Waterborne mixed type plastic track

A plastic runway and hybrid technology, applied in the direction of roads, roads, buildings, etc., can solve the problems of unfavorable promotion and use, less energy saving and environmental protection, poor comfort, etc., to achieve enhanced overall strength and applicability, suitable roughness, The effect of excellent physical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

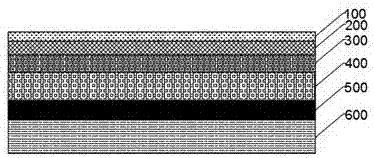

[0023] Such as figure 1 As shown, the present invention provides a technical solution: a water-based mixed plastic runway, including a plastic surface layer, an asphalt concrete layer, an intermediate layer 400 and a surface layer, and the plastic surface layer is made of polyurethane prepolymer, calcium carbonate and PU particles are combined, and ultraviolet absorbers and iron oxide are added. The asphalt concrete layer includes AC-10 fine-grained asphalt concrete layer 200 and AC-20 coarse-grained asphalt concrete layer 300. The middle layer 400 is Ash stone or cement stabilized crushed stone base, the surface layer includes crushed stone layer 500 and notoginseng ash layer 600600, the plastic track from top to bottom is the plastic surface layer, AC-10 fine-grained asphalt concrete layer 200, AC-10 -20 coarse-grained asphalt concrete layer 300, limestone, crushed stone layer 500 and notoginseng ash layer 600600, and several plastic particles are evenly distributed on the s...

Embodiment 2

[0027] The difference from Example 1 is:

[0028] From top to bottom, the plastic runway consists of plastic surface layer, AC-10 fine-grained asphalt concrete layer 200, AC-20 coarse-grained asphalt concrete layer 300, cement-stabilized gravel base, gravel layer 500 and Sanqi ash layer 600600, and several plastic particles are evenly distributed on the surface of the plastic surface.

[0029] The thickness of the plastic surface layer is 13mm, and the plastic surface layer also includes sulfur, stearic acid, anti-aging agent and accelerator, and the parts by weight of each component of the plastic surface layer are respectively: 70 parts of polyurethane prepolymer, carbonic acid 15 parts of calcium, 0.6 parts of ultraviolet absorber, 4 parts of iron oxide, 7 parts of sulfur, 15 parts of stearic acid, 4 parts of anti-aging agent, 6 parts of accelerator.

Embodiment 3

[0031] The difference from Example 1 is:

[0032] From top to bottom, the plastic runway consists of plastic surface layer, AC-10 fine-grained asphalt concrete layer 200, AC-20 coarse-grained asphalt concrete layer 300, cement-stabilized gravel base, gravel layer 500 and Sanqi ash layer 600600, and several plastic particles are evenly distributed on the surface of the plastic surface.

[0033] The thickness of the plastic surface layer is 13mm, and the plastic surface layer also includes sulfur, stearic acid, anti-aging agent and accelerator, and the parts by weight of the components of the plastic surface layer are respectively: 80 parts of polyurethane prepolymer, carbonic acid 20 parts of calcium, 0.9 parts of ultraviolet absorber, 6 parts of iron oxide, 10 parts of sulfur, 20 parts of stearic acid, 5 parts of anti-aging agent, and 8 parts of accelerator.

[0034] Among the above raw materials, the working principle of cement-stabilized gravel is: cement-stabilized gravel ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com