Patents

Literature

61results about How to "Adjust heating power" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

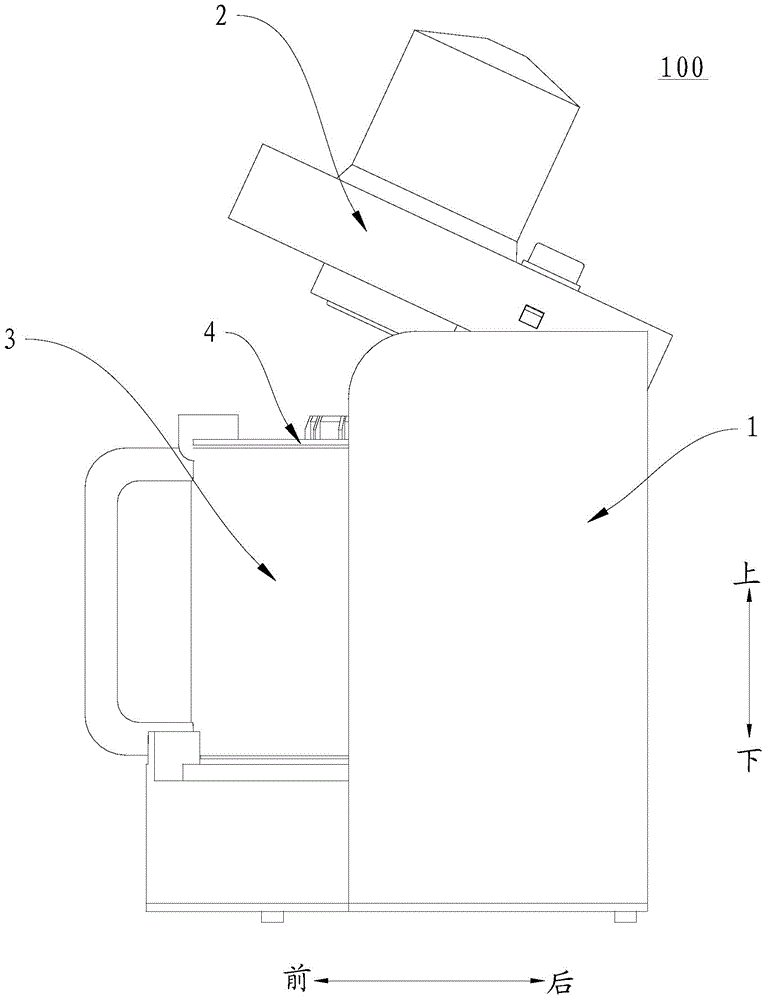

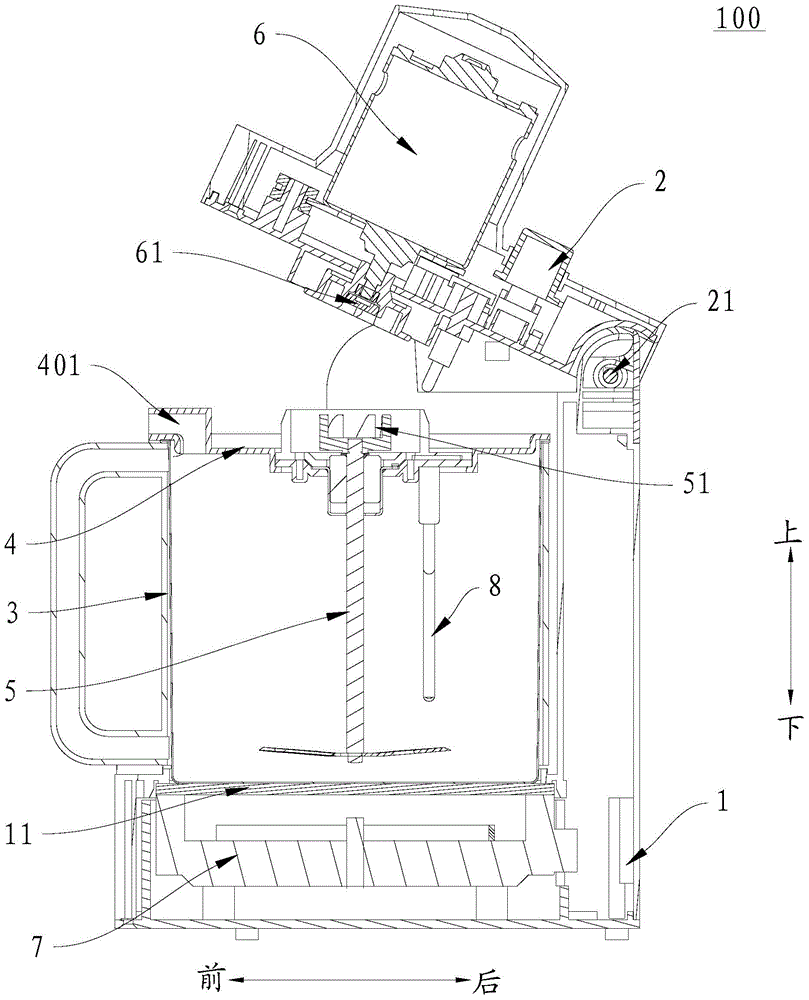

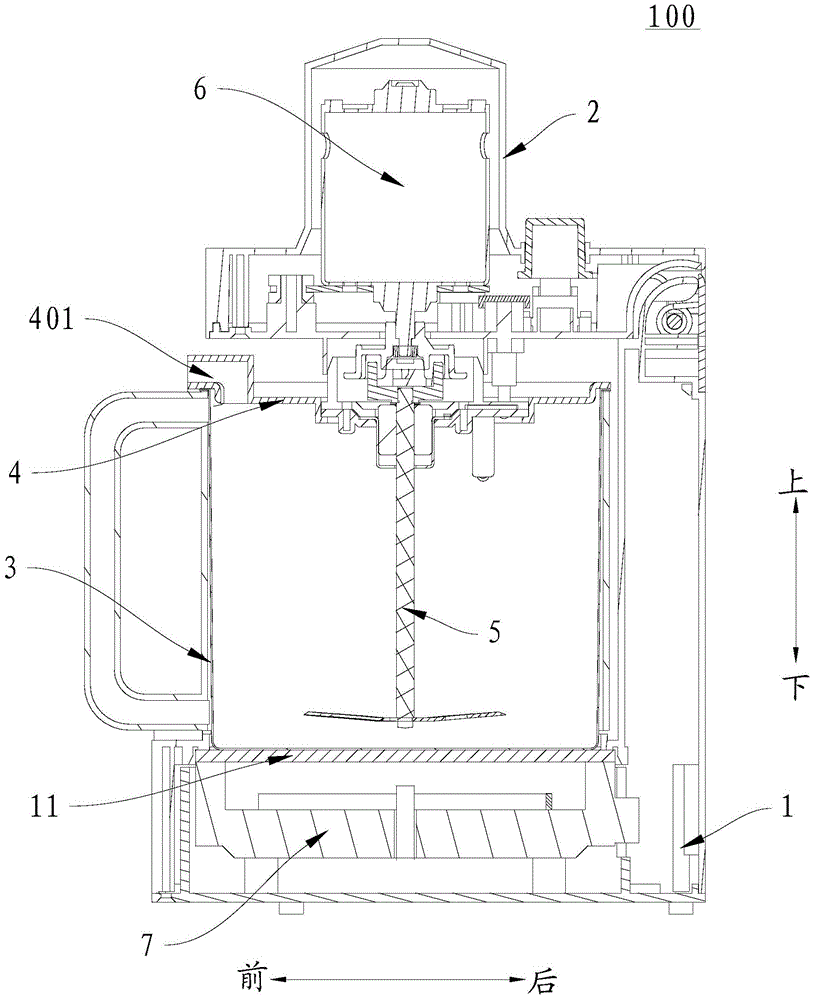

Food processing equipment and method for processing food by adopting food processing equipment

The invention discloses food processing equipment and a method for processing food by adopting the food processing equipment. The food processing equipment comprises a main body, a cover body, a cup body, a cup cover, a stirrer, a motor, a heater and a controller, wherein the cover body is pivotally arranged on the main body between an opened position and a closed position; the cup body is arranged on the main body; the cup cover is used for opening or closing the cup body; the stirrer is arranged on the cup cover in a rotatable manner and extends into the cup body; the motor is arranged on the cover body, and the motor is connected with the stirrer at the closed position of the cover body; the heater is used for heating the cup body. According to the food processing equipment disclosed by the embodiment of the invention, the use of the food processing equipment is facilitated, the workload of the food processing equipment for processing food is alleviated, the use of the food processing equipment is facilitated, and the food processing efficiency is improved.

Owner:MIDEA GRP CO LTD +1

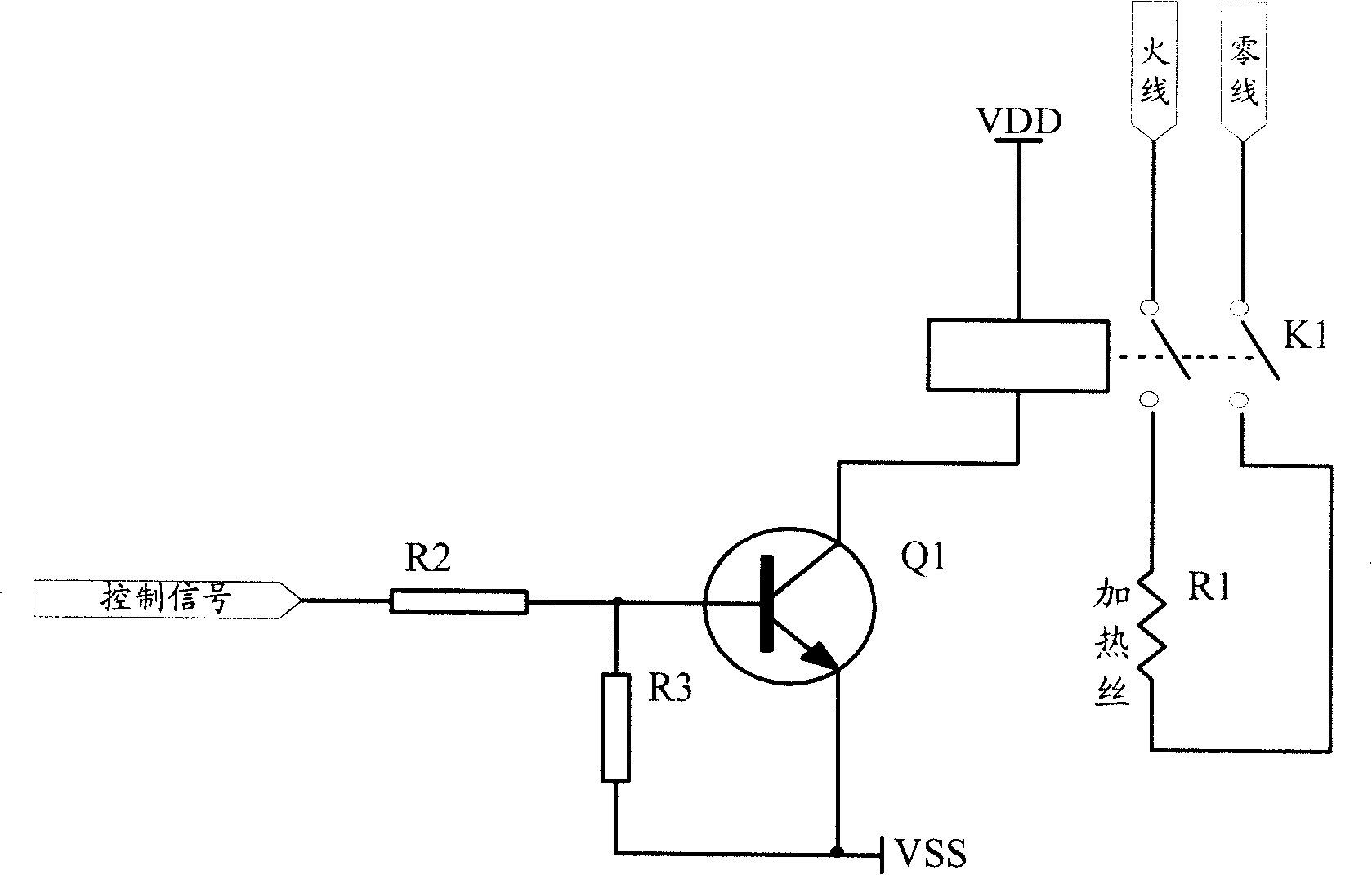

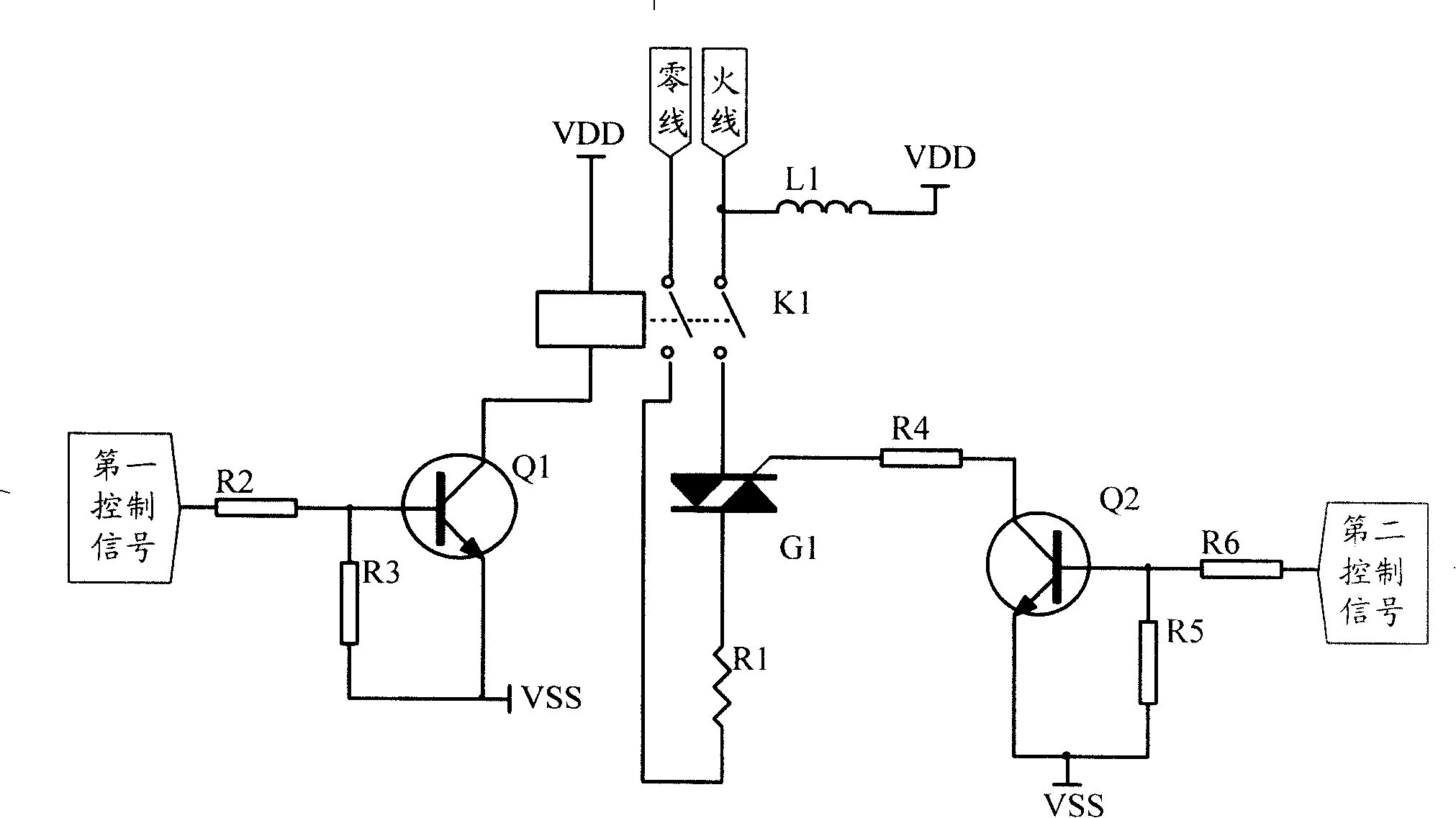

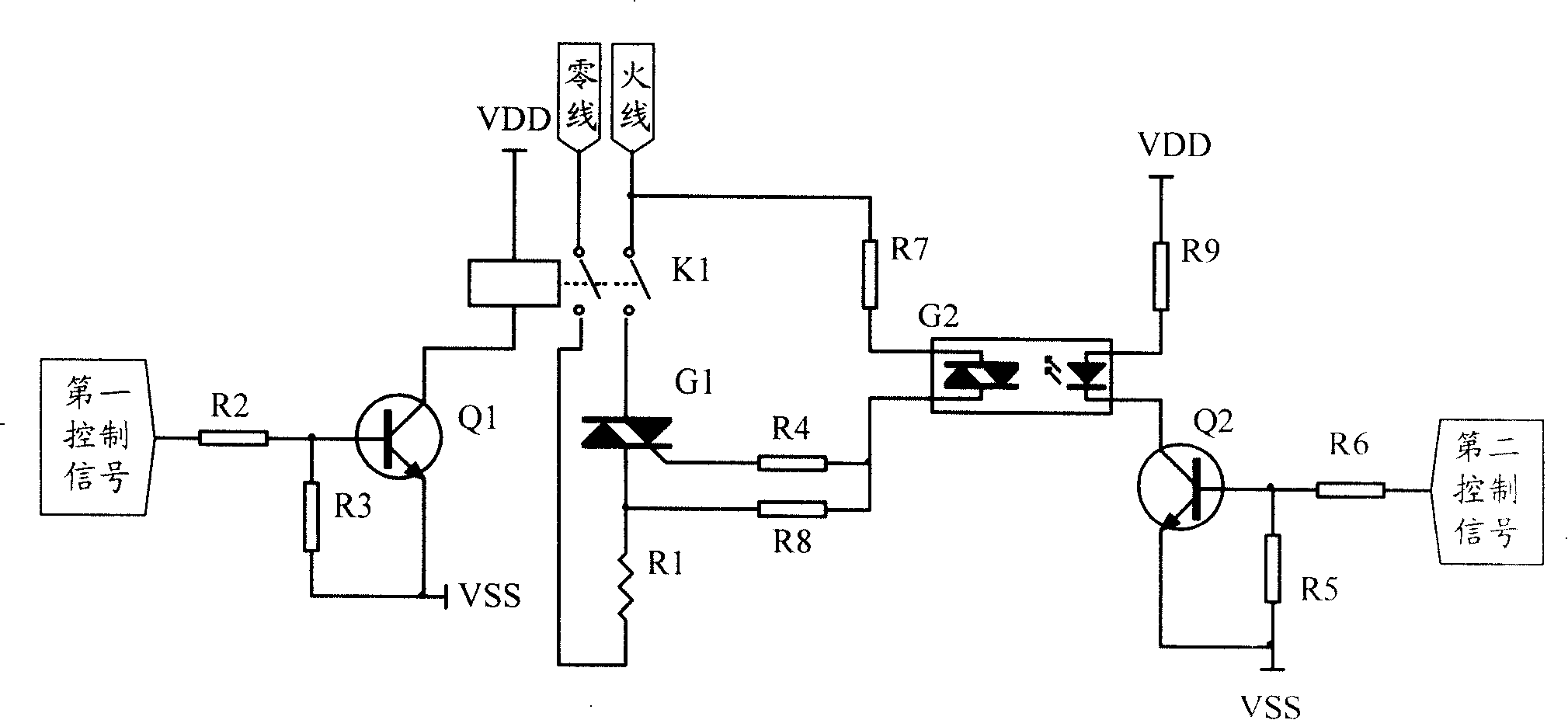

Heating control circuit and heating electrical appliance

ActiveCN101212847AReduce the number of timesExtended service lifeOhmic-resistance heatingTemperature control using electric meansEngineeringHeat control

The invention discloses a heat control circuit, which comprises a relay serially connected with the heat control circuit and a control unit used for adjusting the heating power of the heat control circuit. The control unit is connected with the relay.The invention provides a heat control circuit, which can provide a uniform heating process so as to protect the relay from damaging.The invention also provides a heat control circuit which can acquire uniform heat process so as to adjust the heating power of the heat circuit.The invention also provides a heating electrical appliance, which can provide a uniform heating process so as to protect the relay from damaging.The invention also provides another heating circuit which can acquire uniform heat process so as to adjust the heating power of the heating circuit.

