Heating control circuit and heating electrical appliance

A technology for heating control circuit and control circuit, which is applied in ohmic resistance heating, temperature control by electric method, electric heating device, etc., can solve the problems of relay damage, relay contact ablation, limited number of relay actions, etc., to reduce costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

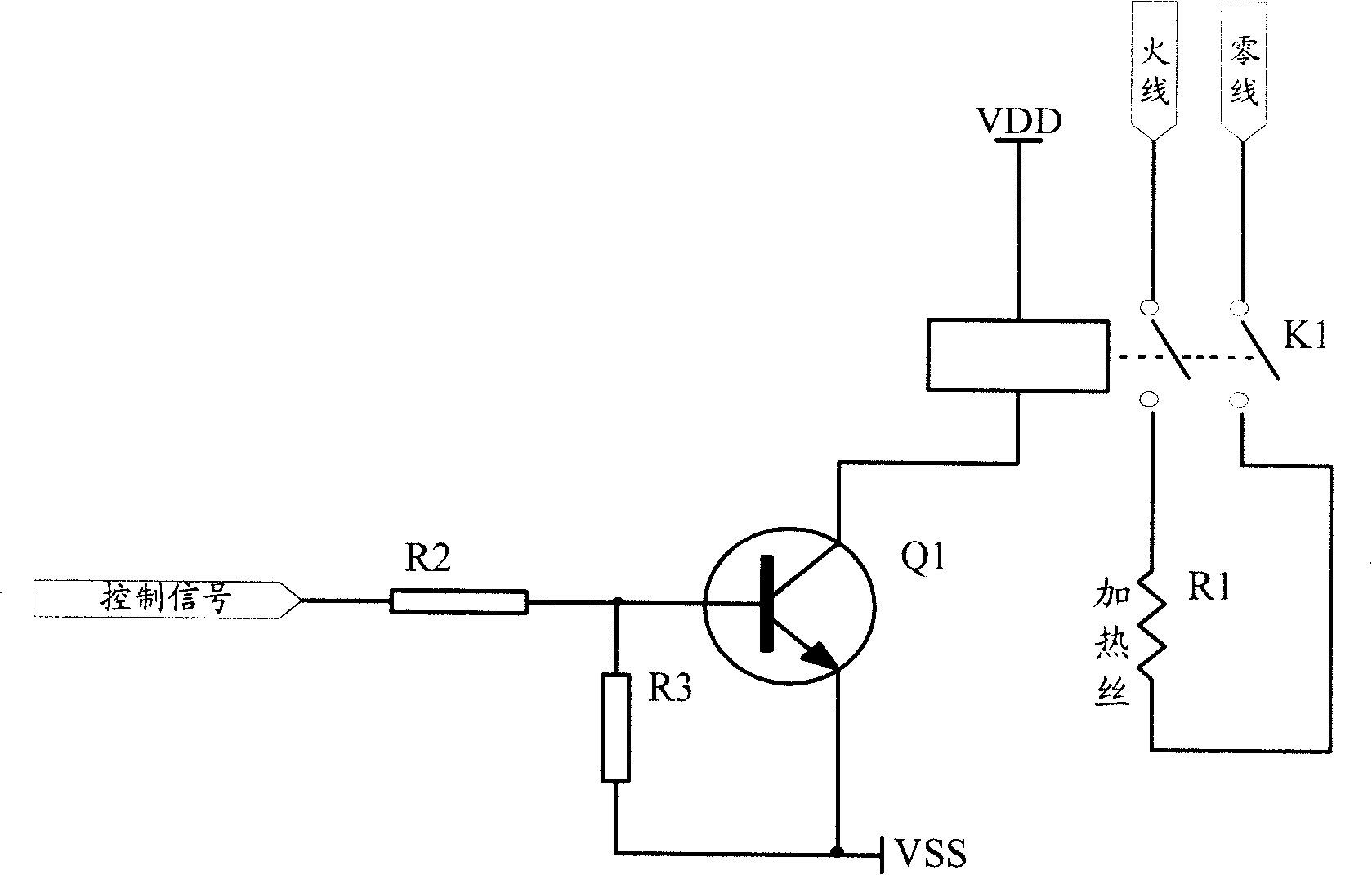

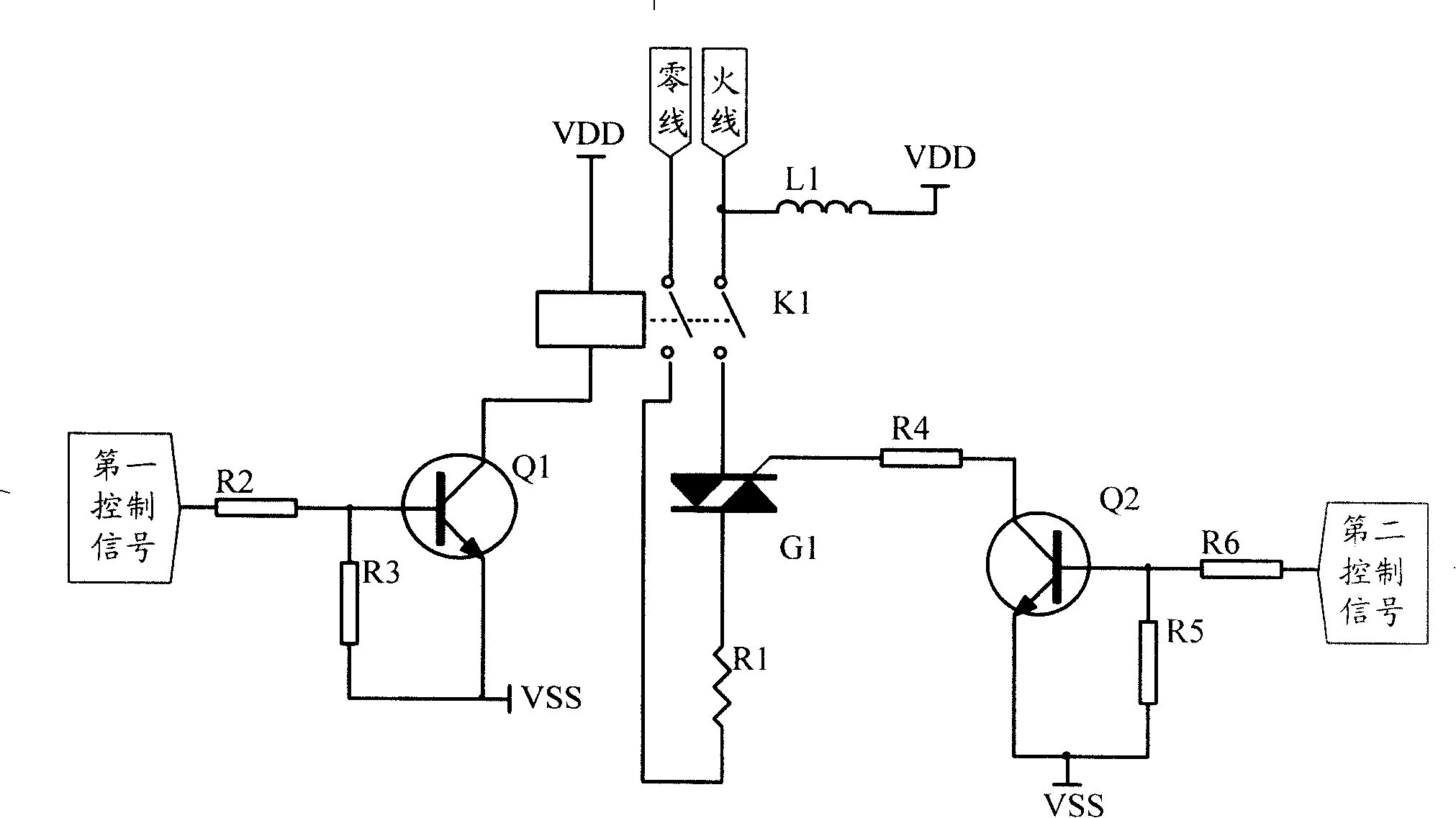

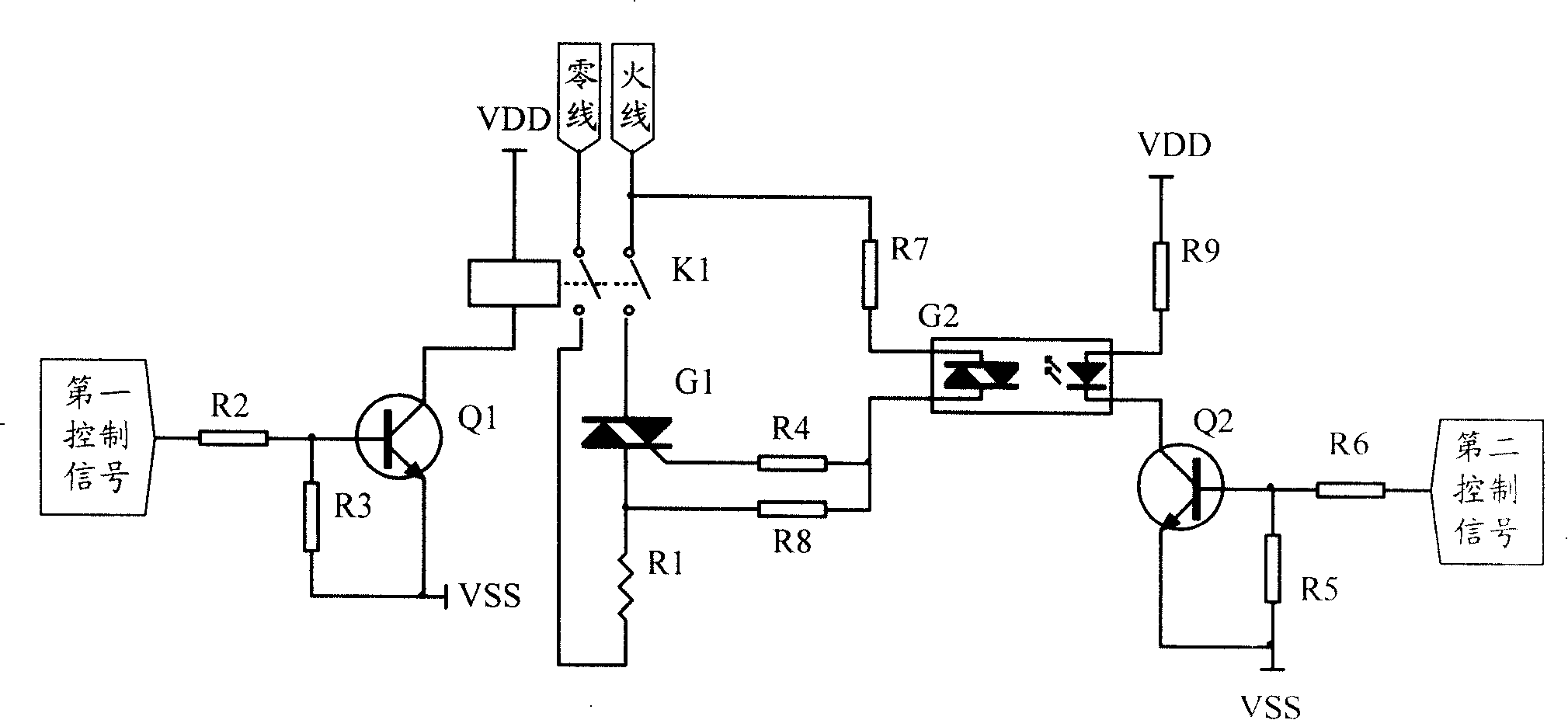

[0030] The invention provides a heating control circuit, which can ensure the uniformity of heating, protect the relay from damage, and prolong the service life of the relay.

[0031] The invention relates to a heating control circuit, comprising a relay and a control unit connected in series in the heating circuit. The control unit is used to adjust the heating power of the heating circuit.

[0032] The control unit includes a control signal receiving unit and a control subunit.

[0033] The control signal receiving unit receives a first external control signal and sends it to the relay; the relay is closed and disconnected according to the first control signal; receives a second external control signal and sends it to the control subunit.

[0034] The control subunit adjusts the heating power of the heating circuit according to the second control signal received by the control signal receiving unit.

[0035] In order to enable those skilled in the art to better understand...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com