Operation method achieved through automatic grouting and drilling fluid circulating system

A technology of circulating drilling fluid and automatic grouting, which is applied to drilling equipment and methods, drilling equipment, earthwork drilling and production, etc., which can solve the problems that the casing cannot be guaranteed to go down to the bottom of the well smoothly, and there are potential safety hazards, so as to reduce the labor of workers Strength, reduced construction difficulty, and high safety effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Below in conjunction with accompanying drawing and specific embodiment the present invention will be described in further detail:

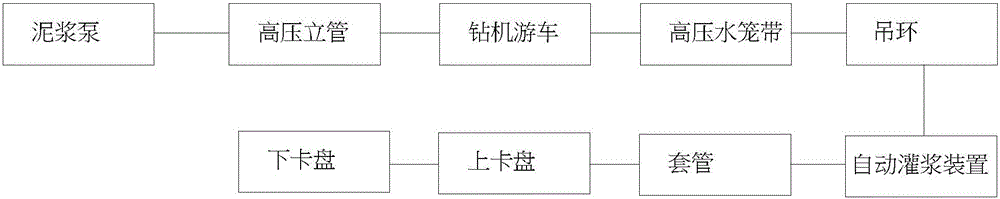

[0023] see figure 1 , an operation method realized by the automatic grouting and circulating drilling fluid system of the present invention, the automatic grouting and circulating drilling fluid system used in the operation method includes mud pumps, high-pressure standpipes, drilling rig swimmers arranged sequentially from top to bottom Car, high-pressure water cage belt, lifting ring, automatic grouting device, casing, upper chuck and lower chuck;

[0024] The operation method includes the grouting operation process in the casing operation and the circulating drilling fluid operation process in the casing operation;

[0025] The grouting process in the casing operation includes the following steps:

[0026] 1) When grouting is required, turn on the mud pump;

[0027] 2) The high-pressure drilling fluid enters the high-pressure water ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com