Owner:HAIER GRP CORP +1

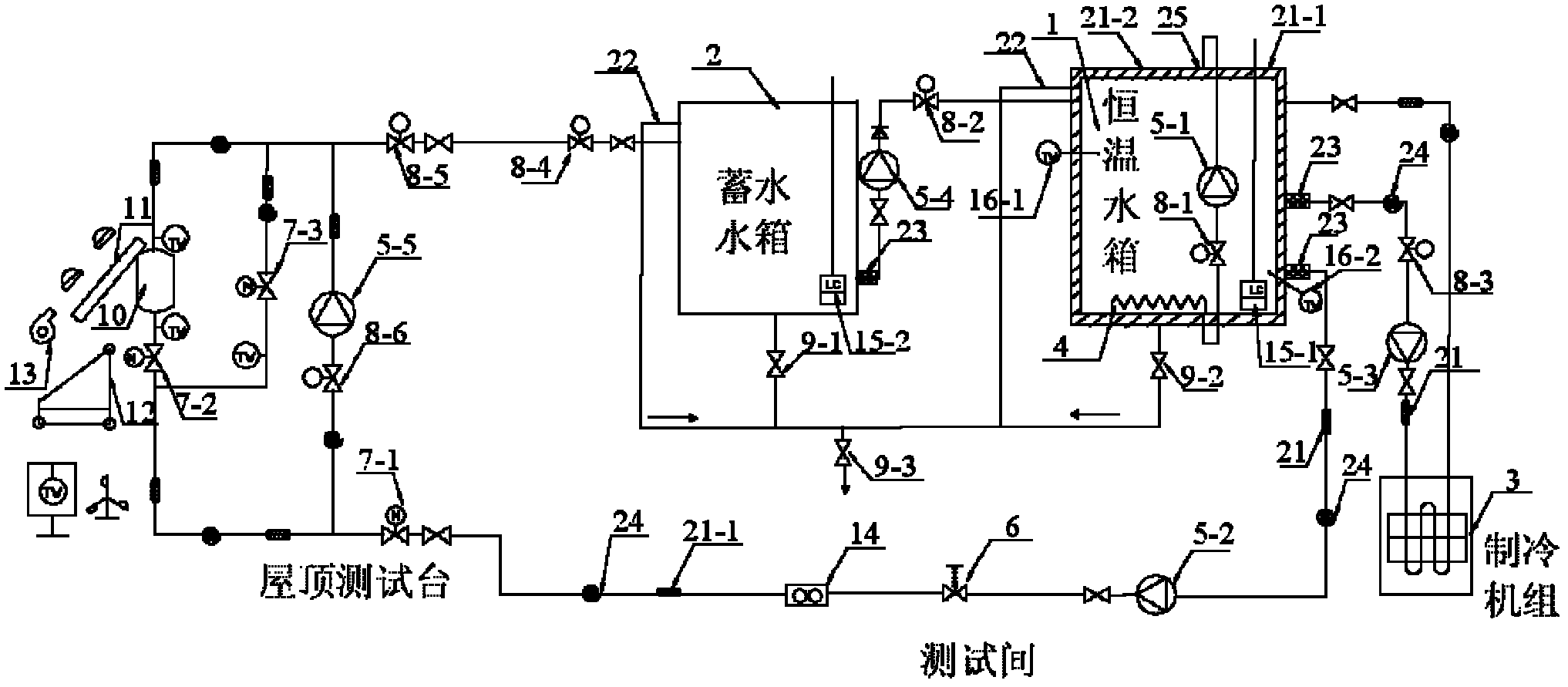

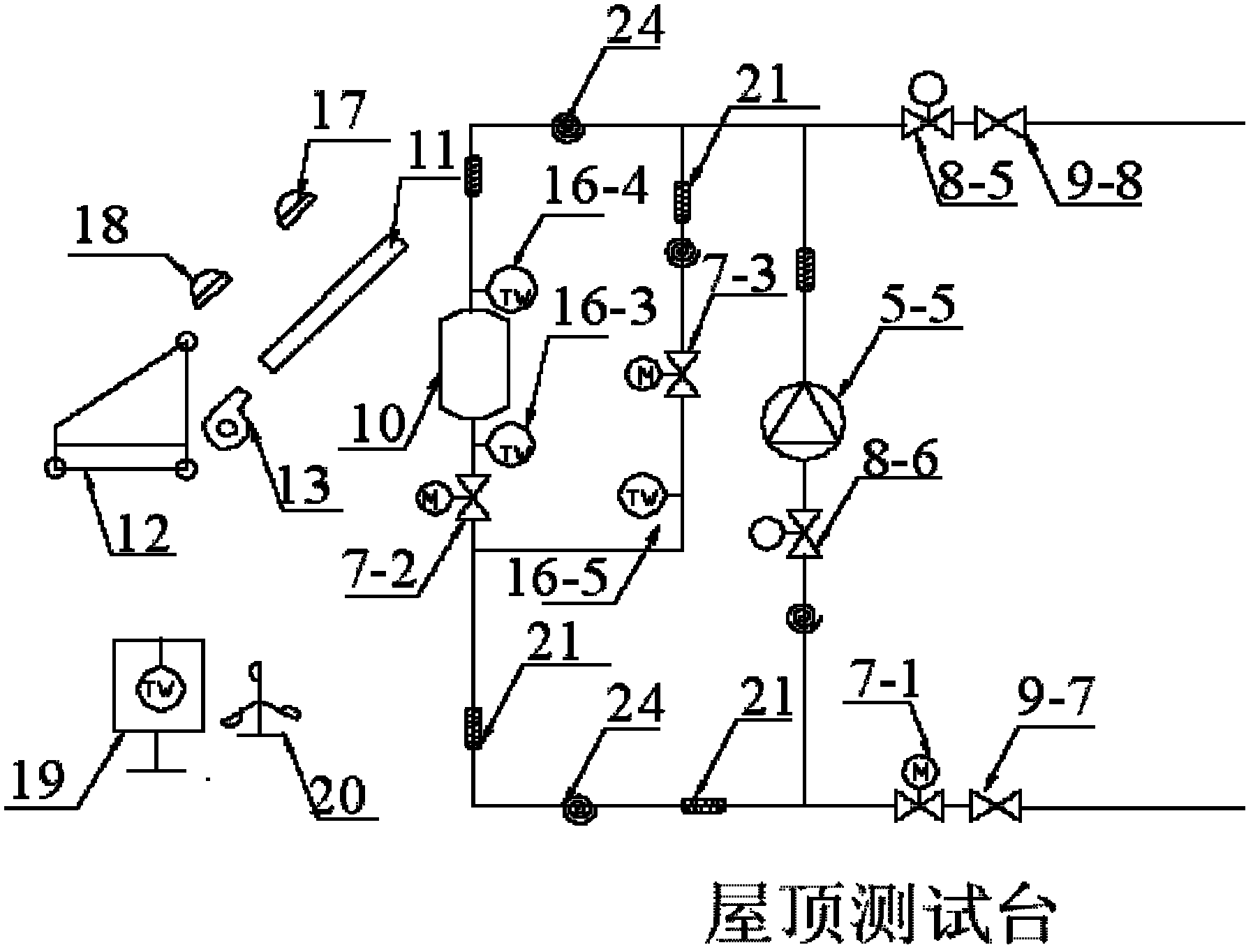

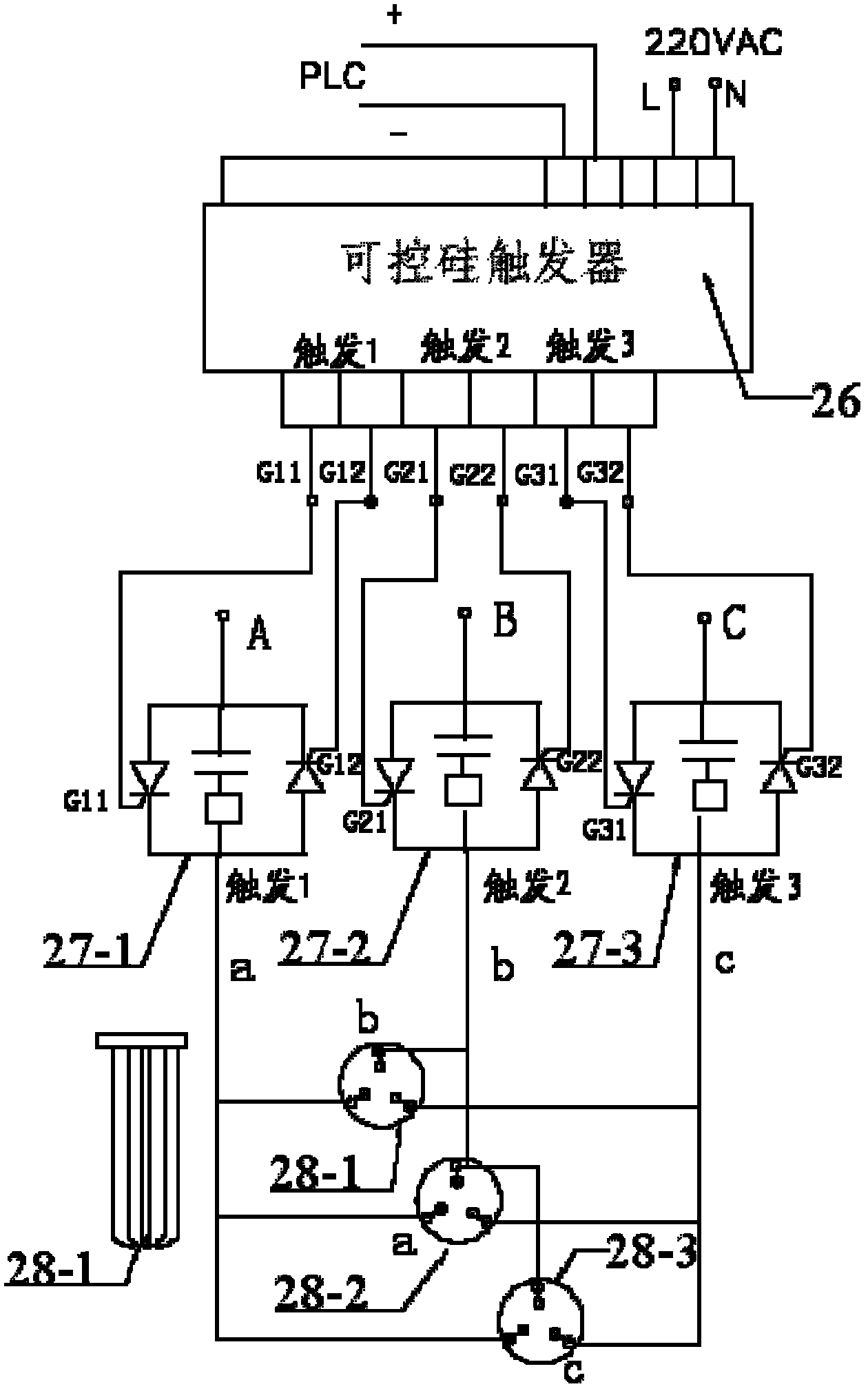

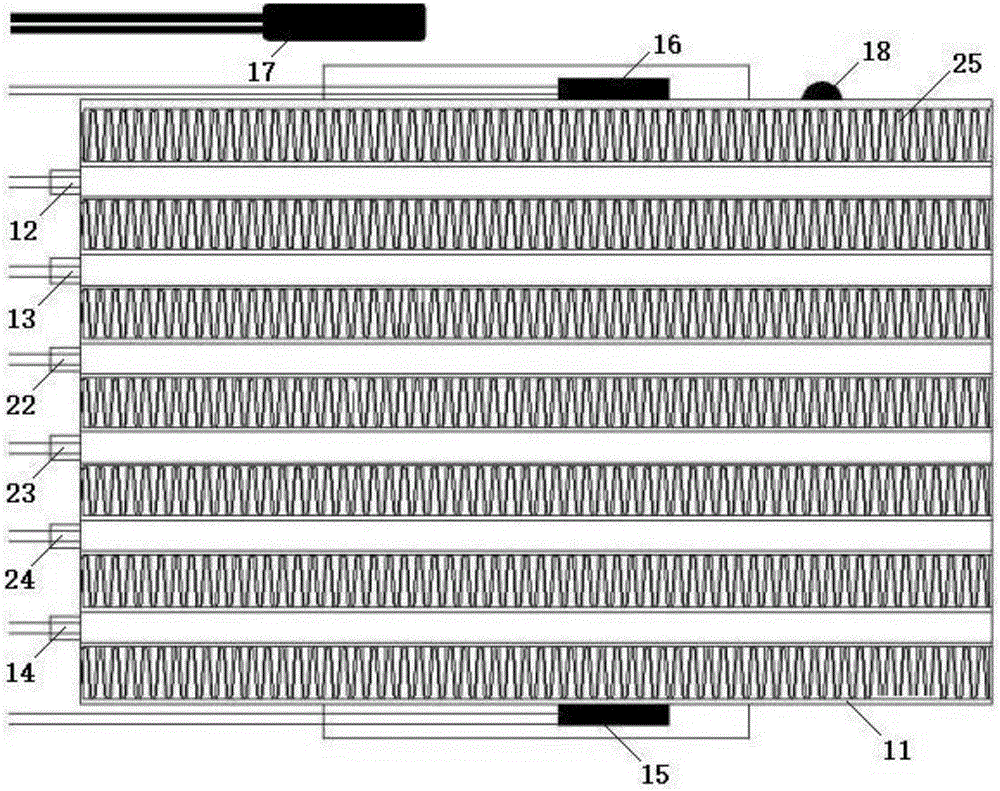

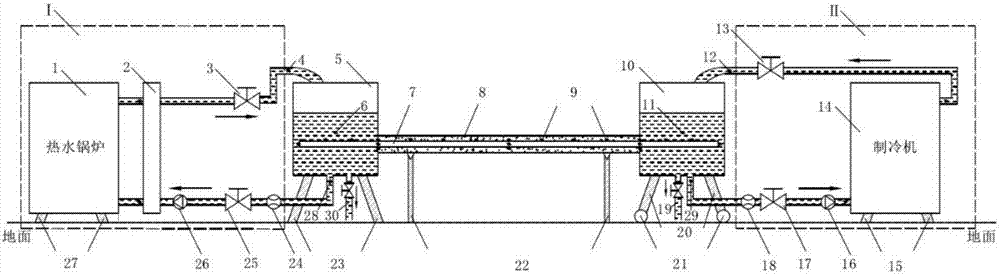

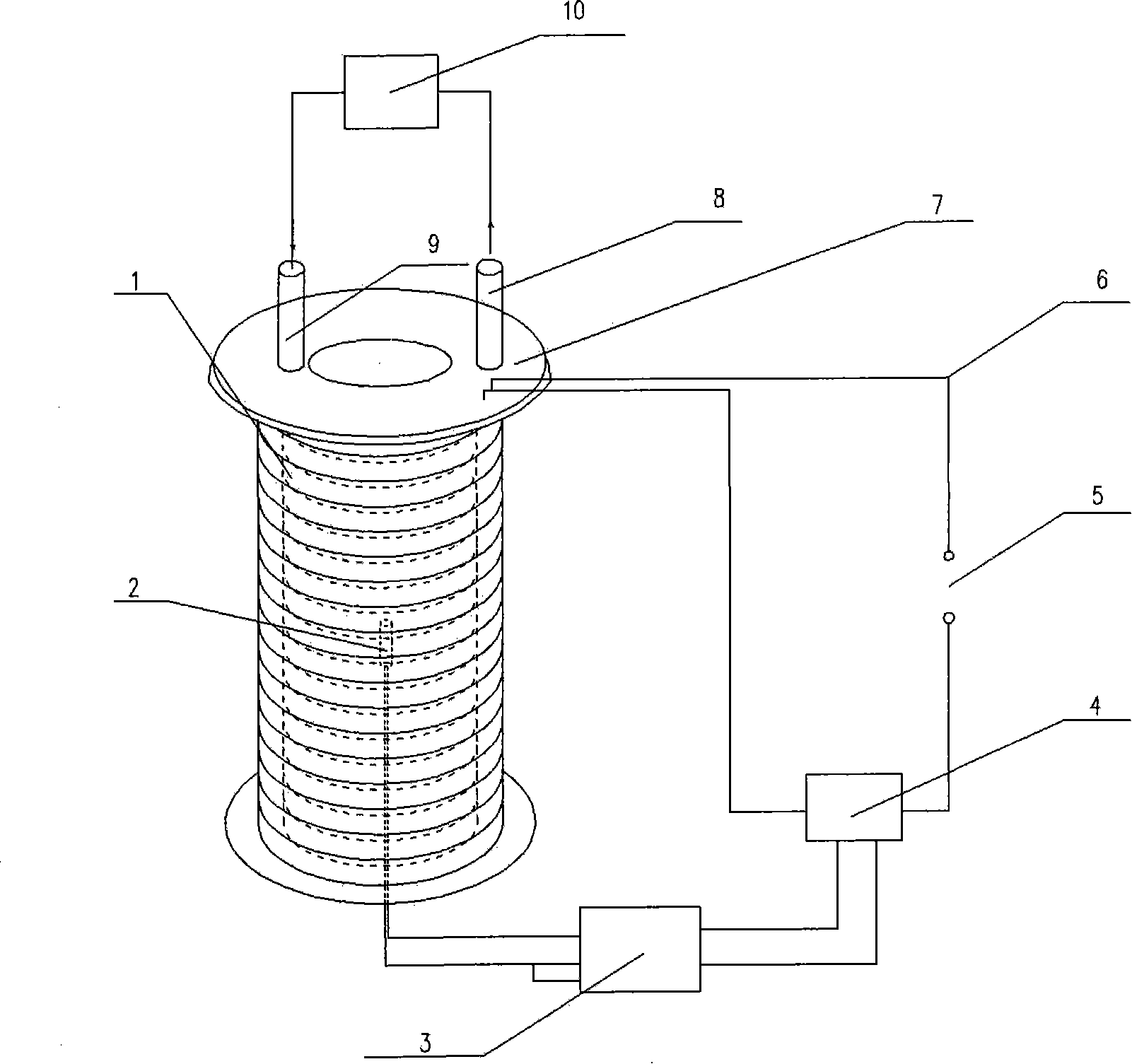

Thermal performance test system of solar water heater

InactiveCN102564783APrevent backflowRealize fully automatic intelligent controlStructural/machines measurementWater storageData acquisition

The invention discloses a thermal performance test system of a solar water heater. The thermal performance test system comprises a pipeline system, a test rack and a full-automatic intelligent control system. The pipeline system comprises a constant-temperature water tank (1), a refrigeration system connected with the constant-temperature water tank (1), a self-circulation system positioned outside the constant-temperature water tank (1), and an electric heating device arranged at the bottom of the constant-temperature water tank; the pipeline system is connected with a thermal storage water tank (10) in a test rack system of the solar water heater; and the pipeline system, the constant-temperature water tank and a water storage water tank form a loop. The full-automatic intelligent control system realizes data acquisition, sequential logic control and real-time regulation and control of temperature and flow by adopting a programmable controller (PLC).

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

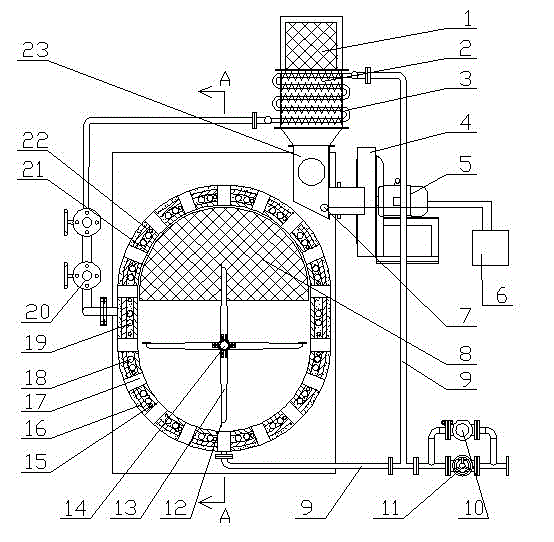

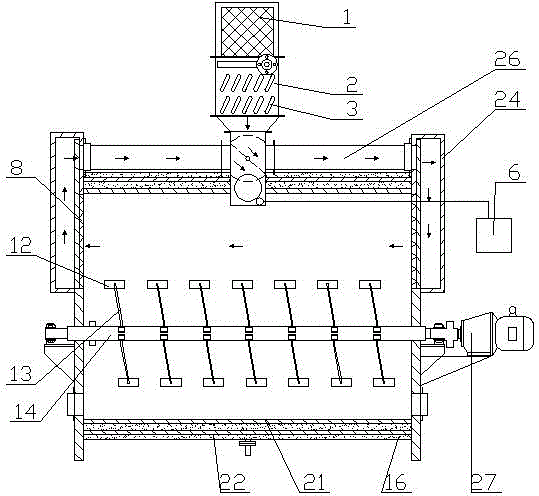

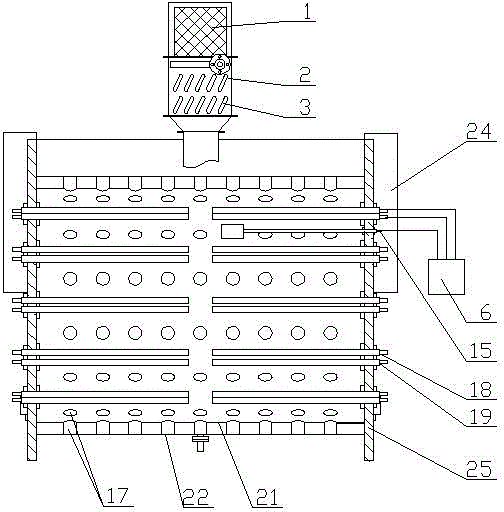

Temperature-controlled heat-conducting oil down drying machine

InactiveCN102878785AReasonable structureImprove loftDrying solid materialsDrying machines with non-progressive movementsAir preheaterHeat conducting

The invention relates to a temperature-controlled heat-conducting oil down drying machine, wherein the interlayer of a barrel body of the down drying machine is filled with heat-conducting oil; a plurality of temperature sensors are distributed in the heat-conducting oil uniformly; a plurality of groups of electric heating tubes are arranged in the interlayer of the barrel body uniformly; sieve plates are arranged on the end covers of the left end and the right end of the barrel body respectively; air tanks are arranged outside the sieve plates; an air flue is connected between the left air tank and the right air tank; an air inlet and a suction opening are connected in the middle of the air flue through a four-way reversing valve; the air inlet is sequentially connected with an air preheater and a fan cover; a radiator connected with the inner cavity of the barrel body is arranged outside the air preheater; air is heated through external heat source; the suction opening is sequentially connected with a dehumidifying draft fan and a driving motor I of the dehumidifying draft fan; a humidity sensor is arranged at the suction opening; and the motor I, the humidity sensor, the electric heating tubes and the temperature sensors are respectively connected with a programmable logic controller (PLC).

Owner:徐州腾宇羽绒制品设备有限公司

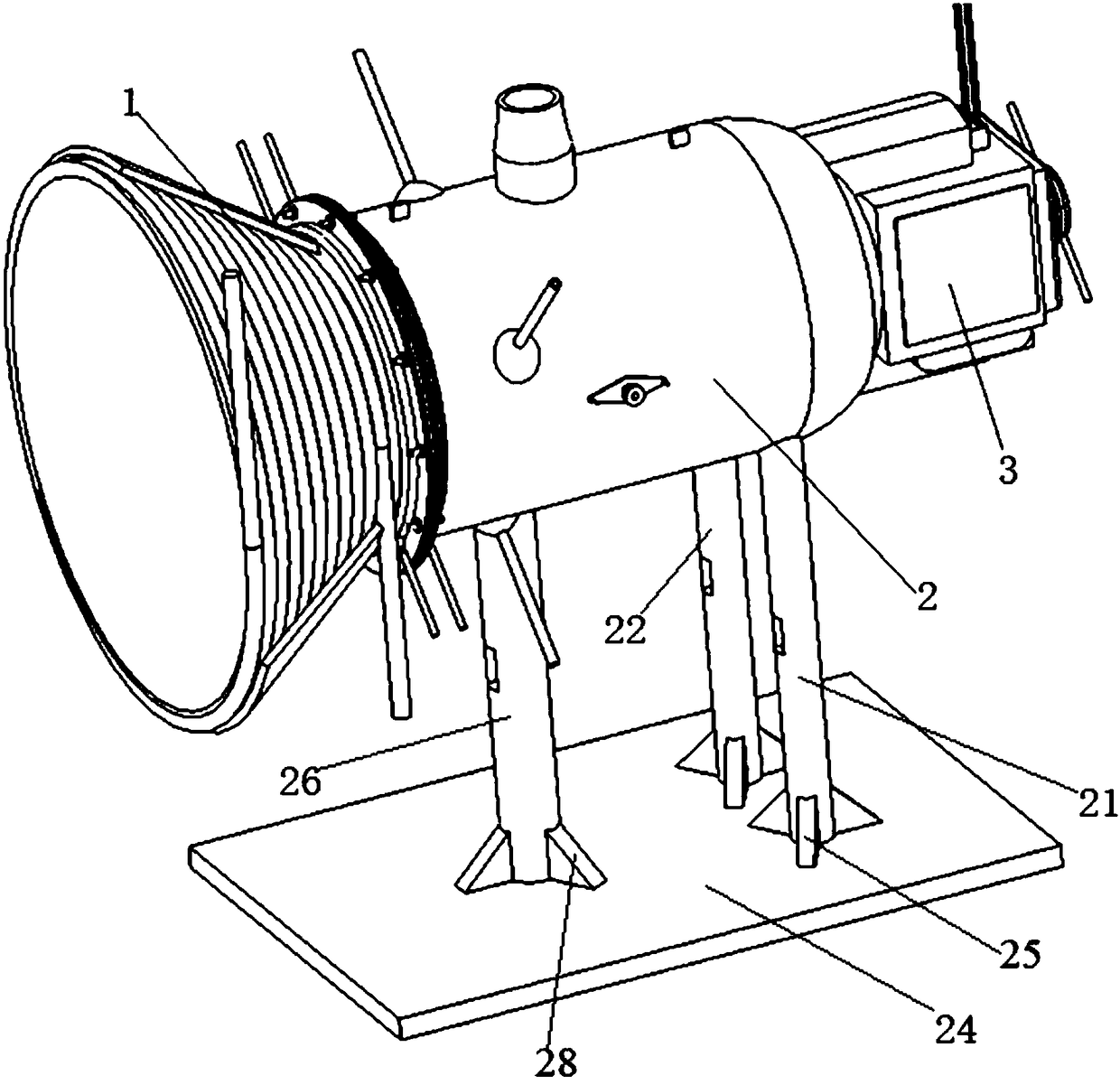

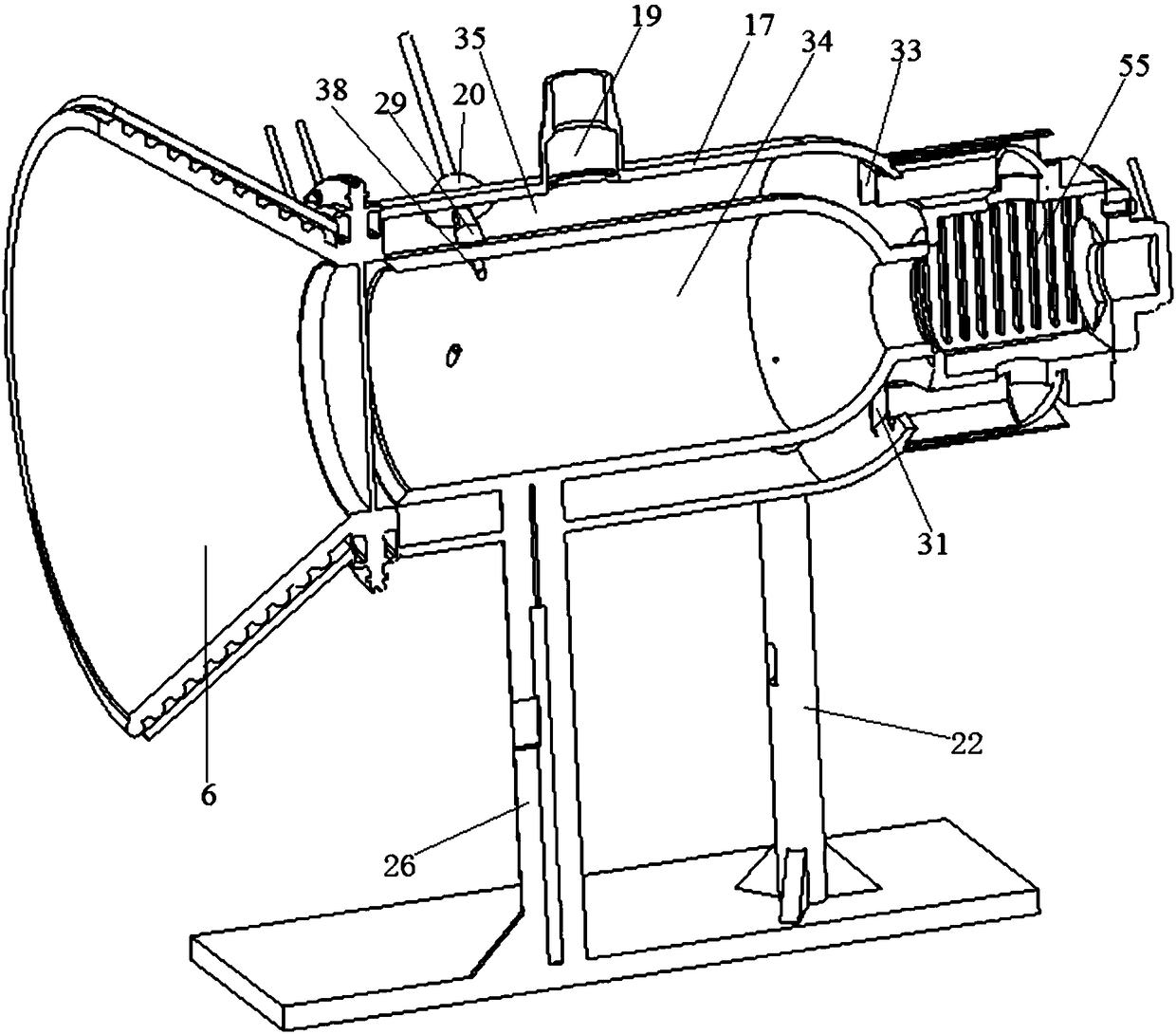

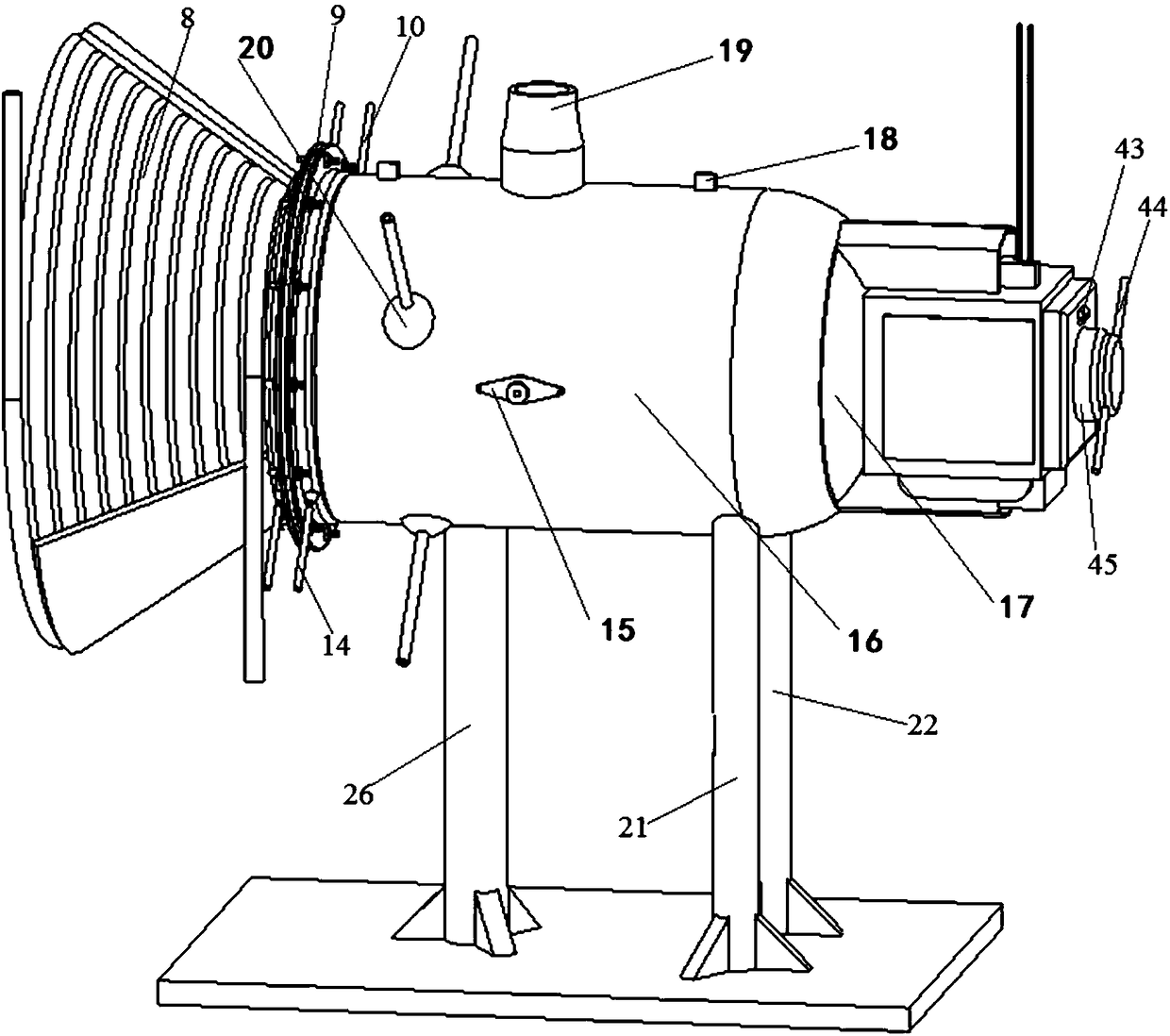

Energy-saving and environment-friendly solar reactor for hydrogen production by methanol reforming

