Pulse on-off valve type metal 3D printing device

A technology of 3D printing and on-off valve, which is applied in the direction of additive manufacturing, process efficiency improvement, additive processing, etc. It can solve the problems of difficult control of ejection speed and deposition accuracy, impurity removal and purification of melt, and low viscosity of molten metal To achieve high-precision spray deposition forming, avoid uneven solidification, and improve printing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

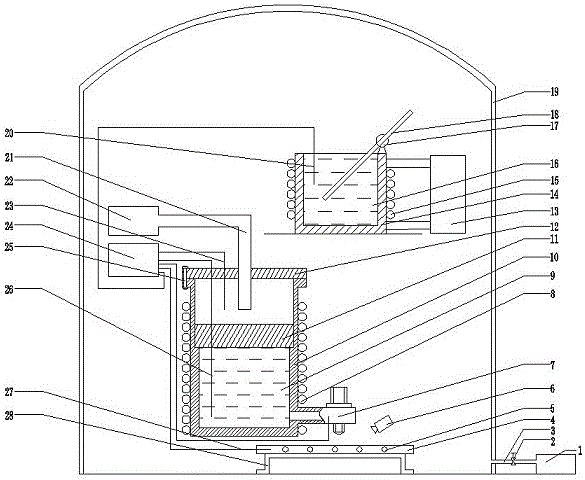

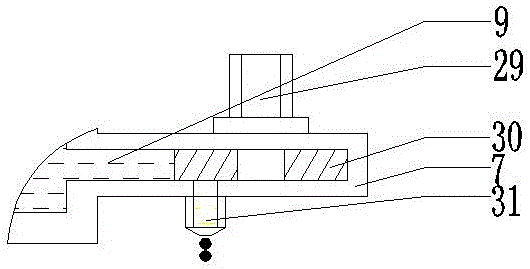

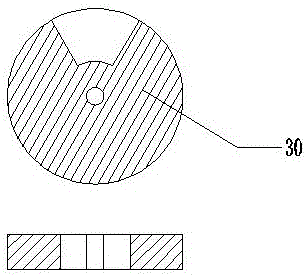

[0035]A pulse on-off valve-type metal 3D printing device, which consists of: a vacuum system that provides a vacuum environment for the spray deposition process, a spray head (7) for realizing precise control of metal spray forming, and a multi-stage purification system for refining molten metal A device, a printing substrate (4) providing a stable deposition and forming environment, and a three-axis motion platform for realizing directional deposition of molten metal. , in order to realize the measurement and control part of the whole fused deposition process in a stable and orderly manner.

Embodiment 2

[0037] Before the spray deposition 3D printing starts, the printed metal material is put into the solid metal melting device (14), the two-stage vacuum pump (1) works, the vacuum valve (2) is opened, and the entire printing system is evacuated through the vacuum pipeline (3). After a certain degree of vacuum is reached, the metal material is heated by induction, and the refining agent is added, and the stirring rod (18) driven by the fixed ring (17) moves to make the refining agent diffuse evenly and generate slag. After the alloy is completely melted, carry out the slag removal treatment, and let it stand for a period of time to stabilize the alloy composition. Turn on the next-level melting device (9), and when the temperature reaches the preset value, pour the molten metal from the upper-level melting device into the current-level melting device, filter through the filter screen (11), and close the pressure cover (12) after completion. The pressure cover is connected with t...

Embodiment 3

[0039] Stable air pressure on the surface of the melt is realized by the air pressure control system, the pressure data is collected by the pressure sensor (23), and uploaded to the industrial computer for collection and analysis. When the air pressure is higher than the set value, open the solenoid valve (33) to communicate with the exhaust pipe (34) to deflate the system and reduce the pressure; when the air pressure is lower than the set value, open the solenoid valve (33) to communicate with the gas cylinder ( 31), inflate the system to increase the pressure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com