Method for producing organic solderability preservative on surface of circuit board

An organic solder protection film and surface production technology, which is applied in the fields of printed circuit manufacturing, printed circuit, and printed circuit secondary treatment, can solve the problems of color difference and blackening of the film surface, and achieve improved yield rate, uniform color, and copper surface moderate roughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

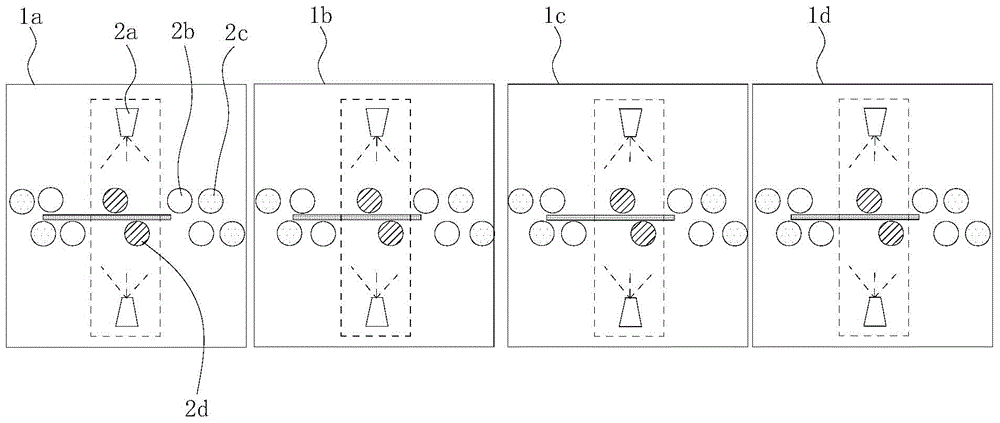

[0019] This embodiment provides a method for fabricating an organic solder protection film on the surface of a circuit board. Among them, the production line is equipped with pickling tank, No. 1 washing tank, micro-etching tank, No. 2 washing tank, No. 3 DI water (deionized water) washing tank, strong wind dryer, anti-oxidation tank, No. 4 washing tank, No. 5 DI water washing tank, hot air dryer, and the circuit board pass through the above-mentioned cylinders, strong wind dryer and hot air dryer at a speed of 0.8-1.2m / min (preferably 1.0m / min) through the transmission mechanism.

[0020] The method for making an organic solder protection film on the surface of a circuit board comprises the following steps:

[0021] (1) pickling

[0022] Move the circuit board into the pickling tank, under the condition of 25-35 ℃, use acid solution at 1.5Kg / cm 2 For pressure washing circuit boards, the acidic solution is 5wt% H 2 SO 4 solution. The circuit board is cleaned by pickling t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com