ActiveCN108190834AWide range of usesImprove securityHydrogenEnergy inputEnergy conservationHydrogen production

The invention relates to an energy-saving and environment-friendly solar reactor for hydrogen production by methanol reforming and belongs to the technical field of photovoltaic heating equipment. Thereactor comprises a solar reception system, a methanol reforming reaction system, a tail gas dedusting treatment system and a support base, wherein the solar reception system, the methanol reformingreaction system and the tail gas dedusting treatment system are fixedly arranged on the support base sequentially, located on the same horizontal plane and communicated mutually. The energy-saving andenvironment-friendly solar reactor has the advantages that energy use ratio can be increased greatly, and losses of optical energy and waste heat can be reduced; dust pollution caused by nanoparticles and thermal pollution caused by excessive released waste heat are reduced, environment is protected, and energy is saved; operating data is monitored in real time by the equipment, feedback controlis realized by a computer, and the reactor has the characteristics of being high in automation degree, efficient, clean, environmentally friendly and energy-saving.

Owner:KUNMING UNIV OF SCI & TECH

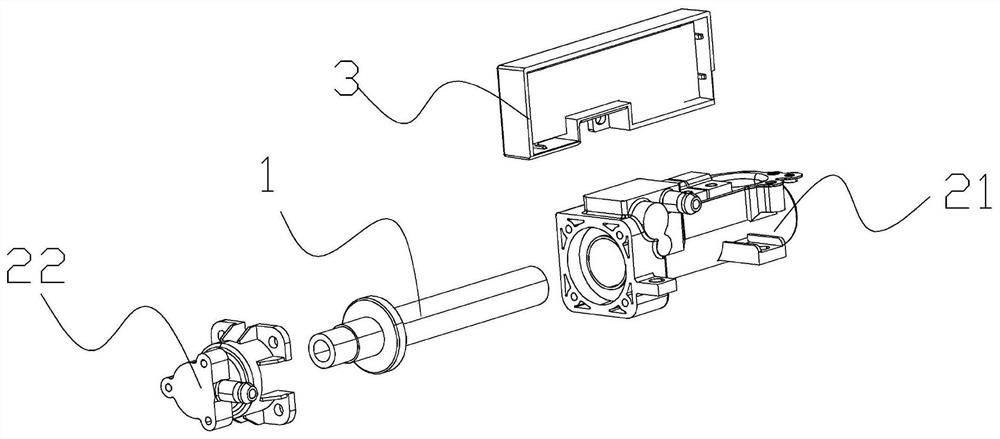

Pulse on-off valve type metal 3D printing device

ActiveCN106378454AReal-time monitoring of melt temperature changesAdjust heating powerAdditive manufacturing apparatusIncreasing energy efficiencyMolten metalMaterials science

The invention discloses a pulse on-off valve type metal 3D printing device capable of realizing precise spray-deposition 3D printing formation of molten metal under the control of a pulse on-off valve. More specifically, the pulse on-off valve type metal 3D printing device is characterized in that a metal liquid is purified through melting and filtering, the precise controllable continuous spray of the molten metal is realized through controlling the pulse on-off of a rotating blade-shaped valve at a printing spray head, the movement of the spray head is controlled through a three-dimensional coordinate platform, a forming platform is provided with stable temperature by a printing substrate, and low-cost additive manufacturing equipment capable of realizing rapid metal melting, multistage purification and precise controllable spray deposition is finally designed.

Owner:ADVANCED MFG TECH CENT CHINA ACAD OF MASCH SCI & TECH

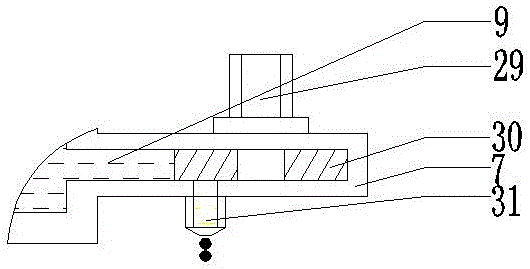

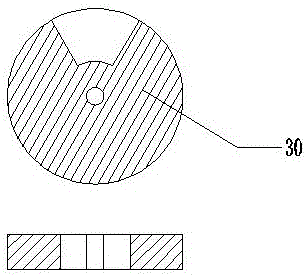

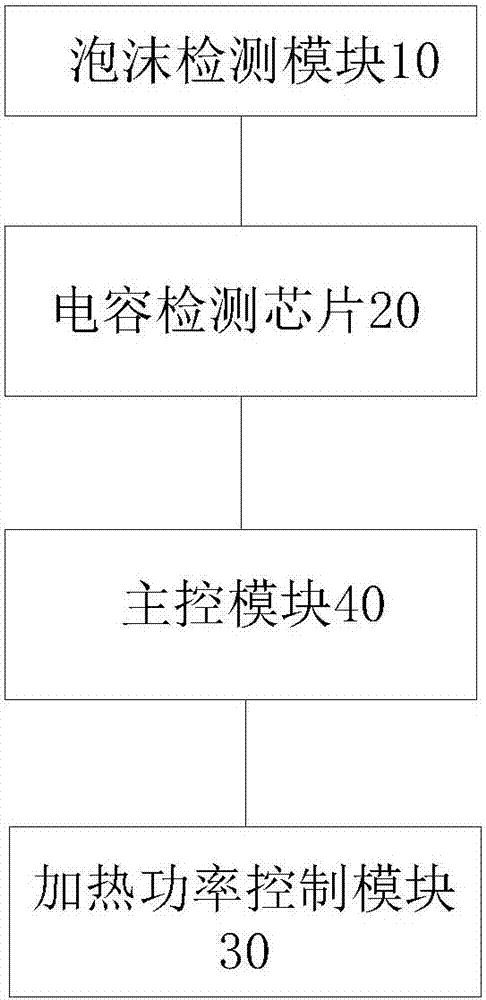

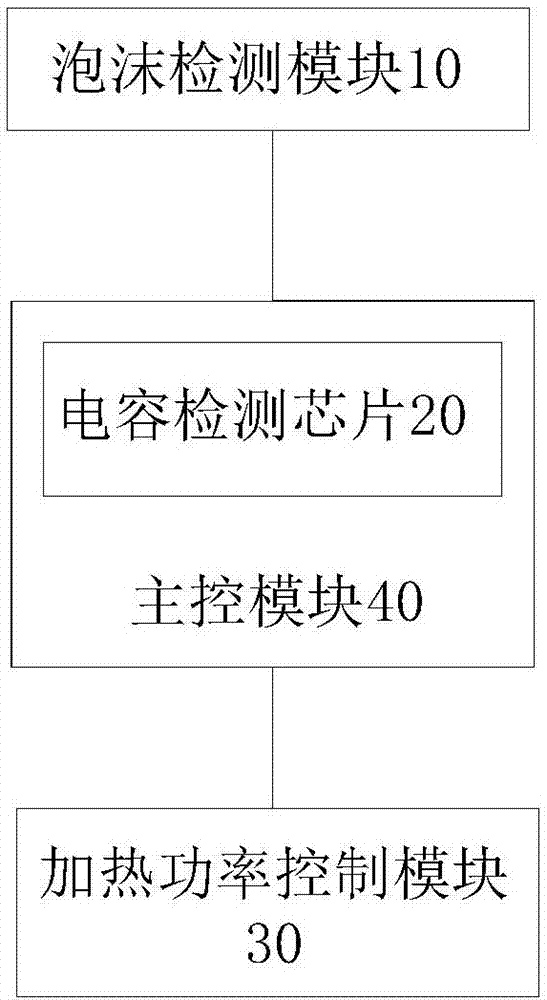

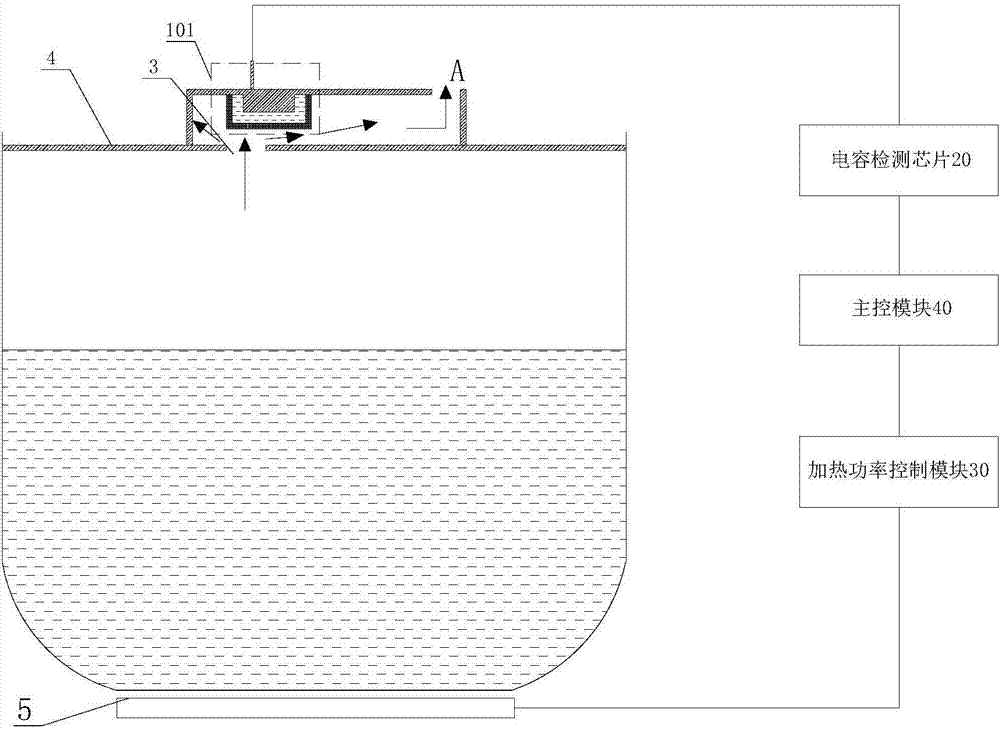

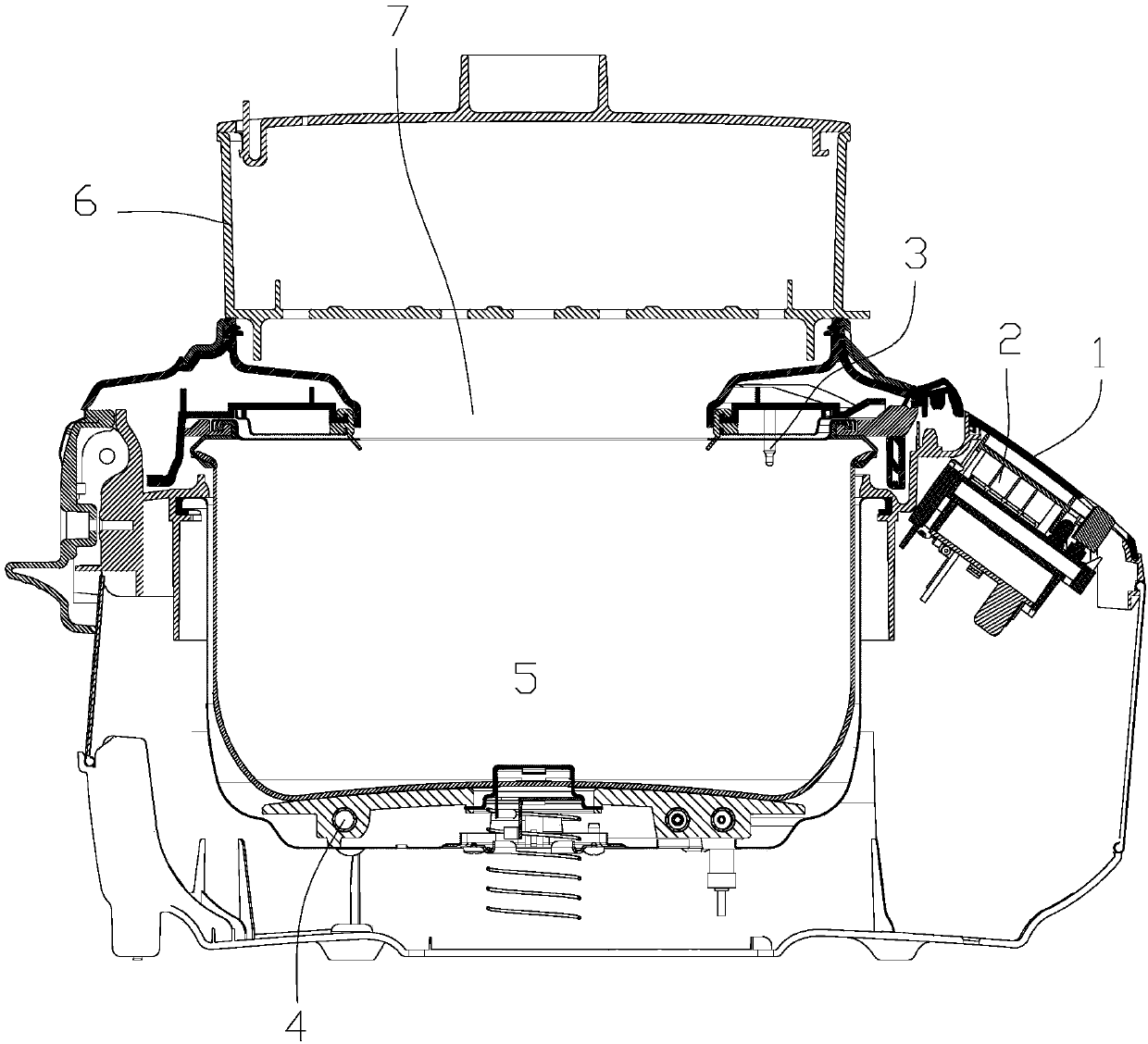

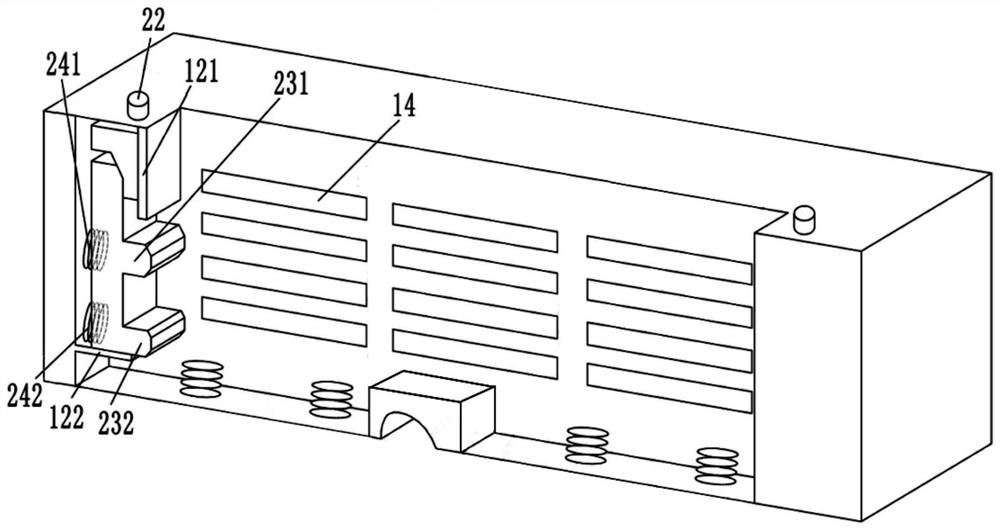

Electric cooker and heating control system and control method thereof

The invention discloses an electric cooker and a heating control system and control method thereof. The system comprises a foam detection module, a capacitance detection chip, a heating power controlmodule and a main control chip; the foam detection module is arranged in an upper cover of the electric cooker and comprises at least one foam sensing component, wherein the capacitance value of the foam detection module changes when each foam sensing component senses steam foam generated by the electric cooker; the capacitance detection chip is connected with the foam detection module and generates a foam detection signal by detecting the change condition of the capacitance value of the foam detection module; the heating power control module is used for controlling the heating power of the electric cooker; the main control module is connected with the capacitance detection chip and the heating power control module separately and used for controlling the electric cooker to stop heating orreduce the power for heating through the heating power control module when the capacitance value change of the foam detection module is determined according to the foam detection signal, so that an overflow phenomenon is prevented from occurring on the electric cooker, full boiling is ensured, and the non-electric contact detection of the foam is achieved.

Owner:FOSHAN SHUNDE MIDEA ELECTRICAL HEATING APPLIANCES MFG CO LTD

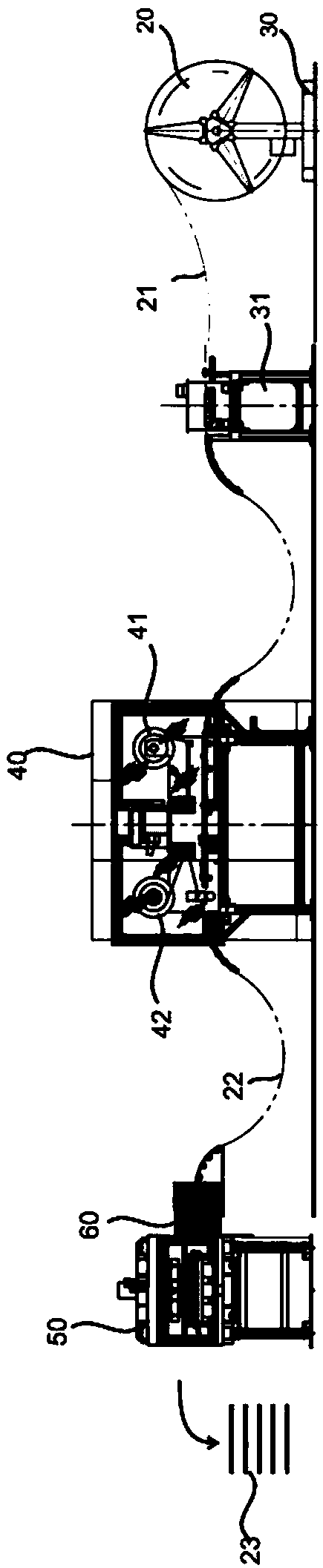

Production system and method for producing motor vehicle number plate blanks

InactiveCN107567400ASo as not to damageIncrease the number of strokesLamination ancillary operationsLayered product treatmentMetal stripsEngineering

The invention relates to a production system (10) and a method for producing a plurality of motor vehicle number plate blanks (23) within said production system (10), wherein the motor vehicle numberplate blanks (23) are produced from a metal strip (21; 22) guided continuously through the production system (10), wherein the metal strip (21; 22) is fed by at least one drive (60) to at least one laminator (40) and at least one press device (50). The laminator (40) applies a film to the metal strip (21) while the press device (50) compression-forms the metal strip (22) that is provided with thefilm and separates individual motor vehicle number plate blanks (23). According to invention, the at least one drive (60) is designed as a contactless feed which moves the metal strip (21; 22) in a contactless manner. Said contactless feed is arranged directly in front of the press device (50) and is designed to inductively warm the metal strip (21; 22) while the metal strip is moving (21; 22).

