Airborne camera low-temperature heating system and heating method thereof

A heating system and camera technology, applied in the direction of transparent/reflective heating devices, cameras, electric heating devices, etc., can solve problems such as low work efficiency, poor environmental adaptability, complex heating circuits, etc., and achieve low maintenance and repair costs and environmental protection The effect of strong adaptability and high safety factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The drawings constituting a part of the present invention are used to provide a further understanding of the present invention, and the schematic embodiments and descriptions of the present invention are used to explain the present invention, and do not constitute an improper limitation of the present invention.

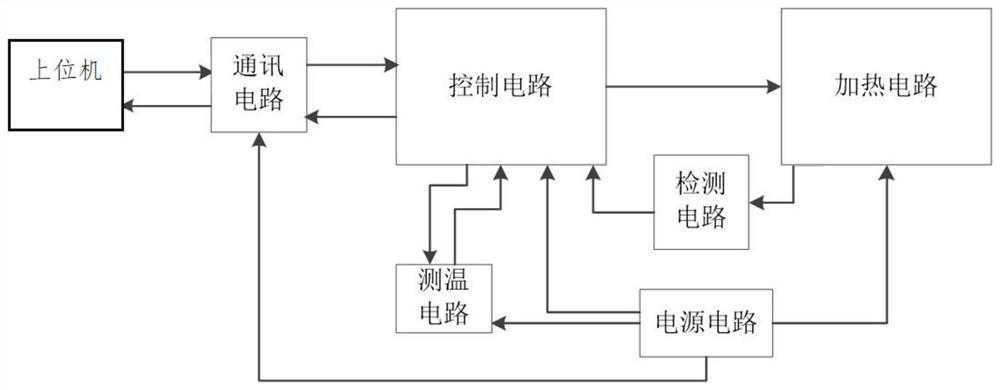

[0037] Such as figure 1 As shown, the present invention provides a low-temperature heating system for an airborne camera lens, including a control circuit, a temperature measurement circuit, a heating circuit and a power supply circuit.

[0038] The control circuit is used to receive the data information fed back by the temperature measurement circuit, and control the heating circuit to complete the heating work;

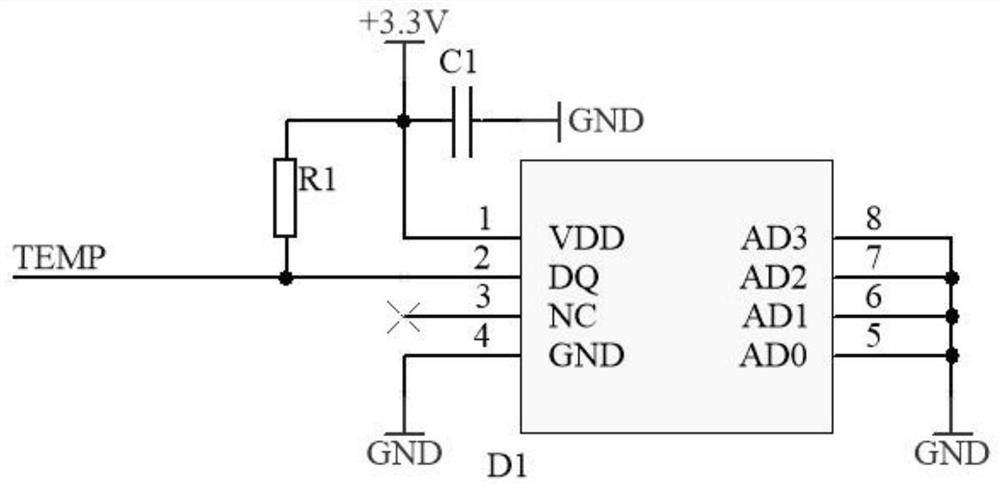

[0039] A temperature measuring circuit for detecting the ambient temperature of the outside world;

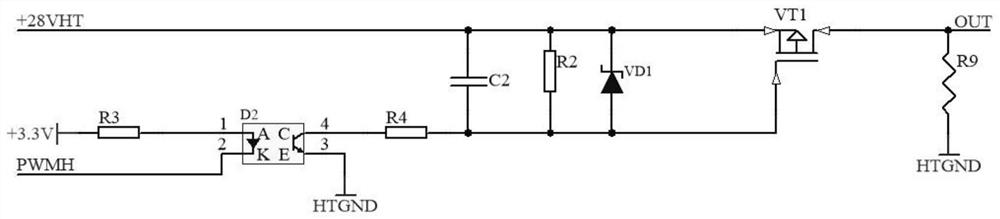

[0040] Heating circuit for heating the lens of the camera;

[0041] The power supply circuit is used to provide working power for other circuits. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com