Temperature-controlled heat-conducting oil down drying machine

A heat-conducting oil and dryer technology, applied in the field of down processing equipment, can solve problems such as untimely discharge of moisture or excessive discharge of hot steam, affecting the drying speed and quality of down and down, and insufficient use of heat energy, etc., to achieve Optimized air volume control, shortened drying time, high quality results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

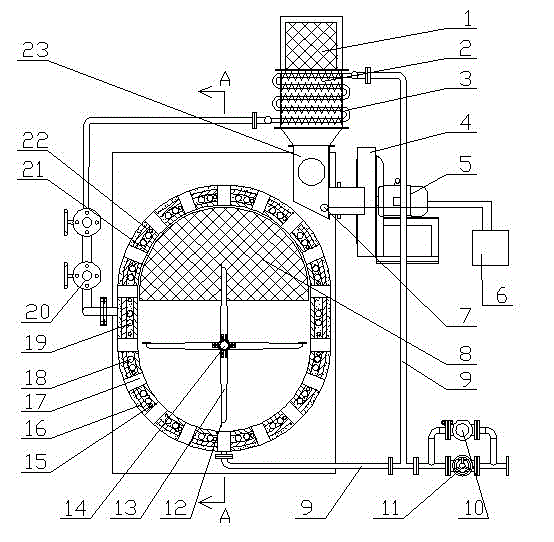

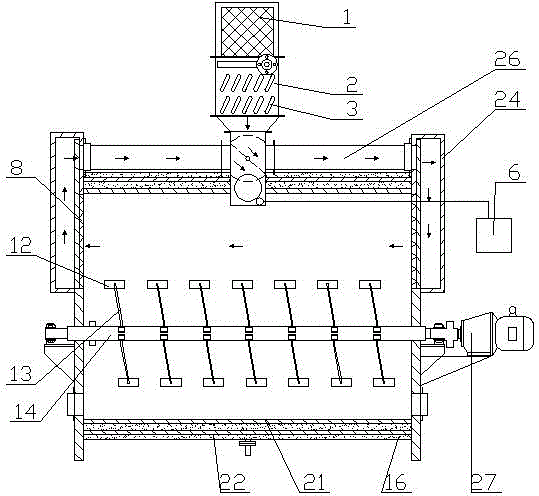

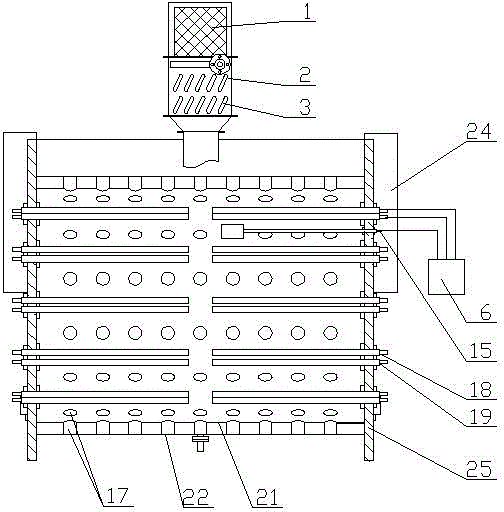

[0011] In the accompanying drawings, the temperature-controlled heat-conducting oil down dryer includes a double-walled cylinder body composed of an outer shell 22 and an inner shell 21. ; The cylinder body is provided with heat dissipation holes 17, a burr opening, a burr outlet, an oil filling port, an oil discharge port, an air pressure valve 20, an oil pressure valve, an air pressure gauge and an oil pressure gauge; The stirring shaft 14 is equipped with a plurality of stirring rods 13 evenly along the axial direction, and the ends of the stirring rods 13 are respectively connected with paddles 12, and the stirring shaft 14 is driven by the motor 2 17; the interlayer of the cylinder is filled with heat-conducting oil , a plurality of temperature sensors 15 are evenly distributed in the heat transfer oil; several groups of electric heating tubes are evenly arranged in the interlayer of the cylinder; the end caps 25 at the left and right ends of the cylinder are respectively ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com