Owner:ERICH UTSCH

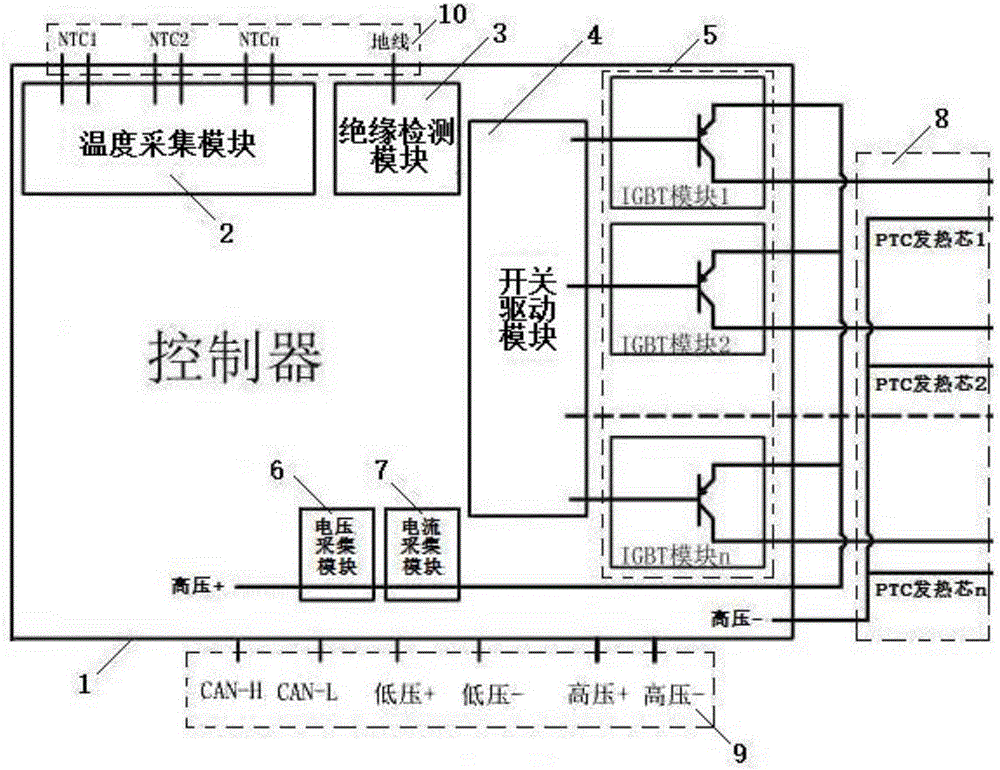

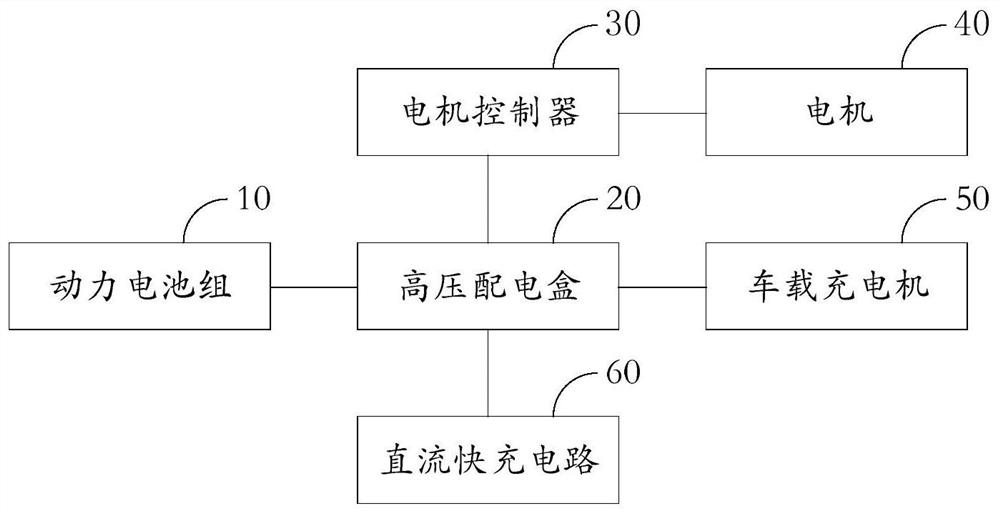

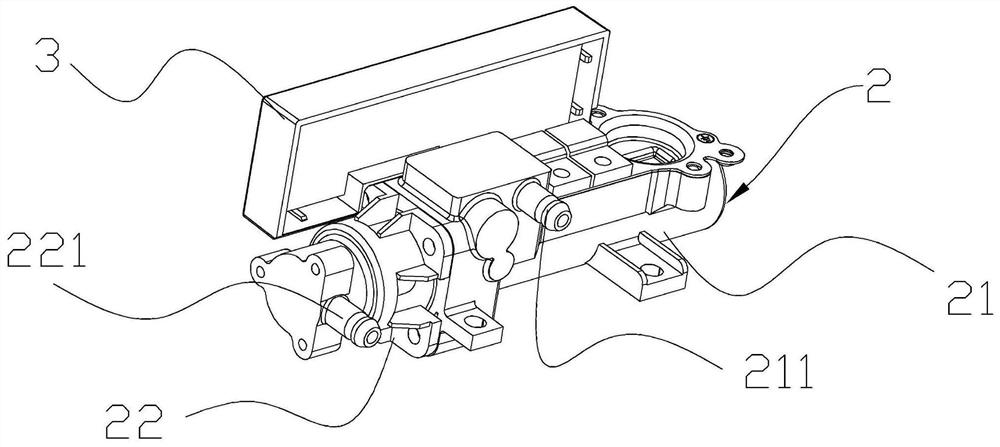

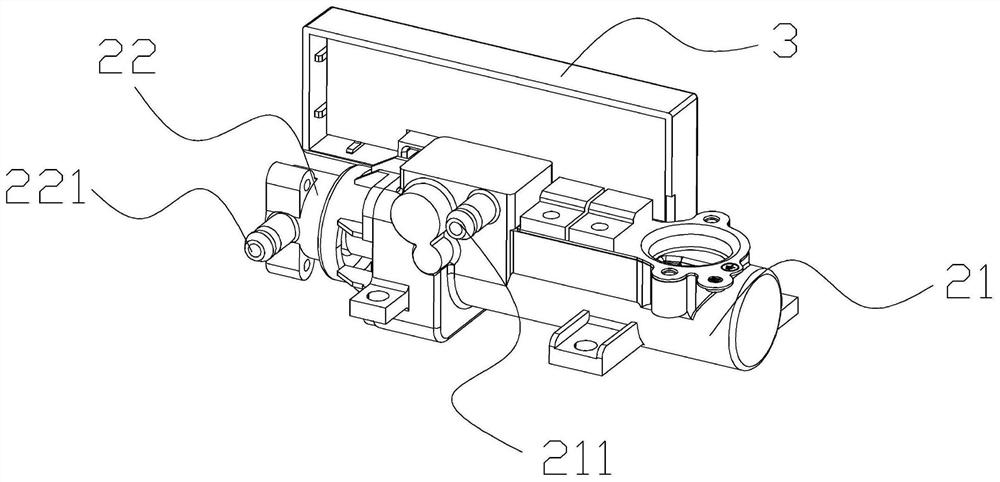

PTC heater for novel electric car, and integrated control system

InactiveCN106252789AExtended service lifeEliminate potential safety hazardsProgramme controlComputer controlElectrical batteryElectric cars

The present invention discloses a PTC heater for a novel electric car, and an integrated control system. The PTC heater comprises a heater body and a radiator. The heater body is disposed inside a shell of the heater. The shell of the heater is provided with at least one a temperature sensor and a ground line, wherein N is a natural number greater than 2. According to the radiator, the heater body is provided with a fluid vessel, wherein the fluid vessel is provided with a fluid inlet and a fluid outlet; or the radiator is array heat sinks disposed on the heater body. The control system comprises a controller, a temperature collection module, an insulation detection module, a switch drive module, a voltage collection module, a current collection module, and a control and power supply wiring terminal. The controller is connected with the temperature collection module. The temperature collection module is connected with a temperature detection wiring terminal. The switch drive module is connected with a switch device. The switch device is connected with the heater body. The PTC heater has the advantages of providing a hot air source, sharing a piece or a device with a battery heat dissipation system, being efficient and saving energy. The whole system is stable, is highly integrated, is convenient to use, and is easy to maintain.

Owner:SHENZHEN SHARING ELECTRONICS

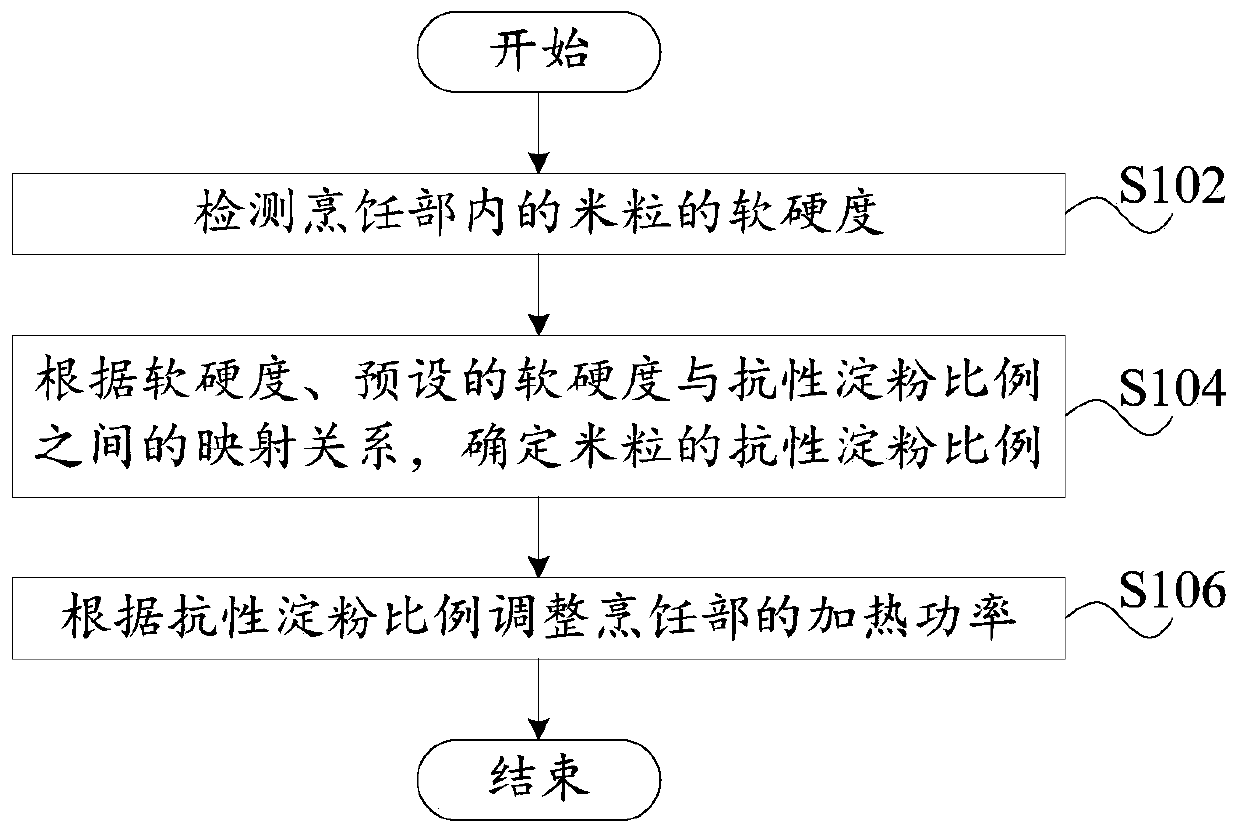

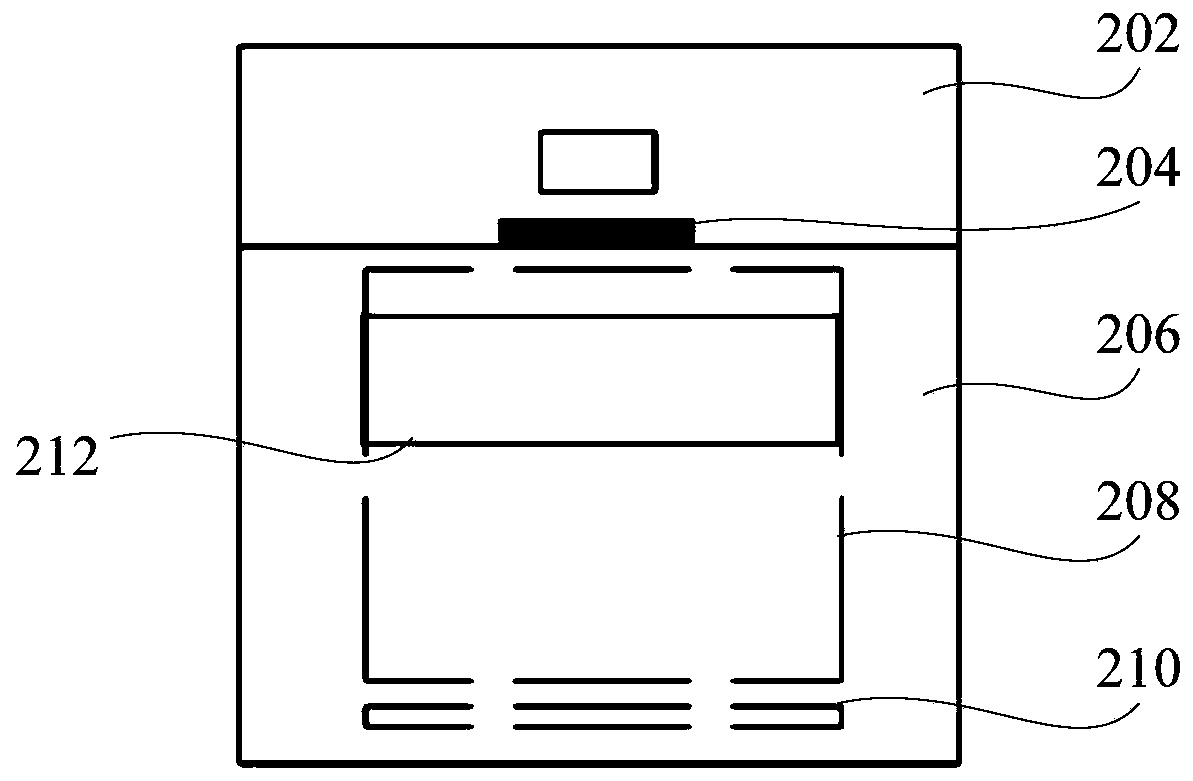

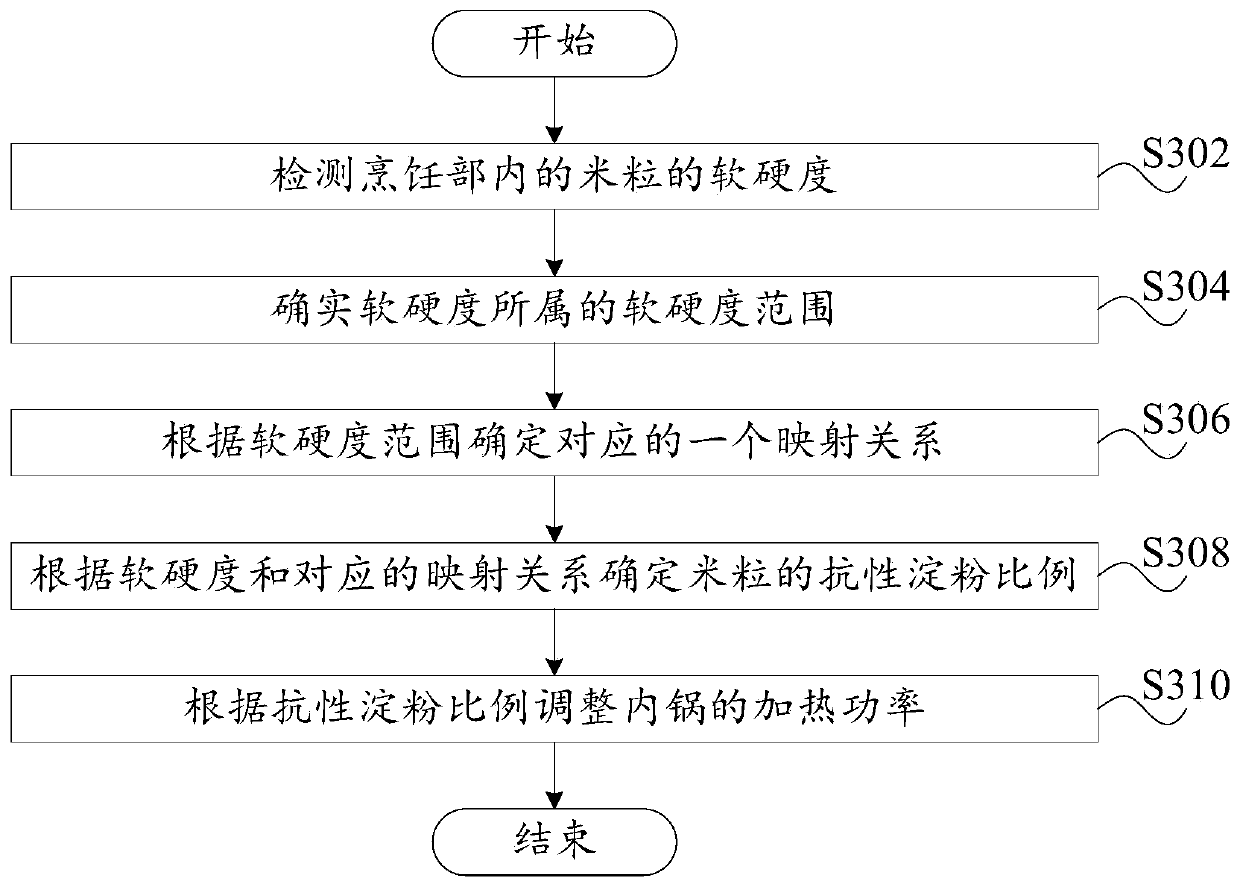

Cooker, control method and device thereof and readable storage medium

ActiveCN110658775AFlexible adjustment of boiling timesFlexible adjustment of boiling timeProgramme controlComputer controlResistant starchRice dishes

The invention provides a cooker, a control method and device thereof and a readable storage medium. The cooker is provided with a cooking part used for containing rice grains, and a hardness detectionassembly is arranged in the cooking part, and configured to detecting the hardness of the rice grains. The control method of the cooker comprises the steps detecting the hardness of the rice grains in the cooking part; determining the proportion of resistant starch in the rice grains according to the mapping relationship among the hardness, the preset hardness and the resistant starch proportion;and adjusting the heating power of the cooking part according to the resistant starch proportion. According to the control method of the cooker, the content of the resistant starch in staple food canbe fed back by detecting the hardness of the rice according to the relationship between the hardness of the rice grains and the content of the resistant starch, so that the low-sugar effect of the rice is reflected, a user can know the low-sugar effect of the cooked staple food, and the illness risk of hyperglycemia can be relieved.

Owner:FOSHAN SHUNDE MIDEA ELECTRICAL HEATING APPLIANCES MFG CO LTD

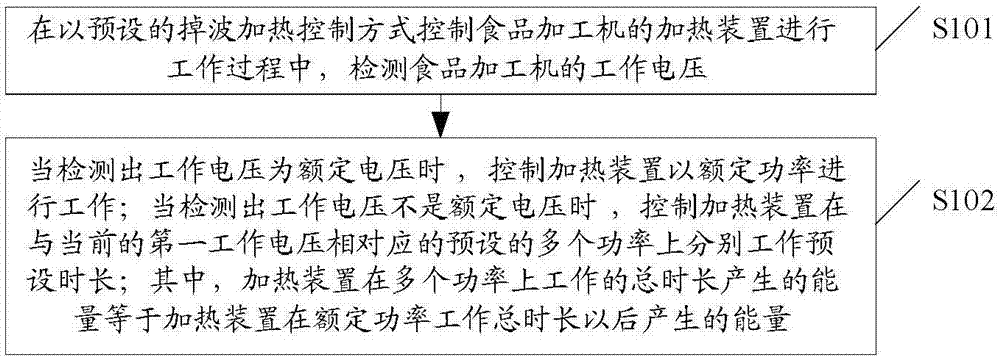

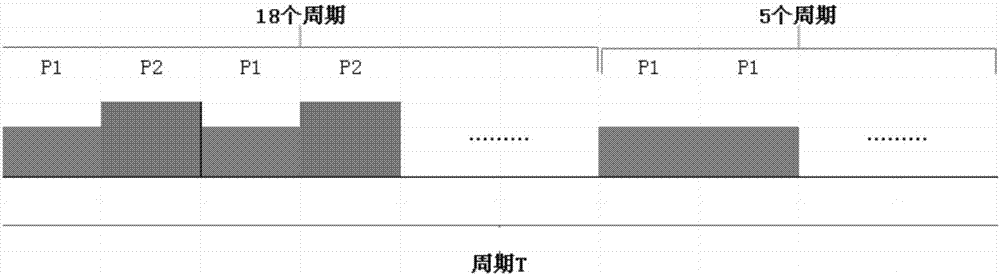

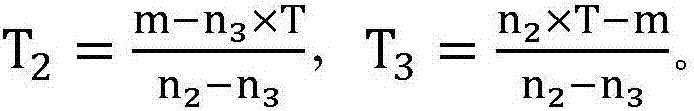

Power control method for food processor

ActiveCN107544581AAdjust heating powerGuaranteed stabilityTemperatue controlCooking vesselsVoltage variationVoltage range

The embodiment of the invention discloses a power control method for a food processor. The method includes the steps that when a heating device of the food processor is controlled to work in the preset mode of wave-drop heating, the working voltage of the food processor is detected; when the detected working voltage is rated voltage, the heating device is controlled to work at rated power P; whenthe detected working voltage is not the rated voltage, the heating device is controlled to work for preset time length at multiple kinds of preset power corresponding to current first working voltage,wherein energy generated when the heating device works at the power by total time length is equal to that generated after the heating device works at the rated power P by the total time length. In the scheme of the power control method, the heating power of the heating device is accurately and reliably adjusted according to voltage changes within the full-voltage range.

Owner:JOYOUNG CO LTD

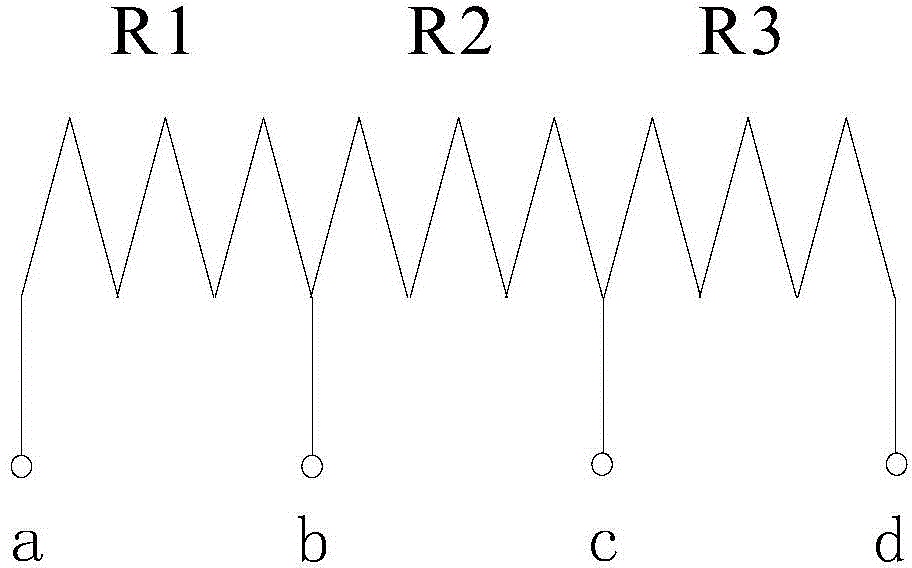

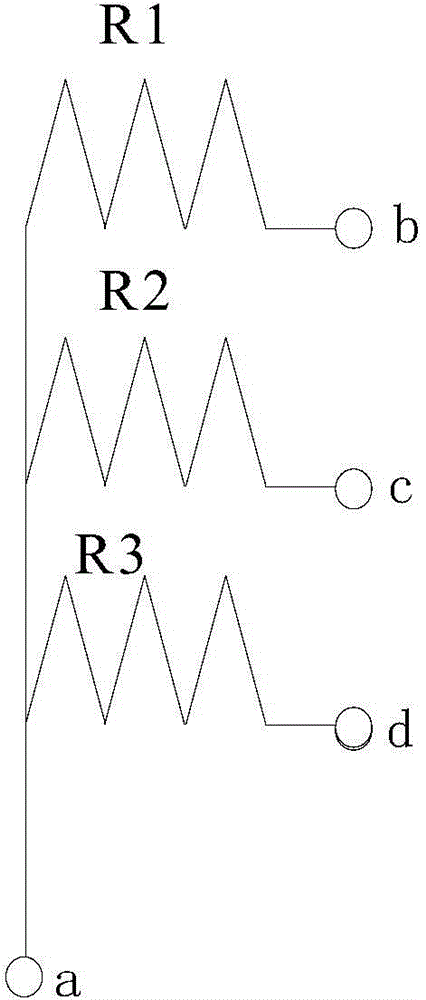

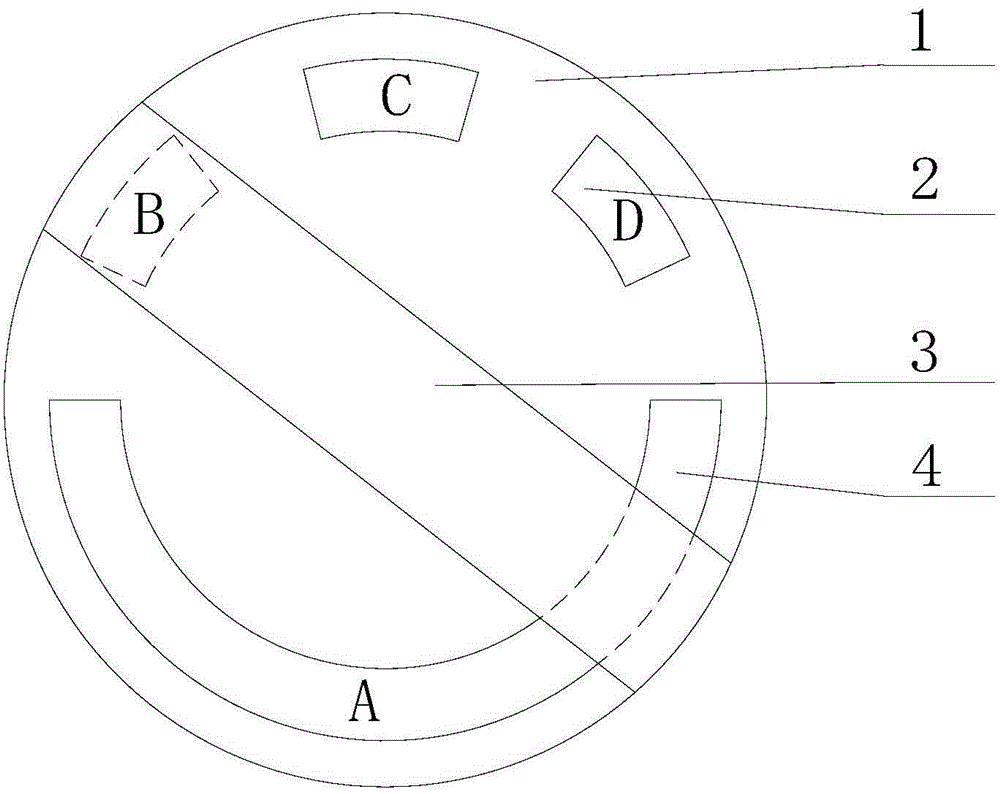

Method for realizing multiple resistance values of electronic cigarette atomizing heating wires and arrangement structure

PendingCN106333387ARealize random combinationResistance adjustmentTobacco devicesOhmic-resistance heating detailsMulti valuedResistance wire

The invention relates to a method for realizing multiple resistance values of electronic cigarette atomizing heating wires. Multiple groups of heating resistance wires are jointly arranged in an atomizing chamber of an electronic cigarette atomizing core; each group of heating resistance wire is provided with a connecting lead to lead out of the atomizing chamber; and different groups of heating resistance wires are in combined connection outside the atomizing chamber to generate resistance wire combination with different resistance values, and different power combination can be generated after electrification. According to the atomizing wire multi-value-resistance arrangement structure using the above method, multiple groups of heating resistance wires are arranged in the atomizing chamber of the electronic cigarette atomizing core, and each group of heating resistance wire is provided with the connecting lead to lead out of the atomizing chamber; a resistance value adjusting device is arranged outside the atomizing chamber and is directly connected with the connecting leads which are led out by the heating resistance wires in the atomizing chamber; and the adjusting device sets up various different connecting modes for leading out the connecting leads.

