Power control method for food processor

A food processing machine, power control technology, applied in the direction of temperature control, non-electric variable control, control/regulation system, etc., can solve the problems of high cost, accuracy and reliability, harmonic current disturbance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

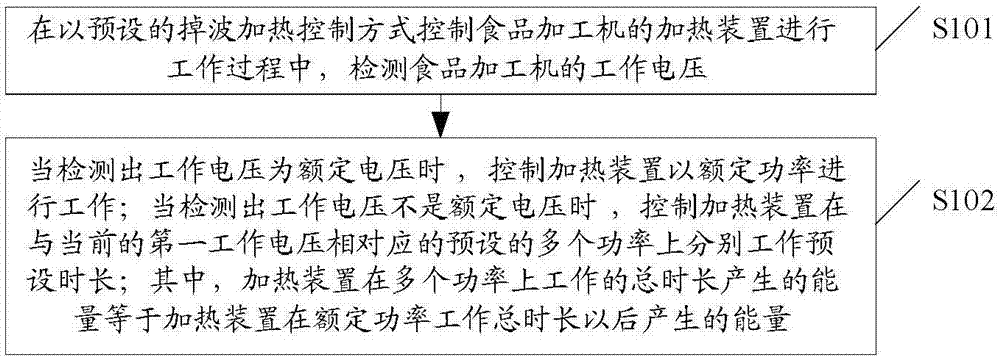

[0053] A power control method for a food processor, such as figure 1 As shown, the method may include S101-S102:

[0054] S101. During the working process of controlling the heating device of the food processing machine in a preset drop-wave heating control mode, detect the working voltage of the food processing machine.

[0055] In the embodiment of the present invention, during the working process of the food processor in the wave heating control mode, the set power gears may include:

[0056] 1. Rated power (full power) P 额 (AC half-wave full conduction), control wave drop ratio n=1;

[0057] 2, 3 / 4P 额 (3 AC half-wave guides are on, and 1 is off), control the wave-off ratio n=3 / 4;

[0058] 3. 2 / 3P 额 (2 AC half-wave guides are on, and 1 is off), control the wave-off ratio n=2 / 3;

[0059] 4. 1 / 2P 额 (1 AC half-wave conduction, 1 off), control wave drop ratio n=1 / 2;

[0060] 5. 1 / 3P 额 (1 AC half-wave conduction, 2 off), control wave drop ratio n=1 / 3;

[0061] 6. 1 / 4P ...

Embodiment 2

[0081] On the basis of the first embodiment, this embodiment further limits the ways of obtaining the first power P1 and the second power P2.

[0082] Optionally, the first power P1 and the second power P2 are determined according to the conduction half-wave ratio m in the control period in the wave-drop heating control mode;

[0083] in, u 额 Indicates the rated voltage, U 实 Indicates the actual working voltage, n indicates the drop-off ratio of the heating device, and T refers to the control period of the AC half-wave, which is T AC half-waves.

[0084] In the embodiment of the present invention, the food processing machine controls heating with T alternating half-wave cycles, and the rated voltage AD value of the food processing machine is V 0 , real-time voltage AD value V 1 , if the wave drop ratio of the heating power P is n, and the resistance value of the heating device is R, then when the voltage is the rated voltage V 0 hour, During the control period T there ...

Embodiment 3

[0100] In this embodiment, on the basis of the first and second embodiments, the acquisition manners of the first duration T1 and the second duration T2 are further limited.

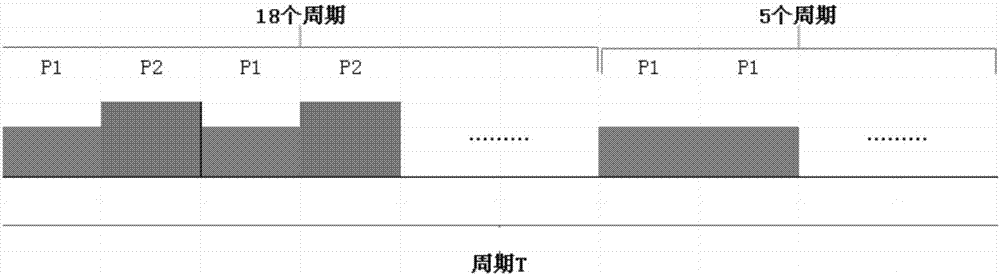

[0101] In the embodiment of the present invention, the working time T1 and T2 of the heating power P1 and P2 can be controlled according to the wave drop ratio n of the heating power P1 and P2 1 , n 2 And m value confirmation, specifically can be realized through the following scheme.

[0102] Optionally, the method may also include:

[0103] Obtaining a second wave dropping ratio n2 and a third wave dropping ratio n3 respectively corresponding to the first power P1 and the second power P2 according to the determined first power P1 and the second power P2;

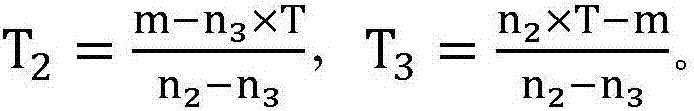

[0104] Calculate the first time length T1 and the second time length T2 respectively according to the conduction half wave ratio m, the second wave drop ratio n2, the third wave drop ratio n3 and the following equations:

[0105]

[0106] In th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com