Rewinding method and rewinding machine that carries out this method

a rewinding machine and rewinding method technology, applied in the direction of transportation and packaging, thin material processing, article delivery, etc., can solve the problems of affecting the final quality of the product, the amount of glue sprayed on the tubular cardboard core can be too much, and the risk of paper web soaking too much

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

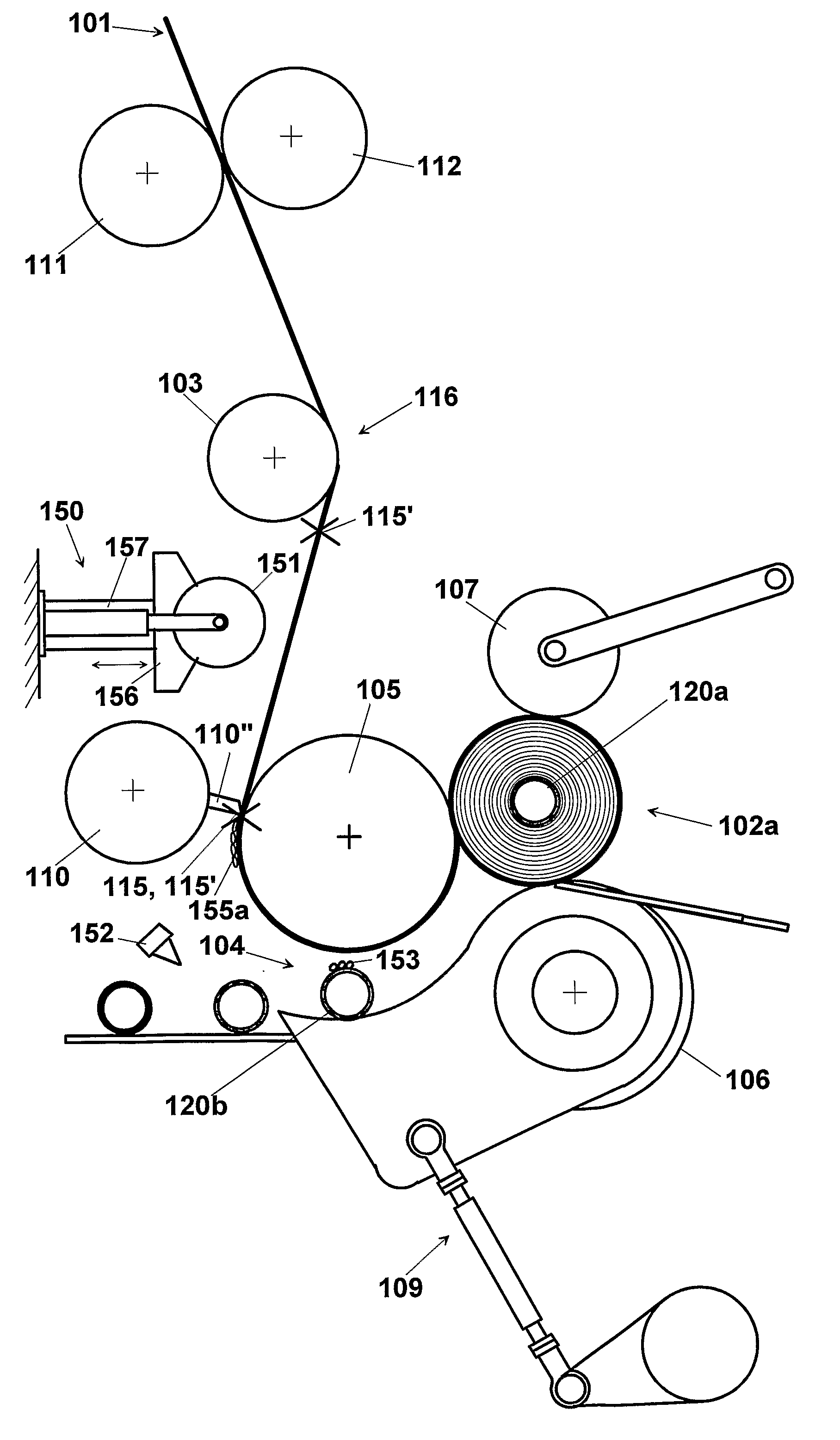

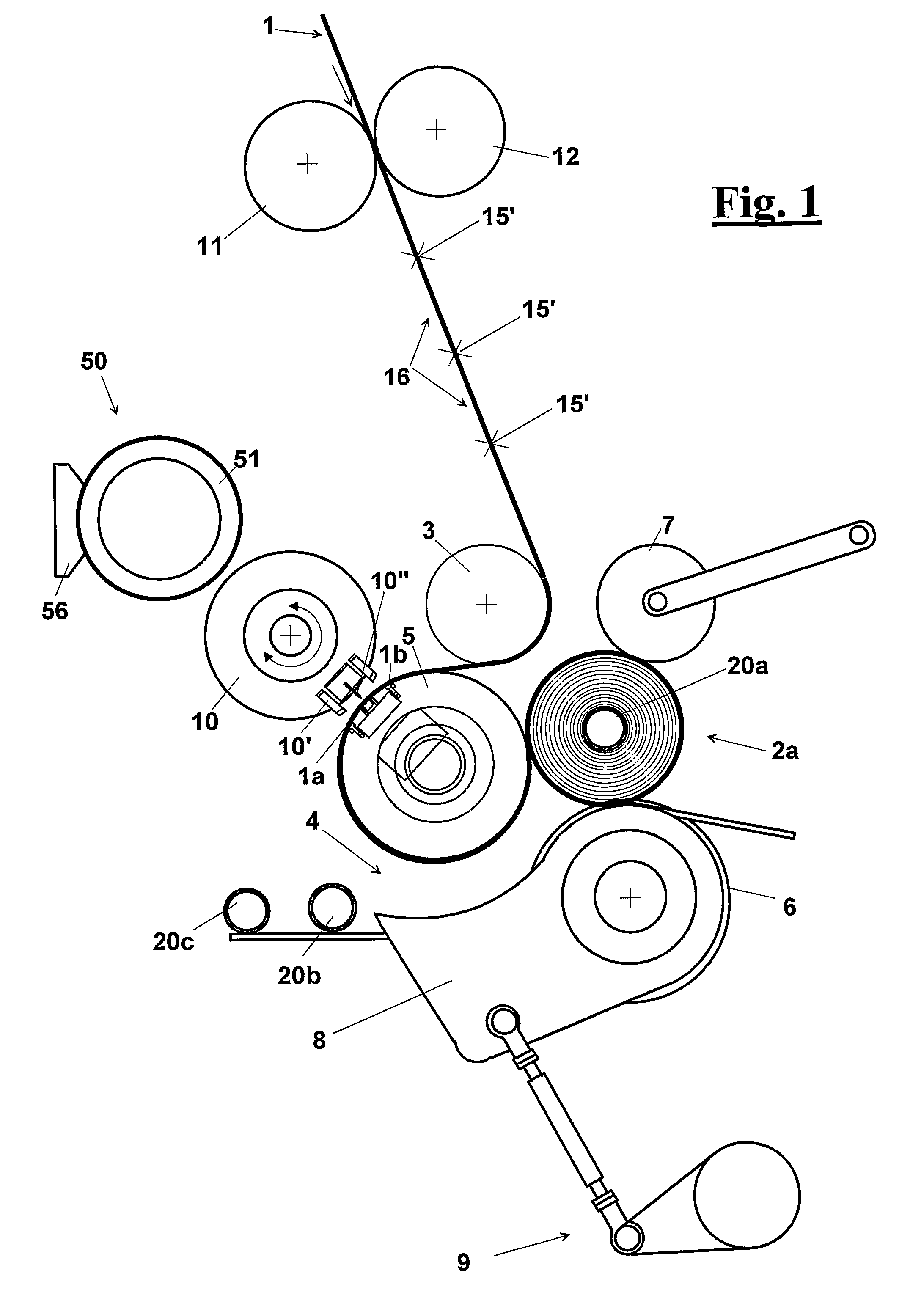

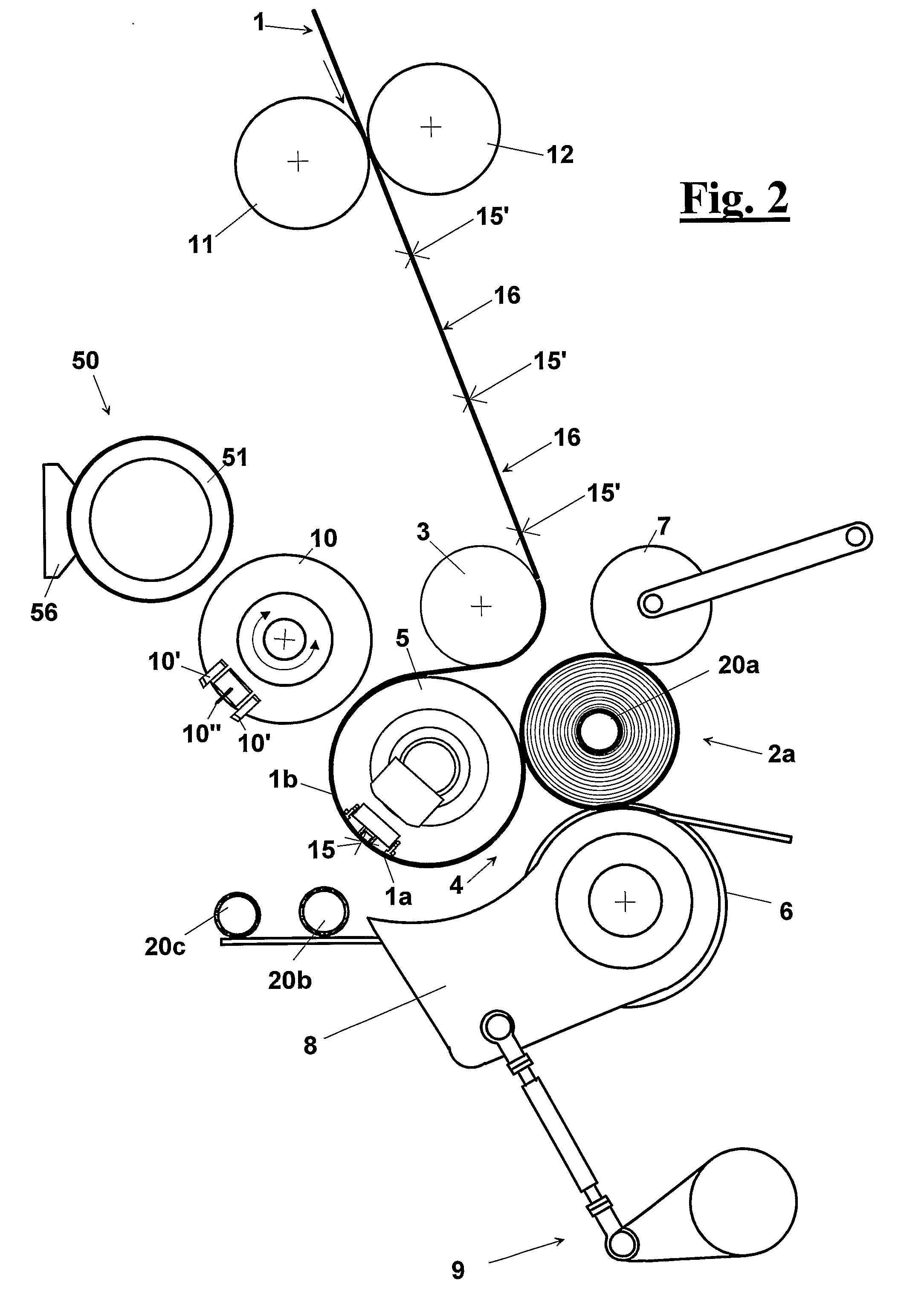

[0075]With reference to FIGS. 1 to 5, a rewinding apparatus machine of a paper web 1 for making a log 2a comprises a feed roller 3 of web 1 and, downstream of it, a winding cradle 4, in which the production of log 2a is carried out for winding web 1 about a core 20.

[0076]The latter is supplied into cradle 4 by suitable introduction means, for example a loading unit that draws the cores 20 from a chute guide, not shown in the figures. Alternatively, in a way not shown but known to a skilled person, a log can be formed without a core. In this case, the web is wound on itself to start forming a new log that then is wound in cradle 4.

[0077]Cradle 4, according to the prior art, comprises a upper winding roller 5, a lower winding roller 6 and a pressure roller 7, which follows the growth of log 2a with the object of assuring its continuous contact with winding rollers 5 and 6, for controlling its progressive diameter growth.

[0078]Upstream from feed roller 3, instead, a perforation roller ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| time | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com