Owner:INNOKIN TECH

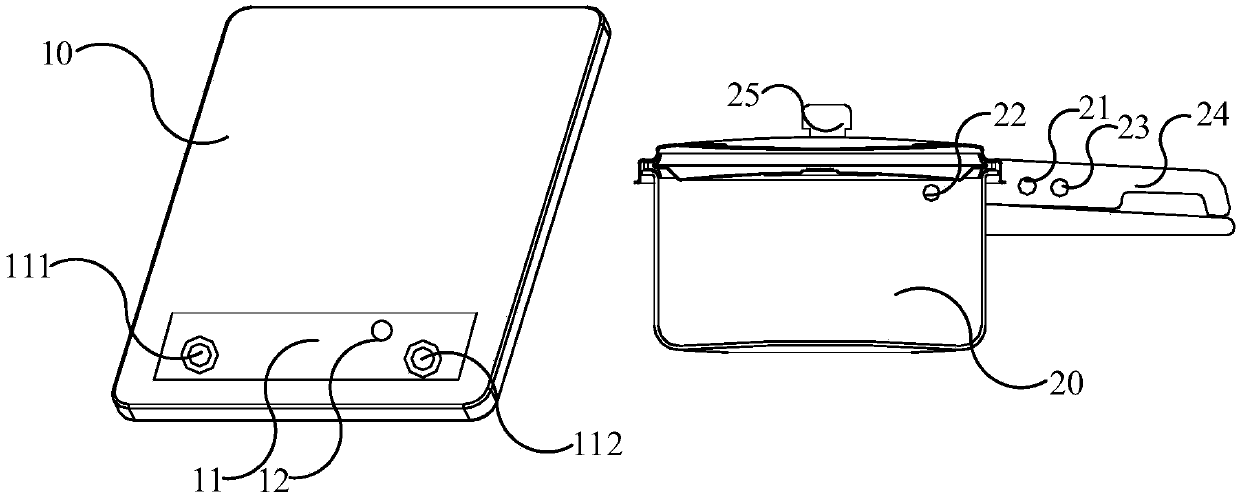

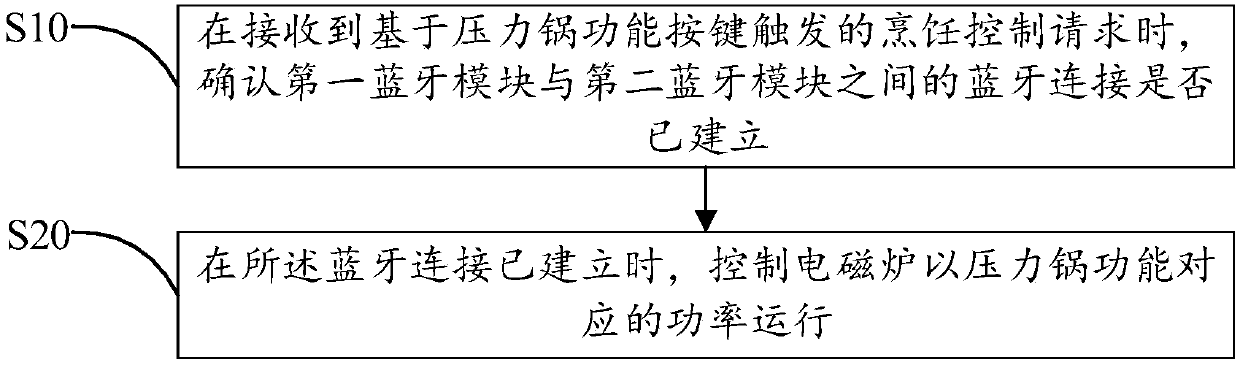

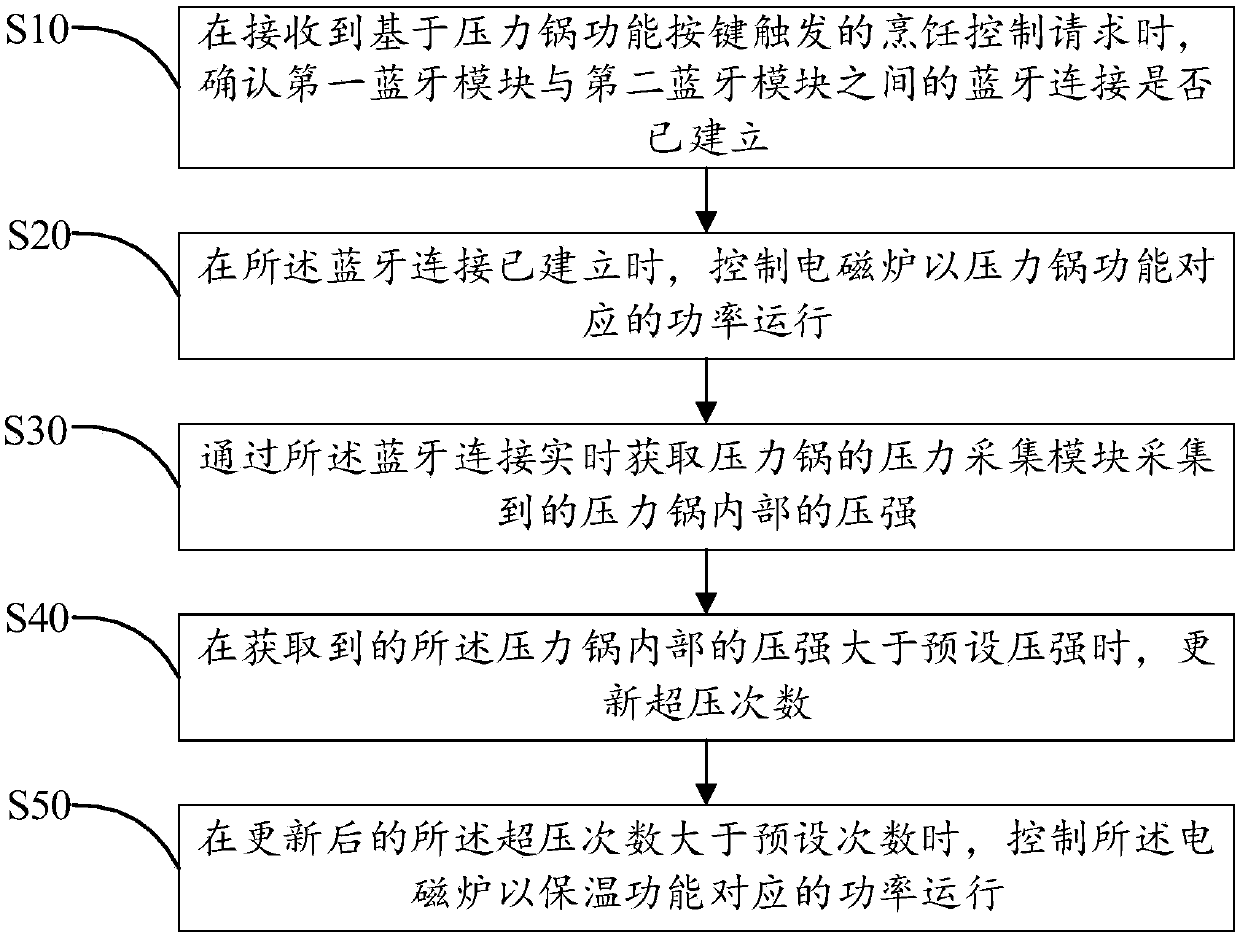

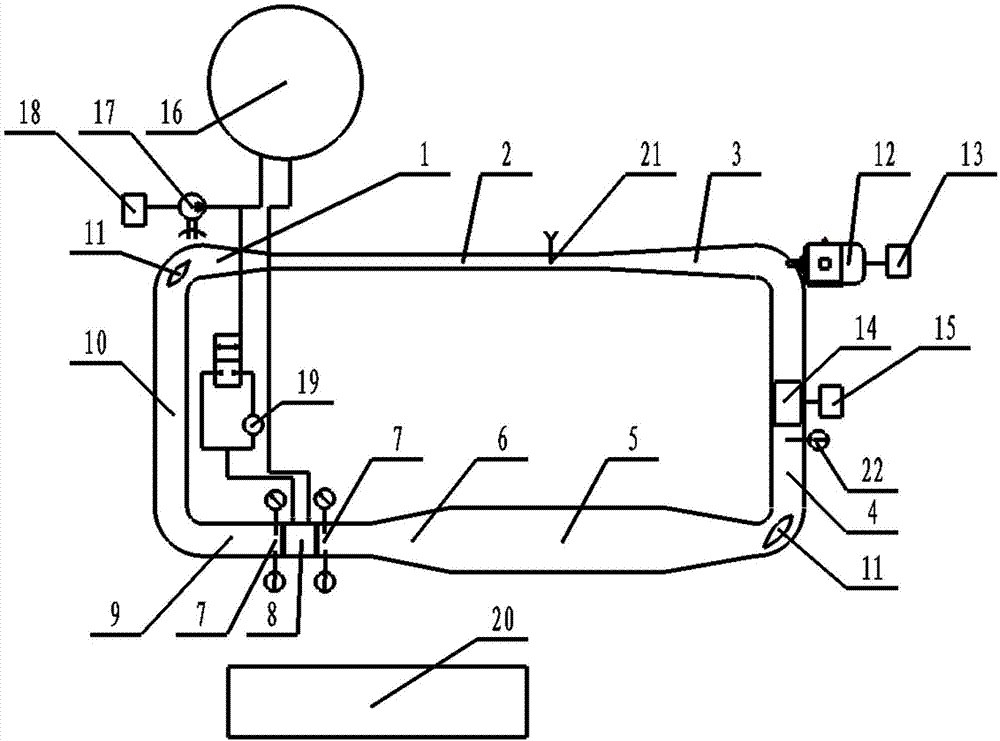

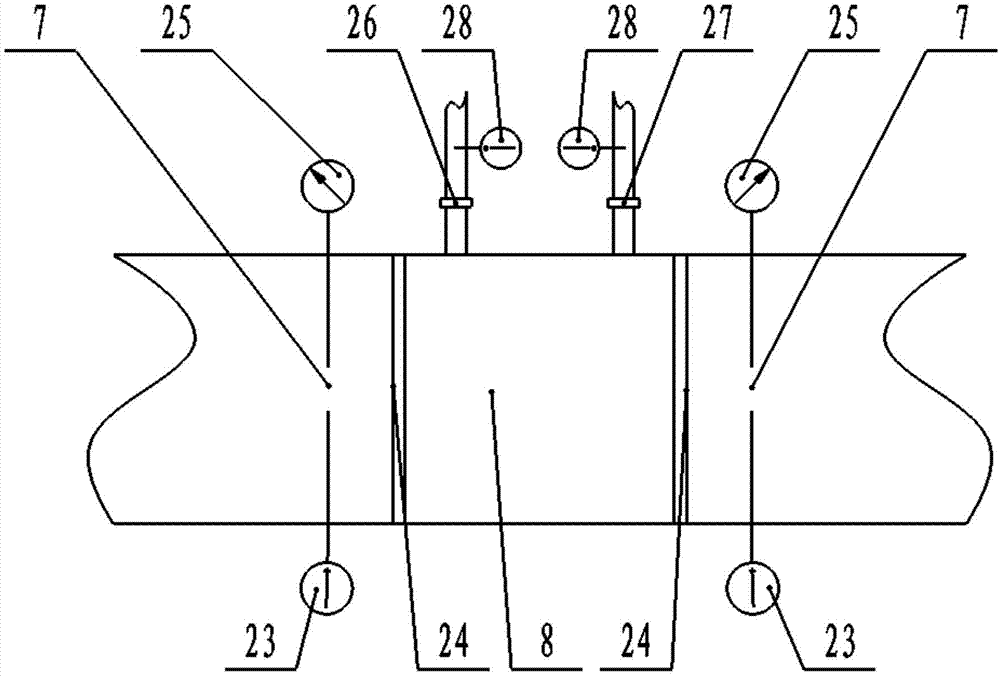

Cooking system and cooking control method and device

PendingCN109691878AAdjust heating powerImprove efficiencyBoiling over preventionPressure-cookersEngineeringCooker

The invention discloses a cooking system which comprises an induction cooker and a pressure cooker matched with the induction cooker. The induction cooker is provided with a control panel and a firstBluetooth module. The control panel is provided with induction cooker function keys and pressure cooker function keys. The pressure cooker is provided with a second Bluetooth module in communication connection with the first Bluetooth module and a pressure acquisition module in communication connection with the second Bluetooth module. The invention further discloses a cooking control method and device. According to the invention, the function of the pressure cooker can be realized through the pressure cooker used in cooperation with the induction cooker, then the induction cooker can be usedfor cooking rice or soup through the pressure cooker, bottom burning or soup cooking will not be caused, and the using efficiency of the induction cooker is improved.

Owner:FOSHAN SHUNDE MIDEA ELECTRICAL HEATING APPLIANCES MFG CO LTD

Intro-motor fluid and heat exchange coefficient testing device

InactiveCN104198201AQuality assuranceEasy to installStructural/machines measurementAutomatic controlData acquisition

The invention relates to an intro-motor fluid and heat exchange coefficient testing device. Different cooler models are installed at a testing section of a backflow type wind tunnel, heating energy is rightly taken away by cooling water under different wind speed and water speed due to adjustment of the heating power of a heater and in and out water flow of a cylindrical container, and measured physical variables are collected when thermal stability is achieved. Research of the heat dissipation performance and wind resistance performance of testing coolers are achieved due to processing of numerical values of the measured physical variables. The intro-motor fluid and heat exchange coefficient testing device which really and reliably stimulates the cooler operation environment in a motor has the advantages of having functions of automatic control, automatic data collection, automatic data processing, real-time monitoring and the like, being advanced in testing mean and accurate in testing data, designing and selecting a most suitable cooler for the motor, providing accurate testing data, providing guarantee for safe and reliable operation of the motor and being applicable to performance tests of gas coolers.

Owner:HARBIN ELECTRIC MASCH CO LTD

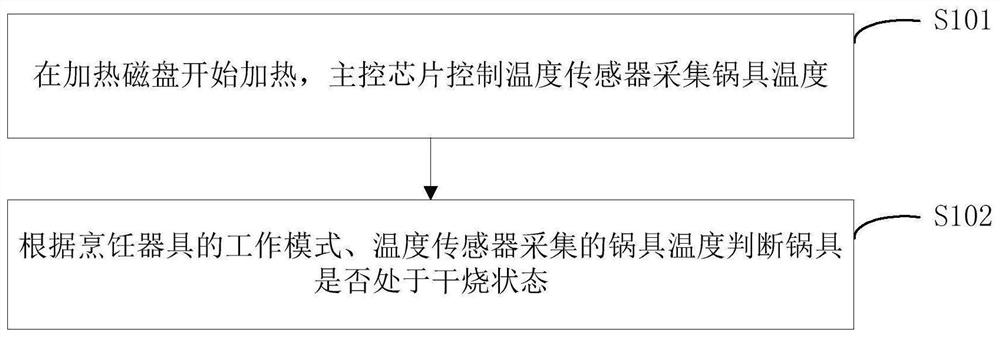

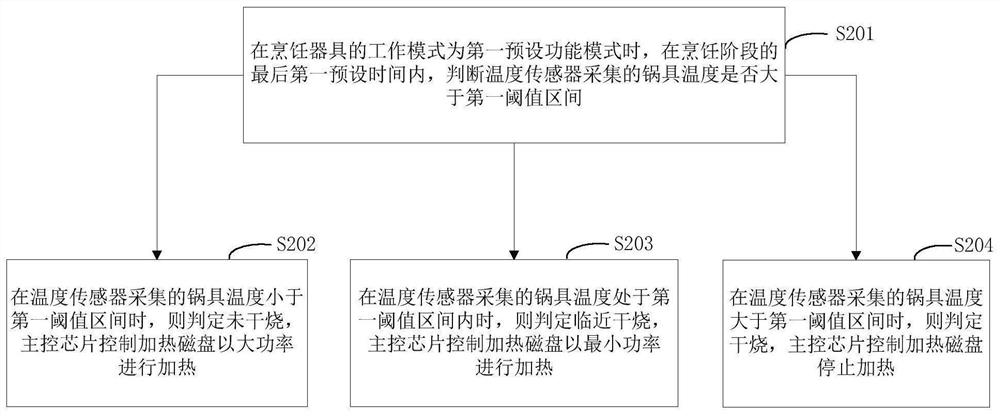

Anti-dry-burning detection method of cooking utensil and cooking utensil

ActiveCN113133636APrevention of dry burningActual reaction temperatureCooking vessel constructionsProcess engineeringFood science

The invention discloses an anti-dry-burning detection method of a cooking utensil and the cooking utensil. The method comprises the steps: enabling a main control chip to control a temperature sensor to collect the temperature of a pot when a heating magnetic disk starts to heat; judging whether the pot is in a dry burning state or not according to the working mode of the cooking utensil and the pot temperature collected by the temperature sensor, wherein the working mode comprises a hot oil stage and a cooking stage, and the method comprises the step of judging whether the pot is in a dry burning state or not in the hot oil stage and the cooking stage. According to the anti-dry-burning detection method of the cooking utensil and the cooking utensil disclosed by the invention, the actual temperature of the pot can be quickly reflected, and the pot of the cooking utensil is prevented from being dry-burnt.

Owner:JOYOUNG CO LTD

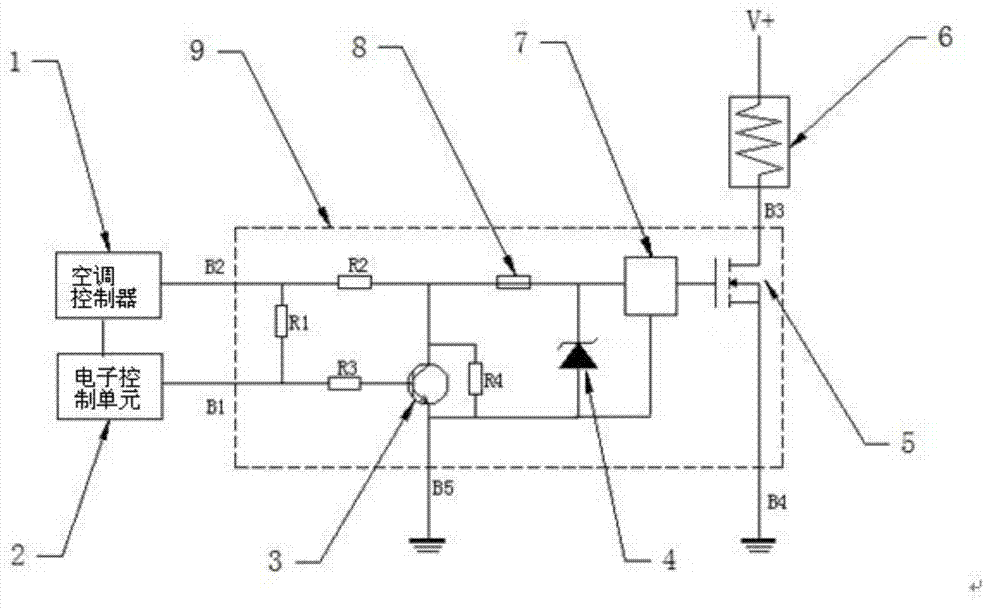

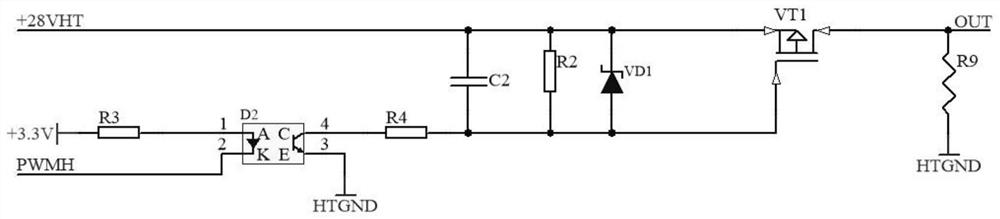

Positive temperature coefficient (PTC) heater driving module for electric automobile air conditioner

The invention discloses a positive temperature coefficient (PTC) heater driving module for an electric automobile air conditioner. The PTC heater driving module comprises a PTC driving module, wherein one end of a pin B2 of the PTC driving module is connected with an air conditioner controller, and the other end of the pin B2 is connected with resistors R1 and R2; one end of a pin B1 is connected with an electronic control unit and the other end of the pin B1 is connected with resistors R1 and R3; the other end of the resistor R3 is connected with a base of a triode; the other end of the resistor R2 is connected with a collector of the triode, a resistor R4 and a fuse; the other end of the fuse is connected with a negative electrode of a diode and the input end of a power field effect tube driving integrated circuit; the output end of the power field effect tube driving integrated circuit is connected with a gate of a power field effect tube; an emitter of the triode, the resistor R4, a positive electrode of the diode and the ground end of the power field effect tube driving integrated circuit are grounded; a drain of the power field effect tube is connected with the PTC heater; and a source of the power field effect tube is grounded. A P-channel metal oxide semiconductor field effect transistor (P-MOSFET) replaces an electromagnetic relay, so that the PTC heater driving module is high in switching speed and does not generate impact and noise when running.

Owner:NANJING XIEZHONG AUTO AIRCONDITIONER CO CO LTD

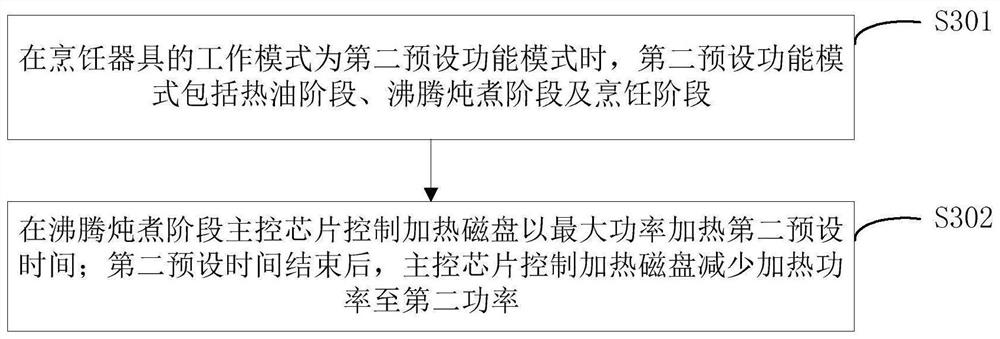

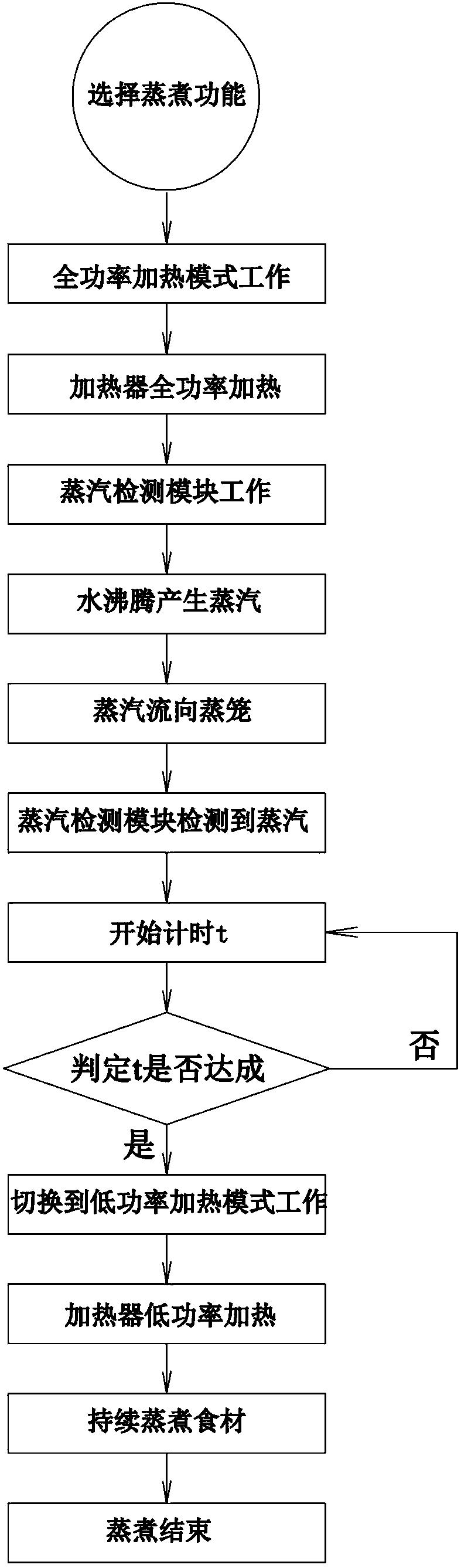

Cooking control method, cooking utensil body and cooking utensil

PendingCN110279283AAdjust heating powerProduce quicklyTemperatue controlSteam cooking vesselsHeating timeSteam cooking

The invention relates to the technical field of steam cooking, and discloses a cooking control method, a cooking utensil body and a cooking utensil. The cooking control method comprises the steps that a high-power heating mode is selected for heating; after steam generated by water boiling is detected, a first heating time t in which the high-power heating mode continues to be used for heating is started to be timed, and when the first heating time t reaches a preset value, a low-power heating mode is started to continue heating, wherein the heating power of the low-power heating mode is less than the heating power of the high-power heating mode. According to the cooking control method, the steam can be quickly generated to cook food earlier, and it is ensured that enough steam heat is provided for the food to be steamed, so that the problem of dry burning due to the fact that water in a pot is burnt dry quickly is solved.

