Temperature control device, method and system

A temperature control device, a technology of preset temperature, applied in thermal storage heaters, fluid heaters, lighting and heating equipment, etc., can solve problems such as exceeding the set temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

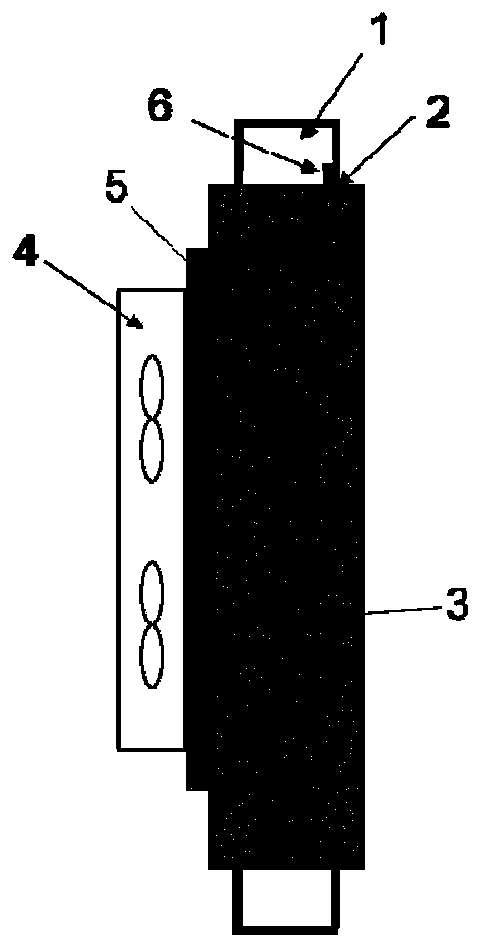

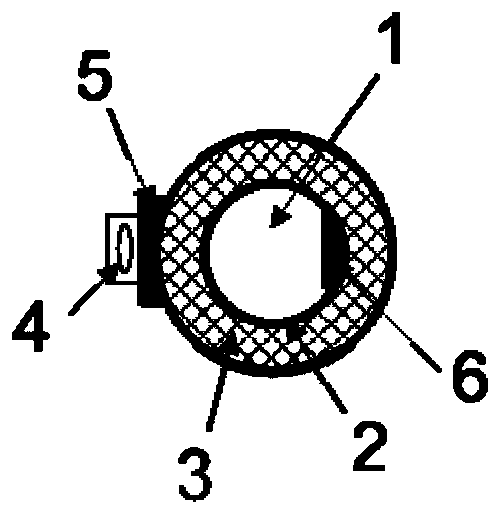

Image

Examples

example 1

[0063] Example 1, the diameter of the pipe cavity is 6mm, the total length is 2.5m, the fluid is water, and the temperature of the fluid measured by the first sensor is 40°C. Optionally, in the phase change heat storage material filling layer, the main component of paraffin is The molecular formula is C28H58, the mass fraction is 71.5%, the mass fraction of metallic copper is 8.5%, and the mass fraction of graphite is 20%.

[0064] Take the precise temperature rise mode when the set temperature is 60°C as an example. Correspondingly, the control circuit drives the heating component to raise the temperature of the fluid in the pipeline. When the first temperature sensor detects that the temperature of the fluid in the pipeline reaches the phase change of the heat storage material point (60°C), the phase change heat storage material begins to absorb the heat emitted by the heating component, so that the heat received by the fluid is greatly reduced; according to the temperature c...

example 2

[0066] Example 2, the diameter of the pipeline cavity is 6 mm, the total length is 2.5 m, the fluid is non-methane total hydrocarbon (NMHC), and the temperature of the fluid measured by the first sensor is 100 ° C. Optionally, the phase change heat storage material 2 In the filling layer, the molecular formula of the main component of paraffin is C 30 h 62 , the mass fraction is 23.7%, the metal alloy adopts Bi(56%)-Sn(40%)-Zn(4%) composite, accounting for 68.3%, and the graphite addition accounts for 8%.

[0067] Take the rapid temperature rise mode when the set temperature is 130°C as an example. First, the control circuit drives the heating component to heat. The variable heat storage material begins to absorb the heat emitted by the heating component, so that the heat received by the fluid is greatly reduced; according to the temperature collected by the second temperature sensor and the temperature collected by the first temperature sensor, the fuzzy control algorithm is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Total length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com