Production system and method for producing motor vehicle number plate blanks

A technology for production equipment and motor vehicles, applied to chemical instruments and methods, vehicle components, control lamination, etc., can solve problems such as inaccurate feeders, achieve favorable accuracy, reduce waste products, and increase the number of strokes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

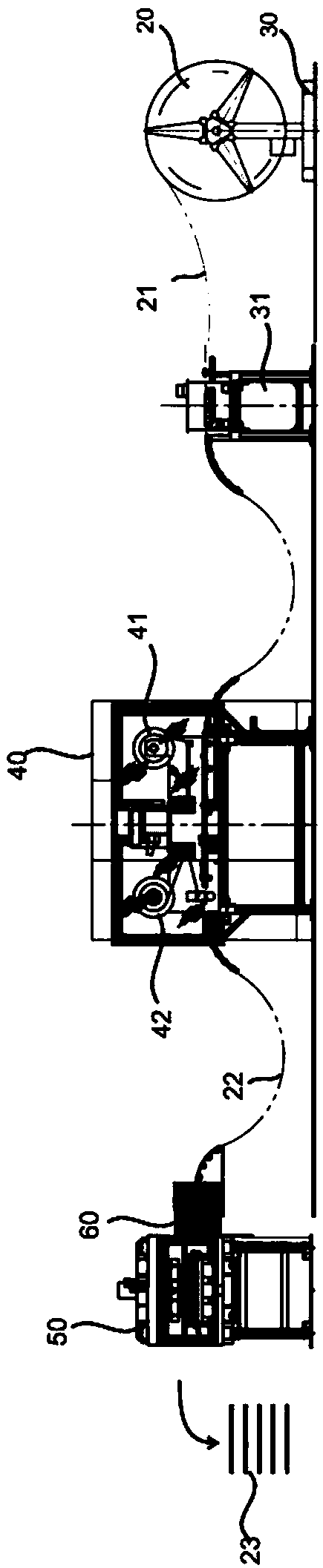

[0027] figure 1 A schematic illustration of a production plant 10 is shown, which is used to produce a motor vehicle license plate blank 23 from a metal strip. The metal strip 21 is inserted as a coil into the uncoiler 30 at the beginning of the production line, so that the metal strip can be continuously unwound by the uncoiler. The metal strip is a rolled aluminum strip having a width which, in the stamping process to be carried out, forms a blank motor vehicle license plate of the desired width. The aluminum strip preferably has a thickness in the range of 0.7 mm to 1.5 mm and a width in the range of 80 mm to 305 mm.

[0028] First the metal strip 21 is usually drawn into the straightening machine 31 by means of a drive. The metal strip 21 is oriented by the straightening machine 31 so that it is guided to the laminating machine 40 in alignment. The drive of the straightener 31 can be designed as a non-contact feeder.

[0029] Before the straightener, the metal strip 21...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com