Owner:FOSHAN SHUNDE MIDEA ELECTRICAL HEATING APPLIANCES MFG CO LTD

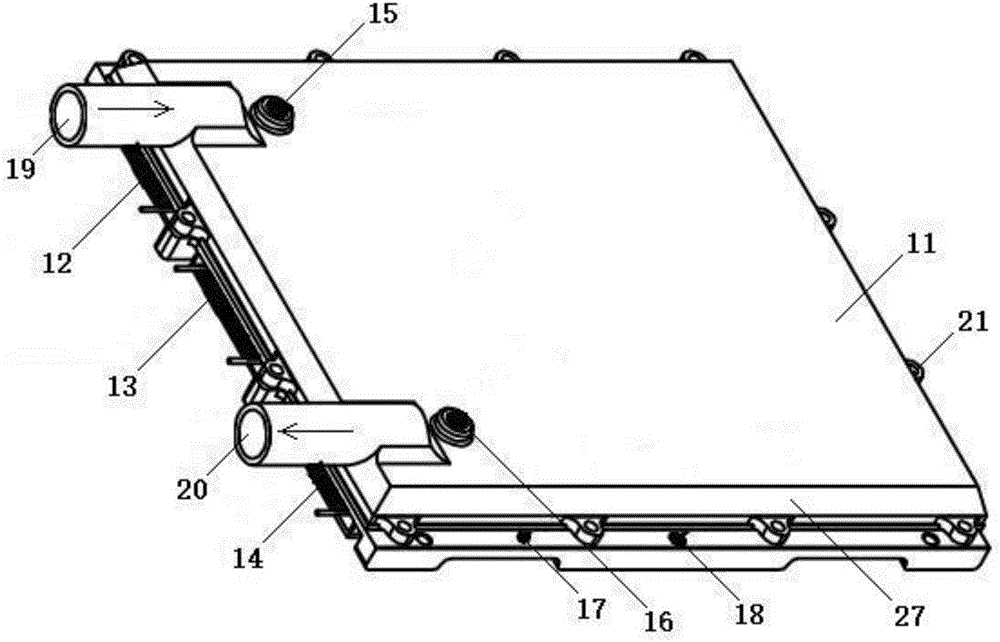

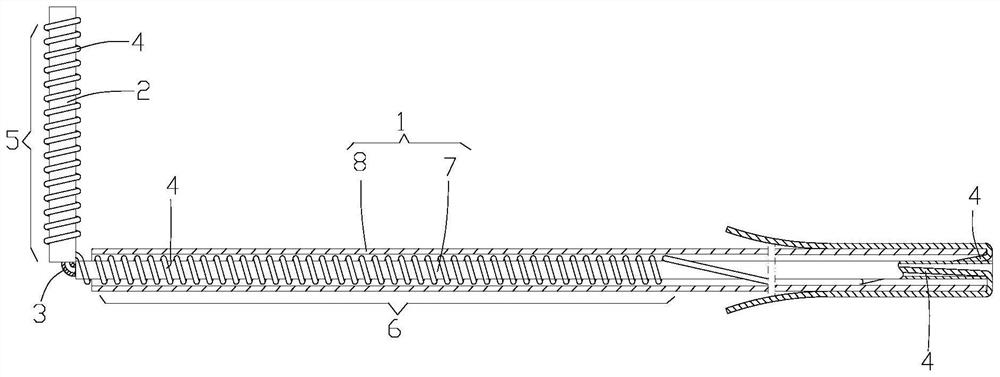

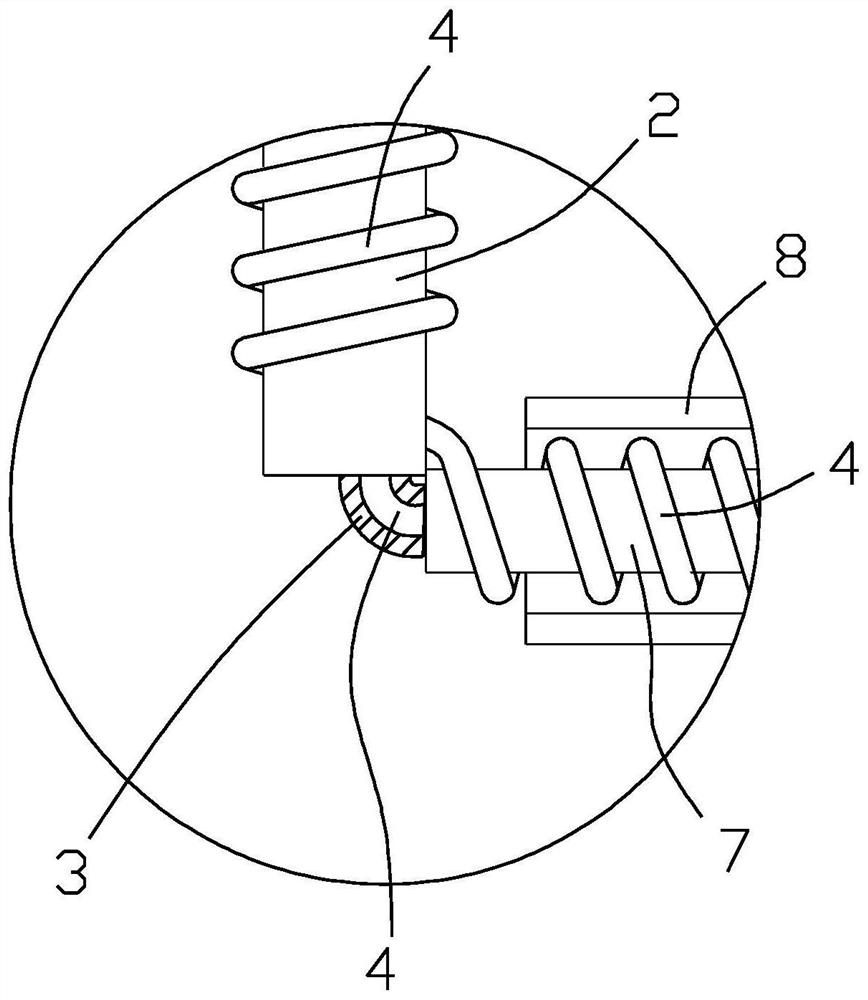

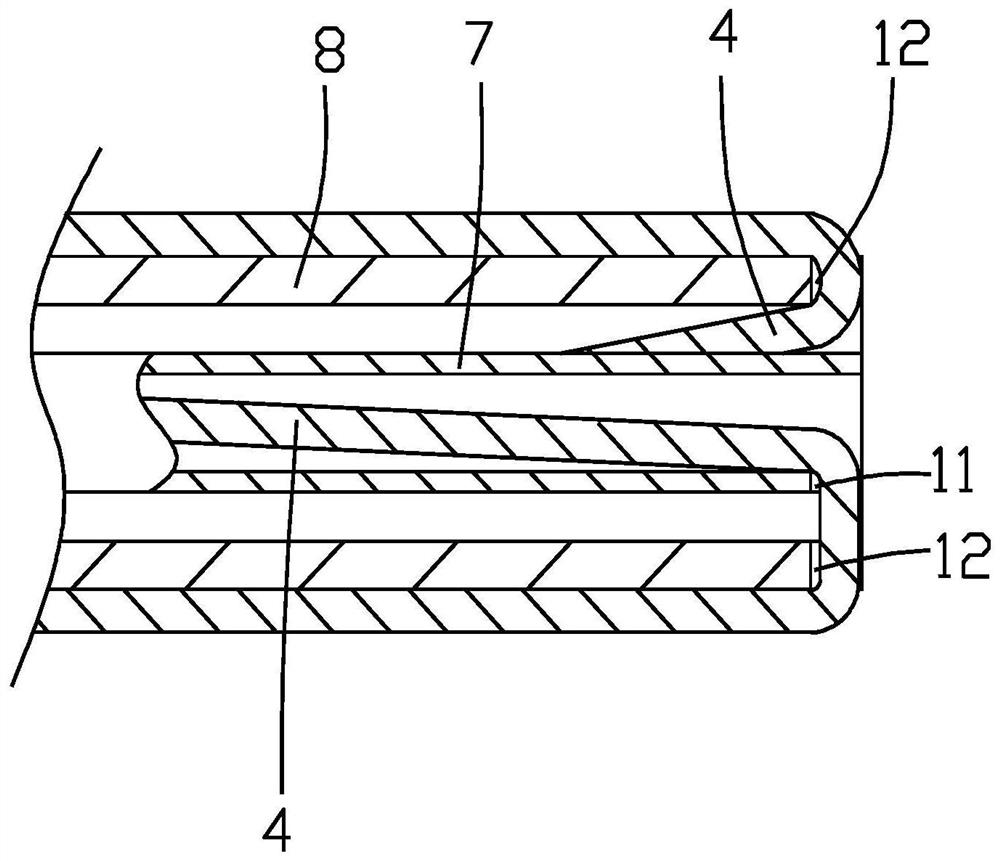

Heating adjustment device and glass thickness adjustment method

The invention relates to the technical field of heating devices, and discloses a heating adjustment device and a glass thickness adjustment method. The heating adjustment device comprises a first insulating pipe section with a first internal channel, a second insulating pipe section with a second internal channel, an insulating structure with a through channel and an electric heating wire, wherein the insulating structure is arranged between the ends, close to each other, of the first insulating pipe section and the second insulating pipe section; the electric heating wire penetrates into the first internal channel and then enters the second internal channel through the through channel; and the electric heating wire penetrates out of the second internal channel and then is spirally wound on the second insulating pipe section in a return direction at a preset screw pitch to form a second heating section, and is arranged on the first insulating pipe section in the return direction; and the insulating structure is movable to allow the second insulating pipe section to be bent to a desired angle relative to the first insulating pipe section. The heating adjusting device can provide a good and stable heating radiation range so as to provide stable and reliable heating.

Owner:WUHU TUNGHSU PHOTOELECTRIC SCI & TECHCO +2

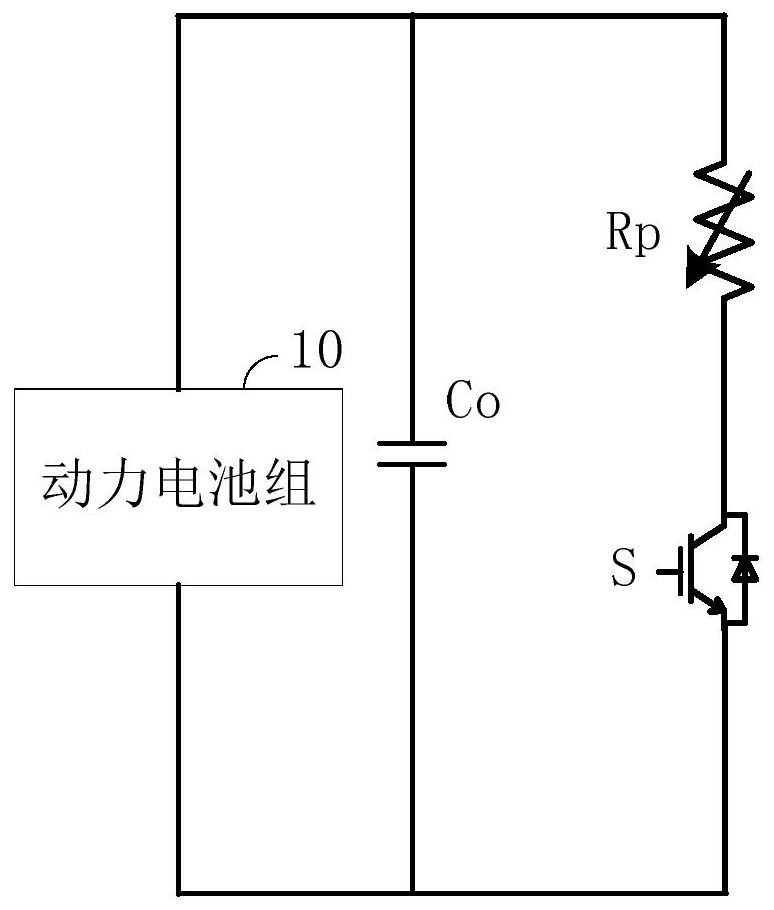

Electric driving system, power assembly, heating method and electric vehicle

ActiveCN114096435ALow costAdjust heating powerElectric energy managementBattery/fuel cell control arrangementPhase currentsSynchronous motor

The invention discloses an electric driving system, a power assembly, a heating method and an electric vehicle, and relates to the technical field of electric vehicles. The electric driving system comprises an inverter circuit, a direct current-direct current conversion circuit and a controller. The input end of the inverter circuit is connected with the input end of the electric driving system, and the output end of the inverter circuit is connected with a three-phase motor winding of the electrically excited synchronous motor; the input end of the direct current-direct current conversion circuit is connected with the input end of the electric driving system, and the output end of the direct current-direct current conversion circuit is connected with an excitation winding of the electrically excited synchronous motor; the inverter circuit converts the direct current into three-phase current and provides the three-phase current to a three-phase motor winding; the direct current-direct current conversion circuit performs direct current conversion on the direct current and then provides the direct current to the excitation winding; the controller is used for controlling the inverter circuit and the DC-DC conversion circuit, so that the temperature of the power battery pack is larger than or equal to a first temperature threshold value. According to the scheme, a heating device does not need to be arranged when the power battery pack is heated, cost is reduced, and space is saved.

Owner:HUAWEI DIGITAL POWER TECH CO LTD

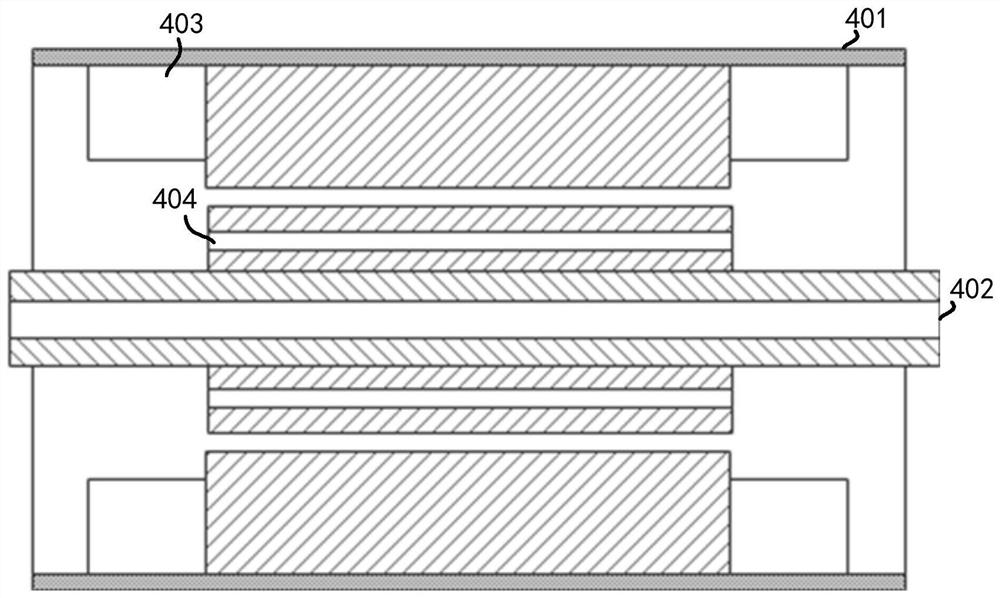

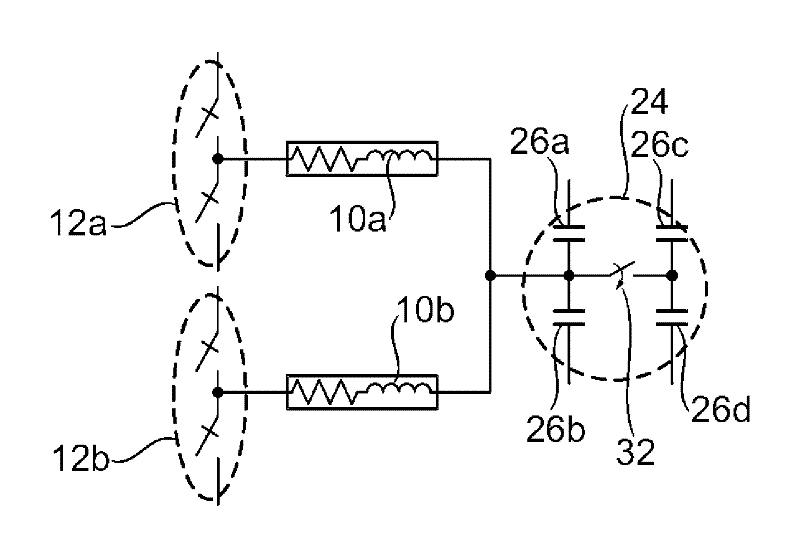

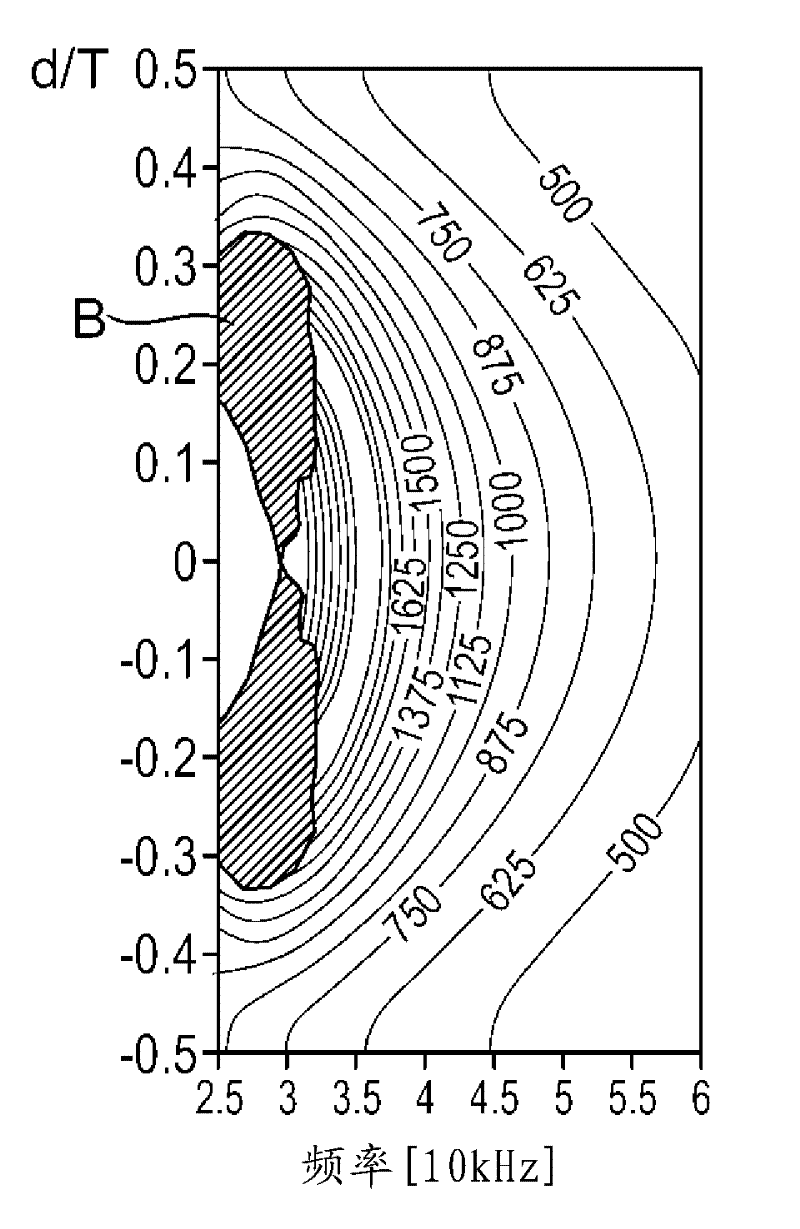

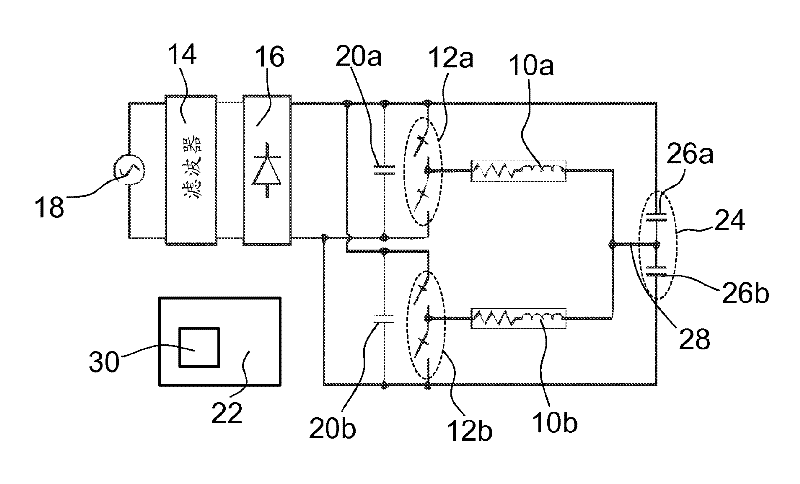

Cook top comprising at least two heating inductors

The invention relates to a cook top comprising at least two heating inductors (10a, 10b), each of which is connected to at least one resonant circuit capacitor (26a, 26b) to form a resonant circuit. In order to provide a cost-saving cook top, at least one common resonant circuit capacitor (26a, 26b) is connected to the two heating inductors (10a, 10b).

Owner:BSH BOSCH & SIEMENS HAUSGERAETE GMBH

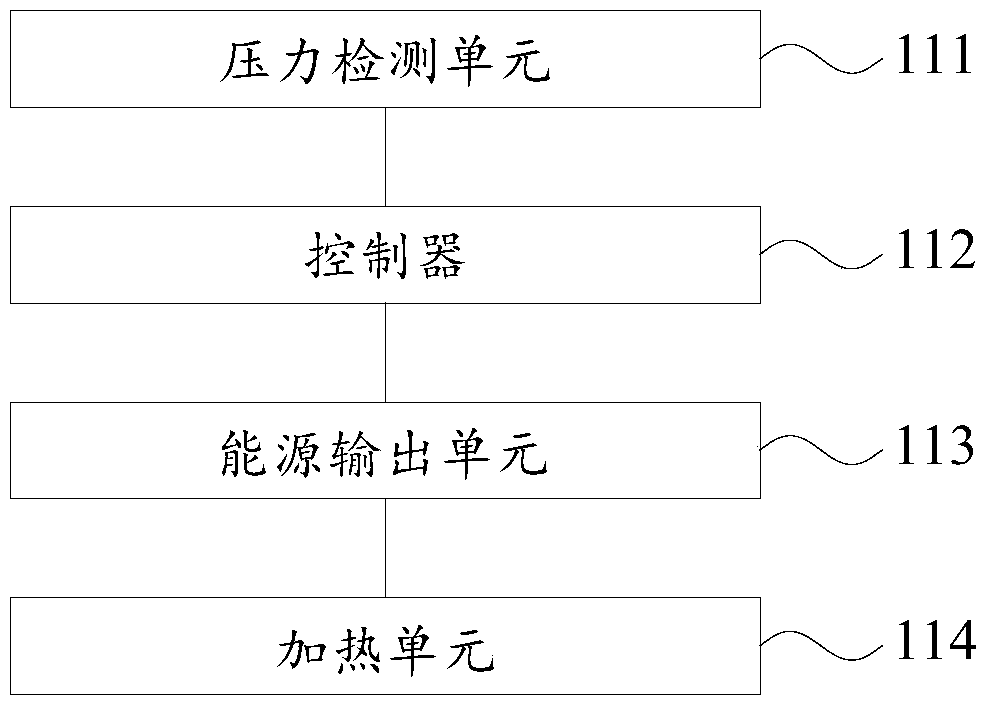

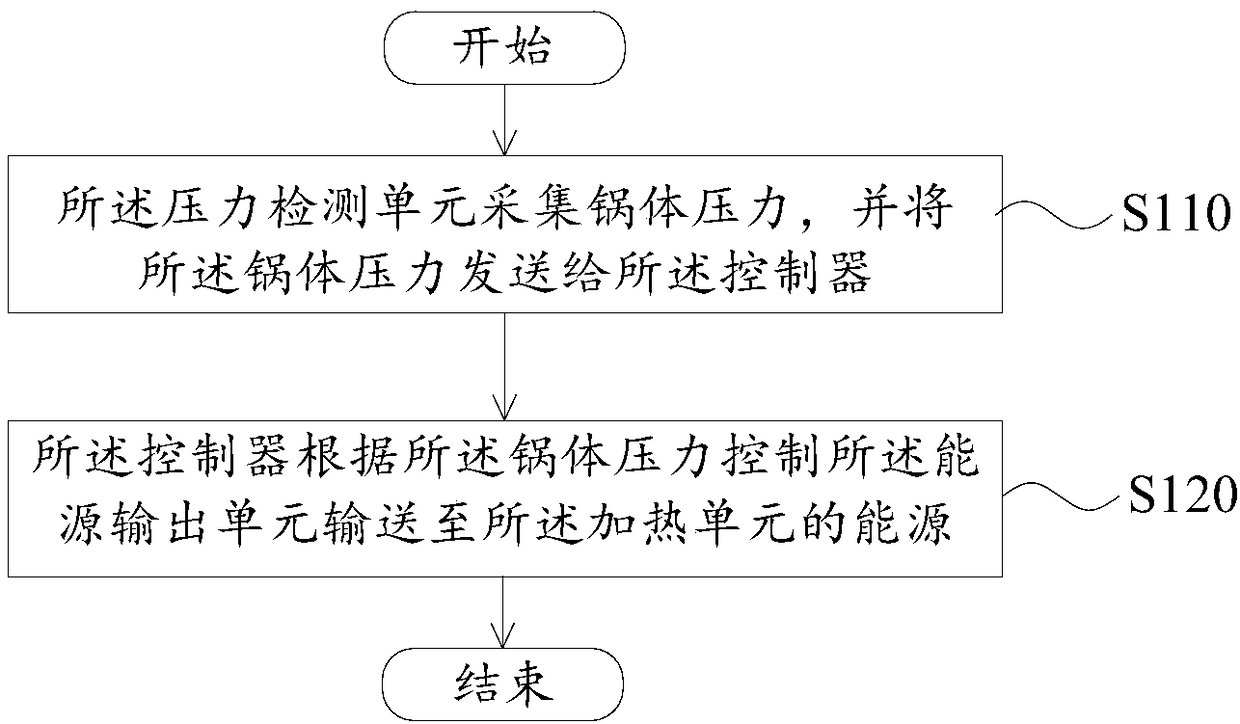

Heating power adjusting method and stove

ActiveCN109059061AAdjust heating powerAvoid frequent manual adjustmentsDomestic stoves or rangesLighting and heating apparatusAuto regulationEngineering

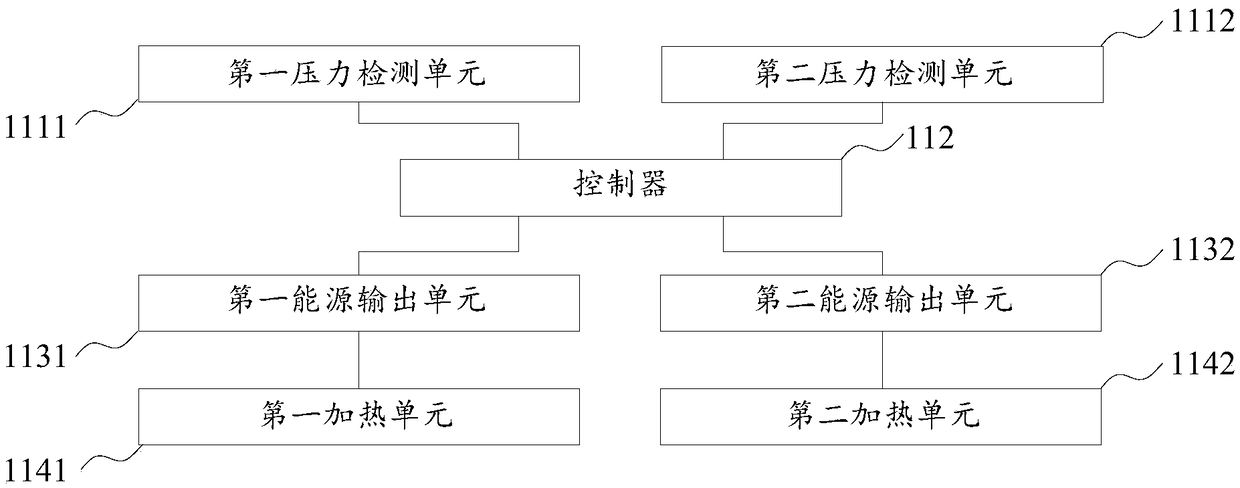

The invention discloses a heating power adjusting method and a stove. The heating power adjusting method is applied to the stove, and the stove comprises a controller, a heating unit, an energy outputunit and a pressure detection unit; the controller is connected to the energy output unit and the pressure detection unit, and the energy output unit is connected to the heating unit; the method comprises the steps that the pressure detection unit is used for acquiring the pressure of a pot body and sending the pressure of the pot body to the controller; and the controller controls the energy which is conveyed from the energy output unit to the heating unit according to the pressure of the pot body. According to the scheme of the method and the stove, the energy to the heating unit can be automatically adjusted according to the pressure of the pot body, so that the heating power of the heating unit is automatically adjusted, and manual frequent adjustment of the stove is avoided.

