Electric driving system, power assembly, heating method and electric vehicle

A technology of electric drive system and power battery pack, applied in electric vehicles, vehicle components, vehicle energy storage, etc., can solve problems such as increasing cost and occupying space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0079] In order for those skilled in the art to better understand the technical solutions provided by the embodiments of the present application, the working principle of the electric drive system of the electric vehicle is firstly introduced below.

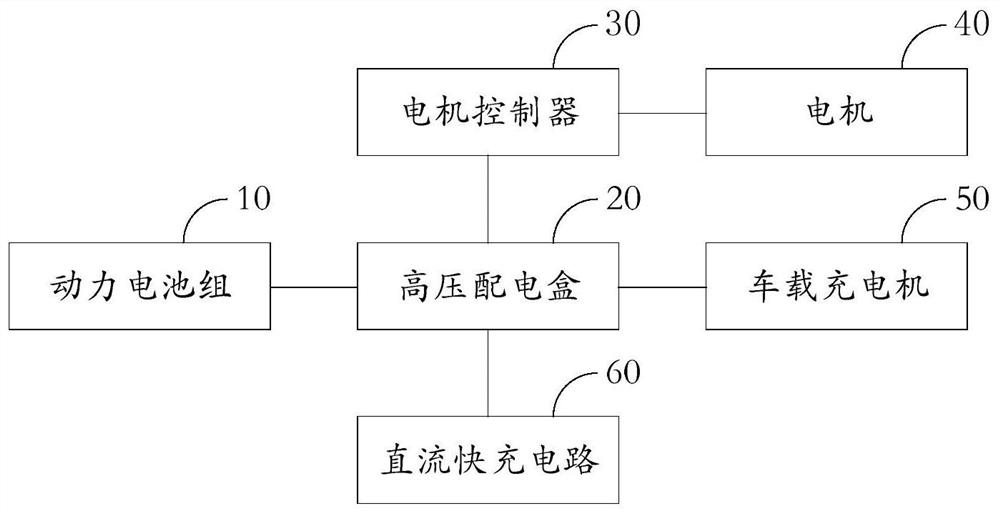

[0080] see figure 2 , which is a schematic diagram of a schematic electric drive system of an electric vehicle provided in the present application.

[0081] The illustrated electric drive system includes a power battery pack 10 , a high-voltage distribution box 20 , a motor controller (Motor Control Unit, MCU) 30 , a motor 40 , an on-board charger (OBC) 50 and a DC fast charging circuit 60 .

[0082] Among them, the power battery pack 10 is used to provide high-voltage direct current, and the high-voltage direct current provided by the power battery pack 10 is converted into alternating current through the high-voltage power distribution box 20 and the motor controller 30, and provided to the motor 40 to drive the electric vehicle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com