Intro-motor fluid and heat exchange coefficient testing device

A test device and internal fluid technology, which is applied in the field of test devices for internal fluid and heat transfer parameters of motors, can solve the problems of lack of new coolers, inability to obtain accurate heat dissipation performance of coolers, and difficulties in calculating and designing coolers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

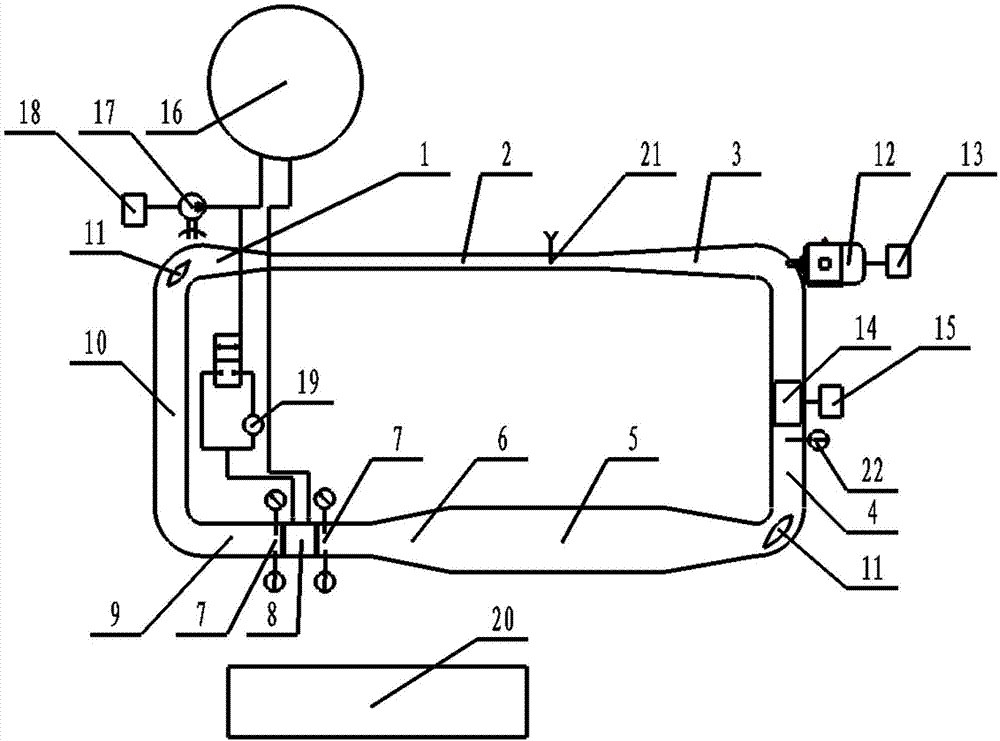

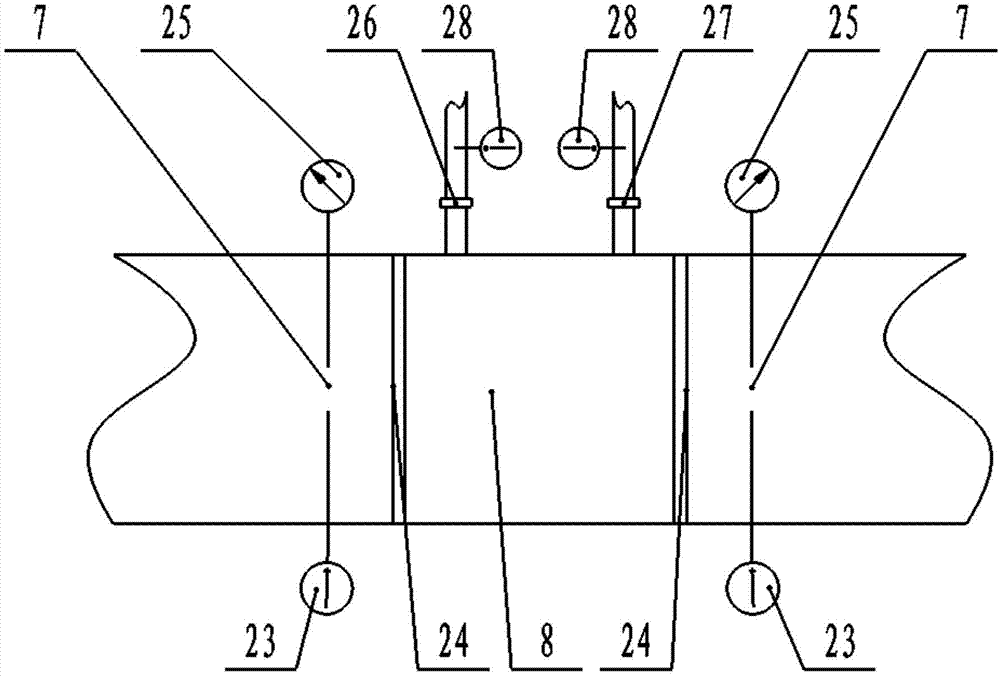

[0011] Such as figure 1 As shown, a test device for fluid and heat transfer parameters in a motor consists of a contraction section 1, a pressure stabilization section 2, a diffusion section 3, a connecting section A4, a damping section 5, a turbulent flow section 6, a testing section 7, a testing section 8, Telescopic section 9, connecting section B10, guide vane 11, centrifugal fan 12, inverter A13, heater 14, three-phase solid state relay 15, cylindrical container 16, water pump 17, inverter B18, turbine flowmeter 19, console 20 components, in which contraction section 1, pressure stabilization section 2, diffusion section 3, connection section A4, damping section 5, turbulence section 6, test section 7, test section 8, expansion section 9, and connection section B10 pass through the flange sequentially Connect to form a backflow wind tunnel, guide vanes 11 are installed at the corners of the connecting section A4 and the connecting section B10, and the cooler model to be t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com