Fluid heater and control method thereof

A technology for heaters and heating containers, which is applied in the directions of fluid heaters, water heaters, lighting and heating equipment, etc., can solve the problems of lag in heating power temperature changes, reduced work efficiency, poor temperature stability, etc. Response time, the effect of improving smoothness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

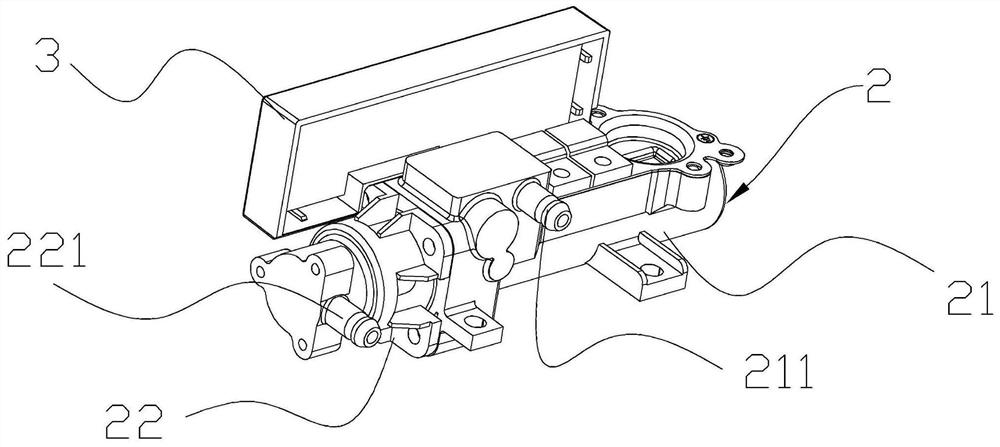

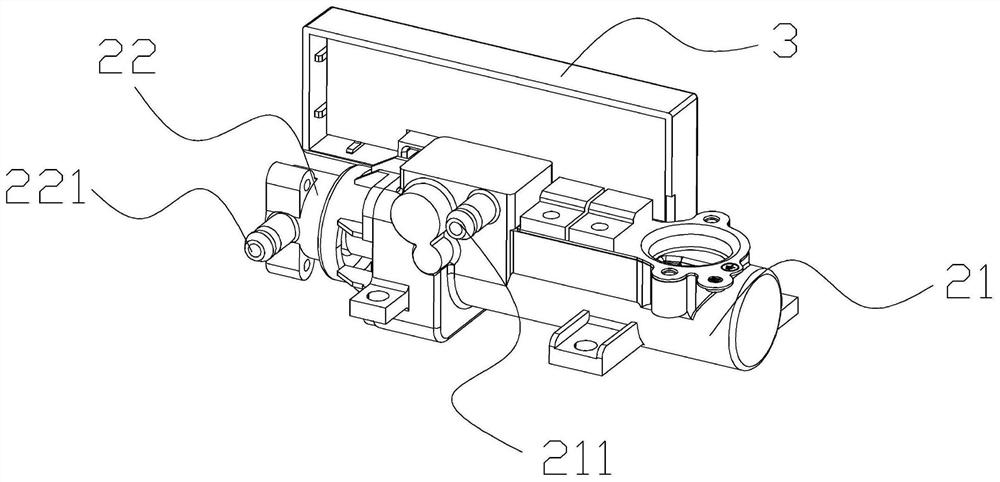

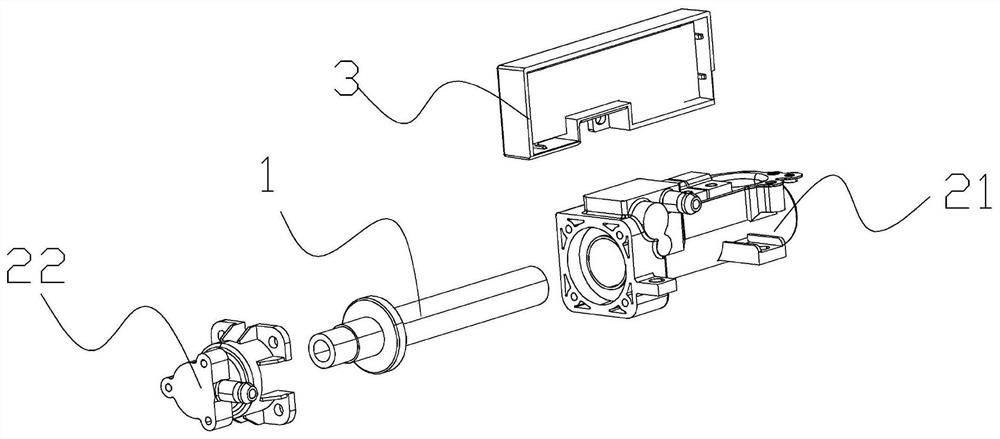

[0059] like Figures 1 to 3 As shown, the present invention provides a fluid heater, comprising:

[0060] The resistance heating element 1 includes a resistance wire 11; the resistance wire 11 includes at least two groups of heating resistance wires 111 with different powers and a group of temperature control resistance wires 112; the temperature control resistance wire 112 is added, which can be more quickly and directly The change of the temperature of the resistance heating element 1 is monitored, the change of the fluid temperature and the actual flow rate are calculated, and then the heating power is adjusted before the fluid temperature changes.

[0061] The fluid heating container 2 includes a main body 21 and a cover 22; the main body 21 and the cover 22 form an accommodating cavity inside, the cover 22 is provided with a fluid inlet 221, and the main body 21 is provided near the cover 22. There is a fluid outlet 211; the fluid enters the fluid heating container 2 fro...

Embodiment 2

[0089] like Figures 1 to 3 As shown, the present invention provides a fluid heater, comprising:

[0090] The resistance heating element 1 includes a resistance wire 11; the resistance wire 11 includes at least two groups of heating resistance wires 111 with different powers and a group of temperature control resistance wires 112; the temperature control resistance wire 112 is added, which can be more quickly and directly The change of the temperature of the resistance heating element 1 is monitored, the change of the fluid temperature and the actual flow rate are calculated, and then the heating power is adjusted before the fluid temperature changes.

[0091] The fluid heating container 2 includes a main body 21 and a cover 22; the main body 21 and the cover 22 form an accommodating cavity inside, the cover 22 is provided with a fluid inlet 221, and the main body 21 is provided near the cover 22. There is a fluid outlet 211; the fluid enters the fluid heating container 2 fro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com