting display portion 22 .

[0070] The plurality of anode wires 12 are wires that connect the anode electrodes to the driver IC 23, and are made of a low-resistance conductive material such as ITO and / or chromium (Cr), aluminum (Al), or their alloys, which are the same material as the anode electrodes. Or their laminated body is formed.

[0071] The plurality of anode wires 12 are divided into a center group 25C as a first group that is a first group that is dire...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com