Owner:HAI DI LAO HLDG PTE LTD

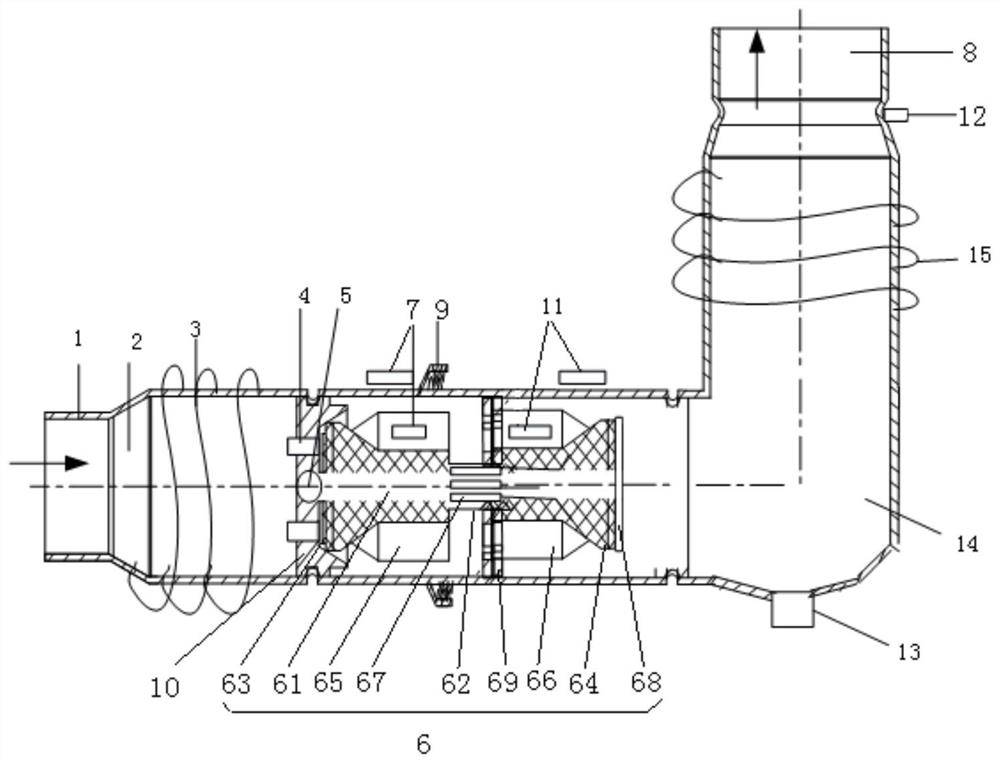

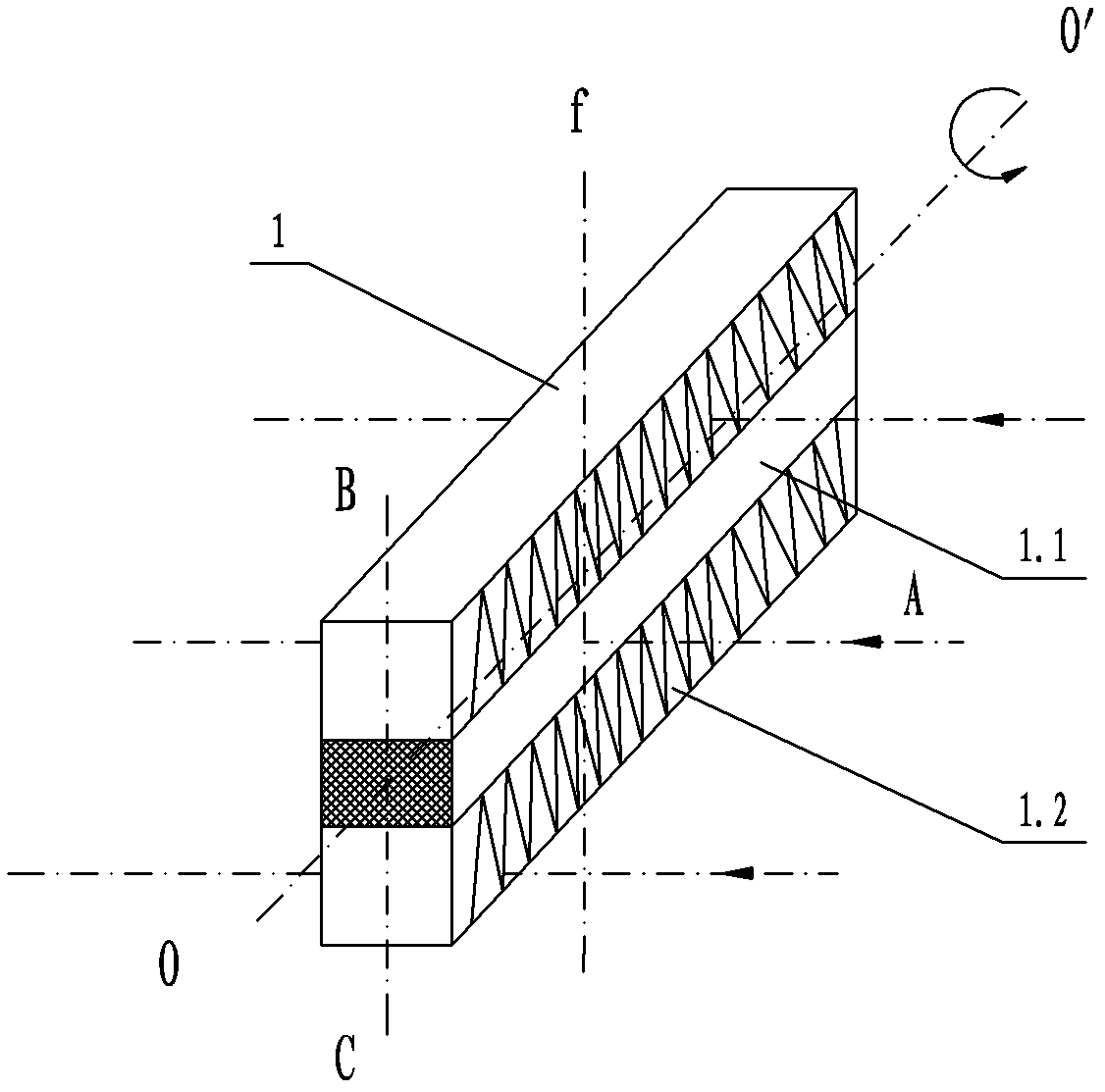

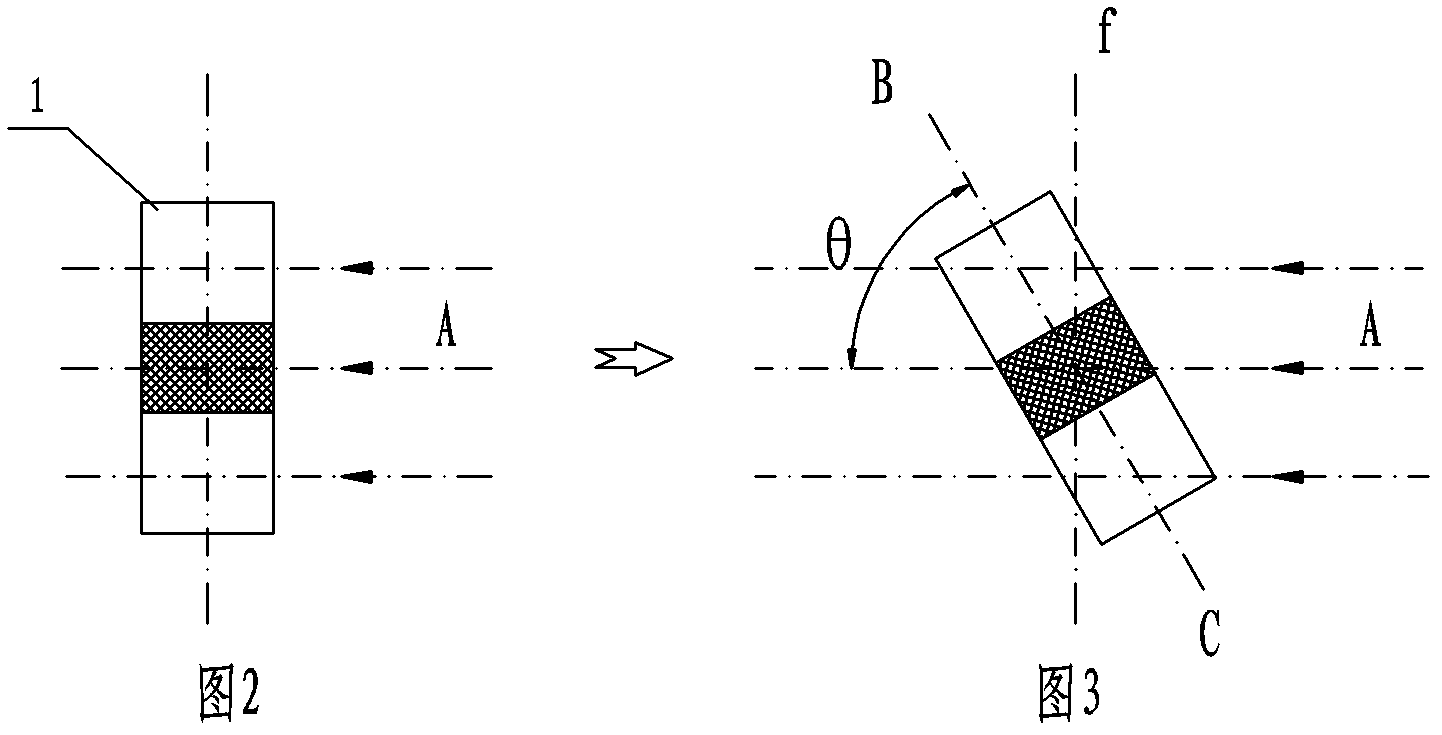

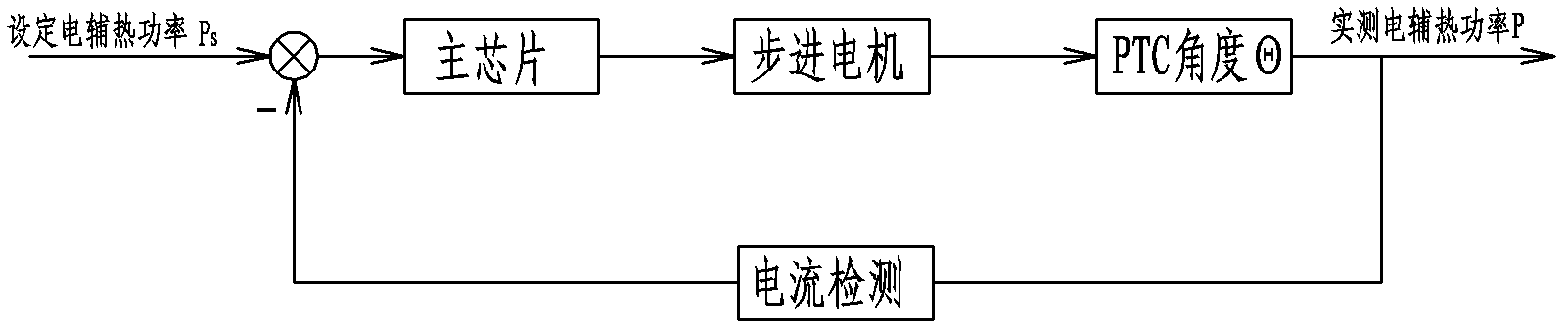

PTC heating device and control method thereof

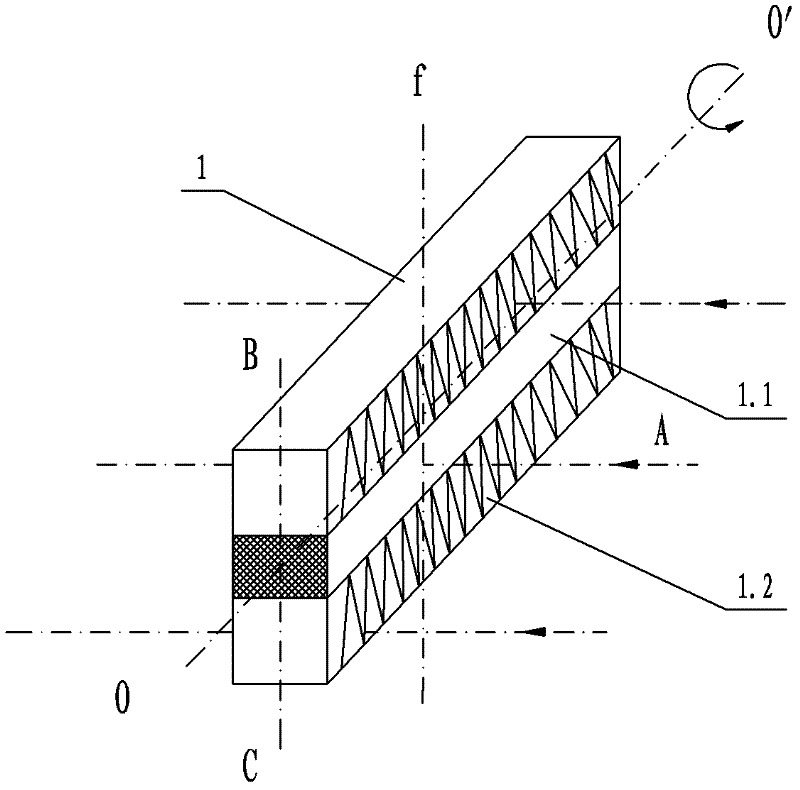

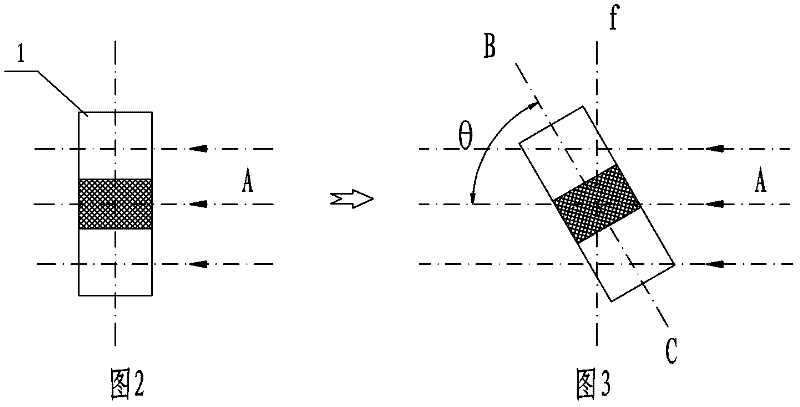

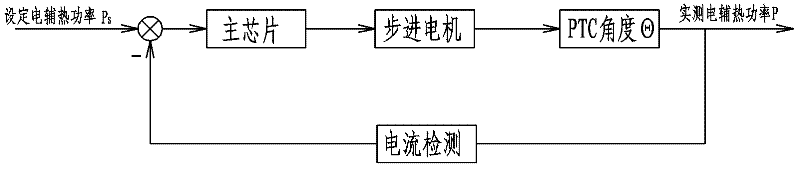

ActiveCN102548059AImprove comfortReduce power consumptionOhmic-resistance heating detailsControl using feedbackControl functionCyclic process

The invention relates to a PTC heating device and a method for controlling the PTC heating device. The PTC heating device comprises a PTC electric heater, a stepping motor, a driving mechanism, a current transformer and a main chip. The stepping motor and the driving mechanism are used for driving the PTC electric heater to rotate around the axis thereof; the current transformer is used for detecting the loop current of the PTC electric heater; and the main chip has calculating, comparing and controlling functions and is connected with the current transformer and the stepping motor in sequence. The control of the PTC heating device adopts the automatic-detection fed-back current closed-loop control. The process for controlling the PTC heating device is the automatic cycling process. The included angle of the controlled object which is the PTC heating device and the air flowing direction can be amended continuously according to the set value of the user so that the heat radiating statecan be changed and hereby the surface temperature of a PTC plate can be changed. Due to the positive temperature coefficient characteristic of the PTC heating device, the resistance of the PTC heating device can be changed, the loop current can be changed, and the hereby power can be changed. The PTC heating device has the characteristics of simple and reasonable structure and flexible operation.

Owner:MIDEA GRP CO LTD

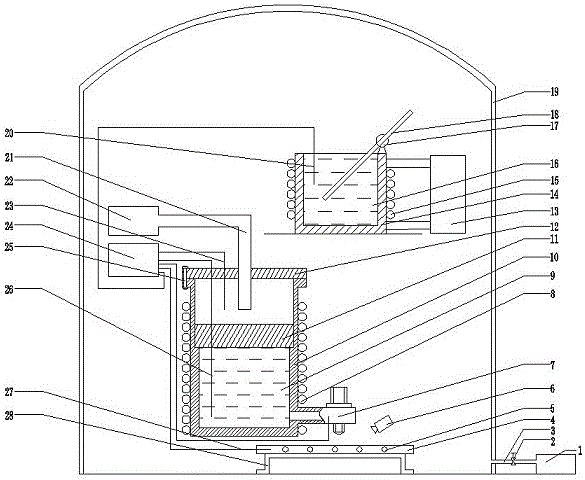

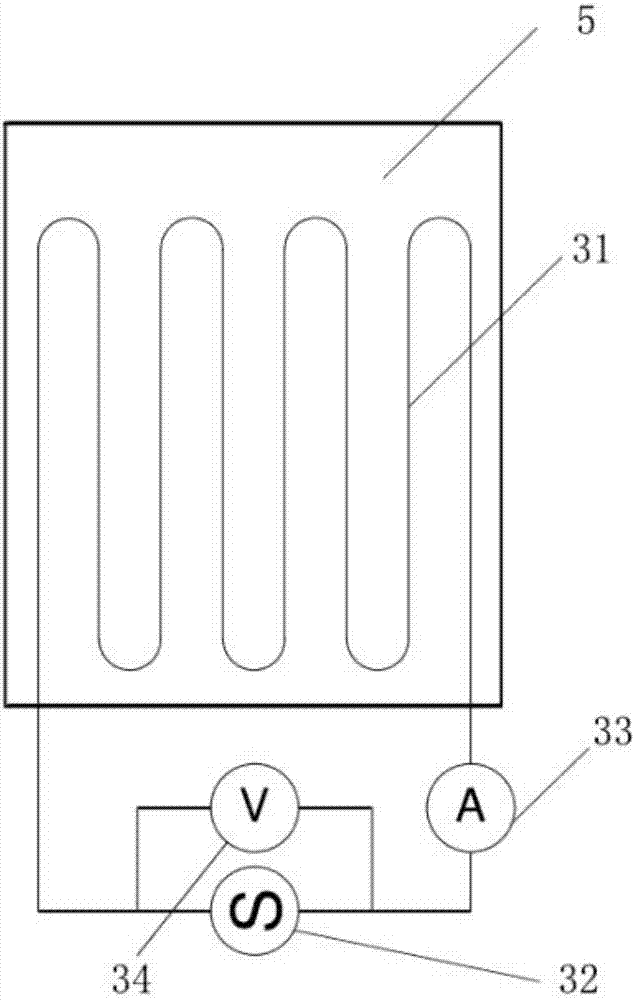

Experiment device used for measuring heat pipe heat conductivity coefficient

InactiveCN106918620AExpand the experimental power rangeIn line with the actual applicationMaterial thermal conductivityInlet valveCistern

The invention relates to an experiment device used for measuring heat pipe heat conductivity coefficient. The experiment device used for measuring heat pipe heat conductivity coefficient comprises a hot water loop I, a cool water loop II, a hot water tank 5 connected with the hot water loop I via a pipeline, and a cool water tank 10 connected with the cool water loop II via a pipeline; a hot end and a cold end of a hot pipe 7 are inserted into the hot water tank 5 and the cool water tank 10 respectively; the cool water tank 10 and the hot water tank 5 are movable, so that the horizontal distance from the cool water tank to the hot water tank can be adjusted; the hot water loop I comprises a hot water boiler 1, a heat exchanger 2, a variable frequency pump 26, and a water inlet valve 3, a flowmeter 24, and a water return valve 25 which are arranged on a pipeline communicated with the hot water tank 5; the cool water loop II comprises a refrigerating machine 14 and a variable frequency pump 16; a water inlet valve 13 is arranged on a pipeline used for communicating the outlet of the refrigerating machine 14 with the cool water tank 10; and a variable frequency pump 16, a flowmeter 18, and a water return valve 17 are arranged on a pipeline used for communicating the inlet of the refrigerating machine 14 with the bottom of the cool water tank.

Owner:TIANJIN UNIV

Fluid heater and control method thereof

ActiveCN111912125ASimple structureImprove stabilityWater heatersComplex mathematical operationsTemperature controlControl system

The invention discloses a fluid heater and a control method thereof. The fluid heater comprises a resistance heating body which comprises a resistance wire, wherein a heating resistance wire and a temperature control resistance wire are arranged on the resistance wire, and the heating resistance wire comprises a thin resistance wire and a thick resistance wire; a fluid heating container comprisinga main body and a cover body, wherein a containing cavity is formed by the main body and the interior of the cover body, the cover body is provided with a fluid inlet, and the position, close to thecover body, of the main body is provided with a fluid outlet; and an electrical control system comprising a heating body temperature detection circuit. The resistance heating body is arranged in the containing cavity in the fluid heating container. The fluid heater and the control method thereof are convenient to use, the temperature of the heating body is sensed in real time by directly monitoring the change of the internal resistance of the resistance heating body, and the temperature of fluid in close contact with the heating body is calculated; and the structure of the fluid heater is simplified, and the stability of the outlet fluid temperature and the safety of the system are improved.

Owner:畅和智能家居(嘉兴)有限公司

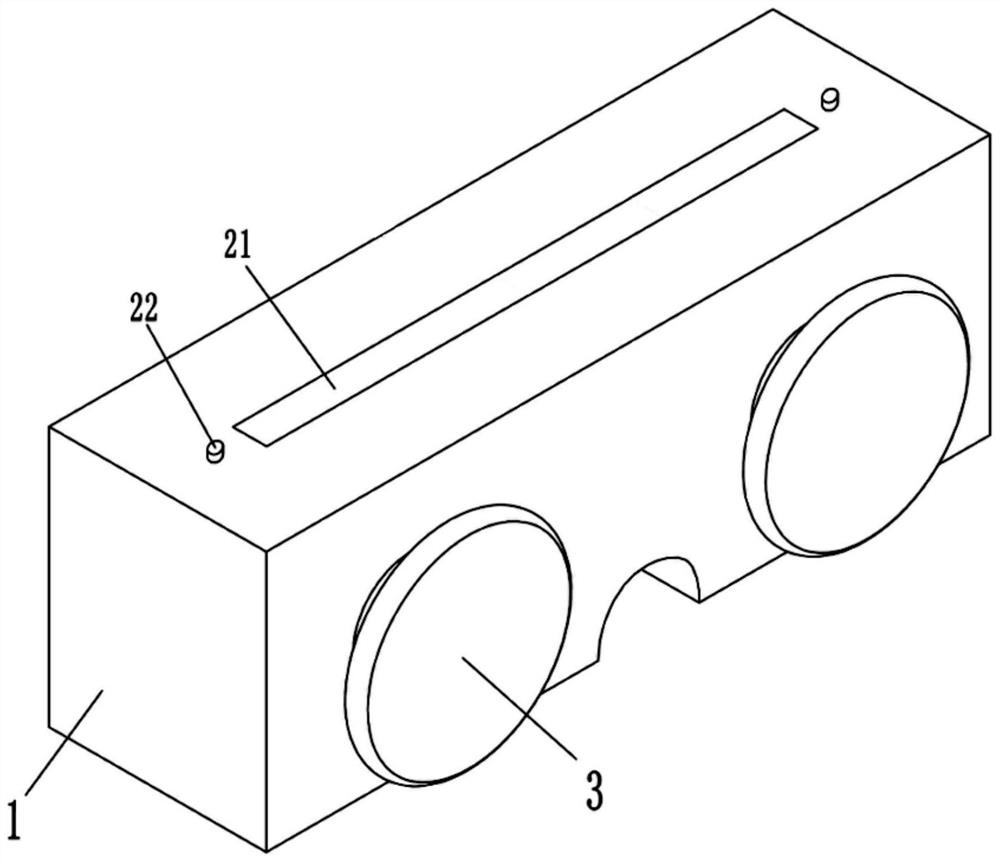

Right-angle hydraulic control one-way valve for Internet of Things terminal information acquisition

ActiveCN113803503AGuaranteed one-way flowPrevent backflowValve members for heating/coolingServomotor componentsInformation controlTemperature control

The invention discloses a right-angle hydraulic control one-way valve for Internet of Things terminal information acquisition, and belongs to the technical field of hydraulic systems. A straight valve body and a right-angle valve body are connected in a sealed mode to form an integral right-angle valve body, a left inner cavity, a middle inner cavity, a right inner cavity and a corner valve cavity are sequentially arranged in the valve body from the liquid inlet side to the liquid outlet side, a valve element is movably installed in the middle inner cavity of the valve body, a partition plate is arranged between the left inner cavity and the middle inner cavity, a center hole is formed in the valve element, a sealing ball is arranged between the center hole of the valve element and the partition plate, a plurality of first through holes are formed in the partition plate, a plurality of second through holes are formed in the position, located around the valve element, of the liquid outlet end of the valve element to form a liquid outlet, liquid discharged from the right inner cavity flows out through the corner valve cavity, electromagnetic coils of a temperature control device are wound around the portions, located at the liquid inlet end of the valve body and the liquid outlet end of the right-angle valve body, of the valve body respectively, and an on-off and temperature information acquisition module is arranged at the part, corresponding to the middle of the valve element, of the valve body and controls heating or heating stopping of the electromagnetic coils according to the acquired information. The one-way valve can be heated, and the heat transfer efficiency is improved.

Owner:SHENYANG INST OF ENG

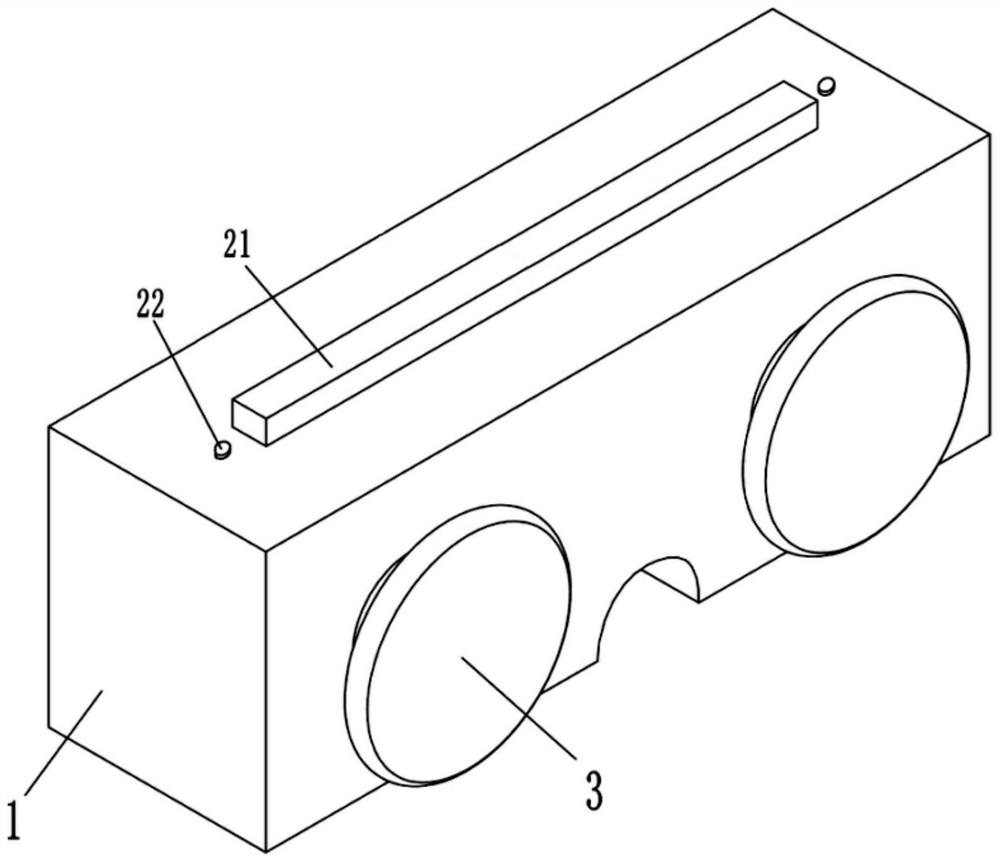

Eye protection instrument

PendingCN114452190AEasy to useGuaranteed medicinal effectMedical devicesBathing devicesAromatherapyProtecting eye

The invention discloses an eye protection instrument, and the instrument comprises a housing which is provided with an eye protection assembly and an accommodation cavity for accommodating aromatherapy; the eye protection assembly is arranged corresponding to the eyes; the containing cavity communicates with the eye protection assembly through a plurality of first through holes. A plurality of second through holes are formed in the eye protection assembly; the heating assembly is arranged in the shell, and the heating assembly is suitable for heating the aromatherapy in the containing cavity; the smell detection assembly is arranged on the shell; the smell detection assembly is in communication connection with the heating assembly; the smell detection assembly is suitable for detecting the fragrance concentration of the eye protection assembly and adjusting the heating power of the heating assembly according to the fragrance concentration. According to the arrangement, the fragrance concentration can be detected through the smell detection assembly to control the heating power of the heating assembly, then the emission amount of fragrance is adjusted, and the experience feeling of a user is enhanced.

Owner:GREE ELECTRIC APPLIANCES INC

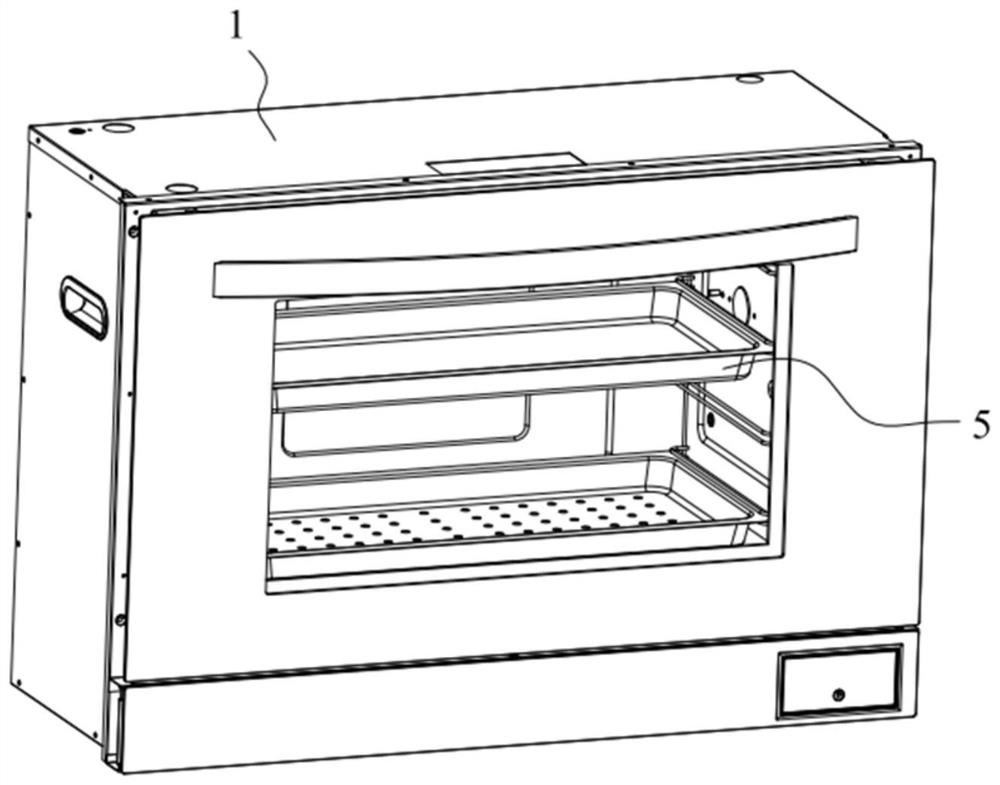

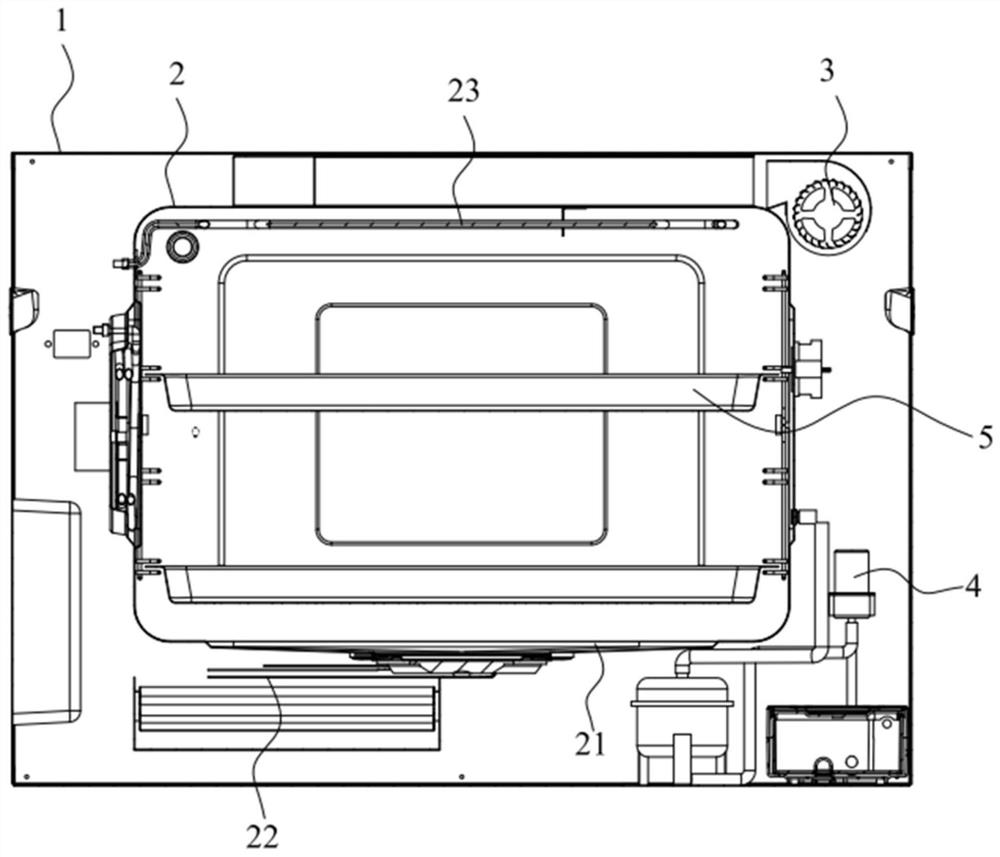

Control method of steaming oven and steaming oven

PendingCN113679256AAdjust heating powerReduce heating powerSteam cooking vesselsRoasters/grillsThermodynamicsProcess engineering

The invention discloses a control method of a steaming oven and the steaming oven, and belongs to the technical field of kitchen appliances, and the control method of the steaming oven comprises the steps that when a steaming function is executed, an air supply device is started to supply steam to a cavity, and a top heater in the cavity heats at first power; and the heating power of the top heater is adjusted according to the actual temperature in the cavity. The steaming oven is controlled by adopting the control method of the steaming oven. As the top heater is arranged at the top of the chamber and is closer to the top wall of the chamber, condensed water can be prevented from being accumulated at the top of the chamber, the heating power of the top heater is adjusted according to the actual temperature in the chamber, the top heater can play an auxiliary heating role while condensed water is prevented from being accumulated at the top of the chamber, rapid temperature rise in the chamber is facilitated, when the temperature rises, the heating power of the top heater can be reduced, and energy can be saved.

Owner:QINGDAO HAIER WISDOM KITCHEN APPLIANCE CO LTD +1

PTC heating device and control method thereof

ActiveCN102548059BChange surface temperatureChange cooling statusTemperature control using electric meansElectrical resistance and conductanceCyclic process

The invention relates to a PTC heating device and a method for controlling the PTC heating device. The PTC heating device comprises a PTC electric heater, a stepping motor, a driving mechanism, a current transformer and a main chip. The stepping motor and the driving mechanism are used for driving the PTC electric heater to rotate around the axis thereof; the current transformer is used for detecting the loop current of the PTC electric heater; and the main chip has calculating, comparing and controlling functions and is connected with the current transformer and the stepping motor in sequence. The control of the PTC heating device adopts the automatic-detection fed-back current closed-loop control. The process for controlling the PTC heating device is the automatic cycling process. The included angle of the controlled object which is the PTC heating device and the air flowing direction can be amended continuously according to the set value of the user so that the heat radiating statecan be changed and hereby the surface temperature of a PTC plate can be changed. Due to the positive temperature coefficient characteristic of the PTC heating device, the resistance of the PTC heating device can be changed, the loop current can be changed, and the hereby power can be changed. The PTC heating device has the characteristics of simple and reasonable structure and flexible operation.

Owner:MIDEA GRP CO LTD

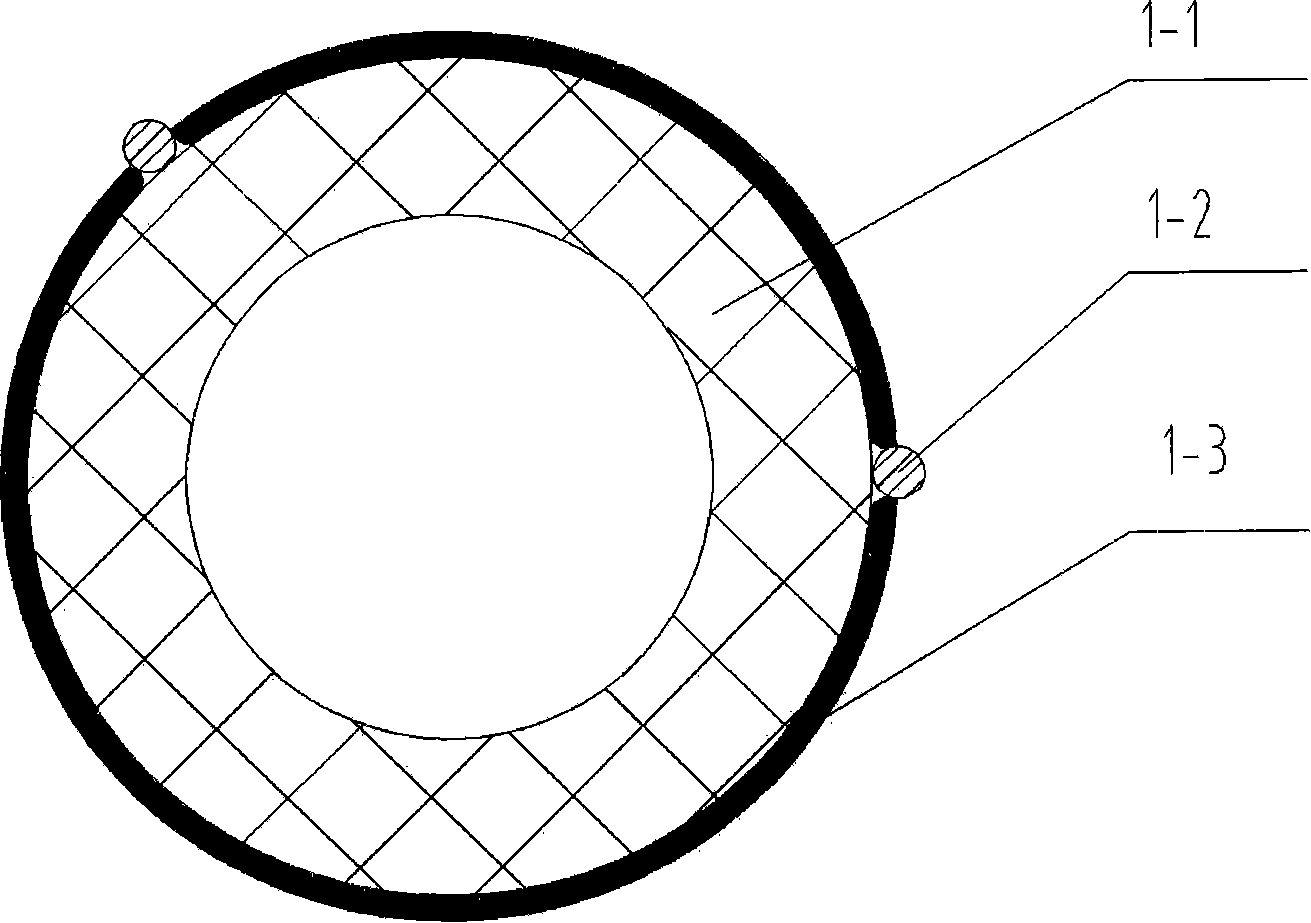

Even heating system for liquid biochemical reaction

InactiveCN101319811BAvoid biochemical reactionsClose contactWater heatersPeristaltic pumpPlatinum resistance

The invention relates to a uniform heating system used for liquid biochemical reaction, comprising a heating pipe, a platinum resistance, brackets, and a control circuit. The invention has the characteristics that the heating pipe and the brackets are enwound for twice; the platinum resistance which is used to measure temperature is arranged between the brackets. The top ends of the brackets are provided with a liquid intake and a liquid outlet of the heating pipe. The liquid intake and the liquid outlet are connected with a peristaltic pump. Under the action of the peristaltic pump, the two liquids are mixed uniformly, flow into the heating pipe from the liquid intake slowly, and flow out of the heating pipe from the liquid outlet slowly. The uniform heating system has the advantages of simple structure, convenient operation, high efficiency, safety and uniform heating.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

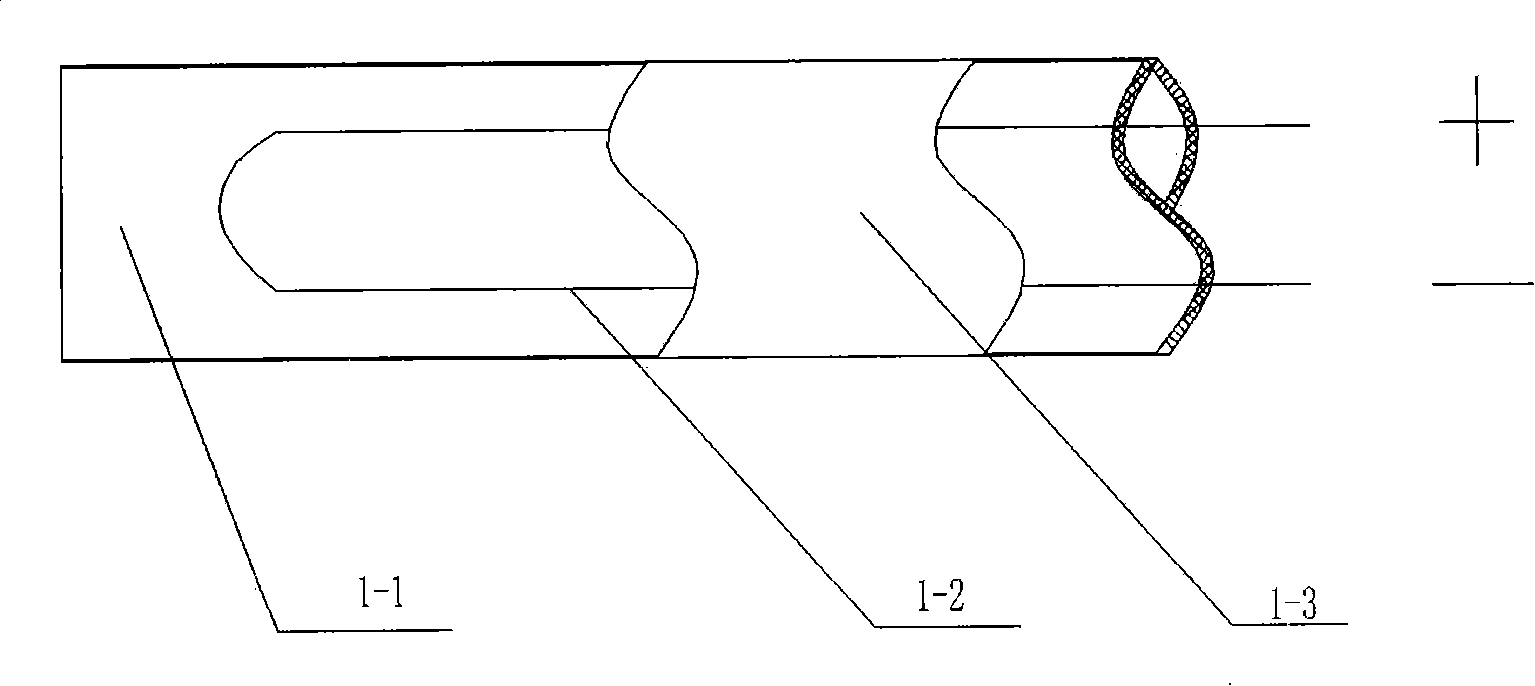

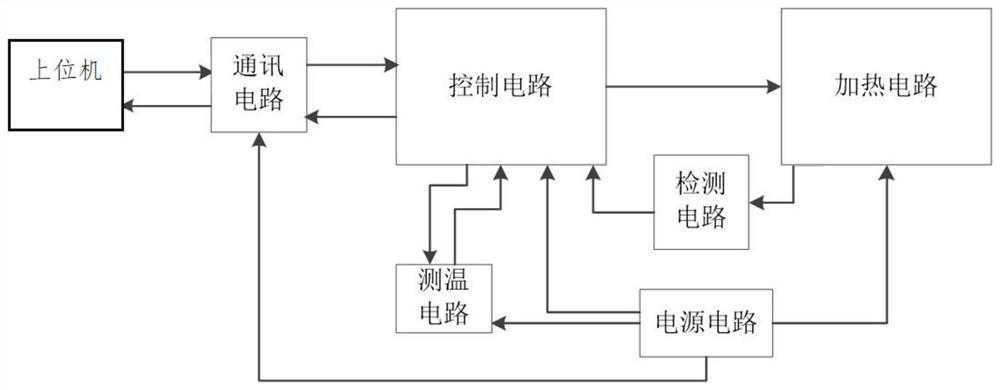

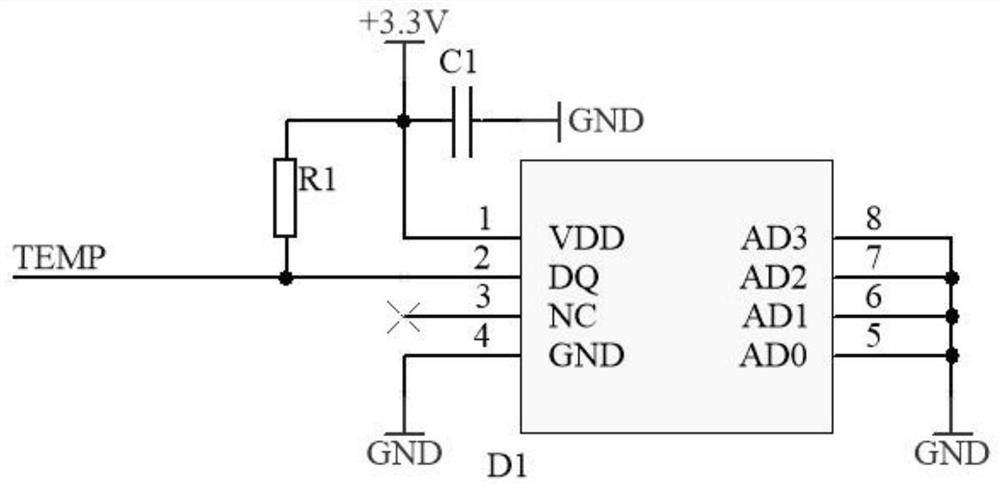

Airborne camera low-temperature heating system and heating method thereof

PendingCN113433779ADoes not affect transmittanceEasy to control power consumptionTransparent/reflecting heating arrangementsCamera body detailsProcess engineeringControl circuit

The invention discloses an airborne camera low-temperature heating system and a heating method thereof. The system comprises a control circuit, a temperature measurement circuit, a heating circuit, a communication circuit, a power supply circuit and an upper computer. The temperature measurement circuit detects the temperature of an external environment and transmits temperature information to the control circuit in real time, and the control circuit judges and processes the temperature information. When the external temperature reaches a preset starting temperature point, the control circuit sends out an instruction, and the heating function is started. According to the invention, the heating power can be dynamically adjusted in real time according to the change of the external temperature, and heating resources can be effectively utilized; and the system has a manual / automatic heating switching function, and is high in flexibility and high in environment adaptability.

Owner:NO 55 INST CHINA ELECTRONIC SCI & TECHNOLOGYGROUP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com