Low-temperature heat energy driven double-container device for distilling and separating water evaporated under negative pressure

A negative pressure evaporation and separation device technology, applied in heating water/sewage treatment, general water supply saving, etc., can solve the problems of high vacuum pump consumption, complex system, difficult maintenance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] From the application of the present invention, the water that is suitable for the negative pressure evaporating water distillation and separation device driven by the low-temperature thermal energy of the present invention includes (but not limited to):

[0026] -seawater;

[0027] - saline inland surface water or groundwater;

[0028] - Contaminated surface or ground water containing solutes that are not vaporizable at the boiling point of water;

[0029] - other waters containing solutes which are not vaporizable at the boiling point of water;

[0030] -etc.

[0031] The "water to be separated" in this document may be (but not limited to) any type of water mentioned above.

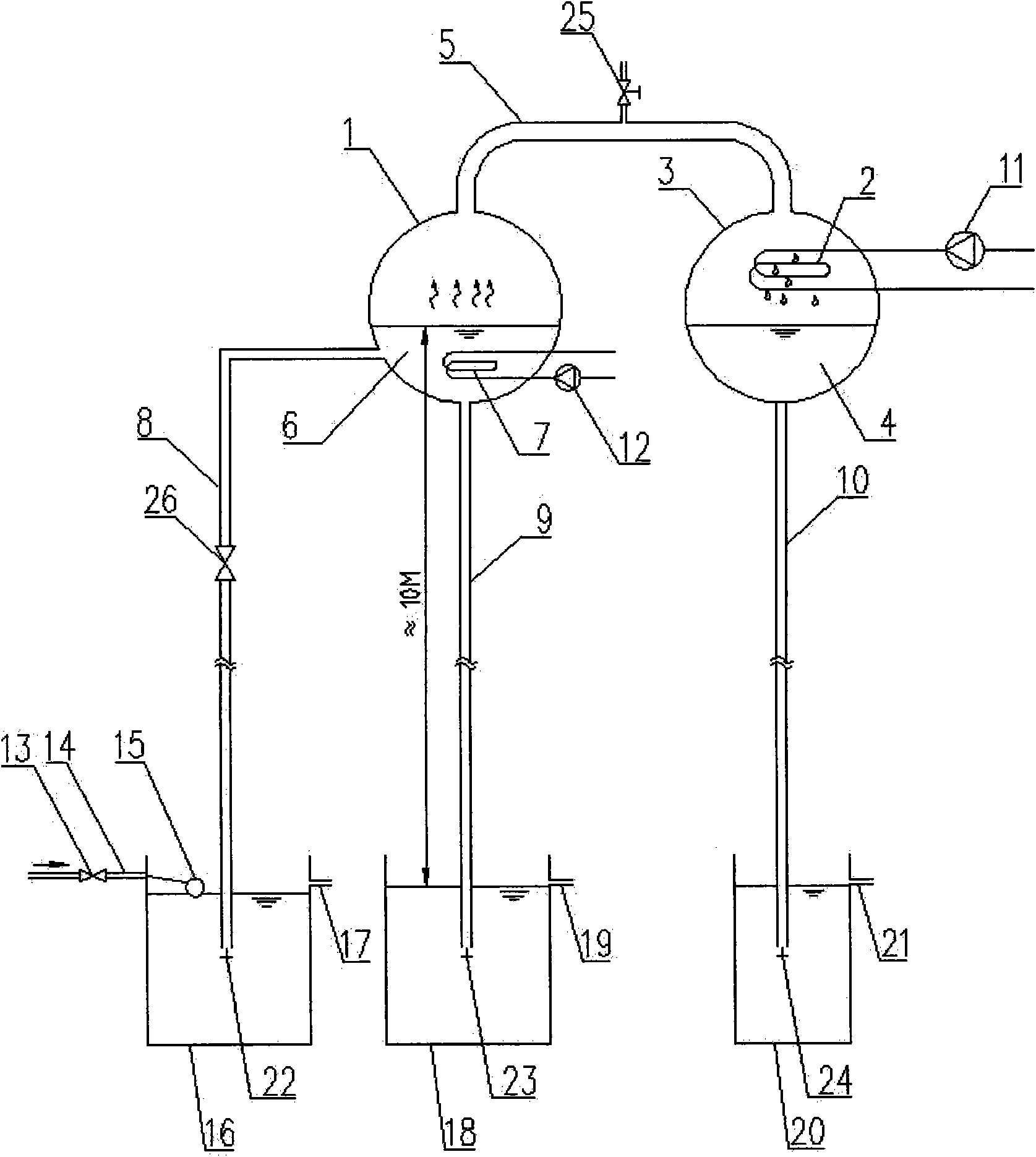

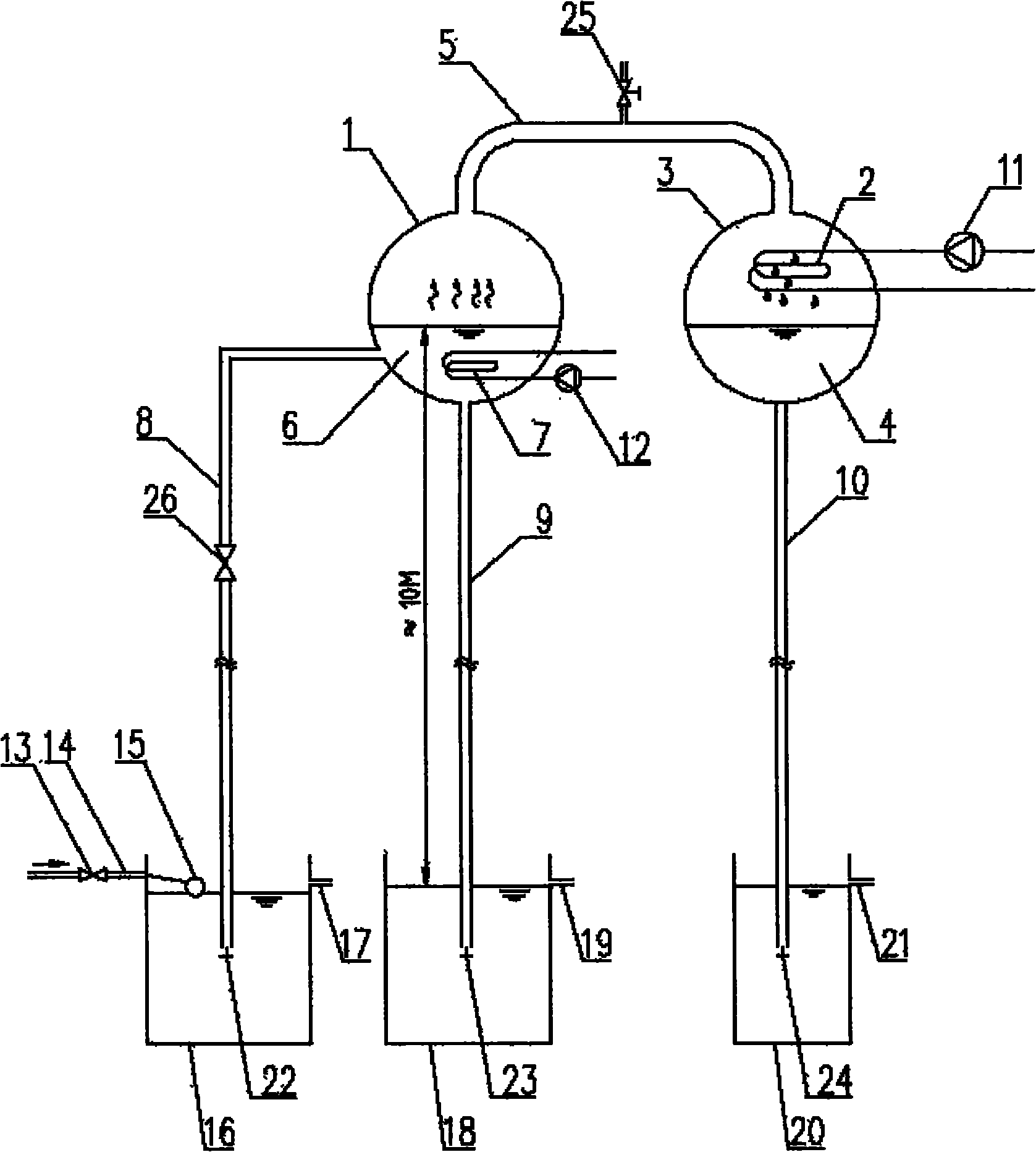

[0032] in such as figure 1 In the shown embodiment of the present invention, an evaporation heating tube bundle 7 is arranged in a sealed evaporation container 1 . The container 16 is a water-to-be-separated storage tank for storing water to be separated by distillation. The